A lined ball valve is an essential solution for industries handling corrosive or abrasive materials. This blog post explores the intricacies of lined ball valves, including their design, key features, and applications. With specialized linings like PTFE, these valves offer exceptional chemical resistance, durability, and low maintenance requirements. Whether it’s a PTFE lined ball valve or a PTFE lined valve. Tthey are critical in sectors like chemical processing, pharmaceuticals, and water treatment. We also discuss how lined ball valves.? Including PTFE ball valves, improve system efficiency, prevent failures, and cut maintenance costs.

Introduction

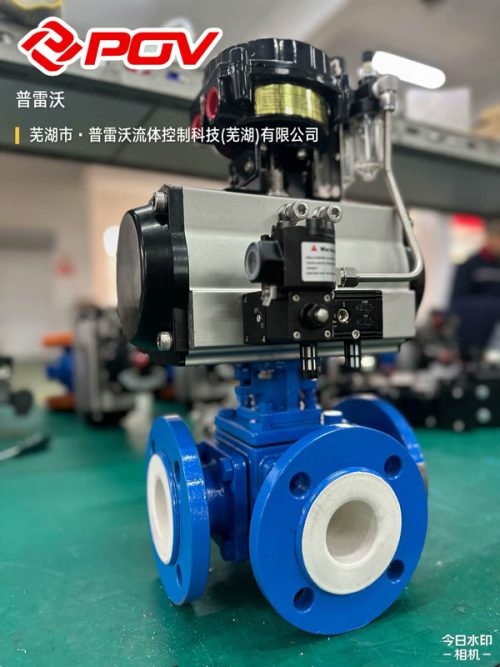

A lined ball valve is a vital component in industrial systems that deal with highly corrosive or abrasive substances. At its core, this specialized valve features a robust ball seated within a protective lining. Such as PTFE (Polytetrafluoroethylene), that shields the valve body and internal components from harsh media. Known for their unparalleled chemical resistance and durability, PTFE lined ball valves are widely employed in demanding sectors like chemical processing, pharmaceuticals, and water treatment.

The lining, whether in a PTFE lined valve or a PFA-lined alternative. Enhances operational reliability by preventing corrosion-related damage and minimizing maintenance needs. By incorporating advanced materials like PTFE, these valves, including the versatile PTFE ball valve. Play a critical role in ensuring process efficiency, reducing system failures. And sustaining long-term performance even in the most aggressive environments. Understanding the functionality and benefits of a lined ball valve is essential for industries seeking high-quality, reliable flow control solutions.

What is a Lined Ball Valve?

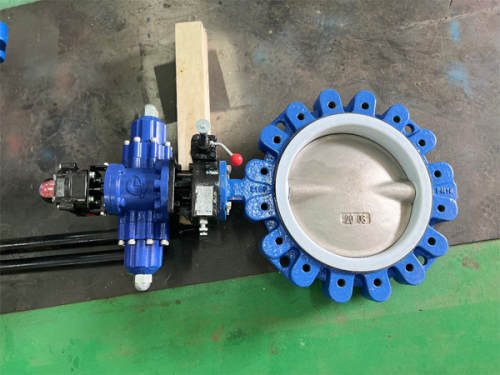

A lined ball valve is a highly specialized type of valve designed to handle abrasive and corrosive substances efficiently. Unlike standard valves, a lined ball valve features a lining material that covers the internal surfaces. Providing robust protection against chemical attack and wear. The lining, often made from materials like PTFE (Polytetrafluoroethylene), ensures exceptional durability and resistance to aggressive media. Making PTFE lined ball valves a preferred choice for industries like chemical processing, pharmaceuticals, and water treatment. The core components of a lined ball valve include the valve body, a ball with a smooth lining for precise sealing,. And a durable lining layer that minimizes damage from reactive or high-pressure environments.

Whether it is a PTFE lined valve or another variant such as the PTFE ball valve. The inclusion of PTFE allows these valves to perform reliably across a wide temperature range while minimizing the risk of leaks, failures, or costly downtime. Lined ball valves are crucial for maintaining operational safety and efficiency in demanding industrial applications. Making them an indispensable solution for handling challenging flow control scenarios.

Lining Materials Used in Ball Valves

Lining materials are a critical consideration in the design and functionality of a lined ball valve. As they directly impact the valve’s ability to withstand aggressive and corrosive substances. PTFE (Polytetrafluoroethylene) is one of the most widely used materials due to its remarkable chemical resistance, non-reactive properties. And ability to perform across extreme temperature ranges. PTFE lined ball valves? specifically prefer in highly demanding sectors like chemical processing. Where exposure to harsh acids, solvents, and other corrosive substances is common.

Another popular material is PFA (Perfluoroalkoxy), which shares PTFE’s chemical resistance but offers additional benefits such as improved mechanical strength and durability under high pressures. Whether choosing a PTFE lined valve or a PFA-lined alternative, these linings create a protective barrier within the valve, preventing corrosion, reducing wear, and enhancing the lifespan of the components. The inclusion of such advanced materials in PTFE ball valves not only ensures reliable sealing and low maintenance but also minimizes the risk of leaks, downtime. Or system failures. Selecting the right lining material is as essential as the valve itself. As it directly correlates with optimal performance and longevity in industrial applications.

a. PTFE Lined Ball Valve

A PTFE lined ball valve is a highly effective solution for controlling the flow of aggressive or corrosive fluids in industrial processes. This type of lined ball valve features a core ball and internal surfaces coated with PTFE (Polytetrafluoroethylene),. A material well-known for its exceptional chemical resistance and non-reactive properties. PTFE lined ball valves are designed to withstand exposure to harsh media such as strong acids, alkalis, and solvents. Making them indispensable in industries like chemical manufacturing, pharmaceuticals, and wastewater management.

The PTFE lining acts as a protective barrier, not only preventing corrosion of the valve’s internal components but also significantly reducing maintenance requirements and prolonging the valve’s lifespan. PTFE lined valves and PTFE ball valves are particularly valued for their smooth operation, reliable sealing. And remarkable durability under extreme temperature and pressure conditions. These attributes make PTFE lined ball valves a top choice for industries that demand precision, safety, and performance in managing corrosive or abrasive materials.

b. PFA Lined Valve

A PFA lined ball valve is a specialized type of lined ball valve designed to deliver superior performance in harsh industrial conditions. Featuring a lining made from PFA (Perfluoroalkoxy), this innovative valve builds upon the properties of PTFE lined ball valves by offering enhanced mechanical strength and durability. PFA combines exceptional chemical resistance with the ability to withstand high temperatures and stresses. Making it an ideal choice for industries handling highly corrosive or abrasive substances. Such as in chemical processing, petrochemical plants, and semiconductor manufacturing.

Compared to standard PTFE lined valves or PTFE ball valves, PFA lined ball valves provide additional resistance to cracking under pressure. Ensuring a longer lifespan and even greater reliability in demanding applications. The lining creates a robust barrier that safeguards the valve’s internal components against wear and corrosion. Minimizing maintenance requirements while ensuring leak-free operation. With their ability to maintain integrity under extreme operating conditions. PFA lined ball valves are a critical solution for industries that prioritize efficiency, durability, and safety in their flow control systems.

Applications of Lined Ball Valves

Lined ball valves essential in a wide range of industrial applications where the handling of corrosive, abrasive, or high-temperature substances is required. These valves, including PTFE lined ball valves and PTFE lined valves, widely use in chemical processing facilities to manage the flow of aggressive chemicals, acids, and solvents. Ensuring safe and efficient operations. They are also indispensable in the pharmaceutical industry, where stringent flow control is vital for producing high-quality medicines. As the non-reactive PTFE lining prevents any contamination during the process.

Additionally, lined ball valves extensively utilize in wastewater treatment plants to regulate the movement of harsh and abrasive sludge. Offering reliability and durability in such demanding environments. The robust construction and chemical resistance of PTFE ball valves make them suitable for petrochemicals, food and beverage production. And even semiconductor manufacturing, where precision and safety are critical. By effectively preventing corrosion, minimizing downtime, and ensuring leak-free performance. Lined ball valves have become the preferred choice for industries seeking to maintain operational integrity in highly challenging flow control scenarios.

How to Choose the Right Lined Ball Valve

Selecting the right lined ball valve is crucial for ensuring optimal performance, safety. And longevity in complex industrial applications. The first step is to evaluate the type of media being handled. Corrosive chemicals, abrasive substances, or high-purity fluids often require a PTFE lined ball valve due to its exceptional chemical resistance and non-reactive properties. For applications that demand enhanced mechanical durability under higher stress or temperature ranges. A PFA-lined option may be more appropriate. Understanding the operating temperature and pressure is also essential, as these factors directly influence the valve’s material compatibility and structural integrity.

Additionally, the specific lining material, whether PTFE lined valve or PFA lined. Must be compatible with the chemicals or compounds in use, ensuring the valve performs reliably without risk of corrosion or leakage. Selecting the right size and flow characteristics for the lined ball valve is equally important to maintain efficiency in flow control systems. Ensuring compliance with industry standards and certifications is critical. As this validates the valve’s ability to operate safely in demanding environments. By considering all these factors and collaborating with trusted manufacturers. Industries can select the perfect PTFE ball valve or lined ball valve, tailor-made to meet their unique operational needs.

Maintenance and Longevity of Lined Ball Valves

Proper maintenance is essential for ensuring the longevity and reliable performance of a lined ball valve. Including PTFE lined ball valves, PTFE lined valves, and PTFE ball valves. Routine inspection is the first line of defense against potential issues. Regularly check for signs of wear, corrosion, or deformation in the valve body, lining, and seals. Cleaning the internal surfaces of the valve is also crucial. Especially when handling chemicals or abrasive media, to prevent buildup that could compromise functionality. Always use cleaning agents that are compatible with the lining material. Such as PTFE, to avoid accidental damage.

To avoid valve failures, do not expose the valve to pressures beyond its rated capacity, as overpressure can cause cracking or deformation. Ensure that the media handled is fully compatible with the PTFE lining to prevent chemical degradation and leaks. When operating or installing a lined ball valve, handle it with care to avoid physical damage to the lining or internal components. Lubricate the moving parts as recommended by the manufacturer to preserve smooth operation and reduce wear. By adhering to these maintenance practices and collaborating with certified suppliers for replacement parts and servicing. Industries can maximize the lifespan and efficiency of their PTFE lined ball valves while ensuring safe and dependable flow control.

Advantages of Using Lined Ball Valves

Lined ball valves, including PTFE lined ball valves, PTFE lined valves, and PTFE ball valves. Offer a range of significant advantages that make them indispensable in various industries. One of their most notable benefits is their exceptional chemical resistance, making them ideal for handling corrosive and abrasive fluids in sectors like chemical processing and wastewater treatment. The PTFE lining acts as a protective barrier. Preventing the valve body from being degraded by aggressive chemicals, thus ensuring a longer operational life and reducing replacement costs.

Additionally, these valves deliver excellent leak-proof performance, thanks to their precision engineering and high-quality sealing mechanisms, which are critical for ensuring safety and environmental compliance in sensitive operations. Their durability in high-stress conditions, including exposure to extreme temperatures and pressures. Further enhances their reliability for demanding industrial applications. Beyond their robustness, lined ball valves are highly versatile, serving a wide range of purposes in pharmaceuticals, food processing, and petrochemical industries. Where precision and contamination prevention are paramount. By ensuring efficient flow control, minimizing downtime, and reducing maintenance needs. Lined ball valves not only enhance operational efficiency but also provide a cost-effective and dependable solution for managing challenging industrial processes.

FAQ

Q1. What is the warranty period for your ball valve?

Ball valve come with a standard warranty period of 12 months (1 years) from the date of delivery. This warranty covers manufacturing defects and materials under normal operating conditions as specified in the product manual.

Q2. How are? ball valve prices determined?

Prices for ball valve is influenced by several factors. Including the valve’s size, material composition (e.g., stainless steel, brass, or PVC), pressure ratings, end connection types. And any additional customisation or certifications required. Specialised features such as fire-safe designs or anti-static devices can also impact the cost.

Q3. What is the standard delivery time for a? ball valve?

Our standard delivery time for? ball valve is 4–6 weeks, depending on the order size and customisation requirements. For urgent requests, we offer expedited delivery options upon request.

Our logistics partners ensure fast and reliable delivery to meet engineering project timelines, regardless of location.

Q4. Common Applications of ball valve

Ball valve a versatile valve type design with three/two ports for fluid flow. These ports can be configured to allow various functions. Such as mixing, diverting, or completely shutting off flow.

Conclusion

A lined ball valve is an advanced flow control solution designed to handle challenging industrial conditions with precision and reliability. Featuring a resilient lining material like PTFE. Which offers exceptional chemical resistance, the lined ball valve serves as a protective barrier against corrosive and abrasive media. PTFE lined ball valves and PTFE lined valves specifically engineer to maintain durability and performance under extreme temperatures and pressures. Making them vital for industries such as chemical processing, pharmaceuticals, and wastewater treatment.

One of the key advantages of a PTFE ball valve is its leak-proof sealing capability. Which ensures safety and operational efficiency. These valves are also versatile, accommodating a wide range of fluids and gases while successfully preventing contamination. By combining strength, flexibility, and outstanding resistance to harsh substances. Lined ball valves reduce wear and tear, prolong operational life, and minimize downtime. Their design ensures cost-effectiveness and environmental compliance, helping industries achieve reliable and seamless flow control even in the most demanding applications. If durability, safety, and efficient performance are paramount, a lined ball valve stands out as an indispensable component in industrial systems, offering unmatched reliability and value.