Choosing the right ball valve for industrial applications often comes down to understanding the differences between a floating ball valve and a trunnion ball valve. Both designs play critical roles in regulating flow, but their construction, performance, and suitability vary significantly based on operational needs. Whether you’re examining the stability of a trunnion mounted ball valve, comparing trunnion vs floating ball valve designs, or ensuring compliance with standards like API 6D ball valve specifications, this guide provides the insights you need to make an informed decision.

Introduction floating ball valve vs trunnion

Choosing the right valve type is crucial for optimal performance in any industrial application. Floating ball valves, known for their simple yet effective design, differ greatly from their trunnion-mounted counterparts in terms of functionality, durability, and specific applications. A float ball valve relies on the force of fluid pressure to create a tight seal, making it ideal for lower-pressure systems. Meanwhile, a trunnion-mounted design offers enhanced stability and is better suited for handling high-pressure conditions. Whether you’re evaluating a ball valve for general use or exploring configurations like a 3 way ball valve for complex flow control, understanding these differences ensures that you select the appropriate solution for your operational needs.

Brief overview of ball valves and their applications.

Ball valves are mechanical devices used to control the flow of fluids through a piping system. They operate by rotating a ball with a bore, which aligns with the flow path to allow or block the passage of fluid. These valves are commonly used in industries such as oil and gas, chemical processing, water treatment, and manufacturing, where precise flow control is required. With designs ranging from basic float ball valves to complex configurations like 3 way ball valves, they serve various operational needs, including isolation, flow diversion, and system shutdowns. Understanding their functions and use cases is essential for selecting the appropriate type for specific applications.

Introduce the floating ball valve vs trunnion comparison and its significance for buyers and engineers.

The comparison between floating ball valves and trunnion ball valves is vital for buyers and engineers involved in selecting equipment for industrial systems. Each type of valve has different operational mechanisms and suitability for specific applications. Floating ball valves depend on fluid pressure for sealing, while trunnion ball valves use a fixed system to stabilize the ball, affecting performance and pressure handling. Understanding these differences helps buyers match the valve to the system’s requirements, ensuring operational efficiency, compliance with standards, and alignment with technical needs.

Understanding the Basics of Ball Valves

Define ball valves and their role in flow control systems.

Ball valves are mechanical components used to regulate and isolate the flow of liquids or gases within a system. They feature a spherical ball with a hole through the center, which rotates to either allow or block the flow. This design enables precise control and efficient shut-off, making ball valves suitable for a wide range of flow control systems. Commonly deployed in industries like oil and gas, water treatment, and manufacturing, ball valves are essential for maintaining system reliability and managing flow patterns effectively.

Highlight key differences between floating ball valves and trunnion mounted ball valves.

Floating ball valves and trunnion mounted ball valves differ in their design and operation. Floating ball valves rely on the fluid pressure to push the ball against the downstream seat to achieve sealing, and they are commonly used in low to medium pressure systems. Trunnion mounted ball valves, on the other hand, have a fixed ball supported by trunnion shafts, allowing them to handle higher pressures and reduce operational torque. These structural differences determine their suitability for specific applications based on pressure, size, and operational needs.

What is a Floating Ball Valve?

Explain the mechanism of the float ball valve.

The float ball valve operates using a spherical ball with a hole through its center, positioned within the valve body. When the valve handle rotates, the ball turns, aligning the hole with the pipeline to allow flow or turning it perpendicular to block flow. The ball remains suspended and is free to move slightly within the valve body, relying on fluid pressure to press against the downstream seat for sealing. This design ensures flow control and shutoff capabilities, with the ball’s movement determined by the force exerted by the operating handle or actuator.

Advantages of ball valve floating ball designs, including simplicity and cost-effectiveness.

Floating ball valve designs offer practical benefits due to their straightforward mechanism and reduced manufacturing requirements. Their construction involves fewer components compared to other valve types, which simplifies installation, maintenance, and overall operation. The design relies on fluid pressure for effective sealing, eliminating the need for complex anchoring components like trunnion supports. This reduces production costs and makes floating ball valves a cost-efficient choice for systems operating at low to medium pressures while still maintaining reliability in controlling flow and system isolation.

Common applications for floating ball valves.

Floating ball valves are commonly used in systems requiring reliable flow control and isolation. These valves are utilized in industries such as water treatment, chemical processing, oil and gas, and power generation. They are particularly suited for systems operating at low to medium pressures, where their design supports effective sealing through fluid pressure. Floating ball valves are also found in pipeline systems, storage tanks, and processing facilities, ensuring efficient regulation of fluid and gas flow within various operational requirements.

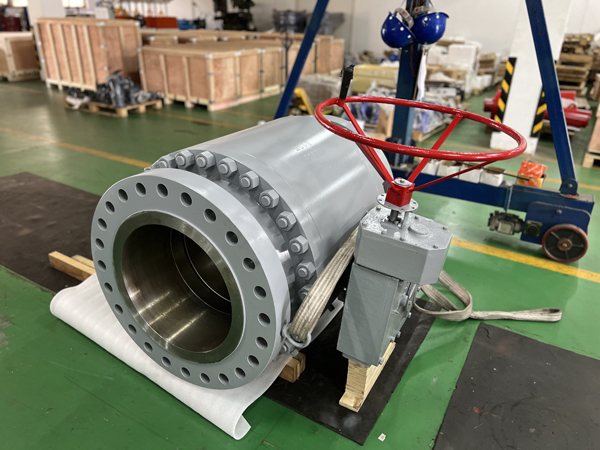

Trunnion Ball Valve Explained

Detailed overview of the trunnion ball valve and how it differs from the floating design.

The trunnion ball valve is designed with a ball component that is anchored by bearings at both the top and bottom, known as trunnions, which provide stability and reduce the stress on the valve seats. This design allows the valve to handle higher pressure applications with lower operational torque compared to floating ball valves. Unlike floating ball valves, which rely on fluid pressure to achieve sealing by pressing the ball against the downstream seat, the trunnion design distributes the force evenly, ensuring consistent performance. These structural differences make each valve type suited for different system requirements, with trunnion ball valves preferred for larger, high-pressure pipelines.

Benefits of the trunnion valve system, such as reduced wear and effective sealing.

The trunnion valve system is designed to minimize wear by anchoring the ball with trunnions, which reduces the stress placed on valve seats during operation. This structure distributes force throughout the valve, rather than concentrating it at a single point, which extends the lifespan of the components. Additionally, the design facilitates effective sealing, as the ball remains firmly in position, allowing for a consistent seal even in high-pressure applications. This ensures reliable performance for flow control and isolation in demanding operational environments.

Discuss the specifications of an API 6D ball valve and its relevance in trunnion designs.

An API 6D ball valve is manufactured to meet the standards set by the American Petroleum Institute for pipeline valves, ensuring compliance with precise operational and safety requirements. These valves include specifications for features such as double block and bleed functionality, bi-directional sealing, and specific material construction to handle various pipeline media. Within trunnion valve designs, the API 6D certification is particularly relevant as it guarantees that the valve can operate under high-pressure and high-temperature conditions while maintaining reliable sealing and flow control. It also ensures the valve supports operational needs in oil, gas, and industrial pipelines, aligning with global quality and performance standards.

Trunnion vs Floating Ball Valve: Key Comparisons

Mechanical differences in operation and structure.

Trunnion and floating ball valves differ in their mechanical operation and structural design. A trunnion ball valve features a ball that is anchored by trunnions at both the top and bottom, allowing the valve to handle higher pressure with reduced operational torque. This anchoring prevents excessive load on the valve seats. The floating ball valve, in contrast, relies on the force of the fluid to press the ball against the downstream seat to create a seal. This design lacks the anchoring points found in trunnion valves, which means the ball in floating designs moves slightly with fluid pressure. These structural variations influence their suitability for different pressure ranges and system requirements.

Performance advantages for specific industries and operating conditions.

Trunnion and floating ball valves provide distinct performance advantages based on industry requirements and operating conditions. Trunnion ball valves are well-suited for applications involving high-pressure pipelines, as their anchored design helps maintain sealing effectiveness and reduces operational torque in oil, gas, and petrochemical industries. Floating ball valves are effective in systems with low to medium pressure, relying on fluid force for sealing, making them widely used in water treatment plants and general industrial processes. These operational differences allow each design to address specific challenges across diverse sectors.

Factors to consider when choosing between trunnion vs floating ball valve.

When selecting between trunnion and floating ball valves, it is essential to evaluate factors such as pressure requirements, flow control needs, and the operating environment. Trunnion ball valves are suited for high-pressure applications due to their anchored design, which reduces stress on valve seats. Floating ball valves, relying on fluid pressure for sealing, are effective for low to medium pressure systems. Additional considerations include the type of medium being transported, the required level of sealing performance, and overall system design compatibility. These factors help determine which valve design provides the most efficient and reliable solution for specific applications.

Choosing the Right Valve for Your System

Evaluate pressure and temperature requirements for both floating ball valves and trunnion mounted ball valve options.

When evaluating pressure and temperature requirements, it is important to consider the operating limits of both floating ball valves and trunnion mounted ball valves. Floating ball valves are typically designed for low to medium pressure systems, as the sealing relies on fluid force to press the ball against the downstream seat. They are commonly used where temperature variations are within a moderate range. Trunnion mounted ball valves are built to handle higher pressure levels due to their anchored ball design, which reduces seat wear and ensures stability under extreme conditions. This design also makes them suitable for applications with more demanding temperature requirements, ensuring reliable performance across a broad range of operating environments.

Impact of valve size and material on decision-making.

Valve size and material are key factors in the decision-making process for system design and operation. The size of the valve must align with the system’s flow rate requirements to ensure optimal performance without causing pressure drops or inefficiencies. Material selection depends on the medium being transported and the operating conditions, such as temperature, pressure, and potential for corrosion. For instance, metallic valves like stainless steel are often chosen for high-temperature or corrosive environments, while thermoplastic options may be preferred for chemical compatibility in specific applications. Analyzing these factors ensures the valve meets the operational needs and provides long-term reliability.

Brief mention of specialized designs like the 3 way ball valve to showcase versatility.

Specialized valve designs, such as the 3 way ball valve, enhance the versatility of fluid control systems. A 3 way ball valve allows multiple flow paths, enabling applications such as mixing, diverting, or isolating flows within a single system. These valves can be configured in T-port or L-port arrangements to accommodate specific operational requirements. Their ability to streamline complex piping systems and adapt to different flow patterns makes them a valuable option for industries requiring efficient fluid control solutions.

Maintenance and Longevity Considerations

Compare maintenance needs of trunnion valves vs floating ball valves.

The maintenance requirements of trunnion valves and floating ball valves differ based on their design and application. Trunnion valves typically involve more components, such as seats and stem bearings, which may require periodic inspection and replacement in high-pressure or high-cycle applications. However, their anchored ball design can reduce wear on sealing surfaces, potentially reducing downtime for seat replacement. Floating ball valves, with fewer components, generally have lower maintenance demands, but their reliance on fluid pressure for sealing may result in accelerated seat wear in certain conditions, requiring more frequent replacement. Understanding these differences helps optimize maintenance schedules and long-term operational costs.

Tips for ensuring long-term performance of each type of valve.

To ensure long-term performance of trunnion and floating ball valves, regular maintenance and proper operational practices are critical. For trunnion-mounted valves, periodic inspection of components such as the bearings, trunnion, and seals is essential to prevent wear-related issues. Lubrication of moving parts helps maintain smooth operation and reduces friction. For floating ball valves, monitoring seat wear is important as the sealing relies on fluid pressure. Replacing worn seats and checking for proper alignment during maintenance can help sustain performance over time. Adhering to manufacturer guidelines for installation and maintenance ensures the valve operates effectively throughout its service life.

Final Thoughts on Floating Ball Valve vs Trunnion Selection

Summarize the critical points discussed.

Selecting between floating ball valves and trunnion-mounted ball valves requires attention to several key factors. Consideration should be given to the system’s pressure and temperature requirements, as these influence the compatibility of each valve type. Maintenance needs differ, with trunnion valves offering potential benefits in high-pressure or high-cycle applications due to their design, while floating ball valves may require less frequent maintenance but can experience faster seat wear in certain conditions. Evaluating material and size compatibility, along with adherence to proper maintenance practices, ensures optimal performance and longevity of the selected valve type.

Reinforce the importance of understanding operational needs when selecting a valve.

Understanding operational needs is crucial when selecting between floating ball valves and trunnion-mounted ball valves. A clear assessment of the pressure, temperature, and fluid type helps determine the valve type best suited for the system. Identifying the application’s frequency of use and maintenance capacity also ensures that the chosen valve aligns with long-term operational goals. Factoring in these requirements reduces risks associated with improper valve selection and supports efficient system performance throughout its lifecycle.

FAQ floating ball valve vs trunnion

What makes a trunnion mounted ball valve suitable for high-pressure applications?

Trunnion-mounted ball valves are designed to handle high-pressure applications through their unique structural features. The trunnion support mechanism stabilizes the ball and reduces excessive load on the seats, ensuring consistent sealing under high pressure. This design minimizes torque requirements for valve operation, enhancing efficiency. Additional sealing components, such as polymer or metal seats, provide reliable containment of fluids under varying conditions. These characteristics make trunnion-mounted ball valves a dependable option for maintaining system integrity in high-pressure environments.

How does the API 6D ball valve standard impact valve performance?

The API 6D standard establishes requirements for the design, testing, and manufacturing of pipeline ball valves, ensuring performance consistency and safety. It mandates guidelines for pressure ratings, materials, body containment, and operational capabilities. By adhering to this standard, manufacturers deliver valves capable of withstanding high-pressure conditions while minimizing leakage risks. Compliance with API 6D also ensures valves perform effectively in applications requiring absolute reliability, supporting the operational efficiency and long-term durability of pipeline systems.

Can a 3 way ball valve be implemented in systems requiring floating ball valves or trunnion valves?

A 3-way ball valve can be implemented in systems requiring floating or trunnion-mounted ball valves if the system design permits flow diversion or mixing. While floating and trunnion valves are generally used for maintaining tight shutoff under specific pressure conditions, 3-way ball valves are designed to manage multiple flow paths. The decision to incorporate a 3-way valve depends on the application’s flow requirements, pressure levels, and operational conditions. Proper evaluation of these factors ensures compatibility and optimal system functionality.

Conclusion floating ball valve vs trunnion

Selecting the right valve type between a floating ball valve vs trunnion depends on a clear understanding of system requirements, operating conditions, and design specifications. A trunnion ball valve, often referred to as a trunnion mounted ball valve, is optimized for high-pressure applications due to its support mechanism and robust sealing capabilities. Comparatively, when evaluating trunnion vs floating ball valve options, the specific needs of the flow path, pressure containment, and operational efficiency must guide the decision. Adherence to standards like the API 6D ball valve ensures reliability and long-term performance. By carefully assessing whether a trunnion valve or a floating ball valve meets the system’s demands, operators can make informed choices that support safety and efficiency.