Controlling ball valves effectively is essential for precise flow management in various industries. This article explores the functionality and applications of advanced solutions like electric actuated ball valves and electronic ball valves. It highlights how electric actuation transforms traditional control methods, with components like the ball valve actuator electric delivering unparalleled reliability and efficiency. Key features, such as programmable functionality and adaptability to extreme conditions, make these systems indispensable. The 3 way electric ball valve is a standout for complex applications, enabling seamless flow diversion or mixing. With insights on choosing the right electrically actuated ball valve and a glimpse into future trends, this article provides a comprehensive guide to optimizing industrial operations with modern ball valve technology.

Introduction

Ball valves are a cornerstone of flow control across countless industrial applications, known for their durability, precision, and versatility. From managing the flow of liquids in chemical processing plants to regulating gases in manufacturing systems, their role is indispensable. However, as industries demand greater efficiency and reliability, methods for controlling ball valves have evolved dramatically. Traditional manual operations have given way to advanced solutions like electric actuated ball valves, which offer unparalleled precision and automation. Technologies such as the 3 way electric ball valve and electronic ball valves further expand functionality, enabling complex operations like flow diversion and mixing with ease. This article explores how these modern control systems are transforming industrial performance, helping businesses optimize operations and stay ahead in an increasingly competitive landscape.

Overview of Ball Valves

Explanation of ball valves’ basic mechanism and design.

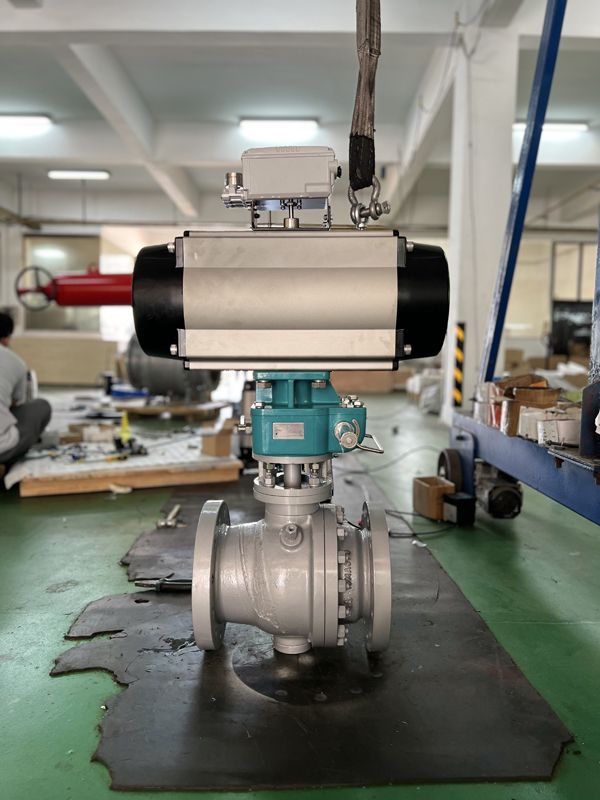

Ball valves are engineered for precise and reliable flow control, making them an integral part of many industrial systems. Their basic mechanism revolves around a spherical disc, commonly referred to as a “ball,” which features a hole or port through its center. When the ball is rotated by 90 degrees, the hole aligns with the flow path, enabling fluid or gas to pass through. Rotating the ball back closes the valve, effectively stopping the flow. This straightforward design ensures quick and efficient operation, offering an on/off control function. Ball valves are built with a compact structure, featuring minimal moving parts, which enhances their durability and reduces maintenance requirements. Their versatility makes them suitable for a wide range of applications, from high-pressure systems in petrochemical plants to water flow management in treatment plants.

Highlight the versatility of ball valves across industries such as chemical processing and water treatment.

Ball valves are renowned for their adaptability, serving critical functions across a range of industries, from chemical processing to water treatment. Their robust design and simple mechanism make them ideal for managing high-pressure systems, regulating the flow of corrosive substances, and ensuring precise flow control. In chemical processing plants, ball valves handle aggressive chemicals with ease, thanks to materials like stainless steel or specialized coatings that enhance corrosion resistance. Meanwhile, in water treatment facilities, their ability to provide seamless on/off control simplifies system operations, ensuring efficiency and reliability in processes like filtration and distribution. Whether used for mixing, diverting flow, or controlling extreme conditions, ball valves offer unmatched versatility, making them indispensable in environments demanding high performance and durability.

Touch on different types, including the 3 way electric ball valve and their applications.

Ball valves are available in a variety of designs to meet the specific demands of industrial applications, with the 3 way electric ball valve being a prime example of innovation and adaptability. Unlike traditional two-way ball valves that control flow in a single direction, 3 way electric ball valves are designed to manage complex flow patterns, such as diversion, mixing, or distributing fluids across multiple lines. These valves are invaluable in industries like manufacturing, where complex systems require precise fluid routing, and in water treatment plants, where they efficiently manage flow between filtration and distribution units.

Additionally, electric actuation automates valve operation, offering benefits like remote control, faster response times, and reduced operational effort. Other types, such as high-pressure and corrosion-resistant ball valves, cater to the rigorous demands of oil and gas operations, handling volatile chemicals and extreme conditions with reliability. Such diversity in design and function underscores the versatility of ball valves in achieving efficient flow control across industries.

Section 2: Role of Electric Actuation in Ball Valve Control

Introduction to electric actuators as a pivotal component in modern ball valve systems.

Electric actuators are integral to modern ball valve systems, providing automation that enhances precision and efficiency. These devices eliminate manual adjustments by enabling remote control, making operations safer and more streamlined, especially in challenging environments. Suited for demanding industrial applications like chemical processing and oil and gas, electric actuators deliver consistent, energy-efficient performance, ensuring optimal flow control in complex systems.

Discuss the functionality of a ball valve actuator electric, converting electrical signals into precise mechanical actions.

Electric ball valve actuators play a pivotal role in automating flow control by seamlessly converting electrical signals into precise mechanical actions. When a signal is received from a control system, the actuator’s motor activates to rotate or position the valve, effectively opening, closing, or modulating its flow. This mechanism ensures exact control over fluid or gas movement while minimizing manual intervention. The precision and speed offered by these actuators are critical in industries such as manufacturing, water treatment, and oil and gas, where accurate flow regulation and system responsiveness are essential. By integrating automation with robust design, electric ball valve actuators enhance operational efficiency, reduce downtimes, and enable complex system management with minimal effort.

Benefits of electric actuation, including enhanced reliability, reduced maintenance, and energy efficiency.

Electric actuation in ball valve systems offers significant benefits that elevate operational efficiency and reliability across industrial applications. Its enhanced reliability stems from a robust design that ensures consistent performance, even under demanding conditions, reducing system downtime and increasing overall productivity. With fewer moving parts compared to traditional actuation methods, electric actuators require less maintenance, translating into lower upkeep costs and minimized disruption to operations. Additionally, they provide impressive energy efficiency by utilizing power only during actuation, which helps reduce energy consumption and operational expenses over time. Together, these advantages make electric actuation a cost-effective, long-lasting solution, ideal for industries prioritizing precision, sustainability, and performance in their flow control systems.

Section 3: Key Features of Electrically Actuated Ball Valves

Advanced control mechanisms for precise opening, closing, and flow modulation.

Advanced control mechanisms in ball valve systems provide precise opening, closing, and flow modulation, ensuring accuracy and efficiency in industrial processes. By integrating features like position feedback sensors and programmable controls, these systems offer real-time responsiveness and optimized flow management. Valuable in industries such as oil and gas, water treatment, and manufacturing, they enhance performance while reducing energy use, waste, and operational downtime.

Programmable functionality for custom operations based on specific industrial needs.

Programmable functionality in ball valve systems allows for tailored operations that meet the unique demands of various industrial applications. By integrating customizable control software, these systems can execute complex sequences, adjust flow rates dynamically, or respond to varying process conditions with precision. This adaptability empowers industries such as manufacturing, water treatment, and oil and gas to optimize performance, streamline workflows, and reduce operational inefficiencies. The ability to program specific parameters enhances process accuracy and consistency, ensuring that systems operate seamlessly under both routine and challenging conditions. By combining flexibility with advanced automation, programmable ball valve systems significantly elevate efficiency and support innovation across critical sectors.

Performance under extreme conditions, such as high pressures or corrosive environments.

Ball valve systems excel under extreme conditions like high pressures or corrosive environments, thanks to their use of durable materials such as stainless steel and Hastelloy. Advanced sealing technologies ensure leak-proof performance, while rugged components withstand wear and abrasion. These features make them reliable choices for demanding industries, ensuring consistent operation and long-lasting performance in the harshest settings.

Section 4: Applications of Electrically Actuated and Electronic Ball Valves

Examples of usage in varied sectors like manufacturing, oil and gas, and wastewater management.

Ball valve systems are integral to a wide range of industries due to their precision, durability, and adaptability. In manufacturing, they regulate fluid control in processes like chemical mixing, cooling systems, and pneumatic operations, ensuring efficient and uninterrupted workflows. Within the oil and gas sector, these valves are used in high-pressure pipelines, refinery applications, and offshore drilling platforms to manage flow and maintain safety under rigorous conditions. Meanwhile, in wastewater management, ball valves play a critical role in controlling the flow of treated and untreated water, preventing contamination, and ensuring compliance with environmental standards. By offering reliable performance across diverse applications, ball valve systems contribute to optimized operations, enhanced safety, and reduced downtime across these essential sectors.

Address the specific function of a 3 way electric ball valve for diverting or mixing flow in complex systems.

A 3-way electric ball valve is a versatile solution engineered to divert or mix flows within complex systems, offering precise control and adaptability. Its T-port or L-port configurations facilitate seamless redirection or combination of fluids, making it ideal for processes requiring efficient flow management. Operated through an electric actuator, this valve ensures smooth, automated transitions between circuits, reducing the need for manual intervention. Applications include HVAC systems, where it regulates temperature control by channeling chilled or heated water, as well as chemical processing, where it handles multiple fluid streams with precision. Similarly, in water treatment plants, it aids in mixing or separating treatment chemicals, ensuring process consistency. This functionality enhances efficiency, minimizes system downtime, and supports high-performance operations across demanding industrial environments.

Integration with automated systems for real-time control and monitoring.

The integration of ball valve systems with automated systems brings real-time control and monitoring, improving efficiency, precision, and safety. With advanced sensors and IoT connectivity, these valves deliver continuous feedback on flow, pressure, and temperature, enabling swift adjustments and anomaly detection. This automation reduces downtime, minimizes human error, and optimizes performance, making it indispensable for industries like manufacturing, oil and gas, and water treatment.

Section 5: Factors to Consider When Choosing an Electrically Actuated Ball Valve

Importance of torque requirements, material compatibility, and actuator type in decision-making.

Selecting the right ball valve system requires careful consideration of torque requirements, material compatibility, and actuator type to ensure optimal performance and durability. Proper torque ensures smooth operation under varying pressures, while selecting compatible materials prevents corrosion or chemical reactions, especially in demanding environments like chemical processing. The actuator type, whether pneumatic, electric, or hydraulic, must match the system’s demands to guarantee precision and efficiency. These factors collectively determine the valve’s reliability and suitability for specific applications, minimizing risks and maximizing operational success.

Cost-efficiency analysis, factoring in both initial investment and long-term operational savings.

A cost-efficiency analysis is vital when selecting ball valve systems to balance initial investment with long-term operational savings. Energy-efficient designs and durable materials reduce ongoing costs by minimizing maintenance and improving reliability. For example, corrosion-resistant valves require less frequent replacement, while precision-driven actuators lower energy consumption in systems like HVAC or water treatment. Factoring in upkeep, lifespan, and efficiency ensures a solution that optimizes performance and maximizes total value over time.

Compliance with industry standards and certifications as a marker of quality.

Adhering to industry standards and certifications, such as ISO 9001 for quality management or API 6D for pipeline valves, is essential to ensuring the quality, safety, and reliability of ball valve systems. These certifications demonstrate compliance with strict design and performance benchmarks, reducing risks and boosting confidence in their operational integrity. By selecting certified systems, industries can meet regulatory demands and safeguard efficient, long-lasting performance in critical applications.

Section 6: Future Trends in Ball Valve Actuation

The future of ball valve actuation lies in the integration of advanced automation, smart technologies, and sustainable practices, revolutionizing how industries manage fluid control. IoT-enabled actuators are at the forefront, allowing real-time monitoring and remote operation to enhance precision and efficiency. These systems facilitate predictive maintenance by analyzing performance data and preempting potential failures, reducing downtime and maintenance costs. Energy-efficient designs, such as low-power actuators, are also gaining traction, aligning with global sustainability goals by minimizing energy consumption. Furthermore, as industries prioritize eco-friendly operations, the demand for solutions with reduced environmental impact continues to rise. These innovations are setting new benchmarks for performance, reliability, and environmental stewardship in the valve actuation landscape.

FAQs

Q1. What is the basic mechanism behind a ball valve?

A ball valve operates using a spherical disc with a hollow center, known as the “ball.” When the ball is rotated so that the hollow passage aligns with the pipeline, flow is allowed through. Rotating it 90 degrees blocks the flow. This simple mechanism provides reliable on/off control and is highly efficient for managing fluid or gas flow.

Q2. What are the different ways to control a ball valve?

Ball valves can be operated manually, using levers or handles, or through automated methods like electric, pneumatic, or hydraulic actuators. Electric actuators are increasingly popular due to their precision, programmability, and ability to integrate into modern automated systems.

Q3. How does an electric actuator control a ball valve?

Electric actuators convert electrical signals into mechanical motion to open, close, or modulate the valve. This process eliminates the need for manual adjustments, allowing for remote operation and real-time flow control. Features like feedback sensors and programmable settings enhance accuracy and performance.

Q4. What is a 3-way electric ball valve, and when is it used?

A 3-way electric ball valve features three ports, allowing it to handle flow diversion, mixing, or distribution between different lines. It is often used in applications like water treatment, chemical processing, and manufacturing, where complex flow routing is required.

Q5. What are the benefits of using electric actuation over manual control?

Electric actuation offers numerous advantages, including precise flow control, programmability, reduced manual intervention, and increased operational efficiency. It also supports remote management, energy-saving designs, and enhanced reliability in demanding industrial environments.

Conclusion

Controlling a ball valve has evolved significantly, transitioning from manual methods to sophisticated electric actuation, which offers unmatched precision, automation, and efficiency. Advanced systems like 3-way electric ball valves have expanded functionality, enabling seamless flow modulation, diversion, and mixing for complex industrial applications. The integration of features such as programmable controls, energy efficiency, and performance under extreme conditions has made electrically actuated valves indispensable across industries like manufacturing, water treatment, and oil and gas. Selecting the right technology to match specific operational requirements ensures optimal performance, long-term reliability, and cost-effective flow management, solidifying the ball valve’s role as a critical component in modern industrial systems.