When it comes to selecting the right cylinder for your application, understanding the differences between a double acting vs single acting cylinder is vital. These essential components play a key role in motion control, with their efficiency often hinging on systems like pneumatic actuator setups or pneumatic valves and actuators. Whether you’re working with a pneumatic actuator valve for precision or an air powered actuator for robust performance, the functionality and application needs vary between these two designs. This guide will help you identify the best choice for your system, ensuring optimal performance and reliability.

Introduction to Cylinders and Their Role in Industrial Applications

Cylinders are fundamental to motion control in industrial applications, offering precision and reliability across various systems. Whether utilizing an electric actuator for automated solutions or integrating an electric valve actuator to regulate flow, these components streamline operations. From the robust capabilities of a double acting actuator to the efficiency of single acting double acting configurations, actuator valve technologies, including electric actuated ball valve systems, drive performance and adaptability in demanding environments.double acting vs single acting cylinder

Brief overview of the importance of actuators pneumatic in modern operations.

Pneumatic actuators play a key role in modern operations by converting compressed air into mechanical motion. These systems are widely used for controlling processes, executing repetitive tasks, and automating movements in industrial machinery. Their design allows for efficient energy use and integration with various control systems, ensuring functionality across different applications such as regulating flow, operating valves, and enabling motion in production lines.

Highlight the functionality of pneumatic actuator systems in industrial settings.

Pneumatic actuator systems operate by converting compressed air into mechanical energy, enabling control over various mechanical processes in industrial settings. These systems are used to automate valve operations, execute linear or rotary motion, and facilitate the precise control of equipment. Their ability to function in high-cycle tasks and integrate with broader process systems makes them essential in applications such as flow regulation and equipment motion control.

What is a Double Acting Cylinder?

Explanation of a double acting actuator and its working mechanism.

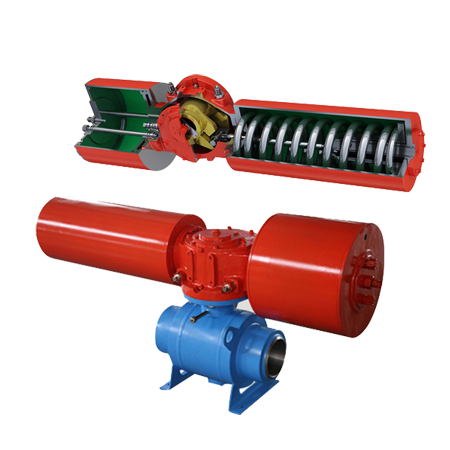

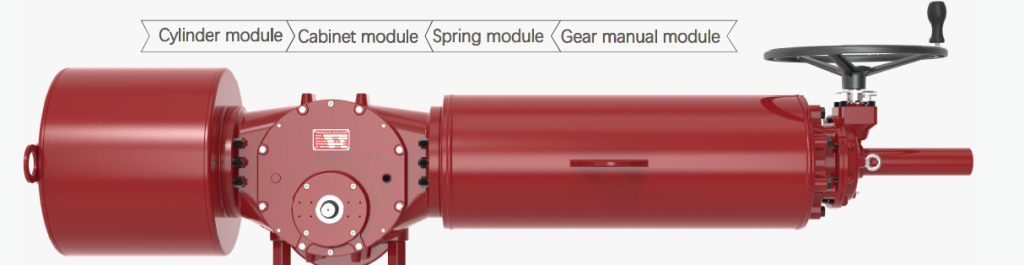

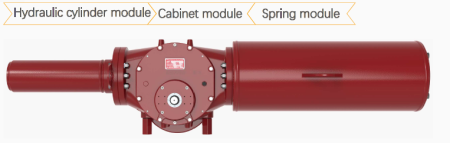

A double acting actuator operates by using compressed air on both sides of the piston to create motion in two directions. This design allows force to be applied alternately on either side, enabling both extension and retraction without the need for external springs or mechanisms. The working mechanism relies on controlled air pressure supplied through valves, which directs airflow to the required side of the piston, achieving precise and efficient motion control for various industrial applications.

Applications where air powered actuator systems are crucial for double acting performance.

Air powered actuator systems are essential in applications that require controlled motion in both directions, as provided by double acting performance. These systems are commonly used in industrial automation, where precision in processes such as material handling, automated assembly, and robotic movement is required. They are also critical in valve control systems, where the ability to open and close valves efficiently is necessary for regulating fluid or gas flow. Their integration into systems requiring high-cycle operations ensures consistent functionality and adaptability to varied industrial tasks.

Advantages of using pneumatic valves and actuators in double acting cylinders.

Pneumatic valves and actuators in double acting cylinders provide effective control over motion by directing compressed air to both sides of the piston. This ensures force can be applied in both extension and retraction strokes, eliminating the reliance on external springs. Their design supports high-cycle operations and allows precise modulation of motion, making them suitable for applications that demand consistent and repeatable performance. Additionally, their integration with control systems facilitates efficient automation and enhances operational flexibility across a variety of industrial processes.

What is a Single Acting Cylinder?

Definition of a single acting actuator and how it operates.

A single acting actuator operates by using compressed air to create motion in one direction, with the return motion achieved through an external spring or a similar mechanism. The working principle involves directing compressed air to one side of the piston via a valve system, generating the required force for the actuation process. Once the air supply is released, the spring or external mechanism restores the actuator to its original position. This design simplifies control in operations that only require unidirectional movement, making it suitable for applications such as clamping, lifting, and pressing.

Which industries benefit most from single acting double acting setups.

Single acting and double acting setups are commonly utilized across industries where precise motion control is essential. The manufacturing sector relies on these setups for automated assembly lines and material handling systems. The energy and utilities industry integrates these systems in valve control for fluid and gas regulation. Food and beverage processing utilizes them for packaging and filling equipment. Additionally, the automotive industry incorporates these actuators in production and testing equipment. Their versatility in enabling motion and force control makes them integral to industries with repetitive or high-cycle operations.

Comparison between pneumatic actuator valve systems and electric actuator systems in single acting functionality.

Pneumatic actuator valve systems and electric actuator systems differ in their operation for single acting functionality. Pneumatic systems rely on compressed air to move the actuator in one direction, with external springs or mechanisms providing the return motion. These systems are suitable for applications requiring simple, straightforward movement and can operate in environments where electric systems might not be practical. Electric actuator systems, on the other hand, use an electric motor to produce motion. Their functionality enables precise control over movement and force without the need for an external return mechanism, as the motor handles the motion in both directions. The choice between these systems depends on factors such as energy source availability, operational requirements, and environmental conditions.

Double Acting vs Single Acting Cylinder: Key Differences You Need to Know

Side-by-side comparison of double acting cylinders vs single acting cylinders.

Double acting cylinders and single acting cylinders differ in their operation and applications. Double acting cylinders use compressed air or fluid to move the piston in both directions, requiring constant input for movement and offering greater control over motion. Single acting cylinders, on the other hand, rely on compressed air or fluid for movement in one direction, with an internal or external spring providing the return force. Double acting cylinders are better suited for applications requiring continuous and bidirectional motion, while single acting cylinders are effective in tasks where unidirectional force is sufficient. The choice between the two depends on the specific operational needs and system design requirements.

How electric valve actuator options compare to air powered actuator systems in efficiency and control versatility.

Electric valve actuator options and air-powered actuator systems differ in efficiency and control versatility. Electric valve actuators use electric motors to provide precise motion control, allowing adjustments in speed, position, and force without the need for external mechanisms. They are well-suited for applications where high levels of control and programmability are necessary. Air-powered actuator systems, in contrast, rely on compressed air to drive movement. These systems offer simple operation and are effective in environments where electric actuators may not be feasible due to safety or environmental factors. The choice between the two systems largely depends on operational demands, available resources, and specific application requirements.

Highlight cost, performance, and maintenance differences when choosing actuator valve types.

When choosing actuator valve types, differences in cost, performance, and maintenance should be considered. Pneumatic actuators typically have lower upfront costs and are widely used in systems where air supply is readily available. They are suitable for consistent performance in environments that require simple motion control. Electric actuators generally have higher initial costs but offer precise motion control and programmability, making them well-suited for applications with complex operational needs. Maintenance requirements also vary, with pneumatic actuators often needing regular inspection and servicing to ensure air supply systems remain functional, while electric actuators tend to require less frequent but specialized servicing. The decision hinges on factors such as budget, desired operational efficiency, and long-term system upkeep considerations.

Factors to Consider When Choosing the Right Cylinder

Importance of understanding system requirements, including pneumatic actuator or electric actuated ball valve preferences.

Understanding system requirements is essential when selecting between pneumatic actuators and electric actuated ball valves. Pneumatic actuators are often chosen for systems with existing compressed air infrastructures, providing straightforward operation for tasks that involve on/off control or simple motion. Electric actuated ball valves, on the other hand, offer programmable control and are suited for applications requiring precise positioning or integration with automated systems. Evaluating factors such as energy availability, control needs, installation constraints, and system compatibility is necessary to determine which option aligns with operational goals and long-term efficiency demands.

Environmental considerations, operating pressures, and the need for specific pneumatic valves and actuators.

Environmental considerations, operating pressures, and system demands play a critical role in selecting the appropriate pneumatic valves and actuators. The operating environment may determine material compatibility, such as resistance to corrosion or temperature extremes, while operating pressures define the valve and actuator specifications required to maintain system performance. Certain applications may necessitate valves and actuators designed for high-pressure operations or compliance with specific industry standards. Additionally, understanding how environmental factors might impact energy consumption or system wear helps ensure that the chosen components meet both operational and regulatory expectations.

Long-term maintenance perspectives for double acting actuator systems vs single acting systems.

Long-term maintenance for double acting actuator systems and single acting systems varies based on operational mechanics and design requirements. Double acting systems, which rely on compressed air or fluid to move the actuator in both directions, often require continuous maintenance of seals and control components to ensure consistent performance over time. Single acting systems, using a single-direction force with a return mechanism such as a spring, may require specific attention to the spring’s integrity and potential wear from repeated compression cycles. Maintenance considerations for both systems should include regular inspections, lubrication, and monitoring of system components to prevent downtime and ensure reliable operation.

Industries That Use Single and Double Acting Cylinders

Key industries using pneumatic actuator valve arrangements for motion and control.

Pneumatic actuator valve arrangements are applied across key industries for motion and control tasks. The oil and gas industry utilizes them in operational systems requiring reliable on/off control for processes such as pipeline management and drilling equipment. The food and beverage industry employs these systems for automated processes like packaging, filling, and sorting. Manufacturing sectors use pneumatic actuators in assembly lines and material handling applications, enhancing operational efficiency. Additionally, the pharmaceutical industry integrates these systems to maintain precision in dosing, mixing, and filling processes. Each industry’s use is determined by operational needs and system-specific requirements.

Examples of applications where electric actuated ball valve systems replace pneumatic ones.

Electric actuated ball valve systems often replace pneumatic ones in applications requiring precise control or where an electrical power source is more accessible than a compressed air supply. Industries such as water treatment adopt electric actuated systems for tasks like flow regulation and automated valve control in environmental monitoring systems. The energy sector utilizes them for processes like pipeline automation involving remote monitoring and control capabilities. These systems are also employed in building automation to manage heating, ventilation, and air conditioning systems, where precision and integration with digital control systems are critical. The choice to transition often depends on factors such as energy availability, control requirements, and the operational environment.

Case studies showcasing real-world use of actuators pneumatic in single and double acting configurations.

Case studies demonstrate the practical use of pneumatic actuators in both single and double acting configurations across industries. A manufacturing facility implemented single acting actuators in an assembly line to control parts movement and reduce air consumption during idle phases. Another example involves a chemical processing plant utilizing double acting actuators to manage valve operations in high-cycle applications, ensuring precise control over fluid flow. Both configurations were chosen based on factors such as energy optimization, cycle requirements, and system compatibility. These examples highlight how actuator selection is guided by operational demands and efficiency goals.

Maintenance and Performance Optimization Tips

Steps to ensure long-term reliability of electric actuator and pneumatic actuator systems.

Regular maintenance is essential for ensuring the long-term reliability of electric actuator and pneumatic actuator systems. For electric actuators, steps include inspecting and testing electrical connections, verifying system calibration, and monitoring for signs of wear in components like motor drives. Pneumatic actuators require regular checks for air leaks, monitoring pressure levels, and ensuring proper lubrication of moving parts. Both systems benefit from routine cleaning to prevent the buildup of debris and periodic replacement of worn or damaged components. Implementing a scheduled maintenance plan and adhering to manufacturer guidelines can help minimize operational downtimes and extend system lifespans.

Guidance on maintaining air powered actuator setups to avoid downtime.

Maintaining air powered actuator setups to avoid downtime involves regular inspections and adherence to maintenance schedules. Key steps include checking for air leaks along connectors, fittings, and hoses, as well as ensuring that air supply lines are free from obstructions or contaminants. Proper lubrication of moving components is critical for reducing wear and maintaining smooth operation. Regularly monitoring air pressure levels helps to ensure consistent performance and prevent strain on the system. Valve assemblies and associated control mechanisms should be inspected for signs of wear or misalignment, with any damaged parts replaced promptly. Adhering to these practices ensures operational continuity and minimizes disruptions.

Preventative care recommendations for pneumatic valves and actuators.

Preventative care for pneumatic valves and actuators involves routine inspections and timely maintenance to maintain system reliability. Key practices include checking for air leaks at all connections, ensuring appropriate air filtration to prevent contaminants from entering the system, and regularly cleaning valve surfaces to remove debris. Lubrication of internal components helps reduce wear and supports efficient operation. Monitoring operating pressure and ensuring it remains within specified limits prevents system strain. Replacing worn parts, such as seals or gaskets, as part of scheduled maintenance minimizes unexpected failures. Following manufacturer guidelines and maintaining consistent maintenance schedules ensures the continued performance of the system.

FAQ double acting vs single acting cylinder

Question 1:What are the key differences between a double acting cylinder and a single acting cylinder in terms of pneumatic actuator functionality?

Answer: The main difference lies in how force is applied in pneumatic actuator systems. A single acting cylinder uses compressed air to move in one direction while relying on an external force, such as a spring, for the return stroke. Double acting cylinders utilize compressed air on both sides of the piston, enabling movement in both directions. This makes double acting cylinders more suitable for applications requiring consistent force in both strokes. When paired with a pneumatic actuator valve, these systems can handle higher loads and offer greater control over motion, making them ideal for more demanding operations involving actuators pneumatic setups.

Question 2:How does the choice between double acting and single acting cylinders affect air powered actuator performance?

Answer: The choice impacts factors like force requirements, energy usage, and system design. Single acting cylinders, typically used in simpler air powered actuator systems, consume less air since they rely on external forces for the return stroke. However, they may not deliver sufficient power or control in applications that require bidirectional movement. Double acting cylinders, often integrated into pneumatic valves and actuators configurations, provide balanced force in both directions, offering improved performance in systems requiring precision and high workload capabilities. Selecting the right cylinder depends on operational needs and the level of efficiency required.

Question 3:What considerations should be made when selecting pneumatic actuator valves for double acting and single acting cylinders?

Answer: When selecting a pneumatic actuator valve for either type, factors like control requirements, response time, and air pressure capacity should be evaluated. For single acting cylinders, valves are often simpler, as airflow is directed to a single side of the cylinder. For double acting cylinders, the valve must control airflow to both sides, requiring more complex configurations. Additional considerations include compatibility with the actuators pneumatic setup, ensuring the valve can handle the operating pressure consistently. Proper alignment of cylinder type with the chosen air powered actuator and valve ensures the system operates efficiently without strain or potential delays.

Conclusion double acting vs single acting cylinder

When deciding between a double acting vs single acting cylinder, understanding the specific operational requirements and system design is critical. Single acting cylinders are often suited for applications with simpler motion needs and lower energy demands, while double acting actuators provide consistent bidirectional force for more complex tasks. For systems incorporating an electric actuator or electric valve actuator, such as those controlling an electric actuated ball valve, seamless integration is crucial to ensure efficiency and performance. The choice of actuator valve also plays a vital role, as compatibility with the cylinder type—whether single acting, double acting, or a combination of both—is essential for reliable operation. By carefully evaluating these factors, along with the demands of the application, operators can achieve optimized performance and system longevity.