Choosing the right valve manufacturers is very important. If you do not check carefully, you may have problems. These problems include stem breakage, gate faults, or sealing surface defects. These problems can cause leaks, shutdowns, and costly repairs. Look at this table to see how picking a bad valve manufacturer can hurt your work:

| Failure Type | Description | Consequences |

|---|---|---|

| Stem Breakage | Thread root or undercut breakage | Fluid control failure, leaks |

| Gate Faults | Gate mechanism issues | Inability to open/close valve |

| Sealing Surface Defects | Defective sealing surfaces | Loss of fluid integrity |

| Packing Failures | Packing problems | Higher maintenance costs |

| Electric Actuator Issues | Actuator malfunctions | System shutdowns |

Smart checking helps you avoid these problems. When you need a butterfly valve, ball valve, Pneumatic diaphragm valve, or Pneumatic control valves, match the manufacturer’s skills to your needs. Careful checking gives you better results and fewer problems.

Key Takeaways

- Picking the right valve manufacturer helps stop expensive problems like leaks and broken equipment.

- Know what your industry needs so you can pick valves that keep things safe and working well.

- Look for industry certifications to make sure the valves meet safety and quality rules.

- Check how the valve works, like its pressure and temperature limits, to see if it fits your needs.

- Choose the right valve type and material to make it last longer and work better.

- Find manufacturers who offer many kinds of valves for different projects.

- Choose manufacturers with good reputations and a history of doing great work.

- Ask about warranties and help after you buy to make sure you get good service for a long time.

Application Needs

Industry Requirements

When you look for valve manufacturers, think about what your industry needs. Each industry has its own problems. Oil and gas, water treatment, and chemical processing need different valves. If you choose the wrong valve, you could get leaks or damage. You might even have safety issues.

Here’s a table that shows what is important in each industry:

| Requirement | Description |

|---|---|

| Preventing Leaks | Good valves stop leaks of dangerous stuff. This keeps people safe and protects the environment. |

| Ensuring Equipment Longevity | Valves control flow and pressure. They help protect machines and lower repair costs. |

| Reducing Downtime | Working valves keep things running. They stop interruptions and help production continue. |

| Enhancing Safety | Valves are key in emergencies. They help keep workers and equipment safe from harm. |

You should also check if the valves follow industry rules. This keeps your business safe from legal problems. It also makes sure your work is safe. If you skip this, you might get valves that do not meet safety rules.

Tip: Always ask your supplier about certifications and rules. This question can help you avoid problems later.

Other things to think about are:

- Temperature

- Pressure

- Corrosion

- Material Compatibility

These points help you choose the best valve for your job.

Performance Criteria

Performance is just as important as industry needs. You want a valve that works well in your system. If your system has high pressure or high temperature, pay close attention.

Here is a checklist to help you check performance:

- Maximum Operating Pressure: Make sure the valve can handle your system’s pressure.

- Operating Temperature: Check if the valve works at your needed temperature.

- Valve Material: Pick materials that resist pressure, temperature, and corrosion.

- Connection End Type: Choose the right connection so it does not leak.

- Leakage Tolerance: Know how much leakage is okay for your process.

- Size Availability: Make sure the valve fits your pipe size.

If you follow these steps, you will find a valve that keeps your system safe and working well. Good performance means less downtime and fewer repairs.

Valve Type & Material

When you choose a valve, think about the valve type and material. These choices help your equipment work well and last longer. Let’s look at what you should check.

Valve Types

There are many valve types in factories and plants. Each type is best for certain jobs. Here are some common types and where you use them:

- Ball Valve: This controls liquid or gas flow in pipes. It is fast and simple to use.

- Butterfly Valve: This helps control how much fluid moves. You see it in chemical plants, water plants, and food factories.

- Check Valve: This stops fluid from going backward. It is important where dangerous materials are used.

- Gate Valve: This lets fluids move through pipes. It has a wedge-shaped seat and disk.

- Globe Valve: This is good for stopping flow. It works well with high pressure and heat.

Tip: Always pick the valve type that fits your system. If you choose the wrong one, you could get leaks or breakdowns.

Material Selection

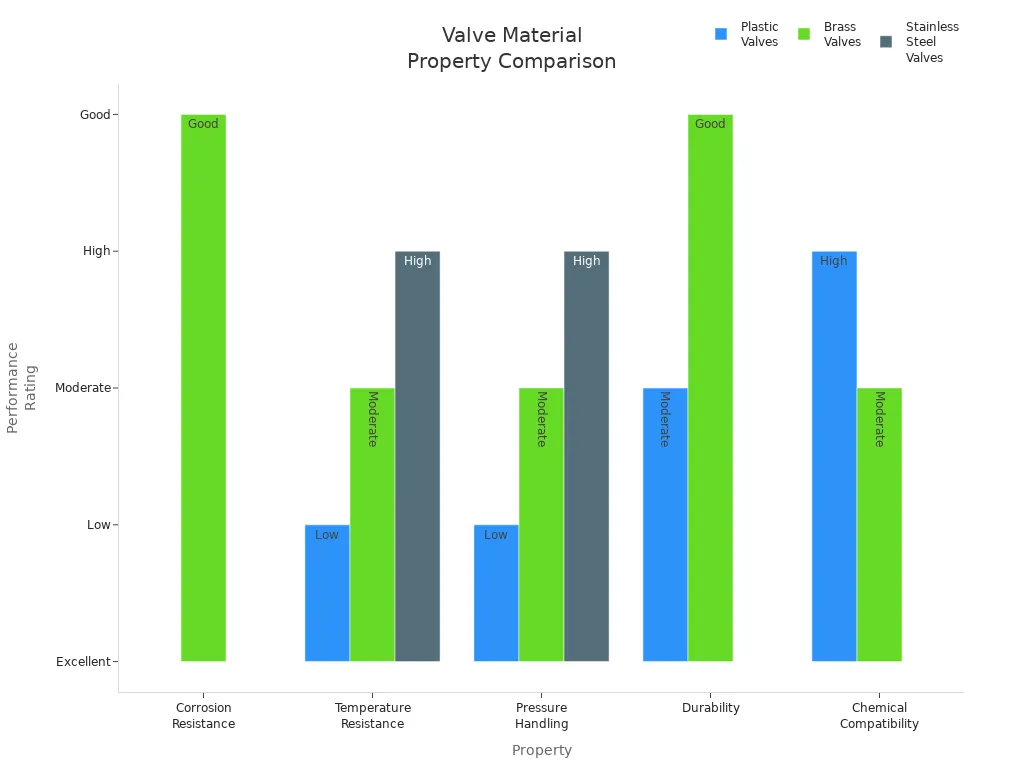

The valve material is just as important as the type. Different materials handle pressure, heat, and chemicals in different ways. Here is a table to help you compare:

| Property | Plastic Valves | Brass Valves | Stainless Steel Valves |

|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Excellent |

| Temperature Resistance | Low | Moderate | High |

| Pressure Handling | Low | Moderate | High |

| Durability | Moderate | Good | Excellent |

| Chemical Compatibility | High | Moderate | Excellent |

Plastic valves work with many chemicals, but not with high heat or pressure. Brass valves are good for homes and small shops, but not for salty or sour things. Stainless steel valves are strong. They do not rust and work in tough places like factories and saltwater.

If you want your system to last, pick a material that fits your place. Think about what goes through your pipes and how hot or cold it gets.

Picking the right valve type and material helps you avoid trouble and keeps your system working well.

Product Range

Range of Valve Manufacturers

When you look for valve manufacturers, you want many choices. A big product range helps you find the right valve for any job. Some jobs need valves for high pressure. Others need valves for special fluids or very hot places. If a manufacturer has many types, sizes, and materials, you have more options.

Picking the best industrial valve is not simple. Valves have many details like pressure ratings, temperature limits, flow features, and control parts. You also need to check if the material works with your system.

Sometimes, your project needs something special. Maybe you need a valve for a hot, harsh place. Or maybe you need one that fits in a small spot. Manufacturers with lots of choices can help you. You can pick from ball valves, gate valves, butterfly valves, and more. This makes your work easier and helps you reach your goals.

- More valve types, materials, and details help manufacturers serve many industries.

- Having many products is important for hard projects that must follow rules.

Compliance with International Standards (ANSI, BS, DIN)

You want your valves to work in any country. That is why international standards are important. When valve manufacturers follow rules like ANSI, BS, and DIN, you know their products are safe. These standards help you avoid problems with safety and fitting.

Here is a table that shows some important standards and what they mean:

| Standard | Description |

|---|---|

| API 600 | For big steel gate valves used in oil, gas, and chemicals. |

| API 602 | For small forged steel gate valves that are strong and reliable. |

| API 608 | For ball valves in oil and gas pipes that must be fire-safe. |

| ISO 9001 | Makes sure manufacturers have good quality systems. |

| ISO 5208 | Lists ways to test valve pressure. |

| ISO 14313 | Sets rules for pipeline valves to make sure they work well. |

| ISO 10497 | Tests valves to see if they work during a fire. |

If you choose valves that meet these standards, you get better quality and fewer problems. You can use them in many countries and industries. You also show others that you care about safety and doing things right.

Tip: Always ask your supplier if their valves meet these standards. This helps you avoid rule problems and keeps your project on track.

Customization Options

Sometimes, you need more than a regular valve. Maybe your system needs a special size. Maybe you need a valve with a different control part. Good valve manufacturers can make changes for you. They can change materials, sizes, and features to fit your needs.

If you work with a manufacturer who listens and changes things, you get better results. Custom valves help you fix problems that normal ones cannot. You also make your system better and safer.

- Picking the right valve means knowing your process and doing some math.

- For hard jobs, you must think about different pressures, temperatures, and fluids.

When you pick a manufacturer with good customization, your project is safer and works better. You also show your team that you care about quality and success.

Quality Standards

Certifications

When you pick valve manufacturers, always check their certifications. These show the company follows strict quality rules. If a manufacturer has good certifications, they care about safety and reliability. Certifications like UL and NSF mean the products are safe. UL certification shows the valve is safe for many jobs. NSF certification is important for valves that touch drinking water. It means the valve passed hard tests and checks.

Here’s a table that shows how different certifications help reliability:

| Certification | Industry/Application | Impact on Reliability |

|---|---|---|

| API | Oil and Gas | Makes sure valves work under high pressure and heat. |

| FDA | Food and Pharma | Checks materials and stops contamination. |

| NSF | Drinking Water | Makes sure safety and performance rules are met. |

| CE | European Union | Meets safety, health, and environment rules. |

If you see these certifications, you can trust the valve. You avoid legal trouble and product recalls. You also build trust with your customers.

Tip: Always ask to see proof of certifications. This helps you check if the manufacturer uses a stamped way to show they follow rules.

Factory System Certifications (e.g., ISO Standards)

Factory system certifications are very important. ISO 9001 is one of the top certifications for valve makers. This means the company uses strong quality rules. ISO 9001 sets up clear steps to stop mistakes and defects. Every step in making a valve gets written down. This keeps the quality high for every valve.

You should look for these certifications when you pick a manufacturer. Here’s why ISO 9001 helps:

- It sets up systems to stop mistakes and keep quality steady.

- It makes sure every step in making a valve is written down and followed.

- It checks and controls suppliers, so the whole supply chain stays strong.

If you see ISO 9001, you know the manufacturer cares about quality and reliability. You get valves that work the same way every time.

Product Certifications (e.g., CE, SIL, ATEX, ABS, CCS, LR, DNVGL, KR, SGS, BV)

Product certifications show a valve meets world safety and quality rules. CE marking is important if you want to sell valves in Europe. It proves the valve meets safety and health rules. CE certification also helps your brand look better and makes it easier to sell in Europe.

SIL certification checks if the valve can lower risks in dangerous places. It follows IEC 61508 rules. If you need high safety, look for SIL-certified valves. ATEX certification is important for valves used in explosive areas. It shows the valve will not cause sparks or explosions.

Other certifications like ABS, CCS, LR, DNVGL, KR, SGS, and BV show the valve passed hard tests for different industries. These certifications prove the manufacturer uses a stamped way to show they follow rules.

- CE marking helps you sell in Europe and shows you care about safety.

- SIL certification means your valve can handle risky jobs.

- ATEX certification keeps workers safe in explosive places.

When you see these certifications, you know the manufacturer follows strong quality rules. You get valves that meet high standards and keep your system safe.

Industry Entry Certifications (e.g., API, Sinopec, CNPC Network Access)

When you want a good valve manufacturer, check their industry entry certifications. These certificates show the company can sell valves to big companies and important industries. If a manufacturer has an API certificate, they follow strict rules for oil and gas. API means American Petroleum Institute. This group makes hard safety and performance rules.

Some manufacturers have network access certificates from Sinopec or CNPC. These are very large companies in China’s energy field. If a manufacturer sells valves to Sinopec or CNPC, they passed many tests. These certificates show the company follows high quality and safety rules.

Why do these certificates matter? You want a manufacturer who can handle big projects. If they have these certificates, their valves work well in hard places. You also know they passed many checks for quality and trust.

Tip: Always ask your supplier if they have API, Sinopec, or CNPC network access certificates. This helps you avoid problems and shows you care about quality.

If you see these certificates, you can trust the manufacturer. Their valves will meet the rules for your project. You also show your team you picked a company with strong quality rules.

Testing & Documentation

Testing and documentation are very important when picking a valve manufacturer. You want to make sure every valve works right. Good manufacturers use strict testing steps. They also keep clear records for each product.

Here’s a table that shows some common testing standards and what they mean:

| Standard | Description |

|---|---|

| API STD 598 | Covers inspection, examination, and pressure test requirements for valves. |

| API SPEC 6FA | Sets rules for testing valves under fire conditions. |

| API STD 607 | Lists fire type-testing for quarter-turn valves. |

| API STD 622 | Checks valve stem packing for fugitive emissions. |

| BS EN 12266-1 | Sets pressure test rules and acceptance for metallic valves. |

| BS EN 12266-2 | Adds extra test rules for metallic valves. |

Manufacturers who follow these rules care about quality. They test every valve for leaks, pressure, and fire safety. They also check if the valve can handle hard jobs. Good records mean you get proof for every test. You can see how the valve did and know it meets the rules.

If you ask for test reports and certificates, you get proof of quality. You can trace every valve back to its tests. This helps you avoid surprises and keeps your system safe.

Note: Always ask for testing documents before you buy. This helps you make smart choices and shows you care about quality.

When you pick a manufacturer with strong testing and clear records, you protect your business. You get valves that work well and last longer.

Manufacturing Technology

Production Capabilities

When you check valve manufacturers, see how they make valves. Good factories use strong machines and smart systems. This helps valves work well and last longer. Top companies use advanced tools to build valves with tight tolerances. Automated machines help make every valve the same. This means you do not worry about leaks or breakdowns.

Here is a table that shows what top manufacturers use to make valves better and faster:

| Evidence Type | Description |

|---|---|

| Strict Quality Control | They check chemicals and mechanical parts during production. |

| Certifications | They follow ISO 9001 and API 6D rules for quality. |

| Innovative Design Approaches | They use computers to design hand wheels for strength and easy use. |

| Quality Management Program | They have programs to meet or beat industry standards and keep improving. |

| Adoption of Advanced Technologies | They use low-emission fuels and digital tools to work better. |

You may wonder why automation is important. Automated machines keep every valve precise. This matters in oil and gas, where small mistakes can cause big trouble. Automation also makes production faster. Manufacturers can handle big orders without waiting.

Here is how automation helps:

- You get valves that are more precise and consistent.

- Production is faster, so you get big orders quickly.

- Manufacturers can change designs fast to fit your needs.

Manual work is slower and can cause mistakes. If a factory only uses people, you may see more defects and higher costs. Automated systems fix these problems. They help manufacturers keep up with changes.

Tip: Ask your supplier about their machines and systems. Automated factories usually give better quality and faster service.

Innovation

Innovation helps valve manufacturers stay ahead. If you pick a company that tries new ideas, you get valves that work better and need less fixing. Manufacturers use new materials, smart designs, and digital tools. This makes valves stronger and safer.

Look at this table to see some new ideas:

| Innovation Type | Description |

|---|---|

| Energy Efficiency | New materials and designs save energy and lower costs. |

| Automation | Automated valves give you better control and fewer mistakes. |

| Customization | Special valve solutions fit your needs and make things safer. |

| Improved Materials | Carbon steel, stainless steel, and aluminum make valves tougher and work better. |

| Advanced Coatings | Coatings protect valves from rust and damage, so they last longer. |

| Emerging Materials | Fiber-reinforced polymers are light, resist corrosion, and make strong valves. |

Manufacturers use computer-designed hand wheels. These make valves easier to use and more reliable. Digital tools help factories watch how valves work and find problems early. You get valves that work better and need fewer repairs.

- Computer-designed parts help valves work better.

- Digital tools help plants run smoothly and catch problems early.

If you choose a manufacturer that likes new ideas, you get valves that keep your system safe and working well. You also save time and money on repairs.

Note: Look for companies that talk about new materials, smart designs, and digital upgrades. These things show they want to give you the best valves.

Reputation & Experience

Industry Reputation

When you pick a valve manufacturer, you want one people trust. The company should be respected in the industry. How can you tell if they have a good name? There are some things you can check.

- Inventory Size: If a company has lots of valves, you get them fast. This helps if you need a valve right away.

- Preventive Maintenance: Good companies make sure valves keep working. They have plans to stop problems before they start.

- Valve Repair Capabilities: You want a company that fixes valves quickly. They should have skilled workers and spare parts ready.

- ISO Certification: This means the company follows strict rules for quality and safety. You can trust their valves.

- Understanding of Industrial Systems: The best companies know how your system works. They help you choose the right valve for your needs.

- Commitment to Safety: Safety is very important. You want valves that follow all safety rules and keep everyone safe.

If a manufacturer has these things, they care about doing a good job. You can feel sure about picking them.

Tip: Talk to other companies in your field. They can tell you which manufacturers are trusted and have a good reputation.

Track Record

A manufacturer’s track record shows how well they do over time. You want proof that they do good work. Look for stories about big projects and long partnerships. Here is a table with some examples of how manufacturers helped their clients:

| Manufacturer | Project Description | Outcome |

|---|---|---|

| Ohio Valve | Worked with big companies to make custom valves. | Got long contracts and made sure valves worked their best. |

| Anix USA | Helped a global electronics company with special ball valves. | Made the system work 20% better and had less downtime. |

| Valmet | Put ball valves in a water treatment plant. | Made flow better and the system more reliable. |

| Powell Valves | Used in petrochemical plants. | Made the system 25% more efficient. |

| Valmet | Worked with many EPCs for many years. | Built strong partnerships that helped projects succeed. |

When you see these results, you know the company can handle big jobs. They help clients reach their goals and keep things running well. You want a partner with real success and experience.

Note: Always ask for stories about past projects. These show how the manufacturer solves problems and helps their clients.

Reliability & Support

When you pick a valve manufacturer, you want more than just valves. You want a company that helps you when you need it. Reliability is very important. If you get good support, your system works better. Let’s see what a good manufacturer should give you.

Technical Support

You need technical support that helps you quickly. Good manufacturers help before and after you buy. They answer your questions and help you choose the right valve. They also show you how to set it up. If something goes wrong, they tell you how to fix it. This kind of help makes you trust them and keeps your work safe.

Here’s a table that shows how different services can make you happier:

| Service Type | Description | Impact on Customer Satisfaction |

|---|---|---|

| Customized Services | Special valves made for your needs, so they work best. | Makes the product better and helps your work go smoothly. |

| Safety Compliance | Valves that follow world safety rules to stop accidents. | Makes you feel safe and happy with your choice. |

| Fast Delivery | Valves arrive on time to keep your project moving. | Stops delays and helps you finish work faster. |

| After-Sales Service | Help after you buy, like fixing and checking valves. | Makes you feel safe and keeps your valves working longer. |

You want a team that listens and helps fast. If you have a problem, you should not wait long for help. Fast support means your system does not stop working. When you know help is always there, you feel good about your choice.

Tip: Ask if the company gives 24/7 technical support. Fast help can save you time and money.

After-Sales Service

After you buy, you still need help. Good after-sales service keeps your system working for a long time. You want a company that checks on you, helps with repairs, and honors their warranty. This stops big problems and keeps your equipment working well.

Look at this table to see how after-sales service helps you:

| Service Type | Description |

|---|---|

| Comprehensive Warranty | Covers many problems, so you do not worry about repairs. |

| Scheduled Maintenance | Regular checks stop things from breaking and make valves last longer. |

| Corrective Maintenance | Fixes small problems fast so they do not get worse. |

Scheduled maintenance means someone checks your system before it breaks. Corrective maintenance fixes small problems quickly. A good warranty makes you feel safe. You know the company will help if something goes wrong.

If you want your system to last, pick a company with strong after-sales help. You will spend less money fixing things and avoid shutdowns. Your team will be glad you picked a company that cares about your work.

Note: Always ask about repair plans and warranty details. Good help now means fewer problems later.

Supply Chain

Lead Times

When you plan a project, you want your valves to arrive on time. If you wait too long, your whole schedule can fall apart. Some big projects, like those in oil and gas, can have lead times for valve delivery that stretch over 24 months. For special equipment, you might even wait up to 48 months. That’s a long time to keep your team waiting and your budget stretched.

Most standard pressure valves arrive much faster. You can expect them in a few days or maybe a couple of weeks. If you need a custom valve, the wait gets longer. Custom designs and special features can take several weeks or even months to finish. Here’s a quick look at how lead times can change:

- Standard valves: a few days to a couple of weeks

- Custom valves: several weeks to months

- Major project valves: up to 24–48 months

Tip: Always ask your supplier about delivery times before you order. Reliable lead times and service help you plan better and avoid costly delays.

If you know how long it takes to get your valves, you can set up your project schedule. You avoid last-minute surprises and keep your team moving forward.

Inventory Management

You want your supplier to have good inventory management. If they run out of valves, your project stops. Smart valve manufacturers use demand forecasting and inventory optimization. They look at past sales and market trends to keep the right amount of stock. This means you get what you need, when you need it.

Some companies use more than one supplier. If one supplier has trouble, they can still get valves from another. This keeps your supply chain strong and steady. You don’t have to worry about running out or waiting too long.

Here are some ways manufacturers keep inventory under control:

- Analyze sales data to predict demand

- Diversify suppliers for steady stock

- Optimize stock levels for quick delivery

- Build strong relationships with suppliers

Note: When you work with a manufacturer who manages inventory well, you lower the risk of supply chain problems. Your project runs smoother, and you spend less time waiting.

Good inventory management means you get your valves on time. You avoid delays and keep your work on track. If your supplier pays attention to inventory, you can trust them to deliver every time.

Cost Factors

Purchase Price

When you start shopping for valves, you probably notice a big difference in price. Valves from well-known manufacturers usually cost more than those from smaller suppliers. You might wonder why you should pay extra. The answer is simple. Trusted companies use better materials and stricter quality checks. Their valves last longer and work better. You spend less time fixing leaks or replacing broken parts.

If you buy a cheaper valve, you may save money at first. Later, you could pay more for repairs and downtime. Imagine your system stops working because a valve fails. You lose time and money. Paying a little more now can help you avoid bigger costs later.

Tip: Think about the long-term value, not just the price tag. A reliable valve keeps your system running and saves you headaches.

Here’s a quick comparison:

| Supplier Type | Initial Price | Quality Level | Risk of Failure | Long-Term Cost |

|---|---|---|---|---|

| Reputable Manufacturer | Higher | High | Low | Lower |

| Lesser-Known Supplier | Lower | Variable | Higher | Higher |

Total Cost of Ownership

You need to look beyond the price when choosing a valve. The total cost of ownership (TCO) tells you what you really pay over time. TCO includes the purchase price, but also covers maintenance, service, and spare parts. If you pick the wrong valve, you might face more repairs and longer downtime.

Here are some things that affect TCO:

- Energy efficiency matters. Solenoid valves use energy every time they operate. Manual valves do not need power, so they cost less to run.

- Solenoid valves may cost more at first. Over time, they can save money because they automate your system and cut down on labor.

- Maintenance and service costs add up. If your valve needs lots of repairs, you pay more.

- Spare parts can be expensive. Some valves need special parts that cost more.

- If your system stops working, you lose money. Picking the right valve helps prevent downtime.

Note: Always think about how your valve will work in your system. If you understand your needs, you can avoid problems and save money.

When you add up all these costs, you see that a good valve is worth the investment. You spend less on repairs, energy, and lost time. Your system runs smoother, and you feel confident in your choice.

Directories & Reviews

Curated Listings

It can be hard to pick the right supplier. You want to choose from trusted places. Curated directories make this easier for you. These lists show only verified valve manufacturers, importers, and distributors in the U.S. You can search by valve type, industry, certifications, or location. This helps you find what you need for your project faster.

Here’s what you get when you use a good directory:

| Feature | Description |

|---|---|

| Comprehensive Resource | Connects you with verified manufacturers, importers, and distributors in the U.S. |

| Filterable Listings | Lets you search by valve type, industry, certifications, and location. |

| Up-to-date Contact Details | Gives you current contact info for quick procurement and engineering help. |

| Product Brochures and Catalogs | Offers detailed product information so you can make smart choices. |

| User-friendly Interface | Makes it easy for project managers and buyers to find the right supplier. |

Tip: Pick directories that update their lists often. This way, you get the newest information and save time.

Client Feedback

You can learn a lot from what other customers say. Reviews and case studies show how valves work in real life. When you read about other companies, you see how a manufacturer solves problems. This helps you avoid surprises and pick a partner you trust.

Check out these real examples:

| Company | Challenge | Outcome |

|---|---|---|

| Company A | Tight deadline for custom trunnion ball valves | Received valves on time with flawless performance, improving operational efficiency |

| Company B | Old valves affecting efficiency | Extended lifespan of valves, lowered maintenance costs, smooth operations |

| Company C | Failing steam control valves | Prevented unplanned shutdowns, boosted system reliability, cut maintenance costs |

When you look at feedback like this, you know what to expect. You see which suppliers deliver on time and help their clients.

Note: Always read both good and bad reviews. This gives you a fair view and helps you choose the best supplier.

Key Questions

Product Details

When you talk to a valve manufacturer, you want to ask smart questions. You need to know what you are buying. If you skip these questions, you might get a product that does not fit your needs. Here are some things you should check before you make a decision.

| Key Product Detail | Description |

|---|---|

| Quality Materials | Ask if they use stainless steel, carbon steel, or alloy steel. These materials last longer. |

| Production Process | Find out if they follow strict quality control, like ISO 9001. This keeps the product safe. |

| Maintenance and Repairs | See if they offer repairs and maintenance. This helps your valve work for many years. |

You should also look for markings and certifications on the valve. These markings show that the product meets safety rules. If you want to be sure about the material, ask for mill test certificates. These certificates tell you what the valve is made of. You can also ask about material grades and where they get their steel. If you check these details, you will feel confident about your choice.

Tip: Always ask for proof of quality. If you see clear markings and certificates, you know the valve is safe and strong.

Support & Warranty

Support and warranty matter just as much as the product itself. If something goes wrong, you want help right away. Good manufacturers offer strong warranties and clear support. Here are some things you should ask about:

| Aspect | Details |

|---|---|

| Warranty Duration | Some companies offer 1-year warranties. Others, like Vent-O-Mat, give you up to 10 years. |

| Conditions for Warranty | Warranties cover defects in materials or workmanship. They do not cover corrosion or misuse. |

| Limitations of Liability | Most warranties do not cover extra costs if something fails. |

| Storage Requirements | You must store the valve indoors. If you do not, the warranty may not work. |

Some companies, like MOGAS, even offer lifetime warranties on materials and workmanship. They promise the valve will not leak and will work as planned. You must install and use the valve the right way to keep the warranty. If you follow the company’s guidelines, you get full support.

- Ask if the warranty covers leaks and performance.

- Check if you need to store the valve a certain way.

- Find out how long the warranty lasts.

- Ask if the company helps with repairs after you buy.

Note: If you know the warranty terms, you avoid surprises. Good support means you fix problems fast and keep your system running.

You want your project to succeed, so follow these steps when picking a valve manufacturer:

- Know what your valve needs to do.

- Pick the right type and material for your system.

- Check the manufacturer’s reputation and certifications.

- Make sure they test their valves well.

- Ask about custom options and support.

- Look at delivery times and costs.

- Read reviews from other clients.

Start your search today and feel confident about your choice!

FAQ

What should you check before buying a valve?

Look at the material, size, and pressure rating. Make sure the valve fits your system. Ask for test reports and certifications. This helps you avoid problems later.

How do you know if a valve manufacturer is reliable?

Check their certifications and read reviews from other customers. Ask about their experience with projects like yours. Reliable companies answer your questions quickly and give clear information.

Why do certifications matter when choosing a valve?

Certifications show the valve meets safety and quality rules. They help you trust the product. Always ask for proof of certifications before you buy.

Can you get custom valves for special projects?

Yes, many manufacturers offer custom options. You can ask for special sizes, materials, or features. Custom valves help your system work better and last longer.

What are buyer-intent questions for valve selection?

These are questions you ask to make sure the valve fits your needs. For example, you might ask about warranty, support, or delivery times. Good questions help you choose the right product.

How long does it take to get a valve delivered?

Standard valves usually come in a few days or weeks. Custom or big project valves can take longer. Always ask your supplier about delivery times before you order.

What kind of support should you expect after buying a valve?

You should get help with installation, maintenance, and repairs. Good manufacturers offer clear warranties and fast support. This keeps your system running smoothly.