Precise pressure measurement is essential for maintaining reliability and efficiency in numerous industrial applications. PSIA, or Pounds per Square Inch Absolute, plays a vital role in this process by measuring pressure relative to a perfect vacuum. Unlike other pressure scales, Absolute pressure provides an absolute reference point, making it indispensable across industries where accuracy is critical.

From fluid control systems to advanced manufacturing processes, understanding PSIA helps optimize the performance of key components like ball valves, gate valves, and butterfly valves. Whether you’re working with pneumatic valves in automated systems or electric valves in sophisticated setups, accurate pressure readings ensure effective operation and long-term durability. By exploring what PSIA means and how it impacts various valve applications, this guide will provide a straightforward foundation for mastering absolute pressure concepts and their industrial significance.

Introduction psia

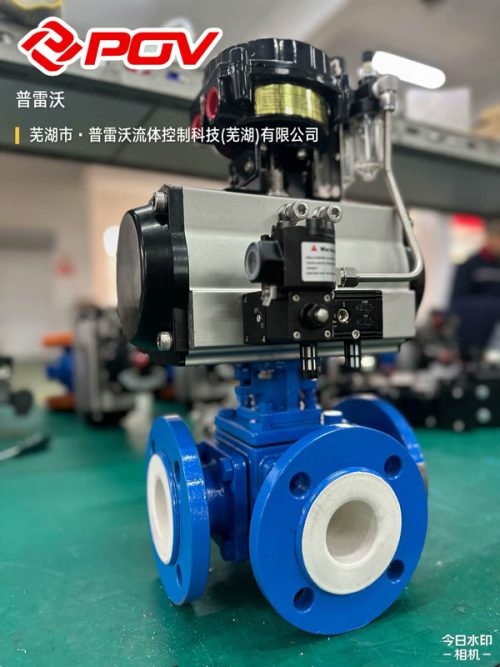

PSIA, or Pounds per Square Inch Absolute, is a critical measure of absolute pressure, offering unmatched accuracy by referencing a perfect vacuum. This precision is essential for optimizing industrial systems reliant on pressure-sensitive components. From the reliable operation of a flanged ball valve or a pneumatic ball valve to the adaptability of a 3 way ball valve or an electric ball valve, understanding PSIA ensures efficiency and safety. Additionally, PSIA plays a key role in ensuring the performance of globe valves and pneumatic control valves, both vital in maintaining precision in fluid control applications.

Brief explanation of PSIA, focusing on its role in measuring absolute pressure.

PSIA stands for Pounds per Square Inch Absolute and measures pressure relative to a perfect vacuum. It provides a clear reference point by including atmospheric pressure in its calculations, unlike gauge pressure, which measures only relative to ambient conditions. PSIA is widely used in industries to ensure accurate pressure readings for various systems and applications.

Importance of understanding PSIA in industries reliant on precise pressure calculations, such as valve manufacturing.

PSIA is essential for industries that require precise pressure calculations, including valve manufacturing. It ensures accurate measurements by referencing a vacuum, which is critical for designing and operating systems like ball valves, gate valves, and control valves. Understanding PSIA helps maintain reliable performance and supports consistent system functionality.

Transition into how PSIA connects with valve applications like pneumatic valves and globe valves.

PSIA provides a reliable measurement framework for ensuring precise pressure levels in various valve applications. Pneumatic valves and globe valves depend on accurate pressure readings to regulate flow and maintain functionality in industrial systems. Understanding PSIA helps align these applications with operational requirements.

What Is PSIA? Understanding Absolute Pressure

PSIA represents pounds per square inch absolute and measures pressure relative to a perfect vacuum. It includes atmospheric pressure along with gauge pressure, providing an accurate measure of total pressure in a system. This measurement is fundamental for calibrating equipment, ensuring proper valve operation, and maintaining system balance in various applications.

Define PSIA (Pounds per Square Inch Absolute) and its significance in pressure measurement.

PSIA, or Pounds per Square Inch Absolute, measures pressure relative to a perfect vacuum by including atmospheric pressure in its calculations. This makes it a fundamental reference point for accurate pressure measurement, as it eliminates variables caused by changing ambient conditions. Industries rely on PSIA for consistent pressure readings to ensure the proper design, operation, and safety of various systems and applications.

Highlight how PSIA differs from PSIG (Gauge Pressure) and why absolute pressure matters.

PSIA measures pressure relative to a perfect vacuum, including atmospheric pressure in its calculation, while PSIG measures pressure relative to ambient atmospheric conditions. The difference lies in the reference point, with PSIA offering a complete pressure measurement. Absolute pressure is crucial for industries requiring precise calculations, as it ensures consistency across varying environments, supporting critical operations and design accuracy.

Discuss applications where PSIA is critical, including systems featuring electric ball valves and 3 way ball valves.

PSIA is essential in applications where precise pressure measurements are required, such as systems utilizing electric ball valves and 3-way ball valves. These valves depend on accurate pressure data to control flow, manage switching functions, and operate under variable conditions. By using PSIA as a reference, these systems ensure reliable performance and maintain operational efficiency in industrial processes.

Why Does PSIA Matter in Fluid Control Systems?

PSIA is important in fluid control systems as it measures absolute pressure, including atmospheric pressure, to ensure accurate system performance. This measurement helps regulate flow, maintain pressure stability, and prevent operational issues, enabling components like valves and actuators to function within specified parameters.

Explore the relevance of PSIA in maintaining system safety and efficiency.

PSIA plays a key role in maintaining system safety and efficiency by providing accurate pressure measurements relative to a vacuum. This ensures consistent data for designing, monitoring, and operating fluid control systems. Accurate PSIA readings help prevent operational issues and improve system reliability across various industrial applications.

Discuss examples such as flanged ball valves, which rely on precise pressure readings to enhance performance.

Flanged ball valves depend on precise pressure readings to optimize flow control and ensure functionality in fluid control systems. By using PSIA as a reference, these valves maintain accurate pressure data, aiding in consistent operation and reducing potential system disruptions in industrial processes.

Include discussion on butterfly valves and their role in industries requiring accurate pressure control.

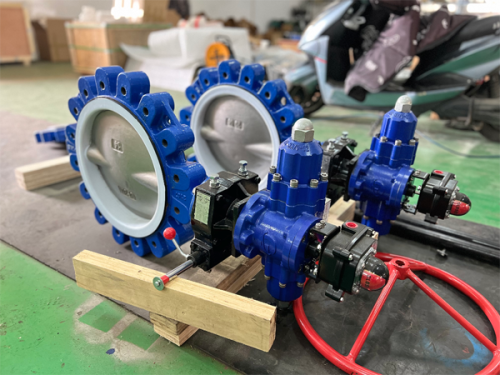

Butterfly valves play a vital role in industries that require accurate pressure control by regulating flow in fluid control systems. Using PSIA as a reference, these valves ensure dependable pressure data, supporting precise system operation and minimizing disruptions across industrial processes.

PSIA and Valve Selection

PSIA is a critical factor in valve selection as it defines the absolute pressure required for safe and effective operation. When choosing a valve, such as a ball valve, butterfly valve, or gate valve, understanding PSIA helps ensure compatibility with system pressure requirements, preventing failure or inefficiencies within the pressure system.

Explain how understanding PSIA aids in selecting the right valve for specific applications.

Understanding PSIA helps in selecting the right valve by providing accurate pressure measurements relative to a vacuum. This ensures compatibility between the valve’s pressure-handling capacity and the system’s requirements, supporting precise operation and reducing the risk of performance issues in specific applications.

Cover types of valves like gate valves, globe valves, and pneumatic valves, highlighting their functionality under various pressure conditions.

Gate valves, globe valves, and pneumatic valves each perform specific functions under varying pressure conditions. Gate valves control flow by opening or closing the passage, globe valves regulate flow with a movable disk, and pneumatic valves operate using compressed air. Accurate PSIA measurements support the performance of these valves by aligning their pressure capacities with system demands.

Provide examples of industrial uses for pneumatic ball valves and electric ball valves requiring accurate absolute pressure readings.

Pneumatic ball valves are used in processing plants to manage high-pressure gases, while electric ball valves are commonly applied in automated systems for fluid regulation. Both rely on accurate absolute pressure readings to ensure proper operation and compatibility with system pressure requirements, supporting efficiency in industrial applications.

Calculating PSIA in Practical Applications

PSIA is calculated by adding atmospheric pressure to gauge pressure, providing the absolute pressure value. This calculation is essential in practical applications to evaluate if pressure levels meet system specifications for tasks like equipment calibration, fluid control, and ensuring safe operational parameters in pressure systems.

Step-by-step guide to calculating PSIA, emphasizing its formula and inputs.

To calculate PSIA, use the formula PSIA = PSIG + atmospheric pressure. Start by measuring the gauge pressure (PSIG) using a pressure gauge. Add the standard atmospheric pressure, typically 14.7 psi at sea level, to the gauge pressure. This provides the absolute pressure, accounting for both the pressure within the system and the surrounding atmospheric pressure.

Illustrate examples, such as using PSIA to measure pressure for systems incorporating pneumatic control valves.

PSIA is used to measure pressure in systems with pneumatic control valves to ensure accurate operation. For example, in a compressed air system, PSIA is calculated by adding atmospheric pressure to the gauge pressure of the air supply. This value helps verify that the control valves are operating within the specified pressure range, maintaining proper flow and system efficiency.

Address key challenges and how to overcome them in real-world applications.

One key challenge in calculating PSIA is accounting for variations in atmospheric pressure due to altitude or weather conditions. To address this, use a reference chart or sensor to determine the current atmospheric pressure specific to the location. Another challenge is ensuring accurate gauge pressure readings, which can be overcome by calibrating equipment regularly and checking for leaks or malfunctions in the system. These steps help maintain precision in pressure calculations and system performance.

How PSIA Impacts the Performance of Valves

PSIA impacts valve performance by providing a measure of absolute pressure that accounts for atmospheric pressure. This ensures valves like globe valves, butterfly valves, and control valves operate within specified pressure ranges. Understanding PSIA helps maintain efficiency, prevent pressure imbalances, and avoid system malfunctions.

Analyze how deviations in pressure measurements can affect the operation of valves like ball valves or butterfly valves.

Deviations in pressure measurements can disrupt the operation of valves like ball valves and butterfly valves by causing mismatches between system pressure and valve capacity. This can lead to improper sealing, flow irregularities, or increased wear on valve components. Accurate PSIA readings ensure that these valves function within their designed pressure limits, maintaining proper system operation.

Delve into how PSIA ensures reliability in advanced systems, including electric valves and specialized 3 way ball valves.

PSIA ensures reliability in advanced systems by providing precise absolute pressure measurements, aligning valve performance with system requirements. Electric valves depend on accurate PSIA values for consistent actuation under pressure, while specialized 3-way ball valves rely on these measurements to maintain proper directional flow in complex configurations.

Highlight the importance of certifications and quality control in valve manufacturing for accurate pressure systems.

Certifications and quality control in valve manufacturing are critical for ensuring compatibility with accurate pressure systems. Standards verify that materials, designs, and manufacturing processes meet required specifications, while quality control ensures each valve operates as intended. Together, they support the reliability and safety of pressure systems by aligning valve performance with system requirements.

Key Takeaways About PSIAs and Pressure Systems

PSIAs is a measurement of absolute pressure, including atmospheric pressure, used in pressure systems to ensure proper operation. It provides accurate data for maintaining system balance, calibrating equipment, and optimizing valve functionality, contributing to efficient and reliable system performance.

Summarize the importance of understanding PSIAs in industrial applications.

Understanding PSIAs is essential in industrial applications as it represents the absolute pressure needed for precise system functionality. It accounts for atmospheric conditions and ensures accurate pressure measurements, which are critical for equipment calibration, proper valve operation, and maintaining system efficiency and safety.

Reinforce the role of PSIAs in optimizing the performance and longevity of valves, from flanged ball valves to butterfly valves.

PSIAs plays a critical role in optimizing valve performance and longevity by ensuring accurate pressure alignment within system parameters. Flanged ball valves and butterfly valves rely on precise PSIAs measurements to regulate flow, prevent overloading, and reduce wear. This alignment supports efficient operation and extends the service life of these components in pressure systems.

FAQ psia

Q1. What is PSIAs and how is it relevant to valve operations?

A: PSIAs, or pounds per square inch absolute, measures absolute pressure, which includes atmospheric pressure. It is crucial for ensuring efficient valve operations such as regulating flow and maintaining system balance. Whether managing a ball valve, gate valve, or butterfly valve, understanding PSIAs helps prevent misalignment in pressures that could impact performance.

Q2. How does PSIA affect the performance of specialized valves like pneumatic or electric valves?

A: PSIAs provides accurate pressure readings that determine the functionality of pneumatic valves and electric valves. These systems rely on precise absolute pressure measurements to actuate correctly and maintain flow control, ensuring they operate as designed under varying atmospheric conditions.

Q3. Why is PSIA important for flanged ball valves and other valve types in industrial systems?

A: Flanged ball valves, along with gate valves and butterfly valves, are designed to handle specific pressure ranges. PSIAs ensures their operations align with these ranges by accounting for total absolute pressure, reducing risks of overloading or underperformance, and extending valve lifespan.

Conclusion psia

Understanding PSIAs is key to maintaining efficient and reliable pressure systems. Valves like the pneumatic ball valve, 3 way ball valve, and electric ball valve require precise absolute pressure calculations to ensure effective flow control and operation. Similarly, components like the globe valve and pneumatic control valve depend on accurate PSIAs readings to maintain system stability and meet performance demands. By integrating PSIA into system design and operations, industries can optimize valve functionality, enhance safety, and improve overall system efficiency.