Valve suppliers sell many kinds of valves for different jobs. Some common types are ball valve, gate, globe, butterfly valve, check, plug, diaphragm valve, pressure reducing, pressure relief, needle, slam-shut, and fire protection valves. Big companies like Emerson, Flowserve, and KSB Group offer these valves for many uses. Each type does a special job, like stopping or controlling flow. Knowing about the types and uses of valves helps people keep things safe, reliable, and follow the rules.

Types of Valves from Leading Valve Suppliers

Ball Valves

Ball valves are easy to use and seal well. They have a ball with a hole in the middle. The ball turns to start or stop flow. Main parts are the ball, shaft, seats, bonnet, and housing. The housing can be one, two, or three pieces. It is made from metal or strong plastic. The ball lines up with the flow to let fluid pass. It turns sideways to block the flow. There are full port and reduced port choices for different jobs.

- Ball valves give:

- Fast shut-off with a quick turn.

- Tight seals using soft seats like PTFE or rubber.

- Manual, electric, or air-powered control.

- Safety features like strong stems and pressure relief bonnets.

Ball valves are best for stopping and starting flow. They should not be used for throttling. Throttling can hurt the seats. Cleaning and care keep ball valves working well.

Ball valves are used in many places. Oil and gas, chemical plants, water treatment, heating and cooling, and factories use them. They are chosen for being reliable and easy to use. Their strong seal stops leaks. This makes them great for shut-off jobs. Food, paper, textiles, medicine, ships, and water plants also use ball valves. They work fast and keep things safe.

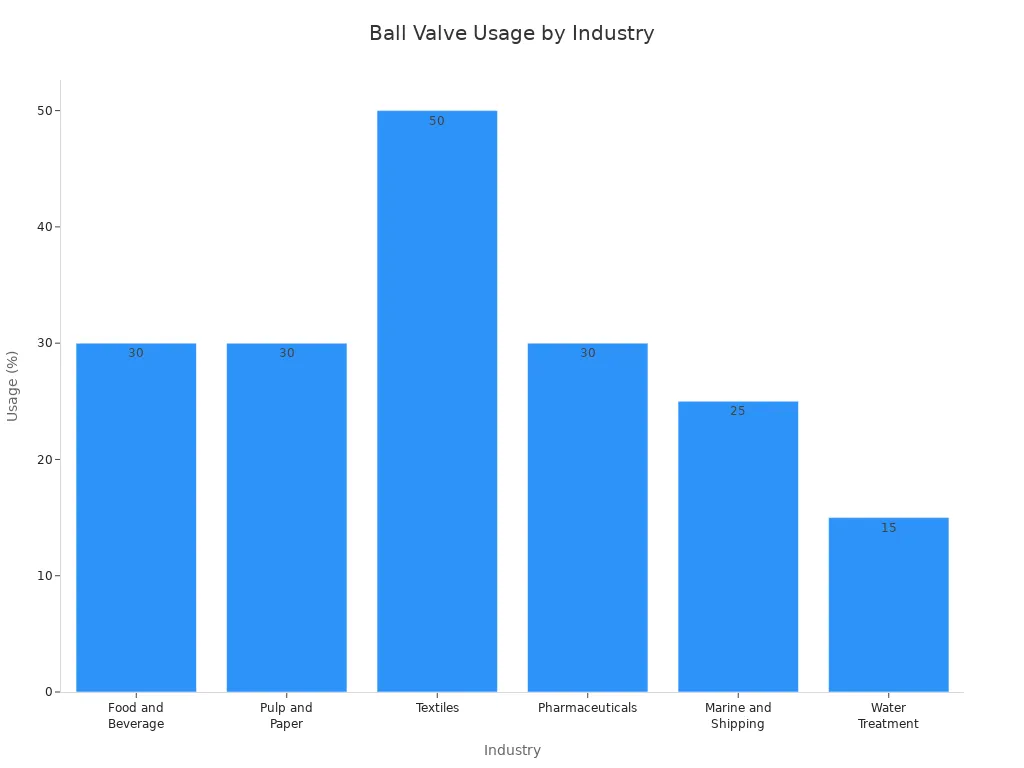

| Industry | Ball Valve Usage % | Key Reasons for Popularity |

|---|---|---|

| Food and Beverage | 30% | Strong seal, quick operation, suitable materials |

| Pulp and Paper | 30% | Secure sealing for chemical handling |

| Textiles | 50% | Leading use for dyeing and finishing processes |

| Pharmaceuticals | 30% | Secure shut-off, easy cleaning, steady flow control |

| Marine and Shipping | 25% | Strength, leak-proof nature for fluid handling |

| Water Treatment | 15% | Precise control under high pressure |

| Oil and Gas | Significant | Accurate flow control, pressure loss reduction, safety and cost benefits |

Ball valves are very common. They last a long time and have a simple design. They can handle high pressure and heat. Ball valves help stop contamination and keep working well for many uses.

Gate Valves

Gate valves are made for turning flow on or off. They use a flat or wedge-shaped gate. The gate moves up or down to open or close. When open, the gate is out of the way. This lets fluid move easily. Gate valves allow flow in both directions. They shut off well, even with high pressure.

- Gate valves are used in:

- Water systems for homes and buildings.

- Gas pipes for safe delivery.

- Power plants for steam and water.

- Farms for watering crops.

- Oil and gas for safe fluid movement.

- Chemical plants for careful flow.

- Water and sewage plants for clean water and waste.

Gate valves come in different types. Some have rising stems, some do not. There are wedge and knife types too. Each type fits different spaces, pressures, and temperatures. Manual gate valves are easy and cheap. Electric, air, and hydraulic types work fast and move big gates.

Gate valves have low flow resistance, work both ways, shut off well, and are cheap for big sizes. They are not good for controlling flow or for clean uses. They are best for blocking pipes and moving thick liquids.

Gate valves are important in oil and gas, water plants, chemical plants, power stations, ships, and factories. They lower pressure drop and let fluid move freely. This makes them a trusted choice for many jobs.

Globe Valves

Globe valves control flow very well. They are different from other valves. They use a disk that moves close to or away from a seat. The seat is inside a round body. This lets users make small changes to flow and pressure. Globe valves are great for controlling and managing pressure.

Globe valves are made from strong metals. These include carbon steel, stainless steel, and forged steel. Special trims help lower noise and shaking. This makes them safer and better.

Globe valves give:

- Careful flow control by moving the disc a little at a time.

- Good sealing by pressing the disc tight.

- Steady flow even when things change fast.

- Smart sensors for leak checks and automation.

Globe valves cause more pressure drop than gate valves. This is because of their inside shape. But they keep flow steady for liquids, gases, and steam. They meet tough rules for stopping leaks and lasting a long time.

Globe valves are used in oil and gas, water plants, and heating and cooling systems. They are picked when control and safety matter most.

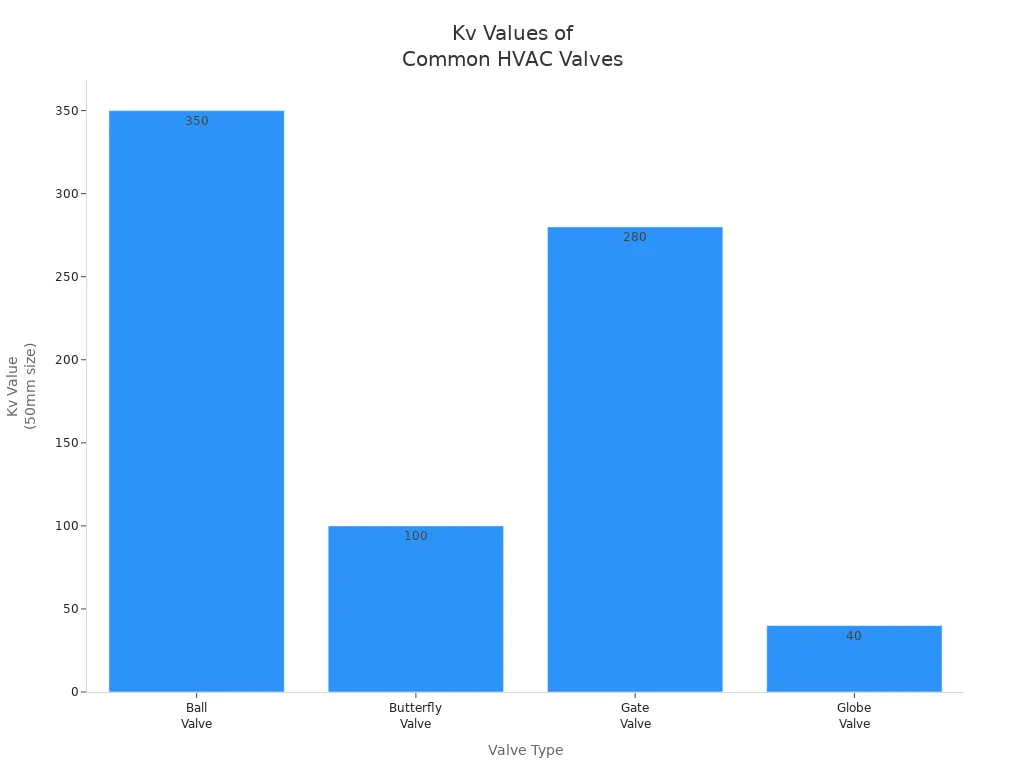

Butterfly Valves

Butterfly valves are used in many industries. They have a disc that turns to open or close flow. The disc sits in the middle of the pipe. You turn the handle or actuator a quarter turn. This opens or closes the valve. Butterfly valves are small and easy to put in tight places.

Butterfly valves can start or stop flow. They also help control flow a little. They are lighter than ball or gate valves. They take up less space too. Many companies pick butterfly valves because they cost less. They do not need much care. The disc makes a small pressure drop. It does not block flow much.

Butterfly valves have different types. Some are high-performance and some are triple offset. These types work with higher pressure. They seal better too. The body, seat, and disc can be made from different materials. The material depends on the fluid and temperature. Common materials are carbon steel, stainless steel, cast iron, and special alloys. Seats can be PTFE or metal.

Butterfly valves use different actuators:

- Manual actuators are used in small water plants. People turn them by hand.

- Electric actuators are used in big HVAC systems. They control air flow exactly.

- Pneumatic actuators are used in gas plants. They help lower spark risks.

- Hydraulic actuators are used in hydroelectric plants. They give strong force.

Butterfly valves are found in many places:

- Chemical plants use them to control chemicals and liquids.

- Oil and gas pipelines use them to block or control flow.

- Water treatment plants use them for seawater and raw water.

- HVAC systems use them for air and water flow.

- Food and drink factories use them to move and clean fluids.

- Drinking water systems use them to block flow and move lots of water.

Butterfly valves work well with thick fluids and slurry. They are small, cheap, and easy to fix. But they do not control flow as well as globe valves. They might leak if the pressure or temperature is very high. The disc always stays in the flow. This can block some fluid.

When people pick valves, they look at how they work, control flow, pressure drop, space, price, care, and leaks. Butterfly valves are chosen for their size, cost, and easy care.

Check Valves

Check valves are important for stopping backflow. They let fluid move one way only. If fluid tries to go back, the valve shuts by itself. This keeps pumps, pipes, and other parts safe.

Check valves help in many systems:

- They stop water from going back into wells.

- They keep pumps ready by holding fluid.

- They protect equipment in oil, gas, and chemical plants.

- They help water and wastewater systems keep clean and dirty water apart.

Check valves give basic backflow safety. They are not as strong as special backflow preventers. Those have extra safety for drinking water. Check valves can get blocked if dirt gets stuck. Water hammer, a quick change in flow, can break them.

Note: For jobs where water safety matters most, backflow preventers are better than check valves.

Check valves come in different types. Some are swing, lift, and ball check valves. Each type fits different flow and pressure needs. When picking valves, people think about the fluid, pressure, and how often the valve opens and closes.

Plug Valves

Plug valves are another main type of valve. They use a solid plug that turns inside the body. This opens or closes the flow. The plug has a round or rectangle hole. Turning the plug lines up the hole with the flow or blocks it.

Plug valves are best for starting or stopping flow. They can control flow a little. They work well with gases, liquid hydrocarbons, and slurry. Plug valves are not good for very high pressure or fine flow control. Globe valves do better for that.

Plug valves have many types:

- Multi-port plug valves send flow in more than one way.

- Eccentric plug valves shut tight.

- Lubricated plug valves use grease to seal and move easily.

- Non-lubricated plug valves use special sleeves to lower friction.

| Feature Category | Details |

|---|---|

| Types | Multi-port, Eccentric, Lubricated, Non-lubricated |

| Port Patterns | Round, Rectangular, Standard, Diamond, Multi-Port, Venturi |

| Operation | Quarter-turn valve; plug turns to open or close flow |

| Components | Stem, Body, Plug Disc (solid metal plug) |

| Advantages | Great shut-off, simple use, versatile, low pressure drop, strong, works both ways, adaptable, cheap, easy care, many materials |

| Disadvantages | Needs more force to turn, big valves need actuators, costs more than ball valves, some designs drop more pressure |

| Typical Applications | On-off jobs, gas and liquid hydrocarbon control, slurry, water lines (if grease is not a problem) |

| Unsuitable Applications | Very high-pressure systems, fine flow control, very clean jobs |

| Special Features | Pressure balanced taper plug valves for high static pressures |

Plug valves are easy to use and last long. They shut tight and work both ways. Some plug valves need more force to turn, especially big ones. Actuators help with this. Plug valves cost more than ball valves but give more flow choices.

Plug valves are not good for very clean jobs. They are also not best for very high pressure. When picking valves, people look at the fluid, flow needs, care, and material.

Diaphragm Valves

Diaphragm valves use a soft, bendy membrane to control flow. The membrane is called a diaphragm. It moves up or down to open or close the valve. Only the diaphragm and valve body touch the fluid. This keeps other parts safe and makes cleaning simple.

| Aspect | Description |

|---|---|

| Operation Principle | Diaphragm valves have a soft membrane that seals against a seat or weir. This controls how fluid moves. The diaphragm connects to a part that lifts or presses it. This opens or closes the valve. Only the valve body and diaphragm touch the fluid. Other parts stay away from the fluid path. |

| Sanitary Suitability | The valve is easy to clean and sterilize. It drains itself. It meets FDA, USDA, ASME BPE, and USP rules. This makes it good for clean jobs like making medicine or biotech products. |

| Materials for Corrosive Environments | Valve bodies are made from strong metals that do not rust. These include 316, 316L, AL-6XN?, and Hastelloy? C-22?. Diaphragms are made from PTFE, EPDM, Butyl, silicone, or Viton. These materials work with harsh fluids. |

| Surface Finish and Cleanability | Smooth finishes like 10Ra and electropolishing make cleaning easier. They help stop germs and dirt. For medicine, valves need a finish between 30Ra-35Ra or better. |

| Limitations | These valves work at medium temperatures and pressures. They handle -40°F to 350°F and up to 150 PSI. The body must be made from metal that does not rust. |

| Specialized Designs | Some valves like EnviZion? and BioviZion? are easier to fix. They seal better and are easier to clean. This means less downtime and less risk of germs. |

| Applications | These valves are used in clean places like food, medicine, and chemical plants. They are good for harsh fluids and clean rooms. |

Diaphragm valves are great for jobs that need clean and safe flow. They are used in food, medicine, and chemical plants. They can handle harsh fluids and stop germs from spreading. Many companies pick these valves because they are easy to clean and seal well. Some have special designs for quick fixes and better sealing. They do not work well at very high pressure or heat. But they are perfect for many clean and harsh jobs.

Needle Valves

Needle valves help control the flow of liquids and gases with high precision. These valves have a long, pointed tip at the end of the stem. This tip fits into a small seat, which allows for very fine adjustments to the flow. Needle valves work best when a system needs careful control, not just simple on or off.

- The long, tapered point at the end of the stem creates a small seating area. This design makes needle valves better for fine flow adjustments than globe valves.

- Many systems use needle valves to control flow into sensitive gauges. This helps prevent damage from sudden pressure changes.

- Needle valves allow for smooth stopping of motion at the end of work cycles. They also let users adjust flow rates very precisely, especially at low flows.

- Some needle valves can be changed to act as variable restrictors. This means they can provide a set flow rate for special system needs.

- The stem of a needle valve has fine threads. It takes many turns to open or close the valve. This feature gives precise control but makes them less useful for quick shutoff.

- Their design supports small, controlled flow rates. They work well in fluid power systems where exact flow matters.

Tip: Needle valves are not the best choice for simple shutoff jobs. They shine when a system needs careful, steady control.

Many industries use needle valves in testing labs, chemical plants, and hydraulic systems. These valves help keep equipment safe and working smoothly.

Slam-Shut Valves

Slam-shut valves act as safety devices in gas systems. When pressure goes above or below a set limit, these valves close right away. This action stops the flow of gas and protects equipment and people.

Slam-shut valves play a key role in safety-critical gas systems. They appear in homes, small businesses, factories, and farms. These valves help control both overpressure and under pressure. By doing this, they keep the system safe and prevent damage or accidents.

Operators trust slam-shut valves to react quickly during emergencies. These valves do not control normal flow. Instead, they act as a last line of defense when something goes wrong. Gas companies and safety engineers rely on these valves to meet strict safety rules.

Fire Protection Valves

Fire protection valves keep fire safety systems working as they should. These valves include pressure relief valves (PRVs) and pressure control valves (PCVs). PRVs protect the system by letting out water if the pressure gets too high. PCVs lower the water pressure to a safe level during both normal and emergency use.

Fire protection valves must meet strict rules. For example, NFPA 20 says when and how to install PRVs, especially if diesel fire pumps create too much pressure. Other standards, like NFPA 13 and NFPA 14, set limits for hose pressure and system design. These rules help make sure fire protection valves work when needed.

- Fire safe valves use strong materials like stainless steel and carbon steel. This helps them stand up to high heat.

- They have a backup metal-to-metal seal. If the main soft seat fails in a fire, this seal keeps the system closed.

- Testing follows standards such as API 607 and API 6FA. These tests check if the valves work during fire conditions.

- Fire safe valves come in full bore and reduced bore types. This gives options for different jobs.

- Meeting these standards means the valves help keep people and property safe. They also help companies follow the law and avoid downtime.

Note: Fire protection valves are a must in places where fire risk is high. They help keep water flowing to sprinklers and hoses during an emergency.

Fire protection valves appear in factories, warehouses, office buildings, and anywhere fire safety matters. These valves help save lives and protect property by making sure fire systems work every time.

Valve Types Classification

Valve suppliers use simple ways to sort valve types. They put valves into groups by what they do, how they work, and how they are built. This helps people pick the right valve for each job.

By Function

Valve functions show what each valve does. The main groups are:

Isolation

Isolation valves stop or let flow happen. Ball, gate, and plug valves are good for this. These valves help shut off parts for fixing or safety.

Regulation

Regulation valves control how much fluid moves. Globe and needle valves change flow rates. These valves let users adjust pressure and flow.

Non-Return

Non-return valves keep fluid going one way. Check valves and directional flow valves stop backflow. This keeps pumps safe and protects systems.

Pressure Control

Pressure control valves manage system pressure. Relief and pressure reducing valves stop pressure from getting too high or low. These valves protect equipment and people.

Tip: Knowing what a valve does helps people pick the right one for each job.

By Operation

Valve types are also sorted by how they work. The main ways are:

Manual

Manual valves use handwheels, levers, or handles. People open or close these valves by hand. Gate and globe valves often use manual operation for simple jobs.

Automated

Automated valves use motors or air to move. These valves work with sensors or control systems. Automated valves help when quick or remote action is needed.

Actuated (Pneumatic, Electric)

Actuated valves use special devices to open or close. Pneumatic actuators use air. Electric actuators use electricity. These valves work fast and can do many cycles. Factories and big plants use actuated valves.

| Valve Type | Operation Type | Typical Applications | Key Characteristics and Notes |

|---|---|---|---|

| Gate Valve | Multi-turn, Manual | Wastewater, power, process plants | Low head loss when open; not for throttling; on/off use |

| Globe Valve | Multi-turn, Manual/Actuated | Cooling water, vents, turbine lube oil | Good shut-off and throttling; high pressure drop |

| Needle Valve | Multi-turn, Manual | Vacuum, metering systems | Fine control of small flows; many turns to close |

| Solenoid Valve | Self-Actuated | Cryogenic processes | Fast response; remote operation |

| Coaxial Valve | Self-Actuated | Precise liquid and gas control | Smaller, lighter, faster; limited fluid compatibility |

| Angle Seat Valve | Self-Actuated | Chemical, water, food systems | Fast acting; longer life than ball valves |

By Construction

Valve types have different designs. How a valve is built changes how it works.

Rotary

Rotary valves turn a part inside to open or close flow. Ball, plug, and butterfly valves use rotary motion. These valves need only a quarter turn to work. Rotary valves are common for on/off and isolation jobs.

Linear

Linear valves move a part up or down. Gate, globe, and needle valves use linear motion. These valves need many turns to open or close. Linear valves are good for control and fine flow changes.

Self-Actuated

Self-actuated valves use built-in devices to move. Solenoid and coaxial valves use electric coils or magnets. These valves act fast and do not need people to move them. Self-actuated valves help in systems that need quick or remote control.

| Valve Type | Motion Type | Operation Mechanism | Examples | Typical Applications |

|---|---|---|---|---|

| Rotary Valves | Rotary (quarter-turn) | Part rotates 90 degrees | Ball, Plug, Butterfly valves | On/off control, isolation |

| Linear Valves | Linear (straight line) | Part moves up/down; rising stem or axial | Gate, Globe, Needle, Coaxial | Flow control, fast on/off |

| Self-actuated Valves | Linear (electromagnetic) | Coil moves part using electricity | Solenoid valves | Fast-acting on/off, small flows |

Valve suppliers use these ways to help people understand valve types. Clear sorting makes it easier to choose the best valve for each job. People should look at what the valve does, how it works, and how it is built before picking one.

Features of Different Valve Types

Key Features

Valve suppliers make valves with many helpful features. Each valve type does a special job and works best in certain places.

- Certifications like ISO 9001 and CE Marking mean the valves are safe and high quality.

- Experts help pick the right size and material for each fluid.

- Custom options let people choose special sizes or parts for their system.

- Good supply chains make sure valves come on time and work right.

- Service centers and engineers help fix problems fast.

- The type and design of the valve are important. Isolation, non-return, and control valves all look and work differently.

- Pressure rating shows how much force the valve can take.

- Picking the right material keeps valves strong against rust and heat.

- Valves can be manual, electric, air-powered, or hydraulic.

- Valve size and ends must match the pipes.

- Following rules like API and ASTM keeps valves safe for many jobs.

Tip: Picking the right features helps valves last longer and work better everywhere.

Advantages

Valves have many good points for people in different jobs.

| Valve Type | Main Advantages |

|---|---|

| Ball Valves | Quick shut-off, tight seal, easy to use |

| Gate Valves | Low flow resistance, good for on/off jobs |

| Globe Valves | Precise flow control, strong shut-off |

| Butterfly Valves | Light, small, saves money |

| Check Valves | Stops backflow, keeps equipment safe |

| Plug Valves | Versatile, simple, low pressure drop |

| Diaphragm Valves | Easy to clean, good for clean jobs |

| Needle Valves | Fine flow control, smooth changes |

| Slam-Shut Valves | Fast action, safety protection |

| Fire Protection Valves | Reliable in emergencies |

Self-expandable valves sometimes work better in some tests. Balloon-expandable valves may lower some risks, like leaks. Suppliers with good reputations and skills help people get the best from their valves.

Disadvantages

Valves also have some downsides.

- Some valves, like gate valves, do not control flow well.

- Globe valves can cause more pressure loss.

- Butterfly valves might leak in very high-pressure jobs.

- Plug valves can be hard to turn, especially big ones.

- Diaphragm valves do not work well with very high heat or pressure.

- Needle valves take longer to open or close because of their threads.

- Prices change because of materials and how they work.

- Not every valve fits every job. People must check if the valve matches their system.

Note: Knowing the downsides helps people avoid trouble and pick the best valve for each job.

Typical Applications

Valve suppliers make different valves for special jobs in many industries. Each valve type works best for certain tasks and places. The table below shows how some valves are used and why people pick them:

| Valve Type | Typical Applications | Key Characteristics and Industry Usage Patterns |

|---|---|---|

| Ball Valve | On/off flow control, emergency shutoff (e.g., sinks) | Easy to use, little pressure loss, used a lot in homes and factories |

| Butterfly Valve | High capacity flow control, small pressure drop (e.g., air intake in older cars) | Cheap, small, good for controlling flow, used in water, HVAC, and factories |

| Globe Valve | Precise flow control where throttling is needed | Good for changing flow, common in places that need careful flow control |

| Plug Valve | Extreme on/off situations, rugged environments | Strong, costs more than ball valves, used in tough factory jobs |

Other valves do special jobs too:

- Knife valves work well with thick liquids or powders. They turn flow on or off when there are fibers.

- Pinch valves are used in clean jobs. Hospitals and medicine makers use them for safe flow.

- Ballcock valves help keep water levels right in tanks. They use floats to stop tanks from spilling over.

- Solenoid valves control flow by themselves. Factories use them for quick and steady switching.

Many industries use these valves every day. Power plants use globe and gate valves for steam and water. Big factories need ball and butterfly valves for cooling and making things. Machine makers put different valves in their products. Data centers use strong valves to keep cooling working. Builders and repair workers pick valves for buildings and safety.

Applications of Different Types of Valves

Oil and Gas

Valves are very important in oil and gas work. They help control how things flow and keep pressure safe. Valves also protect the whole system. Different valves are used at every step, from drilling to storage.

| Valve Type | Operational Mechanism | Common Use in Oil & Gas Applications |

|---|---|---|

| Gate Valve | Linear Motion | Turns flow on or off; used in pipelines for oil and gas |

| Globe Valve | Linear Motion | Controls flow and pressure; used for careful flow changes |

| Ball Valve | Rotary / Quarter-Turn | Shuts off flow fast; used to stop or start flow quickly |

| Butterfly Valve | Rotary / Quarter-Turn | Small and quick; used in big pipes and storage tanks |

| Check Valve | Rotary / Linear | Stops flow from going backward; keeps equipment safe |

| Diaphragm Valve | Linear Motion | Controls flow in harsh fluids; used for special jobs |

| Safety Valve | Linear Motion | Lets out extra pressure; keeps people and machines safe |

Valve makers use cast or forged bodies for industrial valves. Cast valves are best for pipes bigger than 2 inches. Forged valves are picked for smaller pipes or when safety matters most. This choice changes how strong the valve is and how long it lasts.

Water and Wastewater

Water and wastewater systems need valves to move and control water. These systems use many kinds of valves to keep water clean and safe.

- Gate valves open or close water pipes in plants.

- Butterfly valves help control flow in big pipes.

- Check valves stop dirty water from going backward.

- Ball valves shut off water fast in emergencies.

- Globe valves adjust flow for chemicals and filters.

Workers use valves to move water from rivers, lakes, or wells. They also use them to treat and send out clean water. In wastewater plants, valves help remove solids and protect pumps. Good valves stop leaks and keep water systems working well.

Tip: Picking the right valve helps save water and keeps the earth safe.

Chemical Processing

Chemical plants need valves that can handle strong and dangerous fluids. These plants use many valves to control flow, pressure, and heat.

| Valve Type | Function Description | Typical Applications in Chemical Processing |

|---|---|---|

| Gate Valves | Opens or closes flow with a gate | Used in big pipes for straight flow and low pressure drop |

| Ball Valves | Uses a round disc to control flow | Stops flow tightly; good for harsh chemicals and isolation |

| Butterfly Valves | Uses a disc to control flow | Moves lots of fluid; works with harsh materials and low pressure drop |

| Check Valves | Only lets flow go one way | Stops backflow; protects pumps and other parts |

| Diaphragm Valves | Uses a soft part to control flow | Good for thick fluids and slurries |

| Globe Valves | Uses a plug for fine flow control | Controls flow and pressure for harsh fluids |

| Plug Valves | Turns a plug to open or close flow | Turns flow on or off for tough chemicals |

| Pressure Relief Valves | Lets out extra fluid to stop too much pressure | Keeps equipment safe from high pressure |

Chemical plants need valves that do not rust and can take high heat. Ball and gate valves shut off flow tightly in pipes. Globe valves help mix and add chemicals with care. Diaphragm valves work with thick and sticky fluids. Pressure relief valves stop damage from too much pressure.

Plant managers pick valves based on the chemicals, how easy they are to clean, and how often they are used. The right valve keeps the plant safe and running well.

Power Generation

Power plants need valves to work safely and well. Valves control steam, water, and fuel. They help set the right pressure and temperature. Each valve has a special job in power plants.

Operators use gate valves to start or stop flow in big pipes. Gate valves are good for turning flow on or off. They let water or steam move easily. Ball valves shut off flow fast. Workers use ball valves in emergencies because they seal tight and work quickly.

Globe valves help control flow and pressure. Engineers put globe valves where they need careful control. These valves change steam or water flow to fit what the system needs. Needle valves give even more exact control. Technicians use needle valves in small pipes for tiny changes.

Butterfly valves save space in tight spots. Maintenance teams use butterfly valves for cooling water and air. These valves open and close with a quick turn. They move lots of fluid with little pressure loss.

Check valves stop flow from going backward. Power plants use check valves in pump and feedwater lines. These valves close by themselves if flow goes the wrong way. This keeps pumps and turbines safe.

Pressure relief valves keep systems safe from too much pressure. If pressure gets too high, these valves open to let out steam or water. This stops boilers and pipes from breaking. Pressure reducing valves lower pressure before it goes into sensitive parts.

Tip: Picking the right valve helps power plants avoid problems and shutdowns.

The table below shows common valve types and how they are used in power plants:

| Valve Type | Main Function | Typical Application |

|---|---|---|

| Gate Valve | On/off control | Boiler feedwater, steam lines |

| Ball Valve | Quick shut-off | Emergency isolation, fuel systems |

| Globe Valve | Flow regulation | Steam control, cooling water |

| Butterfly Valve | Space-saving on/off | Cooling towers, air ducts |

| Check Valve | Prevent backflow | Pump discharge, condensate lines |

| Pressure Relief Valve | Overpressure protection | Boiler safety, steam headers |

| Needle Valve | Fine flow adjustment | Instrumentation, sample lines |

Power plants must follow strict safety rules. Valves must handle high pressure and heat. Stainless steel and special alloys help stop rust and damage. Engineers pick valves based on pressure, fluid, and how easy they are to fix.

Modern power plants use automated valves for better control. Electric and air-powered actuators let workers control valves from far away. Automation helps workers act fast when things change or go wrong.

Valves are very important for power plant safety and reliability. Picking the right valves and taking care of them helps stop problems and keeps power going to homes and businesses.

Choosing the Right Valve Type

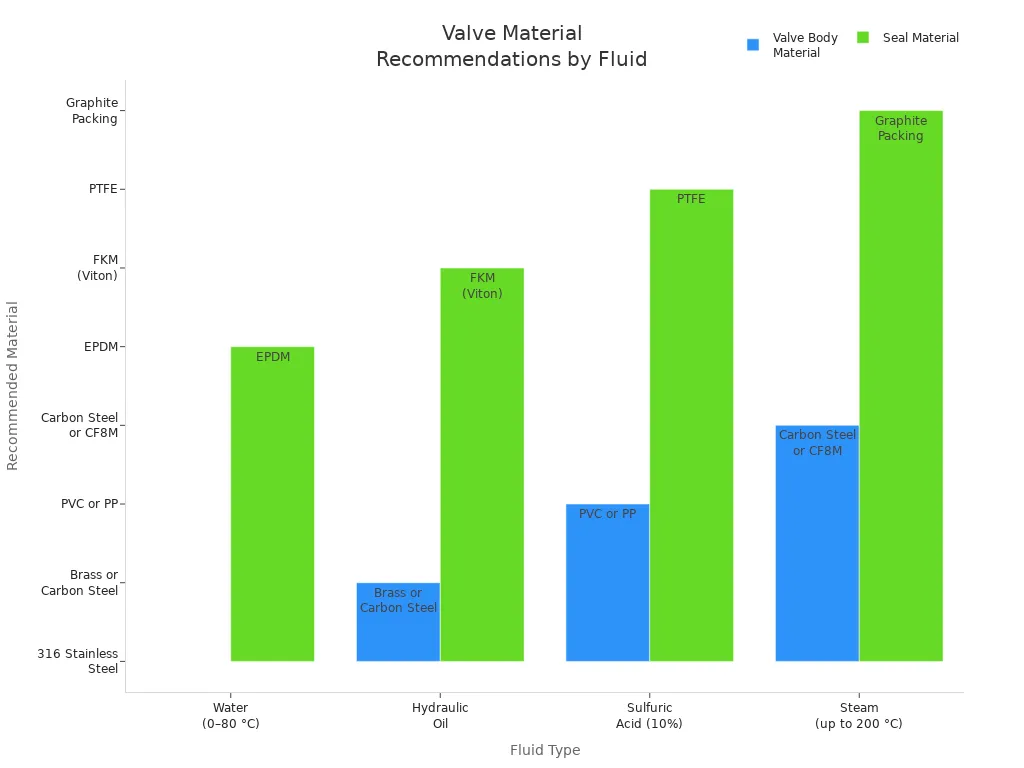

Media Compatibility

When picking a valve, check if its materials match the fluid. Some fluids can damage seals or the valve body. This can cause leaks or break the valve. Suppliers use charts to show which materials work with each fluid. These charts help you pick the right valve and seal. This keeps the system safe and stops leaks.

| Fluid Type | Recommended Valve Body Material | Recommended Seal Material |

|---|---|---|

| Water (0–80 °C) | 316 Stainless Steel | EPDM |

| Hydraulic Oil | Brass or Carbon Steel | FKM (Viton) |

| Sulfuric Acid (10%) | PVC or PP | PTFE |

| Steam (up to 200 °C) | Carbon Steel or CF8M | Graphite Packing |

Picking a valve is not just about the fluid. You also need to think about how thick the fluid is and its temperature. Tough fluids need strong materials. Valves with special shapes, like V-notch, work well with thick liquids. Parts made from stainless steel or anodized aluminum last longer in hard jobs. Suppliers give charts, guides, and advice to help you choose.

Tip: Always look at chemical charts before picking a valve. This helps stop problems and keeps your system working.

Pressure and Temperature

Pressure and temperature are important when picking a valve. Each valve has a normal pressure and a top pressure it can take. Never let the system go past the top pressure. The weakest part sets the limit for pressure.

- Pressure and temperature change how a valve works.

- If temperature goes up, the valve’s pressure rating can go down.

- Both fluid and air temperature matter for the valve.

- Big changes in temperature can make seals and metals grow or shrink. This can cause leaks or break parts.

- Some metals get weaker when they get hot. This lowers the pressure rating.

Valve makers test their valves in tough conditions. They share ratings for the body, trim, seals, and ends. Always check these ratings before you put in a valve. Manuals and charts help you pick the right valve for your job.

Flow Control Needs

You need to think about how much control your system needs. Some jobs only need simple on/off valves. Other jobs need valves that can change flow very carefully. Ball and gate valves are good for quick shut-off. Globe and needle valves are best for fine flow control. Butterfly valves move lots of fluid with little pressure drop.

- Use special valves for thick or dirty fluids so they do not clog.

- Pick valves with fine control if you need exact flow rates.

- Automated valves help when you need to change flow often or from far away.

Note: The best valve depends on what your system needs, the fluid type, and how often you use the valve.

Picking the right valve keeps your system safe and easy to fix. Suppliers give charts, manuals, and advice to help you choose the best valve.

Installation and Maintenance

Putting in and taking care of valves is very important. It helps the system work well. Top suppliers say to follow clear steps for safety.

Installation Steps:

- Look at the valve before you put it in. Make sure nothing is broken or missing.

- Clean the pipe. Take out dirt, old gaskets, and anything else.

- Line up the valve with the pipe. The arrow on the valve shows which way the flow should go.

- Use the right gaskets and bolts. Tighten the bolts in a crisscross way so the pressure is even.

- Test the valve after you finish. Open and close it to see if it leaks or gets stuck.

Tip: Always use the correct tools when you install a valve. This helps keep the valve and pipe safe from damage.

Common Installation Mistakes:

- Tightening bolts too much can break the valve body.

- If the valve is not lined up right, it can leak and not work well.

- Using the wrong gasket can make the valve fail early.

Taking care of valves helps everything run smoothly. Checking valves often helps find problems early.

Maintenance Checklist:

- Look for leaks, rust, or worn-out parts.

- Put oil or grease on moving parts if needed.

- Clean the seats and seals of the valve.

- Change old gaskets and seals.

- Test how the valve works with normal pressure.

| Maintenance Task | How Often | Why You Do It |

|---|---|---|

| Look at the valve | Every month | Find leaks or damage |

| Lubricate parts | Every 6 months | Make moving parts work better |

| Change seals | Once a year | Stop leaks |

| Test how it works | Every 3 months | Make sure it works right |

Workers should read the supplier’s manual for each valve. Some valves, like ball and butterfly valves, need less care. Others, like globe and diaphragm valves, need more checks.

Note: Keeping a record of maintenance helps you remember repairs and changes. This makes things safer and stops long breaks.

Valve suppliers teach people how to install and care for valves. They give manuals, videos, and send service teams. Good care makes valves last longer and saves money.

Maintenance workers should wear safety gear when working with valves. Gloves, goggles, and safety shoes help keep them safe. Safety is important every time.

A valve that is put in right and cared for works better and lasts longer. Regular care stops problems and keeps everything safe. Valve suppliers help with advice and support at every step.

Working with Valve Suppliers

Benefits of Major Suppliers

Big valve suppliers help companies control flow safely. They follow strict safety and quality rules. They test valves in tough places, like high pressure and heat. This testing stops leaks and keeps people safe.

- Big suppliers use standards like ISA-75 and ANSI/ISA-75.11.01-2013. These rules make sure valves work well in many jobs.

- They check for leaks and test valves with hot and cold fluids. This helps valves last longer and work better.

- Suppliers design valves to lower noise and stop damage from bubbles or shaking. This keeps systems quiet and smooth.

- They use tools that watch systems all the time. These tools find problems early and help avoid long stops.

- Standard valve sizes and shapes make putting them in easier. This also helps fix and replace valves fast.

Trusted valve suppliers give companies peace of mind. They know valves will follow rules and keep systems safe.

Customization and Support

Valve suppliers know every system is different. They offer custom choices for special needs. Engineers pick the best materials, sizes, and features for each job. Suppliers use smart machines to make parts that fit just right.

Many suppliers use strong metals and special coatings. These help valves last longer in tough places. Some suppliers make modular designs, like the CANISTER GUARD? valve. This design is easy to take apart and fix. It means companies need fewer spare parts.

Suppliers give good help after selling valves. They help with putting valves in, training, and fixing problems. Service teams can visit to solve issues fast. Many suppliers also give guides, videos, and manuals to help workers use and care for valves.

| Customization Option | Benefit to Customer |

|---|---|

| Special materials | Handles harsh chemicals |

| Modular design | Easier maintenance |

| Patented features | Better performance, less downtime |

Consulting for Special Applications

Some jobs need expert help. Valve suppliers have teams for special projects, like handling dangerous fluids or meeting safety rules. These experts use smart engineering to pick the best valve for each system.

Consultants look at the whole job. They check the fluid, pressure, and temperature. They also think about how often the valve opens and closes. This helps them suggest the right valve and setup.

Companies working with skilled valve suppliers get more than valves. They get advice that helps systems work better and last longer.

Knowing about valve types and how they are sorted helps people pick the best one. Every job needs a certain valve to work well and stay safe. Top suppliers give advice and can make special valves for different needs.

- When you know more, you can make better choices and avoid trouble.

- Picking the right valve keeps things safe, working, and saves money.

To get the best outcome, talk to trusted valve suppliers before you choose.

FAQ

What is the main difference between a ball valve and a gate valve?

A ball valve has a ball inside that turns to open or close flow. A gate valve uses a flat or wedge-shaped gate that moves up or down. Ball valves are good for turning flow off fast. Gate valves are better for pipes that need to be fully open or closed.

How does a check valve prevent backflow?

A check valve lets fluid move in only one direction. If fluid tries to go back, the valve shuts by itself. This keeps pumps and other equipment safe from damage.

Which valve type works best for precise flow control?

Globe valves and needle valves are best for careful flow control. Globe valves use a disc that moves to change flow. Needle valves have a pointed stem for small changes.

Can valves handle both high pressure and high temperature?

Some valves, like forged steel ball or gate valves, can take high pressure and heat. Always look at the valve’s pressure and temperature ratings before using it.

How often should valves receive maintenance?

Most valves should be checked every few months. Maintenance means looking for leaks, cleaning, and putting oil or grease on moving parts. Taking care of valves helps them last longer and work safely.

What materials resist corrosion in chemical plants?

Stainless steel, Hastelloy?, and PTFE do not rust easily. Valve suppliers say these are good for strong chemicals. Always pick a valve material that matches the fluid.

Do automated valves need special installation steps?

Automated valves need careful wiring and setup. Installers must follow the supplier’s directions. Testing the actuator and controls makes sure the valve works safely.

Why do some valves have certifications like ISO or CE?

Certifications mean the valve meets safety and quality rules. These marks help buyers trust that the valve will work well in important systems.