Steam control valves are essential components in numerous industrial operations, ensuring precise management of steam flow and pressure. A steam control valve plays a pivotal role in regulating processes where accuracy and reliability are critical. Key devices, such as the steam flow control valve, ensure the smooth distribution of steam within complex systems, while the steam pressure reducing valve safely adjusts pressure to meet system demands. Similarly, the steam pressure regulating valve balances pressure levels to maintain consistency across applications. These valves enhance efficiency, conserve energy, and uphold safety standards in industries ranging from power generation to food processing. Understanding their functions, benefits, and applications is crucial for optimizing industrial performance and achieving long-term operational success.

Introduction to Steam Control Valve

Steam control valves are vital components in industrial systems, designed to regulate steam flow and maintain precise operating conditions across various applications. Pressure regulating valve manufacturers play a critical role in providing solutions that ensure consistent downstream pressure, improving overall system stability. Temperature regulating valves offer precise temperature control, essential for processes requiring stringent thermal management. Advanced options like the Pneumatic diaphragm control valve and Pneumatic globe valve combine precision and reliability, making them ideal for industries such as chemical processing, power generation, and pharmaceuticals. By integrating these valves into operations, industries achieve enhanced efficiency, safety, and system longevity, ensuring seamless performance even under demanding conditions.

Definition of steam control valve.

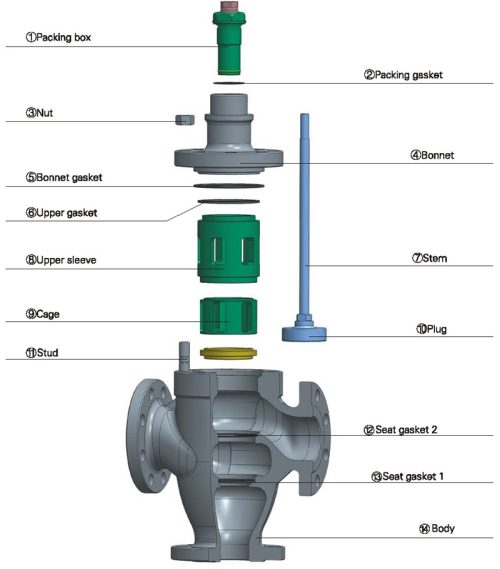

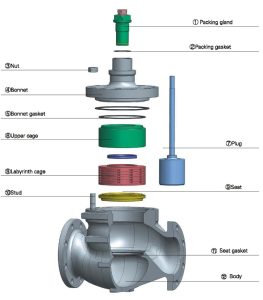

Steam control valves are specialized devices designed to regulate the flow and pressure of steam within industrial systems. Constructed with components such as valve bodies, actuators, and control mechanisms, these valves offer precise operation in demanding environments. Their primary purpose is to manage steam movement effectively, ensuring stable pressure levels and consistent flow rates across processes. This regulation is essential for maintaining system efficiency, preventing equipment damage, and ensuring workplace safety. Widely utilized in power generation, chemical processing, and manufacturing, steam control valves contribute to optimizing energy usage and safeguarding the reliable performance of intricate industrial operations.

Importance of steam control valves in industrial processes.

Steam control valves are indispensable in industrial processes, ensuring high levels of efficiency, safety, and reliability. By regulating steam pressure and flow with precision, these valves maintain optimal operating conditions, preventing system failures and equipment damage. Their capability to control steam parameters reduces energy consumption, contributing to cost-effective and sustainable operations. Furthermore, steam control valves play a key role in safeguarding workplace safety by minimizing risks associated with pressure surges or thermal imbalances. Used across industries such as power generation, chemical manufacturing, and food processing, they are critical for achieving seamless performance and maintaining the longevity of complex systems.

Overview of their role in maintaining operational efficiency.

Steam control valves are vital to maintaining operational efficiency in industrial systems. By precisely regulating steam flow and pressure, they optimize energy usage and create stable operating conditions that enhance system performance. Their ability to prevent excess steam wastage and maintain consistent pressure levels reduces operational costs while extending equipment lifespan. These valves ensure seamless process continuity, minimizing disruptions caused by fluctuations or failures. Industries benefit from their role in safeguarding productivity, improving process reliability, and achieving energy-efficient outcomes. Whether in power generation, food processing, or chemical manufacturing, steam control valves are central to driving efficient, cost-effective, and reliable operations.

Key Functions of Steam Control Valve

Steam control valves perform critical functions that ensure optimal performance and safety in industrial processes. These valves regulate steam flow and pressure with precision, maintaining consistent system stability in dynamic operating conditions. By managing critical parameters, they prevent pressure surges, reduce energy wastage, and safeguard equipment from potential damage. Their ability to maintain controlled environments enhances overall operational efficiency while minimizing downtime. Designed to meet the demands of industries like power generation, chemical manufacturing, and food processing, steam control valves play an indispensable role in delivering energy-efficient solutions and ensuring the reliability of complex industrial systems under varying conditions.

Precise regulation of steam flow.

Steam control valves excel in achieving precise regulation of steam flow, a critical aspect of efficient industrial operations. Utilizing advanced technologies such as pneumatic or electric actuators and feedback control systems, these valves adjust steam flow with remarkable accuracy based on real-time system demands. This precise control ensures consistent pressure and temperature levels, minimizing energy waste and enhancing overall process stability. By preventing issues like over-pressurization or uneven heat distribution, steam control valves contribute to safer working conditions and extend equipment lifespan. Their role in optimizing energy usage and maintaining stable operations makes them indispensable in achieving peak industrial performance.

Pressure and temperature control to meet system requirements.

Steam control valves play a pivotal role in managing pressure and temperature to meet specific system requirements in industrial processes. Leveraging technologies like modulating actuators and feedback control systems, these valves ensure precise adjustments to maintain optimal conditions. By regulating steam flow in response to real-time demands, they prevent pressure surges and temperature fluctuations that could compromise safety and efficiency. This control not only safeguards equipment from damage but also enhances energy utilization and process stability. Across industries such as power generation and chemical manufacturing, the ability to achieve consistent pressure and temperature is critical for reliable and cost-effective operations.

Enhancing safety through controlled steam distribution.

Steam control valves are essential for enhancing safety by ensuring controlled steam distribution in industrial settings. By accurately regulating steam flow and pressure, these valves prevent dangerous scenarios such as over-pressurization and thermal overload, which could lead to equipment failure or system breakdowns. Advanced control mechanisms and real-time responsiveness minimize the risk of sudden pressure surges or uneven steam delivery, creating a stable and secure operational environment. This level of control not only safeguards personnel but also protects valuable equipment and infrastructure. Across industries, from power plants to chemical factories, controlled steam distribution is a critical factor in accident prevention and operational safety.

Types of Steam Control Valves

Steam control valves come in various types, each suited to specific applications. Globe valves are ideal for precise steam flow regulation, offering excellent throttling abilities in demanding environments. Ball valves, known for their durability and tight sealing, are often used in systems requiring quick shutoff and minimal pressure drop. Butterfly valves, lightweight and compact, excel in high-capacity steam flow applications where space is a concern. Pressure-reducing valves play a critical role in maintaining consistent downstream pressure, ensuring operational stability. Each type of steam control valve delivers unique advantages, enabling industries to manage steam effectively, enhance efficiency, and meet tailored process requirements.

Globe Valves for Steam Control:Advantages of globe valves in applications requiring precise control.

Globe valves are highly efficient for steam control in applications demanding precise regulation. Their design allows for accurate flow adjustment, giving operators the ability to fine-tune steam pressure and flow rates. Built with durability in mind, these valves perform reliably even under high-pressure and high-temperature conditions, making them an excellent choice for demanding industrial environments. Industries like chemical processing and power generation rely on globe valves to maintain strict control over steam systems, ensuring process stability, energy efficiency, and operational safety. Their robust construction, coupled with precise modulation capabilities, makes globe valves indispensable for critical applications where control is paramount.

Ball Steam Control Valves:Features and suitability for high-capacity systems.

Ball steam control valves are designed to excel in high-capacity systems, offering durability and efficiency in demanding industrial environments. Their structure, featuring a spherical closure element, allows for superior handling of high flow rates with minimal pressure drop, making them highly effective in large-scale operations. Easy to operate and maintain, ball valves are prized for their ability to provide reliable steam regulation even under challenging conditions. Industries like oil and gas depend on these valves for managing extensive steam systems where consistent flow control is vital. Their robust construction and versatility make ball valves a preferred solution for ensuring productivity and safety in high-capacity applications.

Butterfly Steam Control Valve:Compact design and ease of operation for specific systems.

Butterfly steam control valves are valued for their compact design and straightforward operation, making them an excellent choice for systems with space constraints. Their lightweight construction and small footprint allow for easy installation and efficient use in confined environments. The simple quarter-turn operation provides swift and precise steam control, ensuring optimal system performance with minimal effort. These features make butterfly valves particularly suited for applications like HVAC systems and water treatment facilities, where reliable steam flow management is essential. Their ability to combine space efficiency with ease of use positions butterfly valves as a practical solution for specific industrial needs.

Automatic Steam Control Valves:Application of modern automation for advanced operations.

Automatic steam control valves leverage modern automation to optimize performance and precision in advanced industrial operations. These valves integrate smart technologies, enabling real-time monitoring and adjustments to maintain accurate steam flow and pressure. Automation enhances efficiency by reducing manual intervention, minimizing energy wastage, and improving system responsiveness. Industries such as manufacturing and energy benefit significantly from these innovations, as precise steam control is essential for maintaining productivity, ensuring safety, and achieving cost-effective operations. By adopting automatic steam control valves, industries gain a competitive edge, with streamlined processes and reduced downtime, tailored to the demanding requirements of modern applications.

Industrial Applications of Steam Control Valves

Steam control valves are fundamental to maintaining efficiency, safety, and reliability across diverse industries. In power generation, they regulate steam flow to optimize turbine performance and energy output. Chemical processing plants rely on these valves to control steam for precise temperature and pressure management, ensuring consistent product quality. HVAC systems use steam control valves to maintain thermal balance, improving overall operational efficiency. Additionally, in food and beverage manufacturing, they are crucial for processes such as steam sterilization, ensuring hygiene standards. By effectively managing steam flow and pressure, these valves play a pivotal role in minimizing downtime, conserving energy, and enhancing the safety of industrial operations.

Benefits of Using Steam Control Valves

Steam control valve offer numerous benefits that make them indispensable in industrial operations. They enhance efficiency by ensuring precise control of steam flow and pressure, which reduces waste and optimizes system performance. By maintaining stable operating conditions, these valves improve safety, preventing pressure-related accidents and equipment failures. Their ability to minimize energy consumption directly translates into cost savings and greater sustainability. Additionally, steam control valve extend the lifespan of industrial systems by reducing wear and tear through consistent performance. Their role in minimizing downtime and maintaining operational continuity is critical in industries such as power generation, chemical processing, and food manufacturing.

Maintenance and Troubleshooting of Steam Control Valve

Regular maintenance of steam control valve is crucial for their optimal performance and longevity in industrial systems. Routine inspections help identify issues such as leaks, pressure inconsistencies, or actuator malfunctions before they escalate into costly disruptions. Key troubleshooting approaches include checking for clogged ports, worn seals, or calibration errors in control mechanisms. Cleaning components and replacing damaged parts promptly can restore efficiency and reliability. Advanced diagnostic tools also enable precise identification of system irregularities. By scheduling preventive maintenance and addressing problems proactively, industries ensure the valves continue to deliver consistent pressure and flow control, safeguarding both system integrity and operational productivity.

Future Trends in Steam Control Valve Technology

The future of steam control valve technology lies in the adoption of smart systems and innovative materials. Integration with IoT and smart sensors enables real-time monitoring and predictive maintenance, reducing downtime and optimizing performance. These intelligent systems can adapt to dynamic operating conditions, ensuring precise control of steam flow, pressure, and temperature. Advanced materials, such as corrosion-resistant alloys and self-lubricating composites, enhance durability and extend valve life in demanding environments. Additionally, energy-efficient designs and AI-driven diagnostics are paving the way for greater sustainability and reliability. These advancements promise to revolutionize industrial applications, ensuring superior productivity and operational adaptability.

FAQ Steam Control Valve

Q1: What is the primary role of an electric globe valve in steam control systems?

A1: An electric globe valve is designed to precisely regulate steam flow in industrial applications. Using an electric actuator for control, it ensures accurate adjustment in response to system requirements. This makes it ideal for processes requiring high sensitivity and consistency, such as in chemical or pharmaceutical manufacturing, where maintaining stable flow and pressure is critical. Its capacity for precise modulation enhances efficiency and reduces energy consumption in steam distribution networks.

Q2: How does a pneumatic control valve contribute to efficient steam regulation?

A2: A pneumatic control valve uses compressed air to drive the actuator, providing responsive and reliable steam control in high-demand industrial environments. It is well-suited to applications requiring rapid adjustments, such as in power plants or food processing facilities. These valves excel in harsh settings thanks to their durability and simplicity, allowing operators to maintain control over steam pressure and temperature with minimal downtime or performance loss.

Q3: What are the advantages of using an electric control valve in modern industrial systems?

A3: An electric control valve offers excellent performance in industrial steam systems by integrating advanced digital capabilities. These valves, driven by electric actuators, support seamless communication with automated systems, enabling real-time monitoring and control of steam pressure and flow. Their integration with IoT and smart diagnostics tools not only enhances operational precision but also facilitates predictive maintenance, boosting both the reliability and adaptability of industrial processes.

Conclusion Steam Control Valve

Steam control valves are integral to maintaining system efficiency and safety across diverse industrial applications. Among these, the self-operated pressure regulating valve stands out for its ability to autonomously manage steam pressure without external energy sources, ensuring consistent system performance. Similarly, the self-operated regulating valve and the self-operated control valve offer reliable and efficient steam flow adjustments, enhancing both operational stability and energy conservation. These valves are essential in industries requiring precise control, such as power generation, chemical processing, and food manufacturing. By integrating these solutions, businesses achieve optimized operations while ensuring system safety, adaptability, and long-term sustainability in demanding environments.