Description

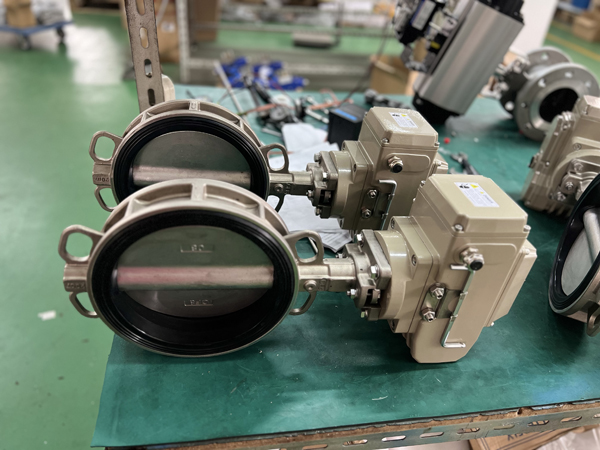

Air actuated valve offers reliable flow control with a butterfly valve with pneumatic actuator. Featuring durable disc materials like SS304, SS316, SS316L, and super duplex steel, paired with seat options in NBR, EPDM, and VITON, it ensures resistance to wear and corrosion. Available connections include wafer, lug, and flanged styles, making this pneumatic actuated butterfly valve versatile for various systems.

| Body | Ductile iron,WCB, stainless steel | |

| Body stlye | Wafer | |

| Disc | SS304,SS316,SS316L,Super duplex steel | |

| Seat | NBR,EPDM,VITON | |

| Connection | wafer,lug,flanged | |

| Size | 2”~60” DN50-DN1500 | |

| Pressure | PN10 PN16 5k 10k 150lb | |

| Medium | Gas, Water and Oil, etc | |

| Pneumatic Actuator | Double acting,Single acting normally closed, acting,Single normally open | |

| Option | solenoid valve,?limit switch box?, filter, E/P positioner, hand wheel | |

FAQ

Which applications are best suited for air actuated butterfly valve?

These valves are ideal for applications in industries such as food processing, chemical manufacturing, water treatment, and gas distribution. They are well-suited for systems requiring frequent flow adjustments or automation.

What materials are commonly used in air actuated butterfly valve?

The disc materials often include SS304, SS316, SS316L, and super duplex steel, which provide high durability and corrosion resistance. Seat materials like NBR, EPDM, and VITON offer excellent sealing properties for a range of operating conditions.

What types of connections are available for air actuated butterfly valve?

Common connection types include wafer, lug, and flanged connections. Wafer is ideal for lightweight applications, lug offers enhanced support for dismantling downstream piping, and flanged provides a secure fit for high-pressure systems.

What factors should be considered when selecting an air actuated butterfly valve?

Key considerations include media type, operating pressure and temperature, connection requirements, material compatibility, and the level of automation needed for the application. Proper evaluation ensures efficient performance and durability.

Are air actuated butterfly valve suitable for high-temperature conditions?

Valve performance in high-temperature environments depends on material selection. Disc materials like SS316L and super duplex steel, paired with temperature-resistant seats like VITON, are ideal for challenging thermal conditions.

Butterfly valve catalog download

? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?

? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?

Wafer butterfly valve pdf? ? ? ? ? ? ? ? ? ? ? ? ? ? Lug butterfly valve pdf