3 way ball valves, the differences between 135-degree and 120-degree Y-type three-way ball valves is key to optimizing industrial flow control systems. These valves, foundational to efficient multi-directional flow management, vary in structural design, flow efficiency, and application. The 135-degree design allows for enhanced versatility in complex redirection systems. While the 120-degree variant excels in tighter spaces. Built with robust materials like the 3 way stainless steel ball valve, these valves ensure durability and performance. Whether utilizing a three way ball valve t port configuration or automating processes with a 3 way actuated ball valve. Knowing which angle suits your system’s requirements can drive efficiency.

3 way ball valve Introduction

3 way ball valve is a vital component in modern industrial systems. Designed to efficiently manage multi-directional flow within a single compact unit. Featuring three ports for inlet and outlet flow paths, the 3 three way ball valve enables operators to control, mix, or divert fluid or gas flow with precision and ease. Its unique design incorporates a rotating ball with internal flow channels. Allowing for various configurations such as T-port or L-port to meet the specific demands of an application.

These valves are integral to industries ranging from chemical processing and water treatment to oil and gas. Where maintaining reliable flow control is paramount. The adaptability of 3 way ball valves makes them an optimal choice for applications requiring multiple flow paths or connection points. Rducing the need for additional piping and minimizing system complexity. Whether used manually or integrated into automated systems. Their durability and robust construction ensure consistent performance even under high-pressure conditions.

?3 way ball valve importance in flow control systems

3 way ball valve, basic structure consists of a rotatable ball with a T-shaped or L-shaped bore that allows fluid to flow through various pathways. Enabling seamless switching or mixing between different lines. This functionality makes three-way ball valves highly versatile. Accommodating a broad range of industrial applications, from chemical processing to water treatment and energy production. By combining flow direction and control within a single valve. They significantly reduce the need for multiple separate valves, simplifying piping systems and minimizing installation complexity. Additionally, their robust design ensures reliable operation under varying pressure and temperature conditions. Enhancing overall system efficiency and reducing downtime. With their adaptability and effectiveness, three-way ball valves play a critical role in streamlining processes and optimizing performance across diverse industries.

comparing the differences between 135-degree and 120-degree Y-type 3 way ball valve

The key differences between 135-degree and 120-degree Y-type three-way ball valves lie in how their angles impact functionality. Space efficiency, and application suitability. The 135-degree Y-Type 3 way ball valve stands out for its ability to handle higher flow capacities with minimal resistance. Making it ideal for industries requiring smooth substance redirection. Such as chemical processing and energy production. Its wider angle reduces turbulence, promoting operational efficiency in systems prioritizing high volume and pressure management. However, its larger configuration may pose challenges in compact installations.

The 120-degree Y-Type 3 way valve is designed for tighter spaces. Offering precise flow control and optimized performance in applications with spatial constraints. Such as water treatment facilities and small-scale industrial systems. While its narrower angle enhances installation flexibility, it may slightly limit flow efficiency in high-capacity scenarios. These differences influence the selection process. As industries must decide between prioritizing flow efficiency with the 135-degree option or maximizing space utility and precision with the 120-degree counterpart, ensuring the valve aligns with their specific operational demands.

What is a Y-Type 3 Way Ball Valve?

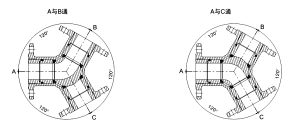

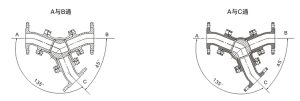

3 way ball valve,Y-Type valve is a specialized variation of the standard 3 way ball valve. Engineered to provide heightened precision and flexibility in flow control systems. Unlike traditional designs, the Y-Type configuration features angled ports that facilitate smoother transitions between multiple flow paths. Making them particularly advantageous in complex piping systems. These valves house a rotating ball with internal passages that align with the ports. Enabling operators to direct, combine, or isolate flow as needed.

3 three way ball valve, of this type is ideal for industries requiring reliable and efficient redirection of fluids or gases, such as chemical manufacturing, water systems, and energy production. The Y-Type design stands out for its ability to manage high-pressure conditions while maintaining compactness. Which reduces space requirements in tight installations. By offering varying angles, like 120-degree and 135-degree options, these valves cater to specific operational demands. Ensuring seamless performance and adaptability in any application.

Key Differences Between 135 Degree and 120 Degree Y-Type Designs

3 way ball valve, The key differences between the 135-degree and 120-degree Y-Type three-way ball valve designs lie in their structural configurations, flow efficiency, and industrial adaptability. A 135-degree Y-Type 3 way ball valve offers greater flexibility for managing complex multi-directional flow patterns. Its wider angle allows for smoother transitions and reduced flow resistance. Making it ideal for systems requiring seamless redirection, especially in applications with high flow rates or diverse operational demands.

On the other hand, the 120-degree Y-Type 3 three way ball valve is more compact. Suited for confined spaces where installation dimensions are a critical factor. While it may not provide the same level of flow optimization as the 135-degree design. Its tighter angle ensures precision in systems with controlled flow requirements. Both designs excel in durability and performance, but the choice between the two often depends on the specific operational environment. The 135-degree version is better for high-capacity systems or those needing extensive flow adaptability. While the 120-degree model is preferred in industries where spatial constraints and precise, straightforward flow control are prioritized.

3 way ball valve Structural and Design Variations

three-way ball valve exhibit notable structural and design variations that significantly influence their functionality and suitability for diverse industrial applications. These valves can feature different port configurations, such as L-port or T-port designs, tailored to specific flow control requirements like mixing, diverting, or isolating mediums. The materials used in their construction, ranging from stainless steel to specialized alloys. Play a critical role in ensuring durability, especially in harsh environments involving high pressure, extreme temperatures, or corrosive substances.

Additionally, the angled port configurations, such as the 120-degree and 135-degree variants, design to enhance flow efficiency and system integration, depending on space constraints and operational complexity. These design choices not only improve the robustness and performance of systems using a 3 way ball valve but also simplify maintenance processes. Further optimizing operational efficiency. By addressing industry-specific needs. Such as pressure management or temperature resistance, these structural variations reinforce the adaptability and reliability of 3 way ball valve systems in a wide range of applications.

Applications of 135 Degree and 120 Degree Y-Type Three-Way Ball Valves

3 way ball valve, 135-degree and 120-degree Y-Type three-way ball valves are essential components in various industries. Each offering unique advantages for specialized applications. The 135-degree Y-Type 3 way ball valve is particularly well-suited for systems requiring fluid redirection with minimal flow resistance. Such as in chemical processing plants, where seamless mixing and diverting of reactive compounds are critical. Its wider angle supports high-capacity flow. Making it ideal for large-scale applications like energy production, where adaptable flow management under high pressures ensures operational efficiency.

The 120-degree Y-Type 3 way valve excels in confined spaces. Such as compact water treatment facilities or industrial setups with limited installation room. Its tighter angle allows for precise flow control. Making it perfect for systems prioritizing straightforward and measured redirection. Both configurations play pivotal roles in optimizing system performance and reliability. By addressing specific needs—whether it’s handling aggressive chemicals. Managing high-pressure environments, or fitting into compact systems—these Y-Type designs highlight the versatility and ingenuity of 3 way ball valve technologies across industries.

Advantages of Y-Type Three-Way Ball Valves (120° and 135° Angles)

Three-Way Y-Type Ball Valves with 120° and 135° angles offer versatile advantages that cater to a wide range of industrial needs. Making them indispensable in systems that require efficient and reliable flow control. The 135° Y-Type 3 way ball valve stands out for its ability to handle complex flow paths with minimal resistance. Enabling seamless redirection and mixing of substances. This design is especially advantageous in high-capacity applications. Such as those in the chemical processing and energy production sectors. Where smooth transitions and adaptability to fluctuating pressures are critical for maintaining system efficiency.

On the other hand, the compact 120° Y-Type 3 way ball valve excels in spaces with constrained dimensions. Providing precise control without compromising performance. Its tighter angle is particularly beneficial in water treatment plants and small-scale industrial setups. Where accurate flow direction is paramount. Both designs are crafted to enhance durability and operational flexibility, ensuring reliable performance under varying conditions. Whether managing aggressive chemicals or optimizing systems with high-pressure requirements. These valves not only streamline processes but also improve overall system reliability by offering tailored solutions for diverse industrial applications.

3 way ball valve Factors to Consider When Choosing Between a 135 Degree and 120 Degree Valve

When choosing between a 135-degree and 120-degree Y-Type 3 way ball valve. Several critical factors must be considered to ensure optimal system performance and reliability. Space constraints are a primary consideration; a 120-degree Y-Type 3 way valve is better suited for installations with limited room. As its tighter angle allows for compact and efficient integration without sacrificing flow control accuracy. Conversely, the 135-degree Y-Type 3 way ball valve, with its wider angle, offers superior flow efficiency. Making it an ideal choice for high-capacity systems that prioritize minimal flow resistance and seamless substance redirection. Flow requirements are another key factor, as the wider 135-degree angle supports the mixing and diverting of greater volumes. While the 120-degree angle is tailored for precise, controlled flow paths in smaller-scale operations.

Additionally, pressure and temperature conditions play a vital role in the selection process. Systems operating under extreme pressures or handling aggressive chemicals may require materials and configurations that align with the specific capabilities of either valve. The decision also depends on the broader industrial application. For instance, the energy and chemical sectors often benefit from the versatility of a 135-degree valve, while water treatment facilities may find the 120-degree valve better suited for confined spaces and straightforward flow management. Ultimately, selecting the right angle involves balancing flow efficiency against installation flexibility. Ensuring the valve aligns with operational demands to deliver both robustness and reliability in any application.

?FAQ 3 way ball valve

Q1. What is the warranty period for your three-way ball valves?

3 way ball valve come with a standard warranty period of 12 months (1 years) from the date of delivery. This warranty covers manufacturing defects and materials under normal operating conditions as specified in the product manual.

Q2. How are 3 way ball valve prices determined?

Prices for three-way ball valves are influenced by several factors. Including the valve’s size, material composition (e.g., stainless steel, brass, or PVC), pressure ratings, end connection types. And any additional customisation or certifications required. Specialised features such as fire-safe designs or anti-static devices can also impact the cost.

Q3. What is the standard delivery time for a three-way ball valve?

Our standard delivery time for three-way ball valves is 4–6 weeks, depending on the order size and customisation requirements. For urgent requests, we offer expedited delivery options upon request.

Our logistics partners ensure fast and reliable delivery to meet engineering project timelines, regardless of location.

Q4. Common Applications of Three-Way Ball Valves

3 way ball valve is a versatile valve type designed with three ports for fluid flow. These ports can be configured to allow various functions. Such as mixing, diverting, or completely shutting off flow. Many three-way ball valves feature an L-port or T-port design. Which determines how the flow paths are arranged and controlled.

3 way ball valve Conclusion

The key differences between 135-degree and 120-degree Y-type three-way ball valves lie in how their angles impact functionality. Space efficiency, and application suitability. The 135-degree Y-Type 3 way ball valve stands out for its ability to handle higher flow capacities with minimal resistance. Making it ideal for industries requiring smooth substance redirection. Such as chemical processing and energy production. Its wider angle reduces turbulence, promoting operational efficiency in systems prioritizing high volume and pressure management. However, its larger configuration may pose challenges in compact installations.

3 way ball valve, the 120-degree Y-Type ball valve is designed for tighter spaces. Offering precise flow control and optimized performance in applications with spatial constraints. Such as water treatment facilities and small-scale industrial systems. While its narrower angle enhances installation flexibility. It may slightly limit flow efficiency in high-capacity scenarios. These differences influence the selection process. As industries must decide between prioritizing flow efficiency with the 135-degree option or maximizing space utility and precision with the 120-degree counterpart. Ensuring the valve aligns with their specific operational demands.