Selecting the right valve type is crucial for ensuring safety and efficiency in industrial systems. When it comes to the “Fail Close Open valve” concept, understanding the distinctions between fail-open and fail-close mechanisms is key. These systems rely on precise engineering, incorporating designs like ball valves, gate valves, and butterfly valves. Actuation options, such as pneumatic and electric valves, drive their functionality, while specialized configurations like flanged ball valves enhance reliability in critical scenarios. This guide explores the design, applications, and advantages of these vital components, helping you make informed choices for your operational needs.

Introduction Fail Close Open valve

A “Fail Close Open valve” represents a critical choice in system safety and functionality, dictating whether a valve remains open or closed during a failure. Designs like the pneumatic ball valve and electric ball valve deliver automated precision, while the globe valve ensures robust shutoff in high-pressure applications. For more complex systems, the 3 way ball valve offers versatile flow control, and the pneumatic control valve provides enhanced accuracy for fail-safe operations. These solutions are pivotal in tailoring system performance to specific industrial requirements.

Understanding Fail-Open and Fail-Close Valve Concepts

Definition and core differences between fail-open and fail-close valve mechanisms.

Fail-open and fail-close valve mechanisms are designed to respond differently during system failures, making them essential for ensuring safety and operational control. A fail-open valve is engineered to open fully when there is a loss of power or pressure, allowing for the release of fluids or gases to prevent dangerous buildup. Conversely, a fail-close valve shuts tightly under the same conditions to block flow, safeguarding systems from uncontrolled leaks or hazardous exposure. The choice between these mechanisms depends on application needs, such as prioritizing containment in fail-close systems or enabling pressure relief in fail-open configurations. These fundamental differences are critical in designing reliable, fail-safe operations for various industries.

Key considerations like safety protocols, system shutdowns, and operational goals.

When selecting fail-open or fail-close valve systems, key considerations such as safety protocols, system shutdowns, and operational goals play a pivotal role. Safety protocols dictate whether containing hazards or relieving pressure is critical during failures, guiding the choice of valve type. System shutdown requirements also influence this decision; industries with high-risk processes may prioritize fail-close mechanisms to prevent leaks, while fail-open configurations might be preferred for pressure management. Additionally, aligning the valve’s function with operational goals ensures efficiency and reliability, creating systems that are both secure and performance-driven under any circumstance.

Fail Close Open Valve Mechanisms and Design Variations

Breakdown of valve designs used in fail-open and fail-close applications.

Fail-open and fail-close applications rely on specific valve designs tailored to meet their operational demands. Ball valves, known for their quick actuation and tight sealing, are frequently used in fail-close scenarios to prevent leaks under critical conditions. Gate valves offer robust shutoff capabilities, making them ideal for systems requiring infrequent actuation yet reliable closure when needed. On the fail-open side, globe valves are favored for their precision in regulating flow during pressure release scenarios. Meanwhile, pneumatic and electric actuation mechanisms enhance automation and responsiveness, ensuring these valves perform effectively during power or pressure failures. These design variations allow industries to customize systems that align with safety and performance objectives.

Valve types explored in detail, including ball valves, butterfly valves, and gate valves.

Ball valves, butterfly valves, and gate valves each play distinct roles in fail-open and fail-close systems due to their unique designs and functionalities. Ball valves excel in fail-close applications, offering swift actuation and leak-proof sealing, which is critical in preventing hazardous leaks. Butterfly valves, with their compact design and quick operation, are often used where space is a constraint and moderate flow control is needed, making them versatile across both fail-open and fail-close setups. Gate valves, designed for robust shutoff capability, are ideal in systems requiring full, infrequent closure, ensuring reliable performance under high-pressure conditions. These valve types are tailored to align with system-specific safety and efficiency needs.

Flanged Ball Valve and Globe Valve Configurations for Fail-Close Applications

Engineering designs tailored for maximum reliability in fail-close scenarios.

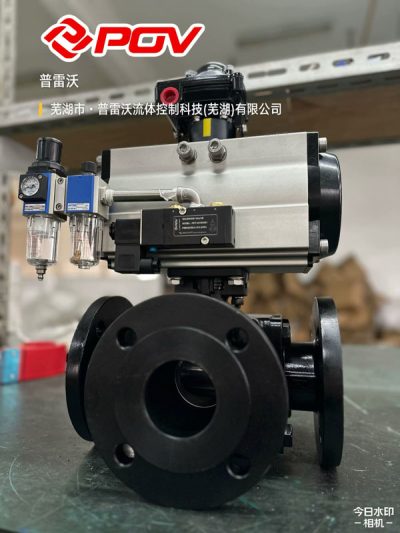

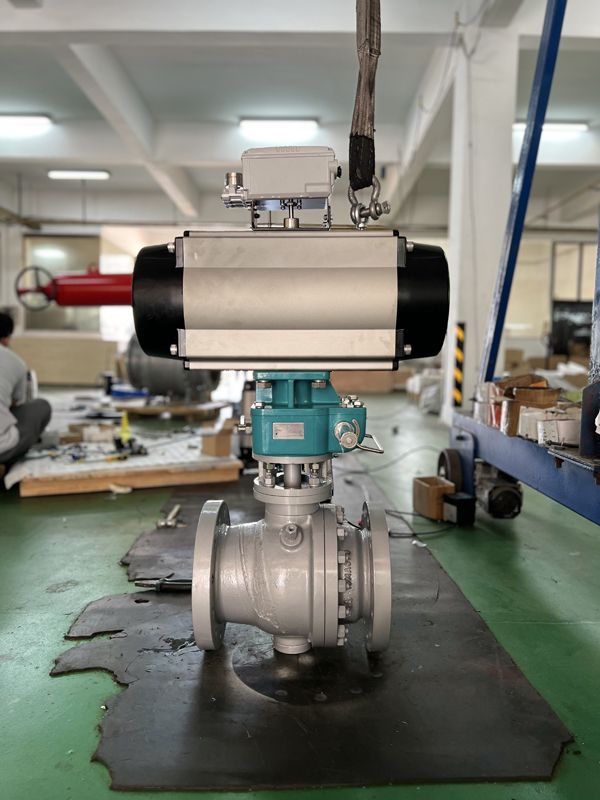

Flanged ball valves and globe valve configurations are meticulously engineered to deliver maximum reliability in fail-close scenarios where system integrity and safety are paramount. Flanged ball valves are valued for their tight sealing and rapid actuation, offering dependable prevention of leaks even under high-pressure conditions. Globe valves, with their precise throttling capability, provide exceptional control over flow during critical operations, ensuring consistent and fail-safe performance. Both designs prioritize material resilience and actuation efficiency, reinforcing their ability to operate effectively during power failures or other emergencies. These tailored configurations enable industries to maintain operational security and minimize risks in demanding environments.

Advantages of flanged ball valves and globe valves in shutting down operation.

Flanged ball valves and globe valves offer distinct advantages for efficient and secure system shutdowns in fail-close applications. Flanged ball valves excel with their quick actuation and exceptional sealing, ensuring instantaneous isolation of flow to prevent leaks or system breaches during emergencies. Their robust construction makes them ideal for high-pressure systems, maintaining integrity under extreme conditions. Globe valves, on the other hand, provide precise flow control, allowing for gradual and controlled shutdowns, which is critical in processes sensitive to sudden operational changes. Both valve types prioritize durability, safety, and precision, making them essential for achieving reliable and fail-safe shutdown operations in critical industries.

Fail Close Open Valve Solutions Using Pneumatic and Electric Actuation

Role of actuation systems in fail-open and fail-close valve performance.

Pneumatic and electric actuation systems play a crucial role in ensuring the performance and reliability of fail-open and fail-close valves in critical applications. Pneumatic actuators, renowned for their speed and simplicity, leverage compressed air to achieve rapid valve movement, making them ideal for fail-open scenarios that demand immediate flow restoration. Electric actuators, with their precision and programmable features, enable controlled and consistent operation, particularly valuable in fail-close systems requiring gradual and secure shutdowns. Both actuation mechanisms are engineered for resilience, ensuring that valves respond accurately during power interruptions or system malfunctions, thereby enhancing operational safety and efficiency in diverse industrial environments.

Use cases for pneumatic valves, electric valves, pneumatic ball valves, and electric ball valves.

Pneumatic valves and electric valves each serve distinct purposes in industrial applications, with their advantages further refined when used with ball valve configurations. Pneumatic valves, including pneumatic ball valves, excel in fast response operations such as emergency shut-offs or quick restorations of flow, making them ideal for fail-open systems in industries like oil and gas. Their simplicity and reliability under extreme conditions enhance their suitability for high-pressure environments. Electric valves, including electric ball valves, are preferred in applications requiring precise control and programmability, such as systems where gradual flow regulation or secure fail-close functionality is critical. These valves are commonly found in automated processes within chemical and pharmaceutical industries. Together, these configurations provide tailored solutions to meet the varied demands of complex operations.

Special Considerations for 3 Way Ball Valves and Pneumatic Control Valves

Application-specific functions offered by 3 way ball valves in multi-directional flow control.

3-way ball valves provide exceptional versatility in multi-directional flow control, making them indispensable in managing complex flow systems across diverse industries. These valves are uniquely designed to allow fluid diversion, mixing, or isolation within a single unit, reducing the need for multiple valves and streamlining system configurations. Commonly utilized in chemical processing, HVAC systems, and water treatment facilities, 3-way ball valves excel in directing flow between multiple pipelines or controlling shared fluid circuits. Their robust construction and smooth actuation ensure reliable performance, even in high-pressure and high-temperature environments. With various port configurations, such as L-port or T-port options, these valves can be tailored to specific application demands, enhancing operational flexibility and efficiency.

How pneumatic control valves provide enhanced precision in managing fail scenarios.

Pneumatic control valves are pivotal in achieving enhanced precision when managing fail scenarios, offering unmatched control and responsiveness critical for maintaining safety and system integrity. These valves operate using compressed air, enabling swift and accurate adjustments even under fluctuating system pressures. Their ability to modulate flow precisely ensures minimal disruption and tightly controlled system behavior during fail-open or fail-close events. This level of precision is particularly advantageous in industries like power generation, chemical processing, and energy sectors where reliability and swift failsafe actions are crucial. Engineered for robustness and adaptability, pneumatic control valves effectively safeguard operations, preventing damage and ensuring seamless recovery in high-stakes environments.

Industry-Specific Use Cases and Best Practices

Fail-open and fail-close valves are integral to ensuring safety and functionality across various industries, with their applications tailored to specific operational demands. Fail-open valves are commonly employed in systems where maintaining flow during a failure is critical, such as cooling systems in power plants or emergency safety circuits in chemical facilities. Conversely, fail-close valves are vital in processes that require immediate shutoff to prevent accidents, such as in oil and gas pipelines or hazardous material handling. Best practices for implementing these valves include thorough system analysis to determine fail-state requirements, regular maintenance checks to ensure actuation reliability, and integrating advanced control systems for seamless operation during critical scenarios. By aligning valve configurations with industry-specific needs, organizations can optimize performance while maintaining safety and compliance.

Quality Standards and Manufacturing Expertise

Adherence to stringent quality standards and exceptional manufacturing expertise are essential in producing reliable fail-open and fail-close valves tailored for critical applications. These valves must meet or exceed industry regulations, such as API, ASME, and ISO certifications, ensuring they perform seamlessly under demanding conditions. Precision engineering, rigorous testing protocols, and the use of high-grade materials are key factors that safeguard the valves’ dependability and longevity. Advanced manufacturing capabilities, including state-of-the-art machining and automated assembly processes, further enhance product consistency and minimize the risk of operational failures. By leveraging technical expertise and a commitment to quality, manufacturers deliver valves that exceed performance expectations, promoting safety and operational efficiency across diverse industries.

FAQ Fail Close Open valve

Q1: What are the advantages of using a fail-close open valve in combination with a ball valve for industrial applications?

A1: Fail-close open valves integrated with ball valves provide exceptional versatility and reliability in critical operations. Ball valves, known for their quick on-off capabilities, ensure efficient flow control during fail scenarios. When paired with a fail-close or fail-open mechanism, these valves enhance safety by responding promptly to emergencies, such as pipeline pressure issues. Additionally, flanged ball valves are commonly used in industries requiring robust connections and easy maintenance, making them a reliable choice for fail-state applications.

Q2: How do fail-close open valves differ when used with gate valves compared to butterfly valves?

A2: Gate valves and butterfly valves function differently when paired with fail-close open systems. Gate valves, ideal for applications where minimal flow resistance is critical, allow for complete isolation during a fail-close scenario. Meanwhile, butterfly valves, valued for their compact design and cost efficiency, excel in throttling operations, making them suitable for fail-open systems. Both valve types can be enhanced with pneumatic valve or electric valve actuation systems, providing precise control and adaptability in diverse operational contexts.

Q3: Why are pneumatic and electric valves crucial for fail-close open valve configurations?

A3: Pneumatic valves and electric valves play a key role in automating fail-close open valve systems, ensuring rapid and accurate responses during emergencies. Pneumatic valves, powered by compressed air, offer consistent performance in fail scenarios, while electric valves deliver precise control through advanced electronic systems. These actuation mechanisms are commonly used with ball valves, gate valves, and butterfly valves, tailoring their functionality to specific industry needs. For example, flanged ball valves equipped with electric actuators are ideal for high-pressure environments due to their durability and precision.

Conclusion Fail Close Open valve

Choosing between a fail-close or fail-open valve is a critical decision that directly impacts the safety, efficiency, and reliability of system operations. Whether utilizing a pneumatic ball valve for rapid response during emergencies, a 3 way ball valve for multi-directional flow control, or an electric ball valve for precise automated operation, selecting the right valve type ensures optimal performance tailored to specific needs. Similarly, the deployment of globe valves for throttling applications or pneumatic control valves for enhanced fail-scenario management highlights the importance of aligning valve functionality with industry demands. By understanding the unique attributes of fail-close open valves and matching them to operational requirements, industries can maintain system integrity, prevent failures, and uphold safety across diverse applications.