Installing a ball valve correctly is essential for system efficiency and safety. This article offers step-by-step guidance, covering everything from preparation to maintenance, with insights into electric actuated ball valves. Learn how to mount and calibrate components like a ball valve electric actuator or an electric ball valve actuator for precise flow control. Ideal for both basic setups and advanced systems using electric ball valves, this guide helps you avoid common mistakes and maximize performance.

Introduction

Installing a ball valve correctly is a critical step in ensuring the efficiency, safety, and longevity of fluid control systems. Whether it’s managing flow in industrial pipelines or controlling pressure in complex machinery, a properly installed ball valve provides the precision and reliability needed for optimal performance. Ball valves, known for their durability and versatility, are essential components across a wide range of industries. With advancements in automation, options like electric actuated ball valves have revolutionized fluid control, allowing for precise handling at the push of a button. By understanding key considerations, such as selecting the right ball valve, installing electric ball valve actuators, and following best practices, professionals can avoid costly mistakes and enhance overall system functionality. This guide will walk you through the essentials, offering expert insights into both manual and electric ball valves, including the benefits of ball valve electric actuators and their role in automated operations.

Understanding Ball Valves

Define what a ball valve is and its primary function in regulating fluid flow.

A ball valve is a robust, quarter-turn valve designed to regulate fluid flow by utilizing a spherical disc with a bore through its center. When rotated, the ball either blocks or allows flow based on the alignment of the bore with the pipeline. Known for its simplicity, durability, and tight sealing capabilities, a ball valve is widely used in industries such as oil and gas, chemical processing, and water treatment. Key features include minimal pressure drop, low maintenance requirements, and resistance to high pressures and temperatures, making it ideal for a range of applications. Its efficiency and reliability in delivering precise flow control underscore its importance in modern fluid management systems.

Highlight the characteristics of ball valves, such as precision sealing, minimal pressure drop, and versatility in industrial use.

Ball valves are valued for their exceptional characteristics, which make them a preferred choice in a wide range of industrial applications. One of their standout features is precision sealing, achieved through their finely engineered ball and seat design, ensuring a tight shutoff even under demanding conditions. This reliability minimizes the risk of leaks while maintaining the integrity of the fluid control system. Additionally, ball valves offer minimal pressure drop, as their full-bore design allows unobstructed flow when in the open position, optimizing system efficiency. Their versatility extends across various industries, such as oil and gas, chemical processing, and water management, due to their ability to handle high pressures, extreme temperatures, and corrosive materials. These features, combined with their durability and ease of operation, solidify ball valves as an indispensable component in modern industrial systems.

Discuss different types of ball valves, including electric ball valves and those equipped with actuators.

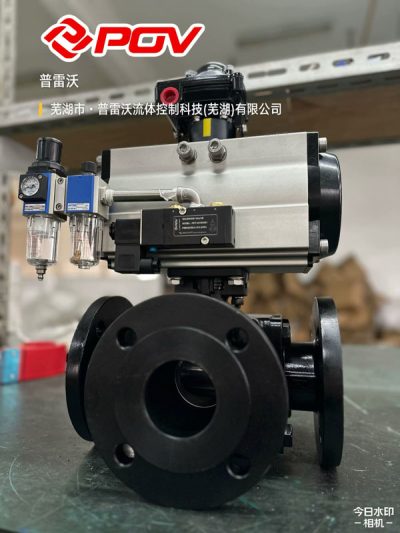

Ball valves are available in several types, each designed to meet specific operational requirements across industries. Manual ball valves are the most common, operated by a hand lever for simple on-off control and ideal for less complex systems. Electric ball valves, on the other hand, integrate with electric motors to automate fluid control, offering a seamless solution for applications requiring frequent operation or remote management. For advanced precision and efficiency, electric actuated ball valves combine a ball valve with an electric actuator, enabling accurate flow regulation and automation in high-pressure or high-temperature systems. This makes them an indispensable choice in industries like chemical processing, power generation, and water treatment, where system performance and reliability are critical. Each type of ball valve brings its own advantages, ensuring there is a solution suited to both standard and specialized fluid control tasks.

Introduce the concept of electric ball valve actuators and their role in automation.

Electric ball valve actuators are cutting-edge devices that combine functionality and automation to revolutionize fluid management systems. Installed atop a standard ball valve, these actuators use electric power to automate the opening and closing of the valve, ensuring precise and efficient control of fluid flow. This eliminates the need for manual intervention, making them especially valuable in modern automation systems. Electric ball valve actuators enhance operational accuracy, allowing the valve to respond instantly to control signals, which is critical in maintaining system efficiency and reliability. Industries such as manufacturing, water treatment, and energy benefit greatly from their integration, as these sectors require consistent performance in high-pressure, high-temperature, or corrosive environments. By streamlining processes and improving overall system responsiveness, electric ball valve actuators play a pivotal role in advancing automation and optimizing industrial operations.

Pre-Installation Preparation

Outline the necessary steps to evaluate system requirements before installation.

Evaluating system requirements before installing a ball valve is essential for ensuring efficiency and safety. Key steps include assessing the system’s operating pressure and temperature to determine material suitability, analyzing the fluid’s characteristics—such as its viscosity, corrosiveness, or particulate content—and confirming compatibility with electric actuators if automation is needed. Additionally, matching the valve size to the system’s flow rate is critical to avoid bottlenecks or performance issues. Proper evaluation of these factors guarantees reliable and optimized operation.

Mention the importance of certified components, emphasizing quality control and compliance with international standards.

Using certified components in industrial systems is essential for maintaining high standards of quality control, reliability, and safety. These components are rigorously tested to comply with international standards, ensuring they can withstand demanding operational conditions. Certified components not only enhance system performance but also reduce risks associated with failures, making them a critical choice for industries seeking to meet stringent regulatory requirements and deliver consistent, dependable results.

Stress safety precautions and preparation, such as shutting off the system and ensuring a clean work environment.

Prioritizing safety precautions and thorough preparation is essential before installing a ball valve. Key steps include shutting off the system and fully depressurizing the line to prevent accidental discharge. Ensuring a clean work environment minimizes contamination risks and allows for precise installation. These measures not only protect personnel and equipment but also ensure a smoother, more efficient installation process while maintaining the integrity of the system.

Subsections:

Tools and Equipment Checklist

Identify essential tools for manual and electric actuated ball valve installation.

A comprehensive tools and equipment checklist is vital for the successful installation of both manual and electric actuated ball valves. Essential tools include adjustable wrenches, pipe cutters, and thread sealant for securing connections, along with a torque wrench to ensure proper tightening. For electric actuated ball valves, additional tools like multimeters and other electrical testing equipment are necessary to verify actuator functionality and connections. Having the right tools on hand streamlines the installation process and ensures safe, reliable operation.

Special consideration for ball valve electric actuators.

Inspection of the Valve and Pipeline

Special considerations for ball valve electric actuators include conducting a thorough inspection of the valve and pipeline before installation. Checking for debris or blockages ensures unobstructed operation, while verifying the alignment between the pipeline, valve, and actuator prevents strain on components. Additionally, confirming compatibility between the actuator and valve specifications is critical to ensuring precise control and long-term reliability. Proper inspection of the valve and pipeline safeguards performance and minimizes the risk of operational issues.

Check for defects or debris in the valve and pipe connections.

Inspecting for defects or debris in the valve and pipe connections is a crucial step before installation. This process ensures proper sealing by identifying imperfections that could compromise the integrity of the connection. Removing debris prevents unwanted obstructions that may lead to leaks or inefficiencies during operation. Careful attention to this step safeguards the system’s reliability and minimizes the risk of future operational issues.

Confirm correct actuator alignment for automated systems like electric ball valve actuators.

Ensuring correct actuator alignment is critical for the optimal performance of automated systems, including electric ball valve actuators. Proper alignment minimizes mechanical strain on components, allowing for smoother, more precise operation. This attention to detail not only prevents unnecessary wear but also extends the system’s lifespan, ensuring sustained reliability and efficiency in demanding industrial environments.

Installation Process

A step-by-step guide to installing a ball valve, with clear headings and subpoints.

Subsections:

-

Manual Ball Valve Installation:

Positioning and orientation guidelines.

A step-by-step guide to installing a ball valve offers clarity and precision, starting with manual ball valve installation. Adhering to positioning and orientation guidelines is crucial to ensuring the valve is properly aligned with the pipeline. Correct alignment not only promotes efficient operation but also prevents potential leaks and mechanical issues. Following these guidelines guarantees a secure and reliable system configuration for long-term performance.

Securing the valve to the pipeline using the proper torque.

Securing the valve to the pipeline using the proper torque is essential for maintaining a leak-proof and durable connection. Utilizing a torque wrench ensures precision, preventing the risks associated with over-tightening, such as thread damage, or under-tightening, which can result in leaks. By adhering to the specified torque ratings, you promote the integrity and reliability of the valve installation, safeguarding the system’s performance over time.

Testing for leaks after installation.

Testing for leaks after installation is a vital step to ensure the integrity of the system and detect any issues early. This process confirms that the ball valve is securely connected and properly sealed, preventing potential damage from leaks or pressure loss. By thoroughly testing for leaks, you can guarantee the reliability of the installation and maintain the system’s operational efficiency over time.

Post-Installation Testing and Maintenance

Outline post-installation testing protocols to verify valve functionality.

Establishing clear post-installation testing protocols is essential to verify valve functionality and ensure robust system performance. These protocols involve steps such as operational checks, pressure testing, and flow assessments, all aimed at confirming the valve operates as intended under actual conditions. By identifying potential issues early, these measures not only enhance system safety but also prevent costly downtime, guaranteeing long-term reliability and efficiency.

Provide maintenance tips to enhance system reliability.

Implementing effective maintenance tips is crucial to enhance system reliability and prolong the lifespan of components. Regular inspections help detect signs of wear or damage early, while routine cleaning prevents buildup that could impede operation. Proper lubrication of moving parts minimizes friction and mechanical strain, ensuring seamless performance over time. Prioritizing these maintenance practices safeguards system efficiency and reduces the likelihood of unexpected failures.

Common Installation Mistakes to Avoid

Understanding common installation mistakes to avoid is key to ensuring the optimal performance of a ball valve. Errors such as improper alignment can lead to operational inefficiencies and potential mechanical damage, while over-tightening can compromise the valve’s structural integrity, increasing the likelihood of leaks. Additionally, neglecting to test for leaks after installation may result in undetected issues that could escalate over time. By recognizing and avoiding these pitfalls, you can maintain a reliable, well-functioning system and minimize the risk of costly repairs.

Benefits of Proper Installation

The benefits of proper installation of a ball valve are substantial, directly contributing to the efficiency and reliability of the entire system. Ensuring correct alignment and secure connections minimizes the risk of leaks, preserving operational performance. Additionally, a properly installed ball valve experiences less stress and wear, extending its lifespan and reducing the need for frequent maintenance or replacements. These advantages underscore how meticulous installation practices safeguard both the durability of the valve and the effectiveness of the system it supports.

Expert Recommendations

Adhering to expert recommendations is essential for the proper installation and maintenance of ball valves, ensuring optimal performance and system reliability. Professionals emphasize the importance of strictly following manufacturer guidelines to achieve accurate alignment and secure connections. Using high-quality materials further enhances durability, while conducting regular inspections helps identify potential issues before they escalate. By implementing these best practices, you can maximize the efficiency and lifespan of ball valves, minimizing downtime and costly repairs.

FAQS

What are the key steps to properly install a ball valve?

To install a ball valve correctly, start by ensuring the pipeline is free of debris. Align the valve with the piping, adhering to the direction of flow marked on the valve. Secure all connections using the appropriate tools and check that all fittings are tight, avoiding over-tightening. Finally, test the system for leaks by slowly pressurizing it and monitoring the valve’s performance.

Why is it important to follow manufacturer guidelines during installation?

Manufacturer guidelines include specific instructions tailored to the design and materials of the ball valve. Adhering to these guidelines ensures proper alignment, compatibility with the application, and optimal valve performance. Neglecting these recommendations may lead to operational inefficiencies, leaks, or even premature failure.

Are any special tools required for installing electric ball valves?

Yes, installing electric ball valves may require additional tools, such as torque wrenches for precise tightening and screwdrivers for securing the actuator. You may also need a multimeter to verify electrical connections. Always refer to the manufacturer’s specifications to use the correct tools.

How can you prevent leaks during ball valve installation?

To prevent leaks, ensure all components are clean and free from damage. Use appropriate sealing materials, like thread seal tape or pipe dope, on threaded connections. Tighten fittings securely and evenly, avoiding excessive force that might damage the valve or threads.

What should you consider when installing an electric actuated ball valve?

When installing an electric actuated ball valve, ensure proper alignment between the valve and the actuator. Verify that the actuator’s voltage matches the system’s requirements. Secure all electrical connections according to the manufacturer’s wiring diagram, and test the actuator to confirm it operates smoothly before putting the system into full operation.

Conclusion

Proper installation of a ball valve is a critical step in ensuring the long-term performance, safety, and reliability of your system. From aligning components accurately to testing for potential leaks, every stage demands precision and strict adherence to manufacturer guidelines. These practices are even more crucial when working with advanced systems that include an electric ball valve actuator. Ensuring the correct setup for electric ball valves is essential to prevent operational inefficiencies and enhance automation capabilities. Similarly, the installation of electric actuated ball valves requires attention to detail, as improper connections or misalignments can compromise not only the functionality of the valve but also the entire system it supports. By following best practices and prioritizing quality at every step, you can optimize system performance, reduce downtime, and maximize the lifespan of your equipment.