Ball valves can indeed be automated, offering significant advantages for industrial systems. Automation, through solutions like a ball valve with electric actuator or an automatic ball valve, ensures greater precision, efficiency, and control. By utilizing automated ball valve systems, industries can minimize manual intervention, reducing errors and increasing operational reliability. Configurations such as ball valve with actuator and ball valve actuators are especially valuable in applications requiring consistency and adaptability. These technologies are widely used across sectors, improving performance while meeting the demands of complex operations. Automation makes ball valves a robust and future-focused choice for modern industrial needs.

Introduction

Automation has transformed the landscape of industrial operations, pushing the boundaries of efficiency, precision, and control. Among the many critical components in these systems, ball valves play a key role in regulating the flow of liquids and gases. But can these essential tools be automated? The answer is a resounding yes. Automatic ball valves opens up a world of possibilities, enabling seamless system management, reducing manual intervention, and improving overall performance. This blog explores the technologies and configurations, from ball valve with electric actuator setups to advanced ball valve actuators, that make automation not only possible but highly effective. Discover how automated ball valves are reshaping industries and driving operations toward a smarter, more adaptable future.

What Does Automation Mean for Ball Valves?

Explanation of automation and how it applies to ball valves.

Automation elevates the operation of ball valves by transforming them into highly efficient and responsive components within industrial systems. By incorporating technologies like electric and pneumatic actuators, as well as advanced control systems, automation enables ball valves to deliver precise and consistent control over fluid and gas flow. The integration of these technologies eliminates the need for frequent manual adjustments, reducing labor requirements and minimizing human error. Automated ball valves not only boost operational efficiency but also enhance reliability, especially in complex, high-demand industrial environments. They allow for remote monitoring and real-time adjustments, ensuring that operations remain streamlined and adaptable. This evolution in valve functionality underscores the importance of automation in achieving superior control and optimized performance in modern industrial processes.

Benefits of automated ball valves in complex industrial processes.

Automated ball valves offer significant benefits in managing complex industrial processes where precision, efficiency, and reliability are essential. By incorporating advanced actuation technologies such as electric or pneumatic systems, these valves enable highly accurate flow control, even under stringent operating conditions. This automation minimizes the need for manual intervention, reducing the risk of human error and associated downtime. Additionally, automated ball valves streamline operations by allowing real-time monitoring and remote adjustments, ensuring processes remain adaptable and uninterrupted. Their ability to maintain consistent performance under demanding conditions optimizes operational efficiency, enhances system reliability, and contributes to cost savings, making them an indispensable asset in modern industrial environments.

How Ball Valves Are Automated

Overview of the components necessary for automation, including actuators.

Automating ball valves requires the integration of several critical components, each playing a vital role in enhancing functionality and efficiency. At the core are actuators, which provide the mechanical force needed to open, close, or modulate the valve. These actuators, which can be electric, pneumatic, or hydraulic, translate control signals into precise motion. Control systems are equally essential, functioning as the brains of the operation by sending commands to the actuators and ensuring the desired valve position at any given time. Sensors further complement this setup, continuously monitoring variables like pressure, temperature, and flow rate to supply real-time data. Together, these components form a cohesive system that allows for precise, automated management of fluid and gas flow. Through seamless communication and coordinated actions, they not only reduce manual intervention but also enhance accuracy, reliability, and adaptability in industrial applications.

Types of actuators used in ball valves

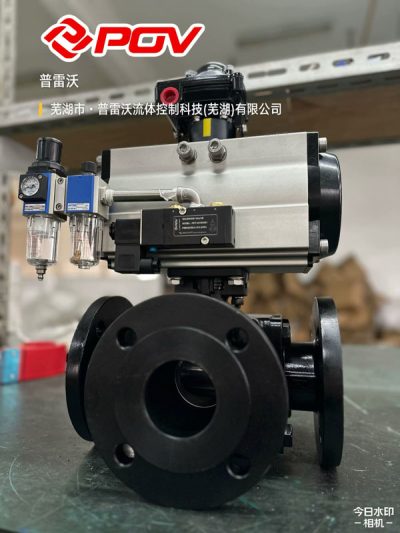

Ball valves are paired with different types of actuators depending on the specific requirements of industrial processes, each offering distinct advantages and operational characteristics. Electric actuators utilize an electric motor to operate the valve, providing precise control and suitability for applications requiring high levels of accuracy and slower operation, such as in chemical processing or water treatment facilities. Pneumatic actuators, powered by compressed air, are valued for their rapid operation and reliability in extreme environments, making them ideal for high-speed applications in industries like oil and gas.

Hydraulic actuators, on the other hand, use pressurized fluid to create mechanical force, offering the highest torque output and endurance for heavy-duty operations, such as in mining or power plants. Each type of actuator is engineered to align with specific environmental demands, ensuring that ball valves perform efficiently and reliably within their intended applications.

Steps involved in automating a standard ball valve.

Automating a standard ball valve involves a series of well-defined steps to ensure optimal performance, precision, and reliability. The process begins with selecting the appropriate actuator, considering factors such as the valve’s size, operating environment, and required torque. This choice is critical, as the actuator ensures the valve’s movement and functionality in automation. Next, control systems are integrated to manage the actuator’s operations and provide real-time control over the valve’s positioning.

The installation of sensors follows, a crucial step to monitor operational parameters like pressure, flow rate, and temperature, feeding vital data back to the control system for adjustments where needed. Finally, comprehensive testing of the automated system ensures all components work cohesively, identifying and resolving any issues prior to deployment. Each step is meticulously executed to create a seamless, efficient, and reliable automated ball valve solution tailored to the demands of industrial applications.

Advantages of Using Automated Ball Valves

Enhanced precision and efficiency.

Automation significantly enhances the precision and efficiency of ball valves by leveraging advanced control systems and real-time data monitoring. Automated systems provide accurate control over flow rates, adjusting valve positions with unmatched accuracy to meet the specific requirements of industrial processes. This level of precision minimizes fluctuations, ensures consistent operation, and eliminates the variability introduced by manual adjustments. Additionally, automation reduces the risk of human error, optimizing resource usage by preventing overflows, leaks, or inefficient energy consumption. These improvements not only streamline processes but also lead to measurable cost savings by extending equipment lifespan and lowering operational expenses. By enabling seamless integration and consistent performance, automation drives productivity and creates a more reliable and efficient industrial environment.

Reduction in manual errors and labor costs.

Automation in ball valves effectively reduces manual errors and labor costs through advanced control systems that minimize the need for human intervention. By automating the operation of valves, the reliance on manual adjustments, which often carry risks of inconsistency or error, is significantly diminished. Automated systems ensure consistent performance, improving accuracy in managing flow rates, pressure, and other critical parameters.

This reliability not only optimizes operations but also reduces the frequency of corrective actions caused by human mistakes. Furthermore, by streamlining processes and reducing dependency on manual labor, automation lowers operational expenses such as wages and overtime, while enabling staff to focus on higher-value tasks. These financial and operational advantages make automation an essential investment for industries aiming to enhance productivity and maintain competitiveness in demanding environments.

Improved reliability and consistency in demanding applications

Automation enhances the reliability and consistency of ball valves in demanding applications by ensuring uniform performance under rigorous conditions. Automated systems eliminate the variability common with manual operations, maintaining precise control over flow rates, pressure, and temperature even in challenging environments, such as high-pressure pipelines or corrosive media.

This consistency reduces unplanned downtime by enabling predictive maintenance and swift responses to potential issues via real-time monitoring and diagnostics. Furthermore, automation allows ball valves to seamlessly adapt to fluctuating industrial demands without compromising performance, which is critical for industries like oil and gas, chemical processing, and energy production. These improvements not only safeguard operational integrity but also provide industries with the confidence needed to meet stringent safety standards and maintain uninterrupted workflows in mission-critical applications.

Applications of Actuated Ball Valves

Key industries that benefit from automated solutions (oil and gas, water management, etc.).

Automated ball valve solutions deliver substantial benefits across various key industries by addressing their unique challenges and operational demands. In the oil and gas sector, automation ensures precise control of high-pressure systems and hazardous fluids, enhancing safety and reducing the risk of costly leaks. Water management facilities depend on automated systems to optimize flow regulation and resource allocation, ensuring efficient operation while conserving water supplies.

For chemical processing, automation mitigates risks associated with handling corrosive or volatile substances by providing consistent and accurate control, while ensuring compliance with stringent industry regulations. Meanwhile, manufacturing processes benefit from seamless integration with automated valves to improve production efficiency, minimize downtime, and enhance quality control. Across these industries, automation not only streamlines operations but also drives safety, reliability, and long-term cost savings, cementing its role as an indispensable solution for modern industrial environments.

Practical examples of actuated ball valves in operation.

Actuated ball valves find extensive practical applications across diverse industries, showcasing their versatility and efficiency in real-world operations. In the oil and gas sector, these valves are integral to pipeline flow control, allowing for precise regulation of high-pressure liquids and gases, ensuring operational safety, and reducing energy losses.

Water treatment facilities utilize actuated ball valves in automated irrigation systems to manage water distribution with remarkable accuracy, optimizing resource usage while meeting sustainability goals. Similarly, in manufacturing, these valves excel in precision fluid handling on production lines, where they control the flow of chemicals and raw materials with unmatched consistency, directly improving product quality and reducing waste. By integrating automation, these applications benefit from enhanced responsiveness, minimal downtime, and improved operational scalability, catering to the rigorous demands of modern industrial processes.

Importance of selecting the right automated solution based on system requirements.

Selecting the right automated ball valve solution is crucial for ensuring optimal performance, cost-efficiency, and reliability in industrial applications. Compatibility with operational requirements, such as flow capacity, pressure levels, and media type, must be carefully evaluated. This prevents inefficiencies or malfunctions. Environmental conditions, including temperature extremes, corrosive media, or hazardous locations, must also be considered.

This ensures the valve material and design can withstand these challenges. Long-term operational goals are equally important, like integrating predictive maintenance features or advanced diagnostics to reduce downtime. These features also support scalability as system demands grow. Tailoring the automated solution to precise system requirements enhances productivity and lowers lifecycle costs. It ensures reliability critical for uninterrupted and safe operations in high-stakes environments.

Choosing the Right Automation for Your Ball Valve

Considerations for selecting the appropriate ball valve with actuator.

Selecting the right ball valve with an actuator involves key factors like valve size, material compatibility, actuator type, and the operational environment. Proper valve sizing ensures efficient flow and prevents pressure issues, while material compatibility extends durability, particularly in corrosive or high-temperature applications. Choosing between electric and pneumatic actuators depends on power availability, speed, and precision requirements. Additionally, the operational environment, including temperature and exposure to harsh conditions, must align with the system’s demands to optimize performance and minimize maintenance. These considerations collectively enhance efficiency and reliability in industrial operations.

Comparison of manual and automated systems for decision making.

Manual decision-making systems rely heavily on human input, making them prone to delays, errors, and inconsistencies. This is especially true when processing large data sets or adapting to complex scenarios. Automated systems leverage advanced algorithms and real-time data analysis. They ensure faster, more accurate decisions with minimal human intervention. Automation offers superior scalability, enabling operations to expand without increasing resource strain, while also enhancing consistency and reliability. These advantages make automated systems indispensable in industrial environments where precision, efficiency, and adaptability are critical.

Highlight on customization options for specific industrial needs.

Customization options for ball valves and actuators allow industries to tailor solutions to their specific needs. This ensures optimal performance and adaptability. Customized valve sizes and material choices handle unique media and environmental conditions. Specialized actuator configurations include torque settings and power preferences to meet precise operational demands. Furthermore, seamless integration with control systems enables enhanced automation and precision. These flexible options empower industries to improve efficiency, durability, and long-term reliability in complex applications.

Future Trends in Ball Valve Automation

Emerging technologies in ball valve automation.

Emerging technologies in ball valve automation are transforming industrial operations with innovations like smart actuators, IoT connectivity, and predictive maintenance systems. Smart actuators enable precise control and real-time monitoring, while IoT integration allows seamless communication between devices, enhancing operational efficiency. Predictive maintenance capabilities minimize downtime by identifying potential failures before they occur. Energy-efficient designs reduce power consumption without compromising performance. These advancements play a critical role in improving the reliability, sustainability, and productivity of modern industrial systems.

Potential for further integration with smart systems and IoT.

The integration of ball valve automation with smart systems and IoT holds immense potential for industrial applications. This synergy enables advanced real-time monitoring, providing precise insights into system performance and operational conditions. Remote control capabilities offer greater flexibility, allowing adjustments from virtually anywhere, while data-driven decision-making ensures improved efficiency and predictive accuracy. By leveraging these interconnected technologies, industries can achieve heightened operational reliability, streamlined processes, and reduced downtime, paving the way for smarter, more adaptive automation systems.

FAQs

What payment terms are available for purchasing automated ball valves?

Payment terms typically depend on the supplier and purchase agreement. Standard options include net 30, partial advance payment, and payment upon delivery. Custom terms can often be arranged based on order volume and partnership.

How long is the delivery time for automated ball valves?

Delivery time varies based on factors such as order complexity, customization requirements, and inventory availability. Standard valves with actuators may ship within 2-4 weeks, while customized orders could take longer. Expedite options may be available for urgent needs.

What price terms are offered for automated ball valve?

Price terms, such as FOB (Free on Board), CIF (Cost, Insurance, and Freight), or EXW (Ex Works), depend on the supplier and the agreed arrangement. These terms define cost responsibility during shipping and should be clarified during the purchase process.

Is transportation included in the automated ball valve price?

Transportation costs depend on the price terms agreed upon with the supplier. For example, under CIF terms, the cost includes shipping to the destination port. Under FOB or EXW, transportation costs are typically borne by the buyer.

Can ball valves with electric actuators be custom-ordered for specific needs?

Yes, automated ball valves, including those with electric actuators, can be customized for specific industrial applications. Options include specialized sizes, materials, and control system compatibility.

Conclusion

Automating ball valves proves to be a game-changer for industries seeking precision, efficiency, and enhanced system control. Through technologies such as a ball valve with electric actuator or other actuated ball valve solutions, businesses can integrate advanced functionality that minimizes manual oversight and reduces operational errors. Automated ball valve systems, with their seamless operation, are particularly suited for complex installations requiring adaptability and reliability. Components like ball valve actuators and ball valve with actuator configurations ensure optimal performance across various applications, including oil and gas, water management, and manufacturing. Investing in automation not only improves system operations but also positions industries for long-term success in an era of increasing technological integration.