Valves play a critical role in industrial systems, serving as essential components for regulating and directing the flow of liquids, gases, and other substances. Whether it’s the reliable performance of a ball valve, the precision offered by a gate valve, or the space-saving design of a butterfly valve, each type is engineered to meet specific operational demands. From automation-driven solutions like the pneumatic valve to the energy-efficient control of the electric valve, understanding the distinct features and applications of these valves is key to optimizing performance, ensuring safety, and maintaining cost-effective operations. This guide explores their characteristics and uses, providing insights to help industry professionals make informed decisions tailored to their needs.

Introduction Pneumatic Valve

Pneumatic valves play a crucial role in regulating fluid flow and ensuring efficiency in industrial systems. From durable flanged ball valves to precise pneumatic ball valves, these components cater to varied operational needs. Options like 3-way ball valves offer flexibility for complex flow paths, while electric ball valves and globe valves provide reliable alternatives in specific scenarios. Additionally, pneumatic control valves deliver accuracy and automation for critical processes, making them indispensable across industries.

Understanding the Basics of a Pneumatic Valve

Definition and general working mechanism of pneumatic valves.

Pneumatic valves are devices that use compressed air to control the flow of fluids or gases within a system. By converting air pressure into mechanical motion, these valves precisely regulate operations, ensuring smooth and reliable performance. Their efficiency and responsiveness make them a critical component in automation, providing accurate flow control for a wide range of industrial applications.

Compare pneumatic valves with electric valves to underline operational distinctions.

Pneumatic valves and electric valves differ primarily in their power source and application benefits. Pneumatic valves rely on compressed air, offering quick responsiveness and durability, making them ideal for high-speed and heavy-duty operations. Electric valves, powered by electricity, provide greater precision and control, making them suitable for systems requiring detailed adjustments. While pneumatic valves excel in robustness, electric valves are often favored for automated setups requiring intricate flow regulation.

Explain how pneumatic control valves ensure precision in fluid regulation.

Pneumatic control valves ensure precision in fluid regulation by modulating flow rates with exceptional responsiveness to system demands. By utilizing compressed air for actuation, they provide accurate adjustments that maintain stability, even in fluctuating conditions. This reliability makes them indispensable for processes requiring consistent and precise flow control across various industrial applications.

Core Features of Pneumatic Valves

Key attributes like durability, responsiveness, and minimal maintenance needs.

Pneumatic valves stand out for their durability, ensuring long-term performance even in demanding environments. Their rapid responsiveness makes them ideal for operations requiring quick adjustments, while their simple design reduces maintenance needs. These attributes combine to deliver reliable and efficient performance, making pneumatic valves a trusted choice across diverse industrial applications.

Material options for valve construction (steel, brass, and copper) and their significance.

Pneumatic valves are constructed using materials like steel, brass, and copper, each chosen for its specific advantages. Steel offers exceptional durability and strength, making it ideal for high-pressure environments. Brass, with its excellent corrosion resistance, is well-suited for applications involving water or non-corrosive gases. Copper, valued for its thermal conductivity, is often used in specialized systems where heat transfer is critical. These material options ensure optimal performance and reliability across a wide range of industrial needs.

Introduction to specialized types such as pneumatic ball valves and 3-way ball valves for diversified usage.

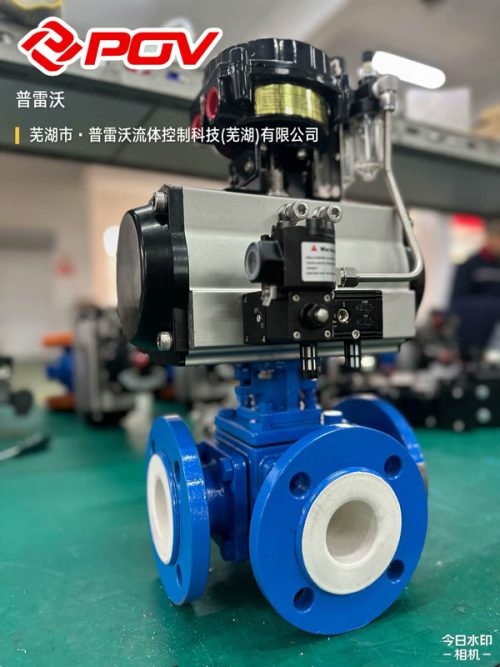

Pneumatic valves include specialized types like pneumatic ball valves and 3-way ball valves, designed to cater to diverse operational needs. Pneumatic ball valves provide efficient on-off control with a robust sealing mechanism, ensuring leak-free performance in high-pressure systems. Meanwhile, 3-way ball valves enable precise flow direction control, making them ideal for systems requiring fluid diversion or mixing. These versatile options enhance functionality, addressing a broad range of industrial applications with precision and reliability.

Exploring Ball Valves in Pneumatic Systems

Design and operation of ball valves for on/off control.

Ball valves in pneumatic systems are designed with a spherical closure mechanism featuring a central hole. When aligned with the flow, the hole allows fluid to pass through effortlessly, providing efficient on/off control. The precision-engineered sealing ensures minimal leakage, even under high pressures. This straightforward, durable design delivers reliable performance, making ball valves an essential component in systems requiring dependable and rapid flow regulation.

Overview of flanged ball valves and benefits for high-pressure environments.

Flanged ball valves are engineered for secure and reliable connections in high-pressure environments. Their bolted flanges create a tight seal, minimizing the risk of leaks even under extreme system stresses. Built with durable materials, these valves withstand demanding conditions, ensuring long-lasting performance. Their robust design makes them especially suitable for industrial applications requiring consistent and efficient fluid control in challenging operational settings.

Applications of pneumatic ball valves in systems requiring quick shut-off capabilities.

Pneumatic ball valves are vital in systems where quick shut-off capabilities are essential. Their rapid actuation and tight sealing ensure efficient and reliable flow control, minimizing downtime and preventing leaks. These attributes make them indispensable in industries like manufacturing and chemical processing, where precision, speed, and robust performance are critical to maintaining operational efficiency and safety.

Applications of Gate Valves in Pneumatic Systems

How gate valves are leveraged for linear fluid flow regulation.

Gate valves are designed to regulate linear fluid flow using a sliding gate mechanism that moves vertically within the valve body. This mechanism allows precise control, enabling operators to fully open or close the flow or adjust it incrementally as needed. Known for their reliability and minimal pressure drop, gate valves are ideal for applications across industries such as water treatment and oil and gas, where efficient and accurate flow regulation is critical.

Typical industries using gate valves, such as water distribution and energy production.

Gate valves are commonly used in industries requiring precise fluid control. The water distribution sector relies on gate valves for regulating flow in pipelines and managing water supply systems. Energy production facilities use them to control the flow of steam, oil, and other fluids in power generation processes. These industries depend on gate valves to ensure effective flow management suited to their operational needs.

Comparison with globe valves and their usage differences in pneumatic systems.

Gate valves and globe valves differ in their mechanisms and applications within pneumatic systems. Gate valves use a linear sliding gate to regulate flow, providing full open or close functionality, making them suitable for straightforward on/off control. Globe valves, featuring a globe-like body and a plug that moves perpendicular to the flow, are designed for more precise flow control and throttling. While gate valves are typically used in applications requiring minimal flow resistance, globe valves are chosen where fine flow adjustments are needed. These operational differences guide their use across varying system requirements.

Butterfly Valves and Their Pneumatic Integration

Advantages of butterfly valves for space-saving designs.

Butterfly valves are compact and lightweight, making them suitable for systems with limited space. Their simple construction consists of a rotating disc mounted on a shaft, allowing efficient flow control without occupying much room. This design reduces the need for large installation footprints, enabling integration into tight system layouts. These characteristics make butterfly valves practical for industries prioritizing efficient use of available space in their pneumatic systems.

Practical use in ventilation, air-conditioning, and water treatment systems.

Butterfly valves are used in ventilation systems to manage air flow by opening or closing the valve quickly. In air-conditioning systems, they regulate air distribution and control cooling or heating processes efficiently. Water treatment systems use butterfly valves for controlling the flow of water and managing treatment stages effectively. These functional roles contribute to the streamlined operation of these systems.

Brief contrast with other valve types, such as electric ball valves, highlighting unique features.

Butterfly valves differ from electric ball valves in design and function. Butterfly valves feature a rotating disc that controls flow by pivoting along a central shaft, making them suitable for quick open and close actions in pneumatic systems. Electric ball valves, on the other hand, use a spherical disc with a hole through the center to regulate flow, typically operated by an electric actuator. These valves are favored for applications requiring automated precise control and isolation. The contrast lies in their mechanisms, operating methods, and suitability for varying pneumatic system needs.

Advanced Control with Pneumatic Control Valves

Role in maintaining pressure, temperature, and flow consistency.

Pneumatic control valves maintain pressure, temperature, and flow consistency by adjusting the valve position based on input signals. They regulate fluid or gas flow within a system, ensuring that operating conditions remain stable. These valves are essential for processes requiring precise control to match system demands and maintain consistency in various industrial applications.

Explanation of automation integration using pneumatic control valves.

Pneumatic control valves integrate with automation systems by using actuators and positioners to respond to control signals. The valves adjust fluid or gas flow in real-time based on input from sensors or control systems. This integration allows continuous monitoring and regulation, ensuring the system operates according to predefined parameters. Automation enhances the efficiency and accuracy of processes requiring dynamic adjustments to varying conditions.

Industries relying on these valves for safety-critical and highly accurate applications.

Pneumatic control valves are used in industries like oil and gas, chemical processing, power generation, and pharmaceuticals for safety-critical and highly accurate applications. These valves help regulate flow, pressure, and temperature to maintain operational safety and comply with strict process requirements. Their ability to provide precise and reliable flow control ensures system integrity and supports demanding industrial standards.

Specialized Types: Electric Ball Valves and 3-Way Ball Valves

Situations where electric ball valves are preferred over pneumatic valves.

Electric ball valves are preferred over pneumatic valves in applications requiring precise control with limited air supply. They operate using electric actuators, making them suitable for environments without pneumatic infrastructure. These valves are often chosen for remote locations or systems needing advanced control features integrated with automated processes. Their design offers reliable operation in applications where energy efficiency or electrical control is prioritized.

The flexibility of 3-way ball valves in handling complex fluid diversion systems.

3-way ball valves manage complex fluid diversion systems by enabling multiple flow configurations within a single valve body. These valves can direct flow between different pipelines, mix fluids, or isolate specific sections, depending on the operational requirements. Their design reduces the need for additional valves and minimizes piping complexity, making them efficient for systems requiring frequent or varied flow adjustments.

Real-world examples of their integration in industry setups.

Electric ball valves are integrated into water treatment plants for automated flow control and energy management, while 3-way ball valves are used in chemical processing for fluid mixing and diversion. These valves are also applied in HVAC systems to regulate heat transfer and manage cooling loops. Their configurations provide effective solutions for systems requiring control, routing, and operational precision across various industries.

Benefits of Selecting the Right Valve Type

Relationship between valve choice, operational efficiency, and system longevity.

Choosing the correct valve type directly impacts operational efficiency and system longevity. Proper valve selection ensures efficient flow regulation, reducing energy waste and maintaining consistent processes. This reduces strain on equipment, minimizes wear, and avoids unplanned shutdowns. Aligning valve capabilities with operational needs also lowers maintenance demands and extends the lifespan of system components.

How flanged ball valves and butterfly valves ensure reliability in high-demand applications.

Flanged ball valves and butterfly valves ensure reliability in high-demand applications through their robust sealing mechanisms and versatile design. Flanged ball valves provide effective sealing under varying pressures, making them suitable for high-flow systems. Butterfly valves offer quick operation and are often used in large-scale setups for flow isolation or control. Both valve types support consistent performance and reduce downtime in systems requiring continuous operation.

Importance of consulting industry-certified manufacturers to meet project-specific needs.

Consulting industry-certified manufacturers ensures that valve selections align with project-specific requirements. Certified manufacturers provide expertise in matching valve specifications with operational demands, ensuring compliance with standards and optimal system performance. Their guidance reduces the risk of mismatched components, streamlines procurement, and supports long-term system reliability.

Best Practices for Maintenance and Quality Assurance

Implementing best practices for maintenance and quality assurance of pneumatic valve types involves regular inspections, proper cleaning, and timely lubrication of key components. Monitoring for wear, seal integrity, and operational alignment is essential to prevent performance issues. Adhering to manufacturer-recommended maintenance schedules and ensuring precise installation further supports consistent functionality and extends valve lifespan.

FAQ Pneumatic Valve

Q1: What are the key features of a pneumatic valve compared to an electric valve in industrial applications?

A1: A pneumatic valve operates using compressed air, offering fast response times and reliable performance in environments where electrical sparks could pose risks. Unlike an electric valve, which uses motors or solenoids for actuation, pneumatic valves are ideal for large-scale systems requiring rapid cycling. Both types can be used for regulating flow, but pneumatic valves are often preferred in high-temperature or hazardous conditions.

Q2: How do pneumatic ball valves and butterfly valves differ in application?

A2: A pneumatic ball valve is better suited for applications requiring tight shut-off and high-pressure control. It utilizes a rotating ball to block or allow flow efficiently. On the other hand, a pneumatic butterfly valve works best in systems with moderate pressure, as its disc design enables quicker flow regulation and minimal pressure drop. Both valves serve specific needs based on flow and pressure requirements.

Q3: Can pneumatic valves replace gate valves in fluid transportation systems?

A3: Pneumatic valves can replace gate valves in certain applications where quicker response time or remote operation is required. While a gate valve provides reliable sealing for on-off control in low-maintenance systems, a pneumatic valve offers greater flexibility with automation capabilities, making it ideal for processes that demand frequent adjustments or faster actuation. However, the choice depends on system design and operational requirements.

Conclusion Pneumatic Valve

Pneumatic valves serve a critical role in diverse industrial applications, offering reliable and efficient control of fluid and gas flow. From the precise operation of a pneumatic control valve to the versatility of a 3 way ball valve, each type addresses specific system requirements. A pneumatic ball valve and flanged ball valve, known for their durability and tight shut-off, are commonly used in high-pressure systems, while an electric ball valve provides automated functionality for streamlined operations. Similarly, the globe valve delivers dependable flow regulation, further showcasing the adaptability of pneumatic valve solutions. Understanding these features ensures optimal performance and longevity across various industries.