Valve position indicators play a crucial role in ensuring precision and reliability across industrial processes, particularly in steam systems. By providing accurate feedback on valve positions, they optimize the performance of components like the Steam Control Valve and the steam flow control valve, essential for regulating steam flow and minimizing energy loss. These indicators are integral to applications that depend on consistent steam pressure, such as those involving the steam pressure reducing valve and steam pressure regulating valve. Their functionality supports process control, safety, and maintenance by streamlining operations in demanding environments. This guide explores the technology behind valve position indicator feedback switches and their use across various industries, offering valuable insights into their role in enhancing system efficiency.

Introduction to Valve Position Indicators

Valve position indicators are vital components in industrial systems, delivering precise data on valve statuses to enhance operational accuracy and efficiency. These indicators ensure seamless integration with various valves, including the Pneumatic diaphragm control valve and Pneumatic globe valve, both pivotal for managing flow and pressure in complex applications. Recognized by pressure regulating valve manufacturers for their reliability, valve position indicators are indispensable in ensuring precise pressure and temperature adjustments in processes that rely on the temperature regulating valve.

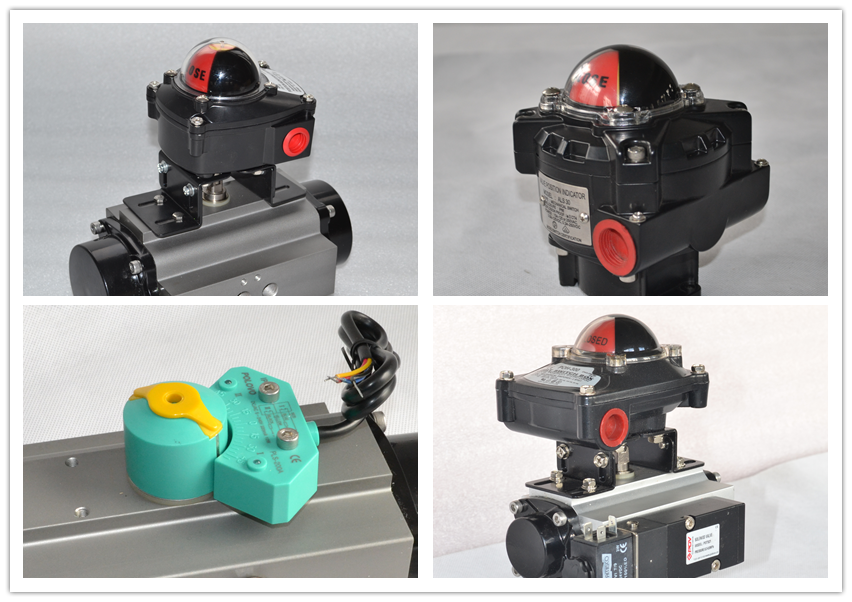

Overview of valve position indicators and feedback switches:

Valve position indicators

Valve position indicators are critical tools in industrial applications, providing precise data on valve status to ensure accurate process control and enhanced system reliability. These devices play a key role in optimizing operations by integrating seamlessly into various systems, enabling real-time monitoring and adjustments. By delivering feedback on valve positions, they support efficient automation, reduce energy waste, and minimize unexpected system downtime.

Feedback switches

Feedback switches are essential components in industrial systems, offering precise and reliable monitoring of valve positions to enhance process control and operational efficiency. These switches provide critical feedback that enables real-time system adjustments, ensuring accurate performance and reducing the risk of errors. By integrating seamlessly with industrial processes, feedback switches contribute to increased automation, optimized workflows, and improved system reliability.

Importance of valve position indicators in industrial processes.

Valve position indicators are indispensable in industrial processes, ensuring precision, efficiency, and operational reliability. By providing accurate real-time feedback on valve positions, these devices enhance process control and support automation, reducing manual interventions and system errors.

They play a crucial role in optimizing workflows, minimizing energy loss, and maintaining consistent performance in complex operations. Furthermore, valve position indicators improve safety by quickly identifying misalignments or malfunctions, enabling proactive maintenance and reducing downtime.

Role of feedback switches in enhancing operational efficiency.

Feedback switches are integral to boosting operational efficiency in industrial environments. By delivering precise and timely information on valve positions, they enable seamless automation and minimize the need for manual intervention. This real-time feedback ensures accurate process adjustments, reducing errors and unnecessary downtime.

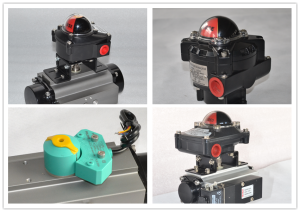

Types of Valve Position Indicators

Valve position indicators come in various types, including mechanical, electrical, and digital options, each designed to meet specific industrial requirements. Mechanical indicators use visual markers or levers to show valve position, offering durability and simplicity in manual operations. Electrical indicators employ limit switches to provide real-time feedback, making them ideal for automated systems.

Mechanical valve position indicators.

Mechanical valve position indicators are reliable and straightforward tools designed to visually convey a valve’s status in industrial applications. Built with robust materials, they offer exceptional durability, making them ideal for challenging environments where complex systems may not be feasible. These indicators use levers, dials, or flags to display real-time valve positions, ensuring simple yet efficient monitoring. Their low-maintenance nature and resistance to wear make them cost-effective solutions for operations requiring minimal upkeep.

Electrical/Electronic valve position indicators:

Electrical valve position indicators

Electrical valve position indicators are critical components in modern industrial automation, providing precise and real-time feedback on valve positions. These indicators utilize limit switches or sensors to transmit accurate positional data to control systems, ensuring seamless integration into automated workflows.

By enabling instant communication between valves and supervisory systems, they help maintain optimal process control and enhance system responsiveness. Electrical indicators excel in environments demanding high efficiency and reliability, reducing manual monitoring and minimizing downtime.

Electronic valve position indicators

Electronic valve position indicators leverage cutting-edge technology to deliver unmatched precision and functionality in industrial environments. Equipped with advanced sensors, these indicators provide highly accurate and continuous feedback on valve positions, making them essential for modern digital control systems. Their ability to integrate seamlessly with intelligent process automation enhances operational efficiency and ensures real-time monitoring.

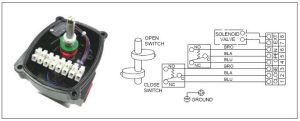

Overview of integrated valve position indicator feedback switches.

Integrated valve position indicator feedback switches streamline system integration by combining position indication and feedback functionality into a single, compact unit. These switches offer precise, real-time data on valve status, enabling efficient automation and enhanced process control. Designed for seamless integration with advanced industrial systems, they support various communication protocols, ensuring compatibility with modern automation frameworks.

Working Principles of Valve Position Indicators

Valve position indicators operate by detecting the open, closed, or intermediate positions of valves and conveying this information through visual or electronic means. Mechanical models use physical markers or dials, while electrical and electronic types rely on limit switches, sensors, or advanced digital circuitry to determine and communicate valve status. These systems ensure precise, real-time feedback by integrating with industrial control networks, thereby enabling accurate monitoring and management of fluid control processes.

How mechanical valve position indicators operate.

Mechanical valve position indicators operate by using a physical connection to the valve stem or actuator, translating the valve’s movement into a clear visual display, such as a dial or flag. These devices rely on simple mechanical linkages to detect whether a valve is open, closed, or in an intermediate position. Built with durable components, they are designed to withstand harsh industrial conditions, ensuring consistent performance over time.

Electrical signaling principles in valve position indicator systems.

Electrical signaling in valve position indicator systems relies on advanced technologies like limit switches, proximity sensors, and digital encoders to detect and transmit valve position data. When a valve reaches a specific position, these devices generate an electrical signal that is communicated to a control system for monitoring and analysis. This seamless interaction enables precise real-time feedback, critical for ensuring operational accuracy and optimizing process control.

Integration of feedback switches in valve position indicators for real-time monitoring.

Feedback switches integrated into valve position indicators enable real-time monitoring by providing instantaneous data on valve positions through advanced sensing and signaling mechanisms. These switches generate precise feedback that is transmitted to control systems, offering operators a detailed, up-to-date view of system performance. This integration enhances accuracy and supports seamless process control by facilitating swift adjustments in response to dynamic industrial requirements.

Key Industrial Applications of Valve Position Indicators

Valve position indicators are indispensable across numerous industries, including oil and gas, chemical processing, water treatment, and power generation. They provide accurate, real-time feedback on valve positions, ensuring precise control over fluid flow and system performance. These devices enhance operational efficiency by supporting automated processes, reducing manual intervention, and improving response times during critical operations.

Use of valve position indicators in the oil and gas sector.

Valve position indicators play a vital role in the oil and gas sector, ensuring precise control and monitoring of critical processes like drilling, refining, and distribution. They provide accurate feedback on valve positions, enabling operators to manage fluid flow and pressure with precision. This enhances safety by minimizing risks in high-pressure and hazardous environments, while also optimizing operational efficiency through real-time process adjustments. Integrated into automated systems, these indicators support seamless control across pipelines, storage facilities, and processing units.

Applications in chemical processing industries.

Valve position indicator feedback switches are critical in chemical processing industries, where precision and safety are paramount. These devices provide real-time feedback on valve positions, enabling accurate control of flow, pressure, and temperature within complex chemical systems. By ensuring consistent operation of valves, they help maintain optimal reaction conditions, reduce the risk of leaks or unintended interactions, and support compliance with stringent safety standards.

Role in water treatment plants and power generation facilities.

Valve position indicator feedback switches play a vital role in water treatment plants and power generation facilities by providing precise control and monitoring of fluid systems. These devices ensure accurate regulation of water flow, pressure, and energy transfer processes, optimizing system performance and reducing the risk of equipment failure. Their real-time feedback capabilities enhance operational efficiency by enabling seamless automation and reducing manual interventions.

Benefits of Valve Position Indicators with Feedback Switches

Valve position indicators with feedback switches offer significant benefits across industrial applications by providing precise, real-time feedback on valve positions. These devices enhance process control by ensuring accurate adjustments to fluid flow, pressure, and temperature, crucial for maintaining optimal operations. By supporting automation, they reduce reliance on manual interventions, minimizing human error and increasing efficiency. Their ability to identify potential issues early contributes to improved safety and proactive maintenance, avoiding costly downtime.

Enhanced operational accuracy and reliability.

Valve position indicator feedback switches significantly enhance operational accuracy and reliability in industrial applications by delivering precise, real-time data on valve positions. This ensures seamless automation, enabling accurate adjustments to fluid flow, pressure, and other critical parameters while minimizing human error. By integrating these devices into control systems, industries benefit from consistent performance and reduced downtime caused by unexpected malfunctions.

Improved process control and automation efficiency.

Valve position indicator feedback switches are instrumental in improving process control and automation efficiency in industrial settings. By delivering accurate, real-time data on valve positions, they enable precise adjustments to fluid and pressure systems, ensuring optimal operation. These devices minimize the need for manual interventions, reducing errors and saving valuable time across processes. Their seamless integration into automated systems enhances productivity by streamlining operations and maintaining consistent performance.

Reduced downtime through effective monitoring systems.

Valve position indicator feedback switches play a key role in reducing downtime through their integration into effective monitoring systems. By providing precise real-time data, these devices enable early detection of potential issues, allowing for prompt corrective actions and proactive maintenance. This reduces the likelihood of unexpected failures and minimizes operational disruptions, ensuring uninterrupted workflow. Their ability to offer continuous monitoring and accurate feedback supports streamlined operations, leading to enhanced efficiency and system reliability.

Installation and Maintenance of Valve Position Indicators

Proper installation and maintenance of valve position indicators are crucial for achieving optimal performance and long-term reliability. During installation, precise alignment and correct calibration are essential to ensure accurate readings and seamless integration into the control system. Regular maintenance, including routine inspections and tests, helps identify potential issues early, preventing malfunctions and avoiding costly downtime. Key tasks such as verifying connections, cleaning components, and adjusting calibration improve operational efficiency and extend the devices’ lifespan.

Best practices for installing valve position indicator feedback switches.

To ensure optimal performance when installing valve position indicator feedback switches, it is crucial to follow manufacturer guidelines meticulously. Proper alignment of the device and thorough calibration are key steps to guarantee accurate readings and integration into the control system. Verifying electrical connections and securely attaching wiring prevents malfunctions, while conducting comprehensive system tests post-installation confirms functionality and accuracy. These best practices not only enhance system reliability but also prevent operational issues, reducing the risk of downtime.

Routine maintenance tips to ensure longevity and accuracy.

Routine maintenance is essential for ensuring the longevity and accuracy of valve position indicator feedback switches. Regular inspections should include checking for wear and tear on components, verifying secure electrical and mechanical connections, and ensuring proper alignment. Cleaning the device to prevent dust and debris buildup helps maintain operational precision, while periodic recalibration ensures accurate performance over time. If the system integrates software, keeping firmware updated can enhance functionality and reliability.

Troubleshooting common issues in valve position indicators.

Routine maintenance is essential for ensuring the longevity and accuracy of valve position indicator feedback switches. Regular inspections should include checking for wear and tear on components, verifying secure electrical and mechanical connections, and ensuring proper alignment. Cleaning the device to prevent dust and debris buildup helps maintain operational precision, while periodic recalibration ensures accurate performance over time. If the system integrates software, keeping firmware updated can enhance functionality and reliability.

Future Trends in Valve Position Indicator Technology

The future of valve position indicator technology lies in advanced integration with IoT and smart systems, enabling seamless connectivity and real-time data sharing. Enhanced data analytics capabilities will support predictive maintenance, identifying issues before failure occurs, thereby reducing downtime. Increased automation and machine learning will allow for more precise control, optimizing process efficiency and minimizing energy consumption. These advancements promise to improve overall system performance while significantly reducing operational costs.

FAQ valve position indicator

Q1. How do valve position indicators enhance the operation of an electric globe valve?

A: Valve position indicators provide real-time feedback on the position of an electric globe valve, ensuring precise control over fluid flow. By monitoring the valve’s position, operators can quickly adjust settings to maintain accurate process parameters. This integration improves operational safety, reduces energy waste, and enhances system reliability, particularly in applications requiring fine-tuned flow control.

Q2. What role do valve position indicators play in optimizing pneumatic control valve performance?

A: For pneumatic control valves, valve position indicators are essential for monitoring and confirming the valve’s position. They ensure that the valve responds accurately to pneumatic signals, minimizing process variability. These indicators also support predictive maintenance by identifying alignment issues, wear, or malfunctions early, helping maintain optimal performance in industrial automation systems.

Q3. Are valve position indicators compatible with electric control valves, and what are the benefits?

A: Yes, valve position indicators are highly compatible with electric control valves. They integrate seamlessly with the valve’s actuator to provide precise position feedback. Their use enhances overall automation by enabling smarter control systems and quick adjustments via real-time data. This not only improves process efficiency but also reduces the potential for operational errors and unplanned downtime.

Conclusion valve position indicator

Valve position indicators are essential for modern industrial processes, offering precise feedback and enhancing the performance of various valve systems. From ensuring the accurate operation of a self-operated pressure regulating valve to optimizing a self-operated regulating valve or self-operated control valve, these devices play a critical role in maintaining efficiency and reliability. They enable seamless control, reduce downtime, and support predictive maintenance, making them indispensable in today’s automated industries. By integrating advanced technologies such as IoT and data analytics, valve position indicators continue to transform operations, providing improved accuracy and sustainable performance in challenging industrial environments.