Diaphragm Material: EPDM, EPDM+PTFE

Connection:Flange, Clam, SW

Size: 3/8″ – 4″

Pressure: PN10

Pneumatic actuator: Double acting,Single acting

Accessories: Solenoid valve, limit switch box , filter, E/P positioner, hand wheel

The post 3 way diaphragm valve appeared first on Control Valve Manufacturers?.

]]>

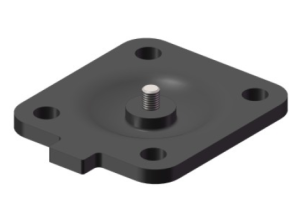

| Body | SS316,SS316L | |

| Diaphragm Material | EPDM, EPDM+PTFE | |

| Size | 3/8″-4″ | |

| Standard | ISO1127, DIN11850, | |

| Connection | Flange, Clam, SW | |

| Actuator material | Aluminum Alloy | |

| Pressure | PN10 | |

| Air supply pressure | 5.5bar | |

| Pneumatic Actuator | Double acting,Single acting normally closed, acting,Single normally open | |

| Option | solenoid valve,?limit switch box?, filter, E/P positioner, hand wheel | |

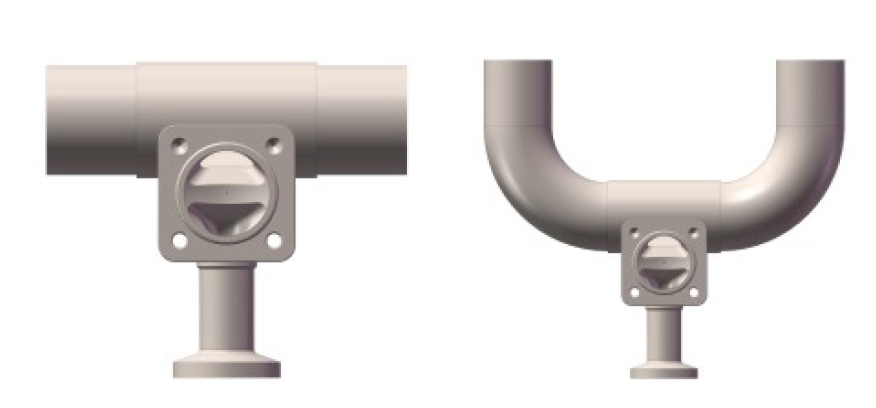

The three-way diaphragm valve comes in T-type and U-type configurations, primarily used for sampling or water intake in main pipelines. Its specific use depends on the application. Based on customer process requirements and installation needs, front and rear elbows matching the main pipe’s diameter can be chosen.

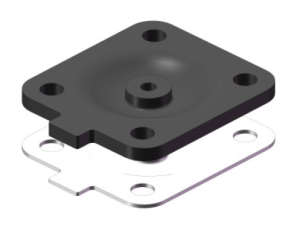

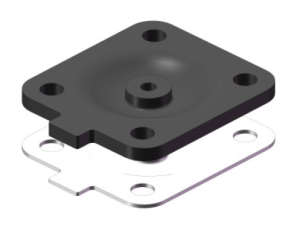

EPDM+PTFE Double layer diaphragm

The EPDM and PTFE diaphragm is engineered for durability and efficiency. When the valve is closed, the diaphragm’s design ensures a secure seal with the valve body, minimizing stress and extending its lifespan. Built to endure high temperatures and demanding working conditions, it offers reliable performance in challenging environments.

Specifications:

- Size range: DN25-DN100

- Double-layer diaphragm temperature tolerance: -20°C to 150°C

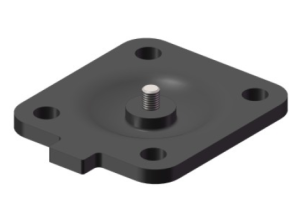

EPDM Single layer diaphragm

The single-layer diaphragm is reinforced with a vulcanized fiber layer, enhancing its mechanical strength and durability. Engineered for high sealing stability under rising pressure and temperature, it ensures reliable performance in demanding conditions. The diaphragm’s reinforcing fiber is hardened on stainless steel bolts, improving rubber-to-metal adhesion and overall cohesion. This design makes it particularly suitable for operations in vacuum environments.

Specifications:

– Size range: DN6-DN100

– Rubber diaphragm temperature tolerance: -10°C to 100°C

FAQ

What is a 3-way diaphragm valve?

3-way diaphragm valve is a flow-control device designed to manage multiple flow paths efficiently. It is particularly useful for diverting, mixing, or stopping the flow of media such as liquids, gases, or slurries in sanitary applications.

How does the T Type Tri Clamp design benefit users?

The T Type Tri Clamp design provides flexibility in directing flow, enabling quick switching between flow paths. It also allows for easy installation, removal, and maintenance, minimizing downtime while maintaining a secure and leak-proof connection.

What industries commonly use this valve?

Industries like pharmaceuticals, food and beverage processing, biotechnology, and cosmetics manufacturing frequently use 3-way diaphragm valves due to their ability to maintain strict hygiene and process control standards.

How does it ensure hygiene and safety?

The valve’s smooth, crevice-free interior prevents contamination by eliminating dead spaces where residues might accumulate. It supports Clean-in-Place (CIP) and Sterilize-in-Place (SIP) protocols, meeting stringent sanitation and safety requirements while maintaining product integrity.

Diaphragm valve catalog download

The post 3 way diaphragm valve appeared first on Control Valve Manufacturers?.

]]>Diaphragm Material: EPDM, EPDM+PTFE

Connection:Flange, Clam, SW

Size: 3/8″ – 4″

Pressure: PN10

Pneumatic actuator: Double acting,Single acting

Accessories: Solenoid valve, limit switch box , filter, E/P positioner, hand wheel

The post Sanitary diaphragm valve? appeared first on Control Valve Manufacturers?.

]]>Available in sizes ranging from 1/2″ to 4″, this sanitary diaphragm valve offers versatile configurations to suit varied system requirements. Its design minimizes dead spaces, enabling efficient cleaning and reducing the risk of contamination, which is crucial for industries like pharmaceuticals, food and beverage production, and other sanitary applications.

Applications

The SW sanitary diaphragm valve is tailored to meet the needs of industries where hygiene and safety are critical.

– Pharmaceuticals: Ensures sterile processing and prevents contamination during the production of medicines and biotech products.

– Food and Beverage: Maintains product purity by delivering hygienic flow control in the handling of liquids, pastes, and semi-solids.

– Sanitary Environments: Perfect for applications involving sensitive processes, such as cosmetics manufacturing and cleanroom operations.

With robust features like SS316L construction and an EPDM+PTFE diaphragm, this valve ensures compliance with strict industry standards while supporting Clean-in-Place (CIP) and Sterilize-in-Place (SIP) processes for efficient maintenance. Optimize your process efficiency and uphold product integrity with this dependable, high-quality valve.

| Body | SS316,SS316L | |

| Diaphragm Material | EPDM, EPDM+PTFE | |

| Size | 3/8″-4″ | |

| Standard | ISO1127, DIN11850, | |

| Connection | Flange, Clam, SW | |

| Actuator material | Aluminum Alloy | |

| Pressure | PN10 | |

| Air supply pressure | 5.5bar | |

| Pneumatic Actuator | Double acting,Single acting normally closed, acting,Single normally open | |

| Option | solenoid valve,?limit switch box?, filter, E/P positioner, hand wheel | |

?

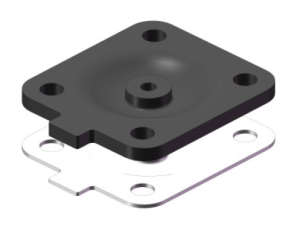

EPDM+PTFE Double layer diaphragm

The EPDM and PTFE diaphragm is engineered for durability and efficiency. When the valve is closed, the diaphragm’s design ensures a secure seal with the valve body, minimizing stress and extending its lifespan. Built to endure high temperatures and demanding working conditions, it offers reliable performance in challenging environments.

Specifications:

- Size range: DN25-DN100

- Double-layer diaphragm temperature tolerance: -20°C to 150°C

EPDM Single layer diaphragm

The single-layer diaphragm is reinforced with a vulcanized fiber layer, enhancing its mechanical strength and durability. Engineered for high sealing stability under rising pressure and temperature, it ensures reliable performance in demanding conditions. The diaphragm’s reinforcing fiber is hardened on stainless steel bolts, improving rubber-to-metal adhesion and overall cohesion. This design makes it particularly suitable for operations in vacuum environments.

Specifications:

– Size range: DN6-DN100

– Rubber diaphragm temperature tolerance: -10°C to 100°C

FAQ

What is a Clamp SW sanitary diaphragm valve?

Clamp SW sanitary diaphragm valve is a flow-control device designed for hygienic applications. It features a clamp-style connection for easy installation and removal, and is engineered to meet the strict cleanliness standards of industries like pharmaceuticals and food production.

How does the clamp connection benefit users?

The clamp connection allows for quick assembly and disassembly without the need for specialized tools. This design simplifies maintenance, system modifications, and cleaning, reducing downtime and improving efficiency in sanitation processes.

What materials are typically used in these valves?

These valves are primarily constructed from SS316L stainless steel, known for its exceptional corrosion resistance and durability. The diaphragm is often made from EPDM+PTFE, which provides a flexible, chemically resistant, and reliable seal, even in challenging process conditions.

What industries commonly use this type of valve?

Clamp SW sanitary diaphragm valves are widely adopted in industries that demand stringent hygiene, such as pharmaceuticals, food and beverage, biotechnology, and cosmetics manufacturing.

How does it ensure hygiene and safety?

This valve incorporates a design that minimizes dead spaces, reducing the risk of contamination. The use of high-grade materials creates a clean, inert surface for the flow of process media. Additionally, it supports CIP (Clean-in-Place) and SIP (Sterilize-in-Place) procedures, ensuring compliance with strict hygiene regulations.

Diaphragm valve catalog download

The post Sanitary diaphragm valve? appeared first on Control Valve Manufacturers?.

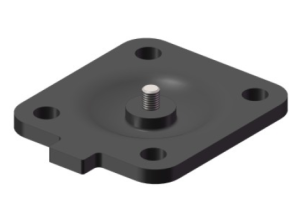

]]>Diaphragm Material: EPDM, EPDM+PTFE

Connection:Flange, Clam, SW

Size: 3/8″ – 4″

Pressure: PN10

Pneumatic actuator: Double acting,Single acting

Accessories: Solenoid valve, limit switch box , filter, E/P positioner, hand wheel

The post Sanitary diaphragm valves appeared first on Control Valve Manufacturers?.

]]>| Body | SS316,SS316L | |

| Diaphragm Material | EPDM, EPDM+PTFE | |

| Size | 3/8″-4″ | |

| Standard | ISO1127, DIN11850, | |

| Connection | Flange, Clam, SW | |

| Actuator material | Aluminum Alloy | |

| Pressure | PN10 | |

| Air supply pressure | 5.5bar | |

| Pneumatic Actuator | Double acting,Single acting normally closed, acting,Single normally open | |

| Option | solenoid valve,?limit switch box?, filter, E/P positioner, hand wheel | |

?

EPDM+PTFE Double layer diaphragm

The EPDM and PTFE diaphragm is engineered for durability and efficiency. When the valve is closed, the diaphragm’s design ensures a secure seal with the valve body, minimizing stress and extending its lifespan. Built to endure high temperatures and demanding working conditions, it offers reliable performance in challenging environments.

Specifications:

- Size range: DN25-DN100

- Double-layer diaphragm temperature tolerance: -20°C to 150°C

EPDM Single layer diaphragm

The single-layer diaphragm is reinforced with a vulcanized fiber layer, enhancing its mechanical strength and durability. Engineered for high sealing stability under rising pressure and temperature, it ensures reliable performance in demanding conditions. The diaphragm’s reinforcing fiber is hardened on stainless steel bolts, improving rubber-to-metal adhesion and overall cohesion. This design makes it particularly suitable for operations in vacuum environments.

Specifications:

– Size range: DN6-DN100

– Rubber diaphragm temperature tolerance: -10°C to 100°C

FAQ

What are sanitary diaphragm valves?

Sanitary diaphragm valves are specialized flow control devices designed for high hygiene and precision. They use a flexible diaphragm to regulate or block the flow of fluids, ensuring contamination-free operation in sensitive applications.

What materials are they made from?

These valves are typically constructed from high-grade stainless steel, such as SS316L, for durability and corrosion resistance. The diaphragm is often made from EPDM+PTFE or rubber, offering chemical resistance and suitability for a wide range of applications.

What industries use these valves?

Sanitary diaphragm valves are widely used in industries that demand strict hygiene, including pharmaceutical manufacturing, food and beverage processing, and sanitary applications like cosmetics and biotechnology.

How do they ensure hygiene and safety?

The design eliminates dead spaces and allows for easy cleaning (CIP or SIP), reducing the risk of contamination. The diaphragm acts as a barrier between the process fluid and the operating mechanism, ensuring high levels of safety and hygiene.

What sizes and configurations are available?

Sanitary diaphragm valves are available in sizes ranging from 1/2″ to 4″ (DN6-DN100), with configurations like straight-through and 3-way options to suit varied system designs and flow requirements.

Diaphragm valve catalog download

The post Sanitary diaphragm valves appeared first on Control Valve Manufacturers?.

]]>Diaphragm Material: EPDM, EPDM+PTFE

Connection:Flange, ASME B16.34 class 150, PN10

Size: 1/2″ – 8″ (15mm – 200mm)

Pressure: PN10

Pneumatic actuator: Double acting,Single acting

Accessories: Solenoid valve, limit switch box , filter, E/P positioner, hand wheel

The post PVDF diaphragm valves manufacturer? appeared first on Control Valve Manufacturers?.

]]>| Body | UPVC, CPVC, PVDF | |

| Diaphragm Material | EPDM, EPDM+PTFE | |

| Size | 1/2”~8” DN15-DN200 | |

| Seat | EPDM, EPDM+PTFE | |

| Connection | Flange, ASME B16.34 class 150, PN10 | |

| Actuator material | Aluminum Alloy | |

| Pressure | PN10 | |

| Air supply pressure | 5.5bar | |

| Pneumatic Actuator | Double acting,Single acting normally closed, acting,Single normally open | |

| Option | solenoid valve,?limit switch box?, filter, E/P positioner, hand wheel | |

?

FAQ

What are PVDF diaphragm valves used for?

PVDF diaphragm valves are ideal for fluid control in industries requiring high chemical resistance, such as chemical processing, water treatment, pharmaceuticals, and food production. Their durability and efficiency make them suitable for handling aggressive liquids and gases.

What are the key features of PVDF diaphragm valves?

PVDF diaphragm valves feature a body made of Polyvinylidene Fluoride (PVDF), known for its excellent chemical resistance and thermal stability. They include diaphragms made of EPDM or EPDM+PTFE for enhanced sealing and compatibility with a range of media. These valves comply with international standards like ASME B16.34 and have a pressure rating of PN10.

What sizes and connection types are available?

PVDF diaphragm valves come in sizes ranging from 1/2″ to 8″ (15mm to 200mm) and offer flange connections conforming to ASME B16.34 Class 150 and PN10 standards, ensuring they meet diverse industrial requirements.

What are the benefits of PVDF as a body material?

PVDF offers high resistance to corrosive chemicals, abrasion, and UV exposure. It performs well in extreme temperatures without compromising structural integrity, making it an excellent choice for valves in demanding environments.

Diaphragm valve catalog download

The post PVDF diaphragm valves manufacturer? appeared first on Control Valve Manufacturers?.

]]>Diaphragm Material: EPDM, EPDM+PTFE

Connection:Flange, ASME B16.34 class 150, PN10

Size: 1/2″ – 8″ (15mm – 200mm)

Pressure: PN10

Pneumatic actuator: Double acting,Single acting

Accessories: Solenoid valve, limit switch box , filter, E/P positioner, hand wheel

The post CPVC diaphragm valve manufacturers appeared first on Control Valve Manufacturers?.

]]>| Body | UPVC, CPVC, PVDF | |

| Diaphragm Material | EPDM, EPDM+PTFE | |

| Size | 1/2”~8” DN15-DN200 | |

| Seat | EPDM, EPDM+PTFE | |

| Connection | Flange, ASME B16.34 class 150, PN10 | |

| Actuator material | Aluminum Alloy | |

| Pressure | PN10 | |

| Air supply pressure | 5.5bar | |

| Pneumatic Actuator | Double acting,Single acting normally closed, acting,Single normally open | |

| Option | solenoid valve,?limit switch box?, filter, E/P positioner, hand wheel | |

?

FAQ

What materials are used in UPVC plastic diaphragm valves?

UPVC (Unplasticized Polyvinyl Chloride) is the primary material, known for its chemical resistance and durability. Many manufacturers also offer optional materials like PVDF (Polyvinylidene Fluoride) and CPVC (Chlorinated Polyvinyl Chloride), which provide enhanced performance in handling corrosive and high-temperature media.

What industries commonly use UPVC diaphragm valves?

These valves are widely utilized in industries such as chemical processing, water and wastewater treatment, pharmaceuticals, food processing, mining, power generation, and electronics manufacturing due to their ability to handle corrosive substances and their precise control features.

What are the benefits of UPVC as a material for diaphragm valves?

UPVC offers excellent resistance to chemical corrosion, is lightweight, and requires minimal maintenance. Its durability and cost-efficiency make it well-suited for industrial fluid management systems used to transport or regulate aggressive media.

What control options are available for UPVC diaphragm valves?

Most manufacturers supply valves with manual, electric, or pneumatic actuation options. These control systems allow for precise and efficient regulation of fluid flow, tailored to a range of operational requirements.

Diaphragm valve catalog download

The post CPVC diaphragm valve manufacturers appeared first on Control Valve Manufacturers?.

]]>Diaphragm Material: EPDM, EPDM+PTFE

Seats: PTFE,RPTFE

Connection:Flange, ASME B16.34 class 150, PN10, PN16

Size: 1/2″ – 8″ (15mm – 200mm)

Pressure: PN10

Pneumatic actuator: Double acting,Single acting

Accessories: Solenoid valve, limit switch box , filter, E/P positioner, hand wheel

The post Pneumatic diaphragm valve appeared first on Control Valve Manufacturers?.

]]>| Body | Stainless steel,CF8,CF8M,CF3M WCB+ EPDM | |

| Diaphragm Material | EPDM, EPDM+PTFE | |

| Size | 1/2”~8” DN15-DN200 | |

| Seat | PTFE,RPTFE | |

| Connection | Flange, ASME B16.34 class 150, PN10, PN16 | |

| Actuator material | Aluminum Alloy | |

| Pressure | PN10 | |

| Air supply pressure | 5.5bar | |

| Pneumatic Actuator | Double acting,Single acting normally closed, acting,Single normally open | |

| Option | solenoid valve,?limit switch box?, filter, E/P positioner, hand wheel | |

FAQ

What are pneumatic diaphragm valves, and why are they used in the chemical industry?

Pneumatic diaphragm valves are control valves that use compressed air to operate a flexible diaphragm to regulate flow. They are widely used in the chemical industry due to their ability to handle highly corrosive media like acids and alkalis. Their design ensures minimal contamination and excellent resistance to aggressive chemicals, making them ideal for demanding environments.

How do pneumatic diaphragm valves provide corrosion resistance?

These valves are constructed from materials that excel in resisting corrosion. Bodies are often available in Stainless Steel, WCB lined with PFA, or PTFE, while diaphragms are made from EPDM or EPDM+PTFE. Their PTFE and RPTFE seats provide an additional layer of protection, ensuring long-term durability even in harsh acid and alkali environments.

What are the advantages of using pneumatic diaphragm valves for acid and alkali media?

The primary advantages include excellent chemical resistance, leak-proof sealing, and ease of maintenance. These valves also offer reliable automation through a pneumatic actuator, ensuring precise control over processes. Their corrosion-resistant materials extend valve life and reduce the risk of equipment failure or downtime in highly aggressive chemical applications.

How do pneumatic diaphragm valves compare to other types of valves in corrosive applications?

Compared to other valve types, pneumatic diaphragm valves are specifically engineered for handling corrosive media without compromising performance. For instance, ball or gate valves may struggle with sealing or corrosion in highly acidic or alkaline conditions, whereas diaphragm valves provide superior sealing and resistance. Their non-metallic lining options, such as PFA or PTFE, and advanced diaphragms make them the preferred choice for chemical applications.

Diaphragm valve catalog download

The post Pneumatic diaphragm valve appeared first on Control Valve Manufacturers?.

]]>Diaphragm Material: EPDM, EPDM+PTFE

Seats: PTFE,RPTFE

Connection:Flange, ASME B16.34 class 150, PN10, PN16

Size: 1/2″ – 8″ (15mm – 200mm)

Pressure: PN10

Pneumatic actuator: Double acting,Single acting

Accessories: Solenoid valve, limit switch box , filter, E/P positioner, hand wheel

The post Diaphragm valves appeared first on Control Valve Manufacturers?.

]]>| Body | Stainless steel,CF8,CF8M,CF3M WCB+ EPDM | |

| Diaphragm Material | EPDM, EPDM+PTFE | |

| Size | 1/2”~8” DN15-DN200 | |

| Seat | PTFE,RPTFE | |

| Connection | Flange, ASME B16.34 class 150, PN10, PN16 | |

| Actuator material | Aluminum Alloy | |

| Pressure | PN10 | |

| Air supply pressure | 5.5bar | |

| Pneumatic Actuator | Double acting,Single acting normally closed, acting,Single normally open | |

| Option | solenoid valve,?limit switch box?, filter, E/P positioner, hand wheel | |

FAQ

What are EPDM diaphragm valve?

EPDM diaphragm valves are flow control devices built with Ethylene Propylene Diene Monomer (EPDM) diaphragms. These valves offer excellent resistance to heat, chemicals, and corrosion, making them ideal for demanding industrial applications.

How do EPDM diaphragm valve provide corrosion resistance?

EPDM material is highly resistant to a wide range of harsh chemicals, including acids and alkalis. This corrosion resistance ensures reliable performance and long service life, especially in environments where aggressive substances are present.

Where are EPDM diaphragm valve typically used in the chemical industry?

These valves are commonly used in processes involving acid and alkali media. Their ability to withstand corrosive environments makes them a preferred choice for handling chemical formulations, manufacturing processes, and fluid systems in the chemical industry.

How do EPDM diaphragm valves compare to PTFE or PFA-lined valves?

While PTFE and PFA-lined valves offer excellent resistance to extreme temperatures and aggressive chemicals, EPDM valves balance durability, chemical resistance, and cost-effectiveness. EPDM is particularly suited for handling a broad range of applications without compromising reliability.

Diaphragm valve catalog download

The post Diaphragm valves appeared first on Control Valve Manufacturers?.

]]>Diaphragm Material: EPDM, EPDM+PTFE

Seats: PTFE,RPTFE

Connection:Flange, ASME B16.34 class 150, PN10, PN16

Size: 1/2″ – 8″ (15mm – 200mm)

Pressure: PN10

Pneumatic actuator: Double acting,Single acting

Accessories: Solenoid valve, limit switch box , filter, E/P positioner, hand wheel

The post Diaphragm valve appeared first on Control Valve Manufacturers?.

]]>Options include pneumatic diaphragm valves for automation and 3 way diaphragm valves for flexible flow operations. With a diaphragm valve pneumatic actuator, these valves deliver precise control, while their robust membrane valve design minimizes contamination.

| Body | Stainless steel,CF8,CF8M,CF3M WCB+PFA or PTFE | |

| Diaphragm Material | EPDM, EPDM+PTFE | |

| Size | 1/2”~8” DN15-DN200 | |

| Seat | PTFE,RPTFE | |

| Connection | Flange, ASME B16.34 class 150, PN10, PN16 | |

| Actuator material | Aluminum Alloy | |

| Pressure | PN10 | |

| Air supply pressure | 5.5bar | |

| Pneumatic Actuator | Double acting,Single acting normally closed, acting,Single normally open | |

| Option | solenoid valve,?limit switch box?, filter, E/P positioner, hand wheel | |

FAQ

What are lined PTFE and PFA diaphragm valves?

Lined PTFE and PFA diaphragm valves are advanced valves designed to provide exceptional chemical resistance, durability, and precise flow control. They utilize PTFE or PFA lining to ensure compatibility with corrosive and aggressive media, making them ideal for demanding industrial applications.

What industries commonly use these valves?

These valves are widely used in industries such as the chemical industry, pharmaceuticals, and water treatment. They are particularly suited for managing acid and alkali media and handling corrosive substances in critical processes.

How do these valves enhance corrosion resistance?

The PTFE and PFA linings provide a robust barrier against chemical attack, ensuring long-lasting performance even in environments with highly corrosive substances. This makes them essential for industries that prioritize safety and reliability.

What types of diaphragm valves are available in lined PTFE and PFA options?

The product range includes pneumatic diaphragm valves for automated operations and 3 way diaphragm valves for versatile flow configurations. Both designs enhance operational flexibility and efficiency.

Diaphragm valve catalog download

The post Diaphragm valve appeared first on Control Valve Manufacturers?.

]]>