?Discover the key differences between a ball valve and a V ball valve to make informed choices for your flow control systems. While a ball valve offers reliable on-off functionality and versatility, a V ball valve is designed for precision flow modulation, ideal for demanding applications like chemical processing. Both can integrate with advanced solutions, including electrically actuated ball valves, motorized ball valves, and electronic ball valves, to enhance automation and efficiency. By understanding their unique capabilities, you can determine whether a ball valve or a V ball valve—equipped with options like ball valve actuators electric or automatic configurations—best suits your needs.

1. Introduction

Selecting the right valve for your flow control system can significantly impact efficiency and performance. When deciding between a ball valve and a V ball valve, understanding their key differences is essential. A ball valve stands out for its reliable on-off functionality and adaptability across various applications, while a V ball valve offers precision and control, making it indispensable for processes like chemical manufacturing. Integrating advanced solutions such as electrically actuated ball valves, motorized ball valves, and electronic ball valves can further enhance automation and system effectiveness. By exploring the distinct capabilities of each valve type—along with options like ball valve actuators electric and automatic configurations—you can ensure your system performs seamlessly and meets all operational demands.

2. What is a Ball Valve?

Definition and basic function of a ball valve.

A ball valve is a versatile component in flow control systems, designed for reliable on-off control. It features a hollow, rotating ball within the valve body that allows or blocks fluid flow depending on its position. Known for its full bore design, the ball valve is highly efficient, offering minimal flow resistance and quick operation, making it an ideal choice for isolating and regulating flow in various industrial and commercial applications.

Key characteristics like full bore design, on-off control, and simplicity.

A ball valve is defined by its full bore design, offering unobstructed flow with minimal pressure loss, making it highly efficient for various systems. Its primary function is on-off control, providing quick and reliable shutoff capabilities. Renowned for its simplicity and durability, the ball valve requires minimal maintenance, making it a preferred choice for applications demanding straightforward and effective flow regulation.

Common types, such as “electronic ball valve” and “automatic ball valve.”

Common types of ball valves include electronic ball valves and automatic ball valves, both designed to enhance automation and precision in flow control systems. An electronic ball valve integrates an electric actuator, enabling remote operation and precise control, making it ideal for modern automated systems. Meanwhile, automatic ball valves streamline processes by autonomously adjusting flow without manual intervention, offering reliability and efficiency in demanding industrial and commercial environments. These advanced configurations ensure seamless operation and improved system performance.

3. What is a V Ball Valve?

Explanation of the V-shaped ball or port in a V ball valve.

The V-shaped ball or port in a V ball valve is specifically engineered to provide precise flow control, even in applications requiring fine adjustments. Its unique design allows for a more controlled and gradual flow rate compared to standard ball valves, making it ideal for throttling and proportional control. This feature ensures consistent, accurate performance, especially in systems managing variable pressures or flow conditions.

Designed for flow modulation or throttling applications.

V ball valves are specifically designed for flow modulation and throttling applications, offering superior precision and efficiency in managing flow rates. Their V-shaped ball or port enables accurate control over fluid dynamics, making them ideal for systems requiring fine adjustments. This design allows for consistent operation under various flow conditions, ensuring optimized performance and adaptability in demanding industrial processes.

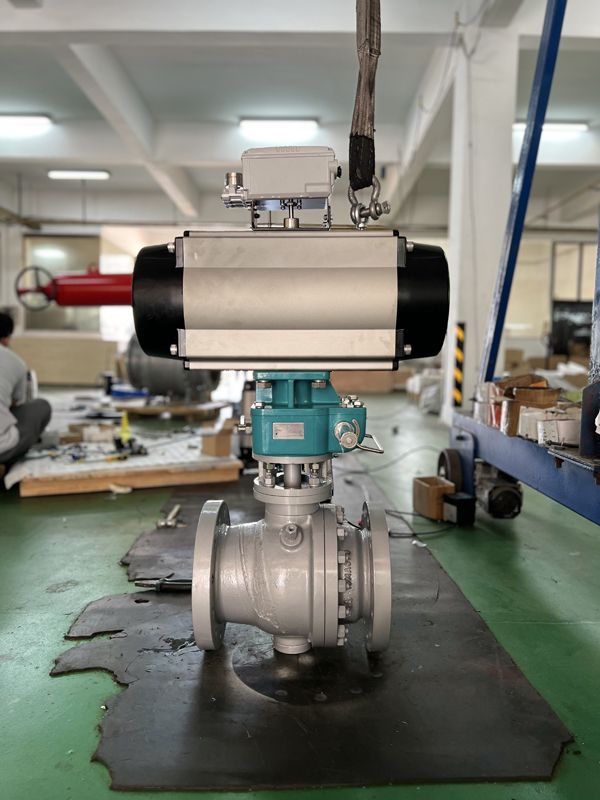

Integration with advanced systems using “ball valve actuator electric” or “electrically actuated ball valve.”

Electrically actuated ball valves, equipped with a ball valve actuator electric, are integral to modern, automated flow control systems. These valves combine the reliability of ball valve mechanics with the precision of electric actuation, allowing for seamless remote operation and real-time adjustments. Their integration enhances system efficiency, enabling precise control, monitoring, and automation across complex industrial processes, making them indispensable in high-performance and smart system applications.

4. Key Differences Between Ball Valve and V Ball Valve

Flow Control:

Ball valve’s on-off function vs. V ball valve’s precision flow control.

A standard ball valve excels at providing on-off functionality, ensuring rapid and reliable shutoff for straightforward flow control applications. In contrast, the V ball valve is engineered for precision flow control, offering a gradual and modulated flow rate through its V-shaped port. While the ball valve is ideal for systems demanding simple open or close operations, the V ball valve shines in applications requiring fine-tuned adjustments and accurate flow modulation for variable conditions. Each serves distinct purposes, tailored to specific operational needs.

Design Features:

Full bore in ball valves vs. V-shaped ports for V ball valves.

The full bore design in ball valves provides maximum flow capacity, as the valve’s opening matches the diameter of the pipeline, ensuring minimal flow resistance and high efficiency for unrestricted fluid transfer. Conversely, V-shaped ports in V ball valves are tailored for precise flow control, allowing gradual and accurate adjustments in fluid dynamics. While full bore ball valves are ideal for applications prioritizing high flow rates and low-pressure drops, V ball valves excel in environments demanding exact modulation and throttling, such as process control and variable load systems.

Applications:

Highlight how “motorized ball valves” or “automatic ball valves” can be used in various industries for each type.

Motorized ball valves, or automatic ball valves, offer remarkable versatility, making them indispensable across a variety of industries. Standard motorized ball valves excel in on-off applications, ensuring efficient and automated fluid control in systems like water treatment, HVAC, and fuel transfer. Meanwhile, motorized V ball valves are designed for precision flow modulation, catering to industries such as chemical processing, food and beverage, and pharmaceuticals where accurate flow adjustments are critical. Their seamless integration with automated systems enhances operational efficiency and reliability in both general-purpose and specialized applications.

Actuation Compatibility:

Use of “electronic ball valve” with actuators for automation.

Electronic ball valves paired with actuators are pivotal in advancing automation across diverse systems. This combination allows for seamless remote operation, precise control of fluid dynamics, and integration into complex industrial processes. The actuators enable responsive adjustments in real time, ensuring efficiency and consistency in performance. From automated manufacturing lines to smart building systems, electronic ball valves enhance operational precision while optimizing workflow and reducing manual intervention.

5. Typical Applications

Common industries where ball valves are used, such as water supply, oil and gas, and HVAC systems.

Ball valves are vital components across numerous industries, including water supply, oil and gas, and HVAC systems, due to their robust design and reliable performance. In water supply systems, they enable efficient flow control and leak prevention, ensuring clean water distribution. The oil and gas sector relies on ball valves for high-pressure and high-temperature applications, where their durability and sealing integrity are critical. Within HVAC systems, ball valves contribute to precise temperature and flow management, enhancing energy efficiency and system reliability. Their versatility and dependability make them indispensable in these and other demanding environments.

Highlight V ball valves in applications needing precise control, like chemical processing and manufacturing.

V ball valves are indispensable in applications that demand precise flow control, such as chemical processing and advanced manufacturing systems. Their V-shaped port design ensures accurate modulation, allowing operators to achieve tight control over fluid dynamics even under varying process conditions. Built for reliability, these valves excel in handling corrosive or high-temperature mediums, making them a trusted component in environments where precision and durability are paramount.

Mention scenarios that benefit most from “electrically actuated ball valve.”

Electrically actuated ball valves are ideal for scenarios requiring seamless remote operation and advanced automation. They excel in managing critical processes in industries such as water treatment, where precision in flow control is essential for maintaining quality and efficiency. The oil and gas sector benefits from their ability to handle high-pressure environments while ensuring safe, reliable operation. In manufacturing, these valves optimize automated workflows by minimizing manual intervention and enhancing process accuracy. They are indispensable in complex and demanding applications.

6. Advantages of Each Type

Ball Valves:

Ball valves offer significant advantages, making them a preferred choice in diverse applications. Their rugged construction ensures exceptional durability, even in high-pressure or corrosive environments. With a simple quarter-turn operation, they provide ease of use and rapid actuation. Additionally, ball valves are renowned for their reliable sealing, minimizing the risk of leaks and ensuring precise flow control. These qualities make them indispensable in industries ranging from water supply and oil and gas to chemical processing and HVAC systems.

V Ball Valves:

V ball valves offer superior precision and adaptability, making them an essential component in advanced flow control systems. Their unique V-shaped ball design ensures accurate modulation, enabling precise control over flow rates, even at low openings. This enhances operational efficiency across various applications, including chemical processing and oil and gas, where performance is critical. Their durability and ability to handle varying pressures and temperatures highlight their versatility. This solidifies their place as a preferred solution for demanding industrial environments.

7. How to Choose Between a Ball Valve and a V Ball Valve

Factors to consider, including flow control requirements, operating conditions, and system automation levels.

When selecting a valve, evaluate flow control requirements, operating conditions, and system automation levels for optimal performance. Consider the desired level of flow precision, operating pressures, and temperatures. Ensure the medium being handled aligns with the application’s demands. Tailor the degree of automation to the system’s complexity and objectives. A thorough analysis of these elements ensures seamless integration, enhances efficiency, and minimizes downtime in industrial processes.

The role of “automatic ball valves” and “electrically actuated ball valves” in making the right choice.

Automatic ball valves and electrically actuated ball valves play a crucial role in achieving precise control and enhancing operational efficiency within industrial systems. Automatic ball valves provide seamless, hands-free operation, making them ideal for applications requiring frequent or rapid cycling. Electrically actuated ball valves deliver precise and reliable control over flow rates. They are ideal for advanced automation systems. Their ability to handle varying operating conditions ensures accuracy and responsiveness. This makes them indispensable for industries prioritizing consistency and system optimization. Selecting the right option ensures alignment with application-specific needs and long-term performance goals.

8. Maintenance and Longevity Considerations

Tips for maintaining both valve types to ensure operational efficiency.

Regular maintenance is essential to ensure the operational efficiency of both automatic and electrically actuated ball valves. Begin with routine inspections to identify signs of wear, leaks, or misalignment. Cleaning the valve components and lubricating moving parts helps prevent buildup and ensures smooth operation. Address any signs of wear and tear promptly to avoid unplanned downtime. Always adhere to manufacturer-recommended maintenance schedules and guidelines, as these are tailored to the valve’s specific design and materials. Proactive care ensures longevity, reliability, and consistent performance in demanding industrial applications.

Benefits of automated setups using “electronic ball valves” to reduce wear and tear.

Automated setups utilizing electronic ball valves offer significant advantages in minimizing wear and tear, ensuring long-term operational reliability. By delivering precise flow control and reducing the need for manual intervention, these systems maintain consistent performance under varying conditions. Automation optimizes valve operation by preventing overuse and mitigating abrupt pressure changes, which are common causes of mechanical strain. This intelligent control enhances durability, extends the lifespan of the valve, and promotes efficiency across industrial processes while reducing maintenance requirements.

9. FAQS

-

What applications are best suited for a ball valve?

Ball valves are versatile and commonly used in applications where straightforward on-off control is required. They are favored in industries like water distribution, gas systems, and HVAC due to their simple operation and robust design.

-

Can ball valves and V ball valves be automated?

Yes, both ball valves and V ball valves can be automated. This is achieved using advanced configurations like electrically actuated ball valves, motorized ball valves, or electronic ball valves. These options offer improved operational efficiency and enable remote control of flow systems.

-

What is the purpose of a ball valve actuator electric system?

A ball valve actuator electric system uses an electric motor to open or close the valve automatically. This reduces operational effort, making it suitable for remote or complex systems with frequent cycles.

-

How do motorized ball valves differ from manually operated ones?

Motorized ball valves use an electric actuator to control valve movement remotely or automatically, unlike manually operated valves that require physical adjustment. They are often chosen for large-scale or inaccessible systems requiring seamless control.

-

What are the advantages of an automatic ball valve?

Automatic ball valves streamline operations by eliminating the need for manual intervention. They integrate with automation processes, offer precise control, and ensure consistent performance in industrial and commercial setups.

10. Conclusion

Choosing between a ball valve and a V ball valve comes down to understanding the specific demands of your application. A traditional ball valve is a trusted choice for straightforward on-off operations, while a V ball valve excels at delivering precision flow control for complex processes. Enhancing performance with options such as electrically actuated ball valves, motorized ball valves, and electronic ball valves enables a higher degree of automation and efficiency. Solutions like ball valve actuators electric and automatic ball valve systems further streamline operations across industries. By weighing the unique strengths of each valve type and their advanced configurations, you ensure that your flow control system is not only efficient but perfectly suited to your operational needs.