Polytetrafluoroethylene, commonly known as PTFE, is a revolutionary material in the valve manufacturing industry, particularly in the creation of the PTFE ball valve. This blog explores the full form of PTFE, shedding light on its chemical composition and outstanding properties like high chemical resistance. Low friction, and wide temperature adaptability.

PTFE plays a critical role in enhancing the performance of PTFE lined valves and lined ball valves. Offering exceptional durability and efficiency. The post also highlights the differences between FEP lined ball valves and PTFE-lined alternatives. Including specific industry applications like chemical processing, pharmaceuticals, and oil & gas.

Introduction

Polytetrafluoroethylene, better known as PTFE, has become a groundbreaking material in the valve manufacturing industry. Especially in the design of the highly efficient PTFE ball valve. Renowned for its exceptional chemical resistance, low friction properties, and adaptability to a wide range of temperatures. PTFE has set a high standard for durability and performance across various industries. When incorporated into the design of PTFE lined valves and lined ball valves. This unique polymer ensures reliable operation even under harsh conditions. Such as exposure to corrosive chemicals or high-pressure environments.

Additionally, advancements in technology have led to the development of FEP lined ball valves. Offering similar efficiency with slight variations in application suitability. Often referred to by its trademark name, Teflon valve. PTFE has earned its reputation as a benchmark material for improving the safety, longevity. And functionality of ball valves across sectors like chemical processing, pharmaceuticals, and oil & gas. This article unpacks the full form of PTFE and explores its pivotal role in revolutionizing valve manufacturing.

What is PTFE?

Polytetrafluoroethylene, commonly abbreviated as PTFE, is a high-performance polymer known for its exceptional chemical resistance, non-reactive nature, and low friction properties. Structurally, PTFE is composed of carbon and fluorine atoms, forming a material that can withstand extreme temperatures and corrosive substances. Making it indispensable in various industrial applications. A key innovation in the valve industry, PTFE is integral to the design of the PTFE ball valve. Where its properties enhance sealing performance and reduce wear and tear.

Similarly, PTFE lined valves and lined ball valves leverage this material for superior durability, reliability. And longevity in handling aggressive chemicals or high-pressure operations. Beyond PTFE-lined options, related systems like FEP lined ball valves. Which use Fluorinated Ethylene Propylene, provide alternatives for specific applications while maintaining similar chemical resistance. Often referred to as Teflon valves due to Teflon being the trademark name for PTFE. These valves underscore the material’s industry-wide importance in ensuring safety, efficiency. And performance in demanding environments like pharmaceuticals, oil & gas, and chemical processing. The versatility and reliability of PTFE make it a central component in modern valve technology.

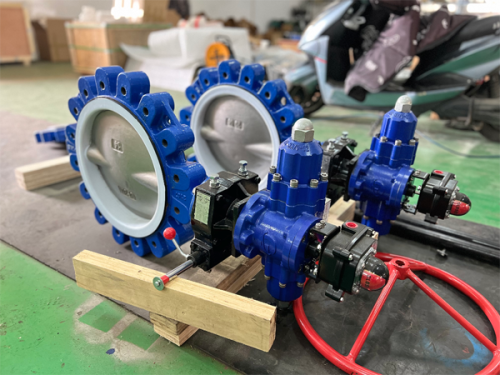

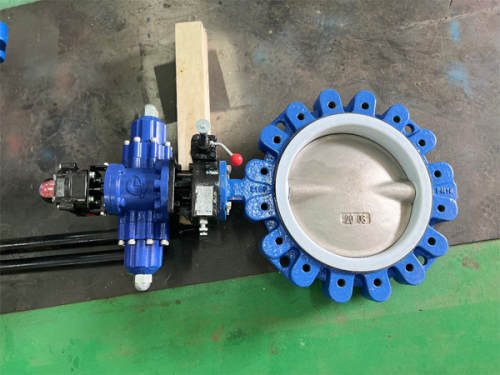

PTFE in Ball Valves

Polytetrafluoroethylene (PTFE) has transformed the performance and functionality of ball valves. Establishing itself as a critical material in the valve manufacturing industry. Its integration into the design of the PTFE ball valve has paved the way for valves that deliver unmatched chemical resistance, low friction, and exceptional reliability. PTFE lined valves and lined ball valves, engineered with a PTFE lining, are ideal for handling aggressive chemicals, abrasive materials, and high-pressure systems. Ensuring durability even in the harshest environments.

Further innovations, such as FEP lined ball valves, offer alternatives tailored to specific industrial needs while maintaining the same exceptional standards for efficiency and safety. Often referred to as Teflon valves, due to the widespread recognition of Teflon as a trade name for PTFE. These valves have become indispensable across sectors like pharmaceuticals, oil & gas, and chemical processing. By minimizing wear and tear, enhancing sealing efficiency, and extending operational lifespans. PTFE has revolutionized ball valve technology, providing industries with solutions that prioritize performance and long-term reliability.

Applications and Industries

PTFE lined valves, including ptfe ball valve, ptfe lined valve, and lined ball valve, are integral to a wide range of industries due to their exceptional chemical resistance and durability. One of their primary applications is in chemical processing. Where they handle aggressive acids, caustics, and reactive chemicals without degrading. Pharmaceuticals also rely on these valves for sterile and contamination-free processes, as PTFE’s non-stick properties ensure clean handling of sensitive media.

In the oil & gas sector, teflon valve solutions are trusted for their ability to endure harsh environments involving high pressures, temperatures, and corrosive substances. Water treatment facilities use fep lined ball valves and PTFE variants to manage highly corrosive cleaning agents and maintain the integrity of potable water systems. Additionally, PTFE’s low friction coefficient and high temperature resistance make these valves suitable for applications in power generation and food processing. Where performance consistency is critical. By offering reliable sealing, longevity, and versatility. PTFE lined valves have become indispensable across these industries, meeting strict safety and efficiency requirements with unmatched precision.

Differences Between PTFE Lined Valves and Other Lined Valves

PTFE lined valves stand out in the industry due to their exceptional chemical resistance, low friction, and ability to withstand extreme temperatures. Making them a preferred choice for handling aggressive or corrosive media in critical operations. Compared to other lined valves, such as FEP lined ball valves. PTFE lined valves demonstrate higher thermal stability. Making them suitable for environments with fluctuating or higher operating temperatures. While both provide excellent chemical resistance, FEP, or Fluorinated Ethylene Propylene, offers better flexibility and clarity. Which may be advantageous in specific applications where mechanical stress or visibility is a concern.A PTFE ball valve or Teflon valve, thanks to its broad compatibility. Also exhibits a longer service life in demanding conditions like chemical processing or pharmaceuticals.

On the other hand, general lined ball valves, which may feature different polymeric linings. Often tailor for less extreme applications, offering cost-efficiency for certain industries without heavily compromising performance. The choice between a PTFE lined valve, FEP lined ball valve. Or other alternatives largely depends on the requirements for temperature tolerance, media compatibility, and mechanical performance. With PTFE remaining a benchmark for durability and reliability in industrial valve technology.

Why Choose PTFE for Valve Linings?

Polytetrafluoroethylene (PTFE) has earned its position as the go-to material for valve linings due to its unparalleled chemical resistance, durability. And versatility in handling extreme operating conditions. This high-performance polymer, famously used in the PTFE ball valve, excels in resisting corrosive chemicals. Ensuring reliability in even the most aggressive environments. Its inclusion in PTFE lined valves and lined ball valves allows for smooth operation with minimal friction. Reducing wear and extending the lifespan of the equipment.

Compared to other materials, such as those used in FEP lined ball valves. PTFE offers superior thermal stability and performance at higher operating temperatures. Making it an ideal choice for industries like chemical processing, pharmaceuticals, and oil & gas. Often referred to as a Teflon valve due to PTFE’s trademark name. Its non-reactive and non-stick properties further enhance its utility in preventing material buildup, ensuring consistent functionality over time. Whether for handling harsh acids, solvents, or high-pressure systems, PTFE remains the material of choice for applications that prioritize safety, efficiency, and long-term value. Making it an indispensable material in modern valve technology.

Common Misconceptions About Teflon Valves

One common misconception about Teflon valves, widely recognized as valves incorporating PTFE (Polytetrafluoroethylene). Is that they are fragile or unsuitable for rigorous industrial applications. This misunderstanding likely arises from the perception of Teflon being a softer polymer. But in reality, PTFE’s unique properties provide unmatched durability for challenging environments. Valves such as the PTFE ball valve, PTFE lined valve, and lined ball valve are engineered to handle extreme conditions. Including highly corrosive chemicals and elevated temperatures, without compromising performance.

Another myth is that Teflon-lined valves are limited to niche uses. But their versatility spans industries like chemical processing, oil & gas, and pharmaceuticals. Where reliability in harsh conditions is a must. Concerns about leakage or degraded performance are also unfounded. As manufacturers extensively test PTFE linings for exceptional sealing efficiency and long-term stability. For applications requiring even greater material flexibility or transparency. Innovations like FEP lined ball valves provide alternatives without diminishing key benefits. Clarifying these inaccuracies demonstrates that Teflon valves excel in both durability and versatility. Proving themselves as indispensable components in modern valve technolog

Considerations When Selecting a PTFE Lined Valve

When selecting a PTFE lined valve, careful consideration of application-specific requirements is crucial to ensure optimal performance and reliability. Key factors include chemical compatibility, as PTFE offers exceptional resistance to aggressive chemicals. Making it ideal for environments dealing with highly corrosive or reactive substances. Temperature range is another significant aspect; PTFE lining, used in products like the ptfe ball valve or teflon valve. Withstands a wide range of operating temperatures, surpassing many alternative materials like FEP. That said, for applications requiring greater mechanical flexibility or transparency. Options like FEP lined ball valves may be more suitable. Pressure requirements should also be evaluated, as the robust lining in PTFE valves enhances durability under high-pressure conditions. Particularly vital in industries like oil & gas or chemical processing.

Other considerations include abrasion resistance, sealing efficiency, and maintenance demands. All of which impact the valve’s long-term performance. Beyond the technical specifications, the versatility of a lined ball valve. Whether PTFE lined or otherwise, makes it a preferred choice across diverse sectors. Including pharmaceuticals and water treatment. Balancing these elements ensures the chosen PTFE lined valve delivers unmatched efficiency, safety, and value in its intended application.

FAQ

What does PTFE stand for in ball valves?

PTFE stands for Polytetrafluoroethylene, a high-performance polymer known for its exceptional non-stick properties, chemical resistance, and durability.

What role does PTFE play in ball valves?

PTFE is commonly used as the material for seats and seals in ball valves. Its low friction coefficient ensures smooth operation of the valve, while its excellent sealing capabilities prevent leaks even under high-pressure conditions.

Why is PTFE widely used in ball valve applications?

PTFE is highly resistant to chemicals, extreme temperatures, and corrosion, making it ideal for applications where the flow media might be aggressive or abrasive. Its durability reduces wear and ensures reliable, long-term performance in demanding environments.

What are the key benefits of PTFE in ball valves?

Key benefits of PTFE include low maintenance, extended service life, resistance to nearly all chemicals, and excellent thermal stability. These properties make it a preferred choice for industries such as chemical processing, pharmaceuticals, food and beverage, and petrochemicals.

Conclusion

Polytetrafluoroethylene (PTFE) is the full form of PTFE, a revolutionary material at the heart of many high-performance valves like the ptfe ball valve, ptfe lined valve, and lined ball valve. Known for its exceptional properties, PTFE offers unmatched chemical resistance, minimal friction, and the ability to endure extreme temperatures. Making it a preferred choice across industries such as chemical processing, oil & gas, and pharmaceuticals. Its integration into valves ensures reliable operation even in harsh environments dealing with corrosive or reactive substances. Variants like the fep lined ball valve provide added flexibility and transparency, catering to specialized needs without compromising on key advantages.

Commonly referred to as teflon valve due to its trademarked counterpart, PTFE continues to lead in durability and efficiency. Preventing leaks, reducing wear and tear, and enhancing overall system performance. The versatility and reliability of PTFE make it indispensable in modern valve technology. Solidifying its role as a benchmark material for industrial applications worldwide. The importance of PTFE lies not just in its technical excellence but also in its ability to address evolving industry demands with precision and consistency.