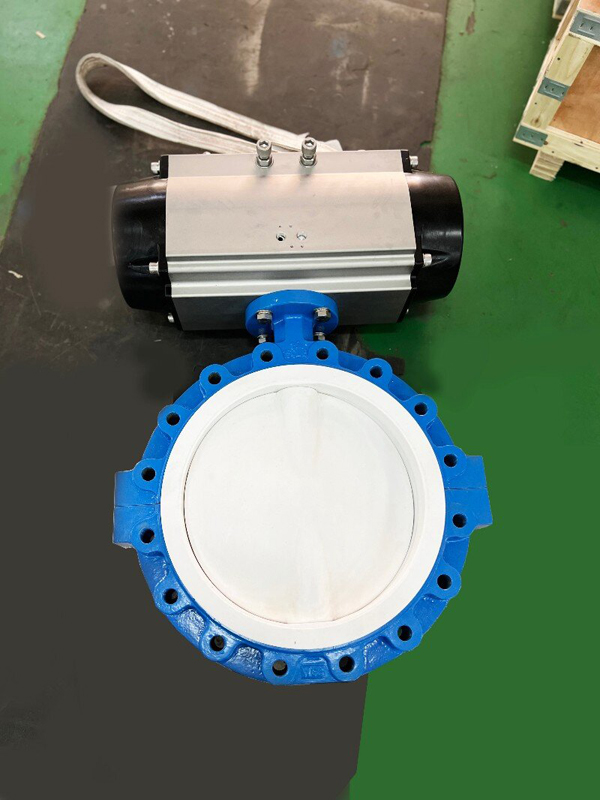

A PTFE lined butterfly valve? a specialized valve design for industrial applications requiring exceptional chemical resistance and durability. Unlike standard butterfly valves, these valves feature a PTFE lining that enhances performance in corrosive environments. Making them ideal for industries such as chemical processing, pharmaceuticals, and food production.

The article explores the unique components and features of PTFE lined butterfly valves. Comparing them to alternatives like PFA and PTFE valves, as well as FEP lined ball valves. It also highlights the benefits of using PTFE lining. Including reduced maintenance needs, extended lifespan, and resistance to high temperatures and caustic materials.

Introduction

A PTFE lined butterfly valve is a high-performance valve engineered for demanding industrial tasks that require superior chemical resistance and durability. Designed to improve upon traditional butterfly valves. These valves are lined with PTFE, a material renowned for its ability to withstand corrosive chemicals and extreme conditions. Industries such as chemical processing, pharmaceuticals, and food production often rely on PTFE lined butterfly valves to ensure consistent and safe operation in aggressive environments. They stand out due to their efficiency and reliability, offering advantages like reduced maintenance costs and extended lifespan.

When compared to other options, such as PFA valve and PTFE valve configurations or even fep lined ball valve systems. PTFE butterfly valves excel in delivering robust and versatile solutions. With their advanced butterfly valve lining and high compatibility across various applications. These lined butterfly valve models remain a top choice for professionals seeking optimal performance and operational integrity.

What is a PTFE Lined Butterfly Valve?

A PTFE lined butterfly valve is a specialized type of valve designed for precision control and reliability in complex industrial settings. Unlike standard valves, a PTFE lined butterfly valve incorporates a lining made from polytetrafluoroethylene (PTFE), a highly resilient material known for its outstanding chemical resistance and ability to endure abrasive and corrosive environments. This design ensures smooth operation and extended durability. Even under high temperatures or with corrosive media.

Commonly compared to other configurations like a PFA valve and PTFE valve or even the fep lined ball valve. PTFE lined butterfly valves are favored for their lightweight architecture, efficient flow regulation, and ease of maintenance. The butterfly valve lining provides an additional layer of protection. Making these valves particularly suitable for industries such as chemical processing, food and beverage production, and pharmaceutical manufacturing. These lined butterfly valves not only minimize the risk of contamination or system failure but also deliver cost-effective solutions with enhanced operational lifespan and energy efficiency. Cementing their role as an indispensable choice in demanding applications.

Components and Features of PTFE Lined Butterfly Valves

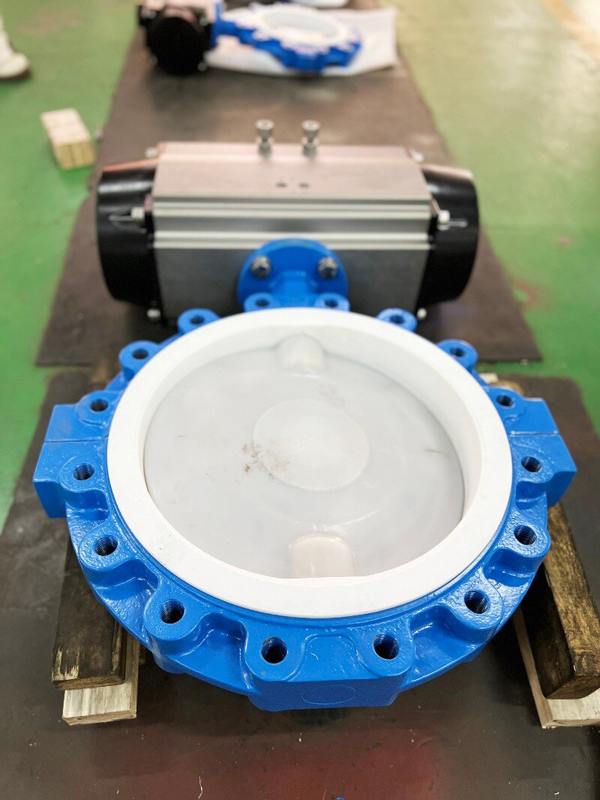

A PTFE lined butterfly valve incorporates advanced components and materials designed to deliver exceptional performance in harsh industrial environments. At its core, the valve consists of a disc that regulates flow, a valve body, and a resilient PTFE lining that provides superior chemical resistance and prevents wear caused by corrosive or abrasive media. The lining acts as a protective barrier, ensuring smooth operation even under extreme pressures and temperatures. The valve’s stem and seal engineer for reliability. Reducing the risk of leakage and enhancing operational efficiency.

When compared to alternatives like a PFA valve and PTFE valve or even an fep lined ball valve. The PTFE lined butterfly valve stands out for its compact design, lightweight construction, and ease of installation. The butterfly valve lining provides superior durability, making the valve suitable for industries such as chemical processing, pharmaceuticals, and water treatment. Additionally, these lined butterfly valves are known for their low maintenance requirements and long service life,. Ensuring cost savings for operators while delivering reliable and consistent performance across a wide range of applications.

Applications and Benefits of PTFE Lined Butterfly Valves

PTFE lined butterfly valves are indispensable across a wide range of industries that require reliable and efficient fluid control in challenging conditions. These valves are particularly vital in sectors like chemical processing, pharmaceuticals, food and beverage production, and water treatment. Where the ability to handle corrosive or abrasive media is essential. The PTFE lining acts as a shield, protecting the valve components from deterioration and ensuring long-term operational longevity. When compared to other options, such as PFA valve and PTFE valve designs or even the fep lined ball valve. PTFE lined butterfly valves excel due to their lightweight structure, compact design. And superior resistance to chemical attacks. The butterfly valve lining not only minimizes wear and tear but also contributes to leak-free performance. Making these valves highly dependable.

Additionally, their easy maintenance and extended life cycle reduce overall operating costs. Making them a cost-effective choice for facilities requiring high performance and durability. These lined butterfly valves are also known for their versatility, seamlessly integrating with various systems to maintain process efficiency and safety, even under the most demanding conditions.

Comparisons with Other Valve Types

When comparing the PTFE lined butterfly valve to other valve types. Such as the PFA valve and PTFE valve or the fep lined ball valve, distinct advantages in design, functionality, and application become evident. The PTFE lined butterfly valve characterize by its compact size and lightweight construction. Which makes it a versatile choice for installations where space is limited or weight constraints are critical. This sets it apart from the fep lined ball valve, which, while robust, is bulkier and often less efficient for quick shut-off applications. The butterfly valve lining in PTFE lined models offers unmatched resistance to corrosive chemicals and abrasive materials. Providing a longer operational life even in extreme environments. Unlike some PFA valve and PTFE valve options that may wear out faster under similar conditions.

Additionally, the simple yet effective design of the lined butterfly valve enables smooth flow control. Reducing pressure drops and improving overall efficiency compared to other valve types. This makes the PTFE lined butterfly valve particularly advantageous in industries like chemical processing and water treatment. Where consistent performance and low maintenance are crucial. By offering higher durability, ease of operation, and superior chemical resistance. The PTFE lined butterfly valve stands out as a cost-effective and reliable solution for demanding industrial applications.

How to Choose the Right PTFE Lined Butterfly Valve

Choosing the right PTFE lined butterfly valve requires a thorough understanding of your application’s specific needs and operating requirements. Start by evaluating the chemical compatibility of the valve with the media it will handle,. As this ensures the PTFE lining provides maximum protection against corrosion and wear. Consider the pressure and temperature ratings of the valve to ensure it can withstand the operating conditions without compromising performance or structural integrity.

Additionally, assess the differences between a PTFE lined butterfly valve, PFA valve and PTFE valve. And an fep lined ball valve, as each offers distinct advantages. For instance, PTFE lined butterfly valves are lightweight and compact, making them ideal for systems with space and weight constraints,. While fep lined ball valves may be better suited for applications requiring higher pressure tolerances. Pay close attention to the butterfly valve lining, as its durability directly impacts longevity and reliability in demanding environments.

Lastly, factor in maintenance needs and ease of installation to optimize long-term operational efficiency and cost-effectiveness. Selecting the correct lined butterfly valve not only enhances system performance but also ensures safety and reduced downtime in industrial processes.

Maintenance and Longevity of PTFE Lined Butterfly Valves

Proper maintenance is key to ensuring the longevity and optimal performance of PTFE lined butterfly valves across a variety of industrial applications. The PTFE lining, known for its exceptional resistance to chemicals and wear, significantly reduces the likelihood of corrosion. Extending the lifespan of the valve components even under harsh operating conditions. Regular inspections to detect wear on the butterfly valve lining. As well as prompt replacement of seals and gaskets, help maintain leak-free operation and prevent system failures. When compared to alternatives like PFA valve and PTFE valve designs or fep lined ball valves. PTFE lined butterfly valves often require less intensive maintenance due to their fewer moving parts and straightforward construction. This simplicity translates into fewer opportunities for mechanical failure.

Additionally, their lightweight and compact design streamline servicing, minimizing downtime during repairs. Using high-quality PTFE lined butterfly valves and adhering to proper maintenance practices. Such as routinely cleaning and lubricating moving components, ensures consistent performance, reduced operational costs, and extended service life. These factors make lined butterfly valves a reliable and efficient choice for industries demanding durable and low-maintenance fluid control solutions.

FAQ

What is a PTFE-lined butterfly valve?

A PTFE-lined butterfly valve is a type of butterfly valve where the internal surface, including the disc and the body, is coated with PTFE (Polytetrafluoroethylene). This lining provides exceptional chemical resistance and low friction, making the valve ideal for handling corrosive or abrasive media.

What are the main features of PTFE-lined butterfly valves?

PTFE-lined butterfly valves feature a robust design with a corrosion-resistant PTFE coating, ensuring reliable performance in challenging environments. They offer smooth operation due to PTFE’s low friction properties, excellent sealing capabilities, and compatibility with a wide range of chemicals.

What are the benefits of using PTFE-lined butterfly valves?

These valves provide superior resistance to harsh chemicals, high thermal stability, and a long service life. They minimize wear and tear, reduce the risk of leaks, and require low maintenance. PTFE’s non-stick property also helps prevent media buildup, ensuring smooth flow and reducing downtime.

What industries commonly use PTFE-lined butterfly valves?

PTFE-lined butterfly valves are a favored choice in industries such as chemical processing, wastewater treatment, food and beverage, pharmaceuticals, and power generation. They are particularly effective when dealing with corrosive fluids, slurries, or media with suspended particles.

Conclusion

A PTFE lined butterfly valve is a highly reliable and efficient solution for managing fluid flow in demanding industrial environments. Featuring a durable butterfly valve lining made from PTFE, these valves offer exceptional resistance to corrosive chemicals, high temperatures, and abrasive materials. Ensuring longevity even under extreme conditions. Unlike other options, such as PFA valve and PTFE valve designs or an fep lined ball valve, PTFE lined butterfly valves stand out for their lightweight, compact design, and simplified functionality. These characteristics make them ideal for installations where space, weight, and maintenance accessibility are critical factors. Lined butterfly valves? commonly use in industries like chemical processing, pharmaceuticals, water treatment, and food production.

Where maintaining system integrity and ensuring safety are paramount. Their easy operation, low maintenance needs, and compatibility with aggressive chemicals make them a cost-effective choice. By combining resilience, operational efficiency, and versatility, PTFE lined butterfly valves have become an essential component in modern industrial fluid control systems. Whether for precise flow regulation, reliable isolation. Or consistent performance under harsh conditions, these valves deliver the durability and quality necessary for optimal system performance.