Description

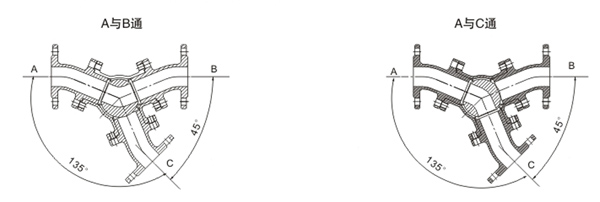

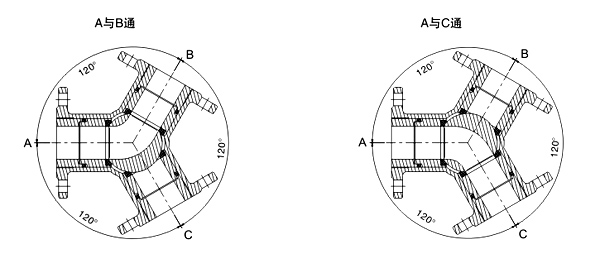

The Y pattern 3 way ball valve is engineered for precision and durability in demanding industrial environments. Specifically designed to handle highly abrasive fluids such as powder and slurry, as well as high viscosity fluids, this valve offers unmatched versatility and performance. Its unique switching angles of 120° and 135° provide exceptional flow control

A distinctive feature of this 3 way valve is its flange options, which include two types: a straight type and a 22.5° bent flange. By combining these two flange types in any three locations, operators can create various configurations to suit specific piping layouts. The innovative design includes a wide 135° angle, which surpasses the standard 90° bend angle of general 3-way ball valves. This expanded angle enables the smooth passage of pigs or spheres for efficient pipe cleaning, ensuring optimal system cleanliness and minimal downtime.

Crafted from robust materials to withstand abrasive media, the Y pattern three way ball valve also facilitates pigging operations, making it invaluable in industries where pipeline maintenance is critical. From managing powder and slurry to viscous fluids, this y type 3 way ball valve guarantees reliable operation, reduced maintenance, and exceptional durability tailored for the rigors of industrial applications.

| Body | WCB, CF8M, CF8M or Other stainless steel | |

| Body stlye | y 3 way 120 degree 135 degree | |

| Ball | SS304,SS316,SS316L | |

| Seat | PTFE,RPTFE, Metal+STL | |

| End | Flanged | |

| Size | 2”~10” DN50-DN250 | |

| Pressure | 1.6Mpa, 2.5Mpa, 4.0MPa | |

| Medium | Gas, Water and Oil, etc | |

| Pneumatic Actuator | Double acting,Single acting normally closed, acting,Single normally open | |

| Option | solenoid valve,?limit switch box?, filter, E/P positioner, hand wheel | |

| DN | L | D | K | R | C | f | n-d |

| 50 | 110 | 160/165 | 125 | 100 | 20 | 3 | 4-18 |

| 65 | 130 | 180/185 | 145 | 120 | 20 | 3 | 4-18 |

| 80 | 150 | 195/200 | 160 | 135 | 20 | 3 | 8-18 |

| 100 | 170 | 215/220 | 180 | 155 | 22 | 3 | 8-18 |

| 125 | 190 | 245/250 | 210 | 185 | 22 | 3 | 8-18 |

| 150 | 210 | 280/285 | 240 | 210 | 24 | 3 | 8-23 |

| 200 | 245 | 335/340 | 295 | 265 | 24 | 3 | 12-23 |

| 250 | 290 | 405 | 355 | 320 | 30 | 3 | 12-25 |

FAQ

What is a Y pattern 3 way ball valve?

A Y pattern 3 way ball valve is a specialized valve designed for precise and versatile flow control in industrial systems. Its unique Y-shaped configuration enables switching between three flow paths, making it ideal for complex piping systems. With its robust construction, it is engineered to handle abrasive fluids, high viscosity materials, and demanding industrial operations.

How does it differ from a standard 3 way ball valve?

Unlike a standard 3 way ball valve, which typically uses a 90° bend angle, the Y pattern 3 way ball valve features a wide-angle design with switching angles of 120° and 135°. This allows for smoother transitions and the passage of cleaning implements like pigs or spheres through the valve, enabling better maintenance and system cleanliness.

What are the benefits of using this valve for abrasive and high viscosity fluids?

The Y pattern 3 way ball valve is specifically designed to handle highly abrasive media, such as powder and slurry, as well as high viscosity fluids. Its durable construction prevents wear and ensures long-term performance even in harsh conditions. The valve’s ability to handle challenging fluids with minimal residue also reduces the risk of clogging and ensures reliable system operation.

How do the flange options enhance its functionality?

This valve offers two types of flanges—straight type and 22.5° bent—which can be configured in any three positions to adapt to various piping layouts. This flexibility allows the valve to fit seamlessly into complex systems. The 135° wide angle further enhances its functionality by enabling the smooth passage of cleaning tools for efficient pipeline maintenance.

What applications is this valve best suited for?

The Y pattern 3 way ball valve excels in industries requiring the handling of abrasive or viscous fluids, such as in chemical processing, mining, food and beverage production, and oil and gas operations. It is also well-suited for systems that require frequent cleaning or pigging to maintain operational efficiency and cleanliness, ensuring optimal performance in even the most challenging industrial environments.

Y pattern 3 way ball valve? PDF

? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?

? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?

120 degree? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?135 degree