Selecting the right valve is critical to ensuring the efficiency and reliability of fluid handling systems. Central to this decision is understanding the CV Value, a key parameter that determines a valve’s flow capacity and its ability to manage pressure drops. Whether you’re working with a ball valve, gate valve, or butterfly valve, the CV Value plays a pivotal role in optimizing system performance. This metric is especially important in industrial applications where precision is required, such as pneumatic valves, electric valves, and flanged ball valves. By grasping what CV Value means and how it’s calculated, engineers and decision-makers can make more informed choices, leading to enhanced system functionality and reduced operational costs.

Introduction CV Value

Understanding CV Value is essential for selecting the right valve to optimize system performance. This flow capacity metric helps determine how valves, like a pneumatic ball valve or a 3 way ball valve, manage pressure and ensure efficiency. Whether using an electric ball valve, a globe valve, or a pneumatic control valve, CV Value provides critical insights that guide decision-making, leading to improved functionality and smoother operations in various applications.

What is CV Value?

Definition of CV Value in technical terms.

CV Value, or flow coefficient, measures the capacity of a valve to allow fluid flow under specific conditions. It represents the volume of water in gallons per minute (GPM) that can pass through a valve with a one-pound pressure drop at 60°F. This parameter is used in sizing and comparing valves for system requirements, providing a consistent standard for calculating flow performance.

Explanation of how CV Value relates to flow rate, pressure drop, and fluid dynamics.

CV Value quantifies the relationship between flow rate, pressure drop, and fluid dynamics in a valve. It indicates the number of gallons per minute passing through a valve at a fixed one-pound pressure drop. By correlating flow rate and pressure, CV Value serves as a critical parameter for predicting a valve’s performance and compatibility with specific fluid dynamics scenarios.

Mention its relevance for different valve types, including flanged ball valve and pneumatic control valve.

CV Value is a key factor in determining the flow performance and efficiency of different valve types. For a flanged ball valve, it helps evaluate flow capacity under varying pressure conditions. Similarly, for a pneumatic control valve, it aids in assessing its ability to maintain precise control over fluid flow. This measurement standard ensures proper valve selection for specific system requirements.

Importance of CV Value in Valve Performance

Understanding why CV Value is a key metric for system efficiency.

CV Value is a fundamental metric for evaluating system efficiency by quantifying the flow rate through a valve under specific pressure conditions. It ensures that valves are matched to system demands, minimizing energy losses and maintaining optimal fluid transfer. Proper assessment of CV Value supports accurate valve selection and system design, reducing operational inefficiencies.

Discussion of valve scenarios like pneumatic valves or electric valves where CV Value plays a pivotal role.

CV Value plays a pivotal role in applications involving pneumatic and electric valves by determining their suitability for specific flow conditions. For pneumatic valves, CV Value helps calculate the flow capacity needed to operate effectively within a pneumatic system. For electric valves, it ensures compatibility with the required flow rates and pressure dynamics, supporting accurate control and efficient system performance.

How the correct CV Value impacts system pressure and overall functionality.

The correct CV Value directly influences system pressure and overall functionality by ensuring proper flow through the valve under set conditions. It helps maintain balanced pressure levels across the system, preventing overpressure or underflow issues. Accurate CV Value selection aligns valve performance with system demands, optimizing fluid transfer and minimizing energy wastage.

Calculating CV Value for Valves

Step-by-step explanation of CV Value calculation.

To calculate CV Value, determine the flow rate in gallons per minute through the valve. Measure the pressure differential in pounds per square inch between the valve inlet and outlet. Use the formula CV = Q / √ΔP, where Q is the flow rate and ΔP is the pressure drop. This result quantifies the valve’s ability to achieve the desired flow under specified conditions.

Examples showing the CV Value calculations for a 3 way ball valve and a globe valve.

For a 3-way ball valve with a flow rate of 50 gallons per minute and a pressure drop of 4 psi, the CV Value is calculated as CV = 50 / √4, resulting in a CV Value of 25. For a globe valve with a flow rate of 100 gallons per minute and a pressure drop of 16 psi, the CV Value is calculated as CV = 100 / √16, resulting in a CV Value of 25. These examples illustrate the application of the CV formula across different valve types.

Tools and guidelines available for accurate CV Values determination.

Various tools and guidelines assist in determining CV Value accurately. Flow analysis software provides precise calculations by simulating conditions like flow rate and pressure drop. Manufacturer-provided charts and datasheets offer reference CV Values for different valve models under standard conditions. Industry guidelines outline standardized methods for testing and calculating CV Values to ensure reliability and consistency in system designs.

CV Values Comparison Across Valve Types

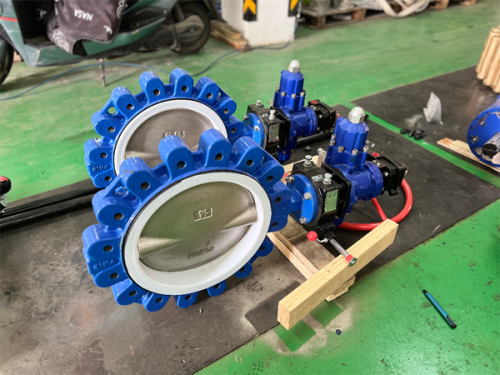

How CV Value differs between a gate valve, butterfly valve, and ball valve.

CV Value varies based on the design and flow characteristics of the valve type. Gate valves have lower CV Values due to straight-line flow paths with increased resistance when partially open. Butterfly valves exhibit moderate CV Values, influenced by the position of the disc within the flow stream. Ball valves offer higher CV Values because of their unobstructed flow paths when open, minimizing pressure drop and resistance.

Analyzing CV Value variations in pneumatic ball valves and electric ball valves.

CV Value variations between pneumatic and electric ball valves are influenced by their actuation methods and operational capabilities. Pneumatic ball valves typically allow for rapid opening and closing, which can impact flow stability and system pressure. Electric ball valves provide precise control over position adjustment, contributing to consistent flow rates. These differences in actuation affect how CV Values are applied and evaluated for specific system requirements.

Benefits of tailored CV Value for specific systems and applications.

Tailoring CV Values to specific systems and applications ensures optimal flow performance and minimizes energy losses. Matching the CV Values to system requirements enhances control accuracy and efficiency, reducing the risk of operational issues like cavitation or excessive pressure drop. This approach supports precise regulation of flow rates, ensuring reliable performance across varying operating conditions.

Choosing the Right Valve Based on CV Values

How to match CV Values with system requirements.

Matching CV Values with system requirements involves calculating the required flow rate and determining the acceptable pressure drop for the application. Using the formula CV = Q / √ΔP, where Q is the flow rate and ΔP is the pressure drop, helps identify the appropriate valve size and type. This ensures the valve meets the specific operational parameters while maintaining efficiency and system stability.

Discussion of scenarios where valves like flanged ball valves and pneumatic control valves excel due to optimized CV Values.

Flanged ball valves excel in scenarios requiring high flow capacity with minimal pressure drop, making them suitable for large-scale systems in industries like oil and gas. Pneumatic control valves are effective in applications demanding precise flow regulation and rapid response to pressure changes, such as in automated process systems. Optimized CV Values in these valves ensures they meet specific performance criteria while maintaining operational reliability.

The Role of Quality and Design in CV Values Accuracy

Importance of precision engineering in valves to achieve accurate CV Values.

Precision engineering in valves is critical to achieving accurate CV Values, as it ensures consistent flow characteristics and minimizes deviations in performance. This involves precise manufacturing tolerances, careful material selection, and meticulous design processes to maintain the intended flow path and control parameters. Accurate CV Values are essential for predictable system performance, efficient energy use, and the prevention of operational issues such as pressure fluctuations or cavitation.

How manufacturers ensure quality through advanced designs (e.g., electric ball valves or globe valves).

Manufacturers ensure quality in advanced valve designs like electric ball valves or globe valves by integrating precise actuation mechanisms, optimized flow paths, and high-grade materials. Electric ball valves leverage motorized actuation for consistent and controlled flow adjustment, while globe valves use a linear motion design to provide effective throttling and flow regulation. Rigorous testing and adherence to strict manufacturing standards ensure these valves consistently achieve accurate CV Values, supporting reliable performance in diverse systems.

Electric ball valves

Electric ball valves are designed with motorized actuation systems to provide precise and consistent flow control. Manufacturers ensure quality by employing advanced engineering techniques, including optimized internal flow paths to reduce pressure loss and using durable materials to enhance performance under varying conditions. These valves undergo stringent testing processes to validate actuation accuracy, sealing integrity, and longevity, ensuring they meet system performance requirements while maintaining reliable operation over time.

Globe valves

Globe valves are engineered with a linear motion design to allow precise throttling and flow control. Manufacturers ensure quality by focusing on optimized valve seating arrangements, which minimize leakage, and by using robust materials to handle demanding operational conditions. These valves are subjected to rigorous testing, such as pressure and sealing evaluations, to confirm their performance reliability. Advanced design features like contoured plugs and guided disc mechanisms further enhance flow accuracy, helping globe valves meet specific system requirements with consistent effectiveness.

Practical Applications of CV Values in Industries

CV Value is applied in industries to determine the flow rate a valve can achieve under specific conditions. It helps in selecting appropriate valves for systems that require accurate flow control and efficiency, such as in chemical processing, water treatment, and oil and gas operations. By calculating CV Value, engineers match valve performance to system demands, ensuring consistent operation and minimizing energy loss.

FAQ CV Value

Q1. How does CV Value differ among valve types such as ball valve, gate valve, and butterfly valve?

The CV Values indicates the flow capacity of a valve, and it varies significantly between valve types due to differences in design. A ball valve typically offers a high CV Values due to its full-bore opening, allowing for minimal pressure drop. A gate valve also provides a high CV but requires full travel to open or close. Butterfly valves, while compact, have lower CV Values due to the obstruction created by the central disc in the flow path.

Q2. What role does CV Value play in selecting pneumatic valves or electric valves?

When choosing between pneumatic valves or electric valves, the CV Values helps determine their suitability for the required flow rate and system pressure. For instance, an electric valve like a flanged ball valve may be selected for its high CV Values in applications demanding precise automated control, while pneumatic valves might be favored for their responsiveness in systems where quick actuation of varying flow rates is needed.

Q3. Why is it important to calculate CV Value for specific applications like a flanged ball valve?

Calculating the CV Values for valves such as a flanged ball valve ensures compatibility with system demands like flow rate, pressure, and energy efficiency. Whether the application involves pneumatic or electric actuation, understanding the CV Values helps engineers avoid issues like inadequate flow or excessive velocity, ensuring proper function and long-term reliability.

Conclusion CV Value

Understanding CV Values is crucial for selecting and optimizing valves to meet specific system demands. Whether it’s a pneumatic ball valve for high-precision flow control, a 3 way ball valve for versatile routing, or an electric ball valve designed for automated accuracy, the CV Values provides a measurable foundation for performance evaluation. Similarly, components like globe valves with their throttling capabilities, or pneumatic control valves used in dynamic industrial applications, depend on CV Values to ensure efficiency, reliability, and proper system integration. By calculating and applying CV Values effectively, engineers can achieve optimal flow, pressure management, and long-term operational success across various industries.