API 608 and API 607 are key standards that guide the selection, design, and testing of industrial valves across various applications. These guidelines ensure optimal performance, safety, and durability for critical components like ball valves, gate valves, and butterfly valves. Whether you’re evaluating a flanged ball valve for high-pressure systems, a pneumatic valve for automation, or an electric valve for precise control, understanding these standards is essential for making informed decisions.

Introduction API 608 API 607

API 608 and API 607 are critical benchmarks for ensuring industrial valves meet stringent safety and performance standards. These standards influence the design and application of components like a pneumatic ball valve or a durable 3 way ball valve, providing reliability in complex operations. From an electric ball valve to a globe valve used in high-temperature systems, or a pneumatic control valve ensuring precision, these guidelines play a pivotal role in selecting the right valve for diverse industrial needs.

Overview of API 608 and API 607 standards

API 608 and API 607 are widely recognized standards that define the requirements for the design, application, and testing of industrial valves. API 608 focuses on specifications for ball valves, including pressure ratings and functionality, while API 607 addresses fire-safe testing for valves used in environments with flammable materials. These standards provide clear frameworks to ensure valve reliability, compliance, and safety across a variety of industrial systems.

Importance of these standards in industrial valve selection

API 608 and API 607 are essential in guiding the selection of industrial valves by ensuring compliance with specific performance and safety requirements. API 608 covers ball valve specifications, while API 607 addresses fire-safe testing, helping industries choose valves suited to operational demands and safety regulations. These standards support consistent performance and reliability in diverse applications.

Brief mention of valve types like ball valves, gate valves, and butterfly valves in the context of choosing the right product for specialized needs

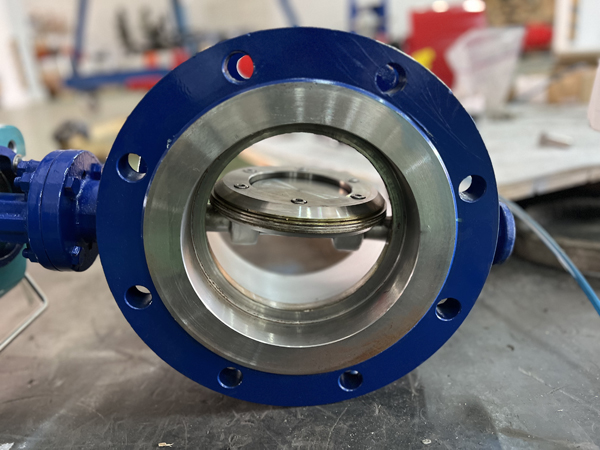

Ball valves, gate valves, and butterfly valves serve distinct roles in industrial applications based on operational requirements. Ball valves offer effective flow control, gate valves are used for on-off service, and butterfly valves manage flow in larger systems. Selecting the appropriate type involves assessing factors like pressure, temperature, and system demands to meet specific functional needs.

What Are API 608 and API 607?

API 608 and API 607 are standards established by the American Petroleum Institute that define performance and safety criteria for valves used in industrial applications. API 608 focuses on ball valves, detailing requirements for pressure rating, leakage prevention, and mechanical integrity. API 607 pertains to fire-safe valve designs, specifying testing protocols to ensure that valves can maintain seal integrity under fire exposure. Together, these standards guide manufacturers and operators in selecting valves that meet essential safety and operational requirements for varied applications.

Definition and purpose of API 608 and API 607

API 608 defines the standards for ball valve design, covering aspects like pressure ratings and operational requirements. API 607 outlines the fire-safe testing procedures for valves used in environments with flammable materials. Both standards ensure valves meet safety and performance benchmarks necessary for industrial applications.

Key differences and similarities between the two standards

API 608 and API 607 both establish guidelines for valve performance and safety but target different aspects. API 608 focuses on the design and functional specifications of ball valves, while API 607 addresses fire-safe testing procedures for various valve types. Both standards aim to ensure reliability and compliance in industrial operations, supporting safety and operational efficiency across applications.

The role these standards play in manufacturing and testing pneumatic valves and electric valves

API 608 and API 607 provide frameworks for manufacturing and testing pneumatic and electric valves by defining design criteria and performance requirements. API 608 focuses on standardizing ball valve construction and ensuring proper functionality, while API 607 outlines fire-safe testing to validate valve performance in hazardous environments. These standards guide manufacturers in producing reliable valves that meet safety and operational specifications.

How API 608 Impacts Ball Valve and Flanged Ball Valve Design

API 608 impacts the design of ball valves and flanged ball valves by setting specific requirements for pressure handling, leakage prevention, and dimensional consistency. These standards ensure that valves meet rigorous operational demands and maintain mechanical integrity in industrial environments. Manufacturers must adhere to detailed guidelines on construction materials, sealing mechanisms, and testing protocols to achieve API 608 compliance, thereby ensuring the valves deliver reliable performance under varied operating conditions. Compliance also supports compatibility across systems, simplifying integration in critical applications.

Requirements outlined in API 608 specifically for ball valves

API 608 specifies requirements for ball valves, including pressure-temperature ratings, material standards, and design features. It addresses factors like valve dimensions, end connection types, and operational testing to ensure compatibility with industrial systems. These criteria guide the production of ball valves that meet functional and safety standards in various applications.

Benefits of adhering to API 608 in terms of safety, durability, and performance

Adhering to API 608 ensures ball valves meet established safety, durability, and performance criteria. Compliance enhances operational reliability by standardizing construction, material integrity, and pressure limitations. The framework minimizes risks and supports consistent functionality in demanding industrial environments.

Highlighting the significance for flanged ball valves in industrial applications

Flanged ball valves play a critical role in industrial applications by providing secure connections and reliable flow control. Their design allows for easier installation and maintenance in piping systems. Compliance with API 608 ensures these valves meet safety, pressure, and performance requirements, supporting consistent operation in various settings.

API 607 and Fire-Safe Certification for Industrial Valves

API 607 plays a critical role in defining fire-safe certification for industrial valves, ensuring they maintain functionality and seal integrity under fire exposure. This standard outlines strict testing protocols that simulate real-world fire conditions, assessing a valve’s ability to prevent leaks of hazardous materials. Compliance with API 607 confirms that a valve can minimize risks during fire-related incidents, safeguarding both personnel and the environment. Manufacturers adhering to this standard demonstrate a commitment to safety and reliability, crucial for high-stakes industrial applications.

Explanation of API 607 requirements for fire-safe valves

API 607 outlines requirements for fire-safe valves, including testing procedures that assess valve performance under fire conditions. These tests evaluate the ability to maintain leak-tight seals and operational integrity during and after exposure to fire. The standard applies to various valve types and ensures compliance with safety measures for minimizing leakage of flammable fluids in industrial settings.

Design and testing procedures for gate valves, butterfly valves, and other fire-safe designs

API 607 defines design and testing procedures for fire-safe valves, including gate valves, butterfly valves, and other types. These procedures evaluate valve performance under fire conditions, focusing on the ability to contain fluids and maintain integrity. Testing includes exposing valves to fire and assessing leakage rates, sealing mechanisms, and operational capability, ensuring compliance with fire safety standards in industrial environments.

Real-world implications for industries requiring this certification

Industries requiring API 607 fire-safe certification rely on valves that prevent fluid leaks and maintain operational integrity during fire incidents. This certification supports compliance with fire safety regulations, reducing risks associated with flammable materials. It ensures standardized safety measures across applications in sectors like oil and gas, chemical processing, and power generation.

Choosing Between API 608 and API 607 for Your Application

Selecting between API 608 and API 607 depends on the specific demands of your application. API 608 is ideal for applications requiring precise pressure ratings, dimensional consistency, and robust mechanical integrity, particularly for ball valve configurations. On the other hand, API 607 is essential when fire safety is a priority, as it certifies valves to withstand fire scenarios while maintaining seal integrity. Understanding the operational conditions and safety requirements of your system will guide you to the appropriate standard, ensuring optimal performance and compliance with industry expectations.

Key considerations for selecting valves compliant with API 608 or API 607, such as operating environments and material compatibility

Selecting valves compliant with API 608 or API 607 requires evaluating operating environments and material compatibility. Factors include the nature of the fluid, temperature and pressure conditions, and the likelihood of fire exposure. API 608 focuses on performance for industrial operations, while API 607 addresses fire-safe requirements, guiding decision-making based on specific application safety and functional needs.

Comparing performance and suitability of pneumatic valves versus electric valves for specific standards

Pneumatic valves and electric valves differ in performance and suitability depending on specific standards. Pneumatic valves rely on compressed air for actuation, making them suitable for environments where electric components are impractical. Electric valves use electrical power and provide precise control, fitting applications that demand automation and integration with monitoring systems. The choice depends on operational requirements, safety considerations, and compliance with standards like API 608 and API 607.

Ensuring Quality Control with API-Compliant Valves

API-compliant valves are key to maintaining rigorous quality control in industrial applications, ensuring safety and performance standards are met. Both API 608 and API 607 establish precise criteria for valve design, testing, and functionality, addressing aspects such as pressure handling, dimensional accuracy, and fire safety. Adhering to these standards not only guarantees reliable operation under challenging conditions but also simplifies regulatory compliance. Procuring valves from certified manufacturers further ensures that each component meets the stringent benchmarks necessary for critical applications.

The importance of working with manufacturers certified to follow API standards

Working with manufacturers certified to follow API standards ensures compliance with established safety and performance guidelines. These certifications confirm that the manufacturing processes, materials, and designs meet industry requirements. By choosing certified manufacturers, industries can reduce operational risks, maintain consistent valve performance, and align with regulatory expectations for quality and reliability.

How API 608 and API 607 ensure long-term reliability and consistent operation in valves like flanged ball valves, butterfly valves, and gate valves

API 608 and API 607 establish performance and safety standards that contribute to the long-term reliability and consistent operation of valves such as flanged ball valves, butterfly valves, and gate valves. These standards mandate rigorous testing for pressure handling, leakage prevention, and fire safety, ensuring the valves can withstand demanding industrial conditions. Compliance with these standards supports uniform quality control across applications, minimizing operational risks and maintaining functionality over time.

Tips for procuring high-quality equipment for critical applications

When procuring high-quality equipment for critical applications, prioritize manufacturers certified to adhere to industry standards such as API. Evaluate the materials, design specifications, and testing procedures to ensure the equipment meets operational and safety requirements. Assess the supplier’s quality control processes and track record in delivering reliable components. Additionally, confirm compatibility with the specific operating conditions and standards of the intended application to ensure consistent performance and minimal risks.

FAQ API 608 API 607

Q1: How do API 608 and API 607 standards impact the use of ball valves and flanged ball valves in industrial settings?

A1: API 608 provides essential guidelines for the design and performance of ball valves, including flanged ball valves, focusing on their mechanical integrity, pressure handling, and dimensional precision. On the other hand, API 607 ensures these valves are fire-safe, certifying their ability to maintain seal integrity during fire exposure. Together, these standards guarantee that ball valves and flanged ball valves meet rigorous safety and operational demands in industrial applications.

Q2: Are gate valves and butterfly valves subject to API 608 or API 607 standards?

A2: While API 608 is specifically tailored to ball valves and their configurations, such as flanged ball valves, gate valves and butterfly valves typically fall under different sets of API standards. However, if fire safety is a critical aspect for gate valves or butterfly valves, they may need to be tested to meet API 607 requirements, ensuring their ability to withstand fire scenarios without leakage.

Q3: Do API 608 and API 607 apply to pneumatic valves and electric valves?

A3: API 608 and API 607 standards primarily address the performance and safety of valve types like ball valves, including flanged ball valves, but their principles are applicable to pneumatic valves and electric valves if these are designed with similar configurations. For example, an electric valve or pneumatic valve designed as a ball valve must adhere to API 608 for operational reliability and API 607 for fire-safe certification, ensuring they perform optimally in demanding environments.

Conclusion API 608 API 607

API 608 and API 607 serve as vital benchmarks for valve selection, offering clear guidelines to ensure safety, reliability, and performance in industrial operations. Whether you require a pneumatic ball valve, 3 way ball valve, or electric ball valve, these standards provide the framework to meet operational demands and regulatory expectations. For other valve types, such as globe valves or pneumatic control valves, understanding their compatibility with these standards can further enhance system integrity. By adhering to APIs 608 and APIs 607 requirements, industries can confidently choose the right valves for their applications while prioritizing safety and efficiency.