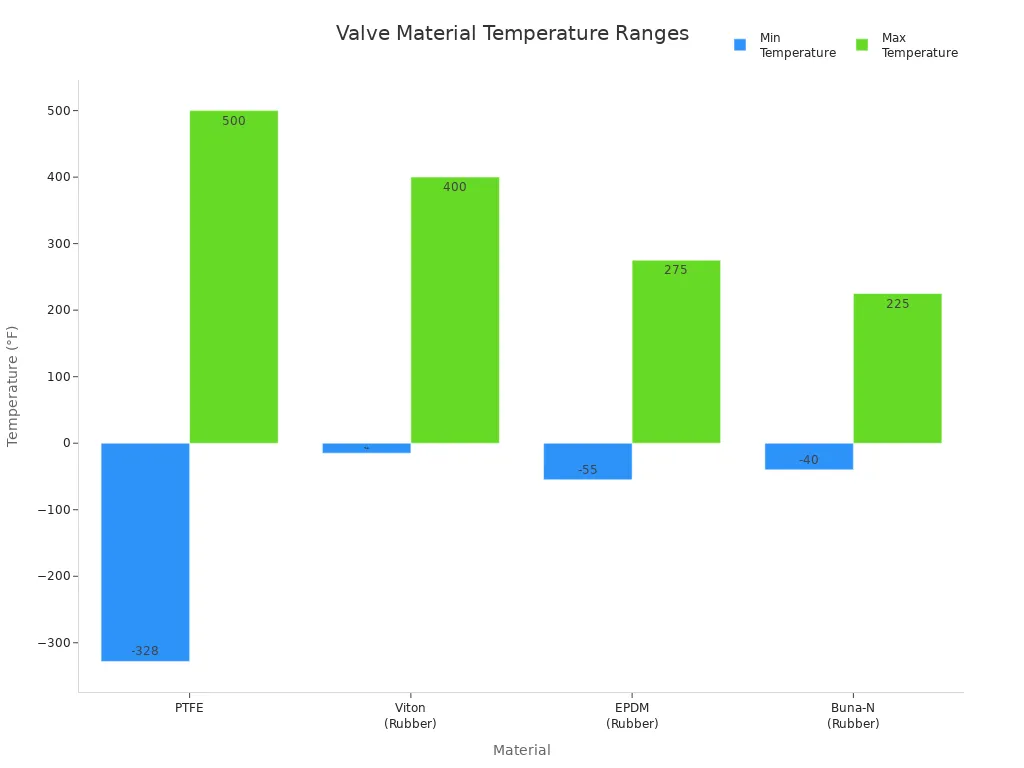

If you use strong chemicals or very hot or cold things, you need a ptfe valve. PTFE is special because it can handle almost any chemical. It works in temperatures from -328°F to 500°F. PTFE has a surface that things do not stick to. It also lasts a long time. You can find ptfe in butterfly valves, ball valves, and Pneumatic diaphragm valves. Look at the table below to see how ptfe, Viton, EPDM, and Buna-N rubber valves are different. They are not the same in how they handle chemicals, how long they last, and how much they cost.

| Material | Chemical Compatibility | Temperature Range | Durability | Cost |

|---|---|---|---|---|

| PTFE | Handles almost all chemicals | -328°F to 500°F | Very strong, does not react | Highest |

| Viton (Rubber) | Works well with oils, fuels, many chemicals | -15°F to 400°F | Strong, bends easily | Moderate |

| EPDM (Rubber) | Good for water, steam, acids, alkalis | -55°F to 275°F | Strong, bends easily | Lower |

| Buna-N (Rubber) | Good for oils, weak chemicals | -40°F to 225°F | Medium strength, bends easily | Lowest |

Tip: Pick ptfe if you work in tough places or need a valve that can handle many chemicals.

Valve Materials

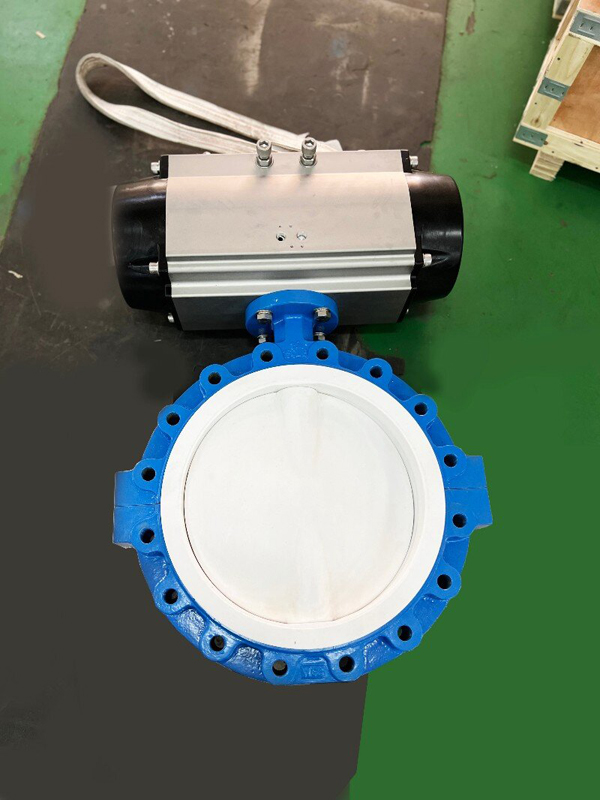

PTFE Valve

Properties

PTFE valves are used in many places. PTFE can handle almost all chemicals. Its surface is smooth, so things do not stick. You can use PTFE valves in hot or cold spots. PTFE valve seats last a long time and do not wear out fast. PTFE stays strong with acids, bases, or solvents. You see PTFE in butterfly valves and diaphragm valves. PTFE valve seats help stop leaks and keep things safe.

Note: PTFE is special because it does not let things stick. It also works in very hot or cold places. PTFE gives you good results in hard jobs.

Applications

PTFE valves are used in chemical plants and labs. They are also in food factories. PTFE works well in butterfly and diaphragm valves. You pick PTFE for strong acids, chlorine, or tough chemicals. PTFE valve seats are good for water cleaning and medicine making. You see PTFE in butterfly valves when you compare it to rubber or metal. PTFE valves work in steam lines and places with big temperature changes. You choose PTFE when you need safety and chemical resistance.

Metal Valves

Properties

Metal valves are made from steel, stainless steel, or cast iron. Stainless steel valves do not rust and last a long time. Cast iron valves are strong and work with water and steam. Alloy valves can take high pressure and heat. Metal valves do not bend or break easily. You find metal valves in butterfly and diaphragm valve designs for hard jobs.

| Material | Market Share (2024) | Key Characteristics and Applications |

|---|---|---|

| Steel (Stainless Steel) | 44% | High strength, excellent corrosion resistance; suitable for corrosive chemicals, oil & gas, extreme environments. |

| Cast Iron | Significant | Robust, cost-effective; used for non-corrosive fluids like water and steam; good for high-pressure applications. |

| Alloy-based | Smaller share | Used in high-pressure and high-temperature environments; materials include duplex stainless steel, alloy 20, Inconel. |

| Plastics & Others | Niche applications | Used for specialized or less demanding applications. |

In the US, stainless steel is picked most for chemicals and oil & gas. Cast iron is still used for water and steam. Alloy valves are chosen for high-pressure systems. Metal valves give you many choices for different jobs.

Applications

Metal valves are used in oil plants, water plants, and steam systems. Metal butterfly and diaphragm valves work in high-pressure places. You pick metal valves for hot liquids or gases. Metal valves are used in factories, cities, and energy plants. You see metal valves in butterfly valves when you need strength and long life.

Rubber Valves

Properties

Rubber valves use Viton, EPDM, and Buna-N. Rubber bends and seals well. It works with water, steam, and weak chemicals. Rubber valves do not cost a lot. You find rubber in butterfly and diaphragm valves for low pressure. Rubber valves do not last as long as PTFE or metal.

Applications

Rubber valves are used in water systems and HVAC. They are also in low-pressure steam lines. Rubber butterfly and diaphragm valves are picked when you need to save money. You pick rubber valves for weak chemicals or when you need them to bend. Rubber valves are used in food, medicine, and city water systems. You see rubber in butterfly valves when you look at cost and bending.

Chemical Compatibility

PTFE

PTFE valves are best for handling strong chemicals. PTFE can resist almost every chemical you use. You see PTFE in chemical plants and labs. It does not react with acids, bases, or solvents. PTFE stays safe with chlorine, sulfuric acid, and hydrofluoric acid.

PTFE is strong because of its special structure. Chemicals do not stick to it or break it down. PTFE valves last longer and need less fixing. PTFE works in hot and cold places. You do not worry about heat or cold changing how PTFE handles chemicals.

Note: PTFE valves work with more tough chemicals than metal or rubber valves. You can use PTFE with many acids, solvents, and hydrocarbons. Other materials might get damaged.

Here is a table to help you compare chemical resistance and compatibility:

| Material | Chemical Resistance | Temperature Range | Key Characteristics and Applications |

|---|---|---|---|

| PTFE | Excellent | -200°C to 260°C | Great for tough chemicals, good for hard jobs |

| Stainless Steel | Good | -100°C to 500°C | Strong, but needs help with some chemicals |

| NBR (Rubber) | Moderate | -40°C to 120°C | Bends easily, not for strong chemicals |

| EPDM (Rubber) | Good | -40°C to 120°C | Good for water and steam, not for oils or tough chemicals |

Pick PTFE if you need strong chemical resistance. PTFE valves help keep you safe in hard chemical jobs.

Metal

Metal valves are strong and handle high pressure. You often see stainless steel or cast iron used. Metal valves work with many chemicals. But they do not resist chemicals as well as PTFE. Metals can rust or break down with strong acids or bases. This can cause leaks or damage.

You need to think about rust when you pick metal valves. Stainless steel does not rust easily, but some chemicals can still hurt it. You can add coatings to help, but this costs more. Some metals, like nickel alloys, resist chemicals better. You should always check charts to see if the metal is safe.

- Metal valves can have different types of rust:

- Uniform rust covers the whole valve.

- Galvanic rust happens when two metals touch in chemicals.

- Pitting and crevice rust make small holes or cracks.

- Stress rust can break the valve under pressure.

Tip: Always look at chemical charts and ask the valve maker before using metal valves with strong chemicals.

Use metal valves when you need strength and pressure. Do not use them for the strongest chemicals.

Rubber

Rubber valves use NBR, EPDM, and Viton. These valves bend and seal well. Rubber valves work with water, steam, and weak chemicals. They do not resist chemicals as well as PTFE. NBR works with oils and weak chemicals. But it breaks with strong acids or high heat. EPDM is good for water and steam. It does not work with oils or tough chemicals.

Rubber valves do not handle all chemicals. They can swell, crack, or get weak with the wrong chemicals. Only use rubber valves when you know the chemicals are safe for that rubber.

- PTFE valves resist stronger chemicals than rubber valves.

- Rubber valves are best for water, air, and weak chemicals.

- Viton rubber works better with oils and fuels. But it still does not match PTFE.

Note: Always check if the rubber is safe before using it in chemical jobs. PTFE is safer for strong chemicals.

Temperature Range

PTFE

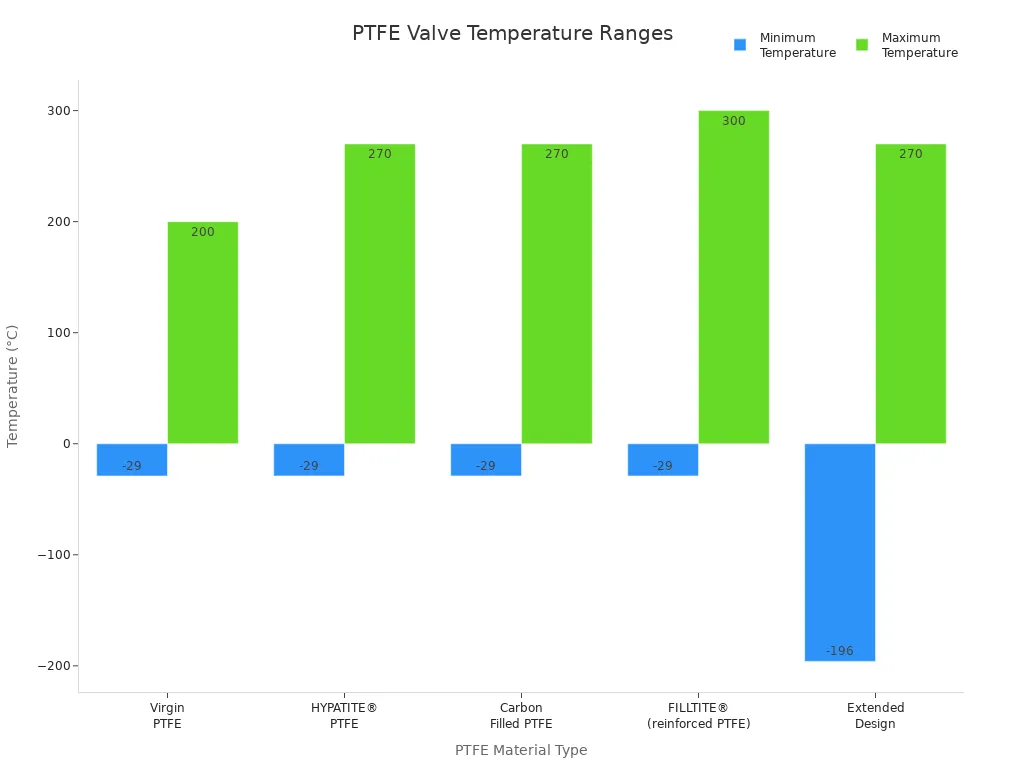

PTFE valves work in very hot and cold places. They can handle big changes in temperature. Most PTFE valves work from -20°F to 410°F. Some special PTFE types go even higher, up to 518°F. These include reinforced or filled PTFE. If you need a valve for a freezer or hot chemicals, PTFE is a good pick. PTFE valves are safe in many temperatures.

| PTFE Material Type | Minimum Temperature Range | Maximum Temperature Range |

|---|---|---|

| Virgin PTFE | -29°C (-20°F) | 200°C |

| HYPATITE? PTFE | -29°C (-20°F) | 260-270°C |

| Carbon Filled PTFE | -29°C (-20°F) | 260-270°C |

| FILLTITE? (reinforced PTFE) | -29°C (-20°F) | 300°C |

| Extended Design (special low temperature) | Down to -196°C (-321°F) | Up to 270°C (518°F) (standard design up to 270°C) |

PTFE valves work in many places. They are used in labs and chemical plants. PTFE keeps its chemical resistance at all these temperatures. You do not have to worry about leaks or damage.

Tip: Pick PTFE valves if you need both chemical and heat resistance.

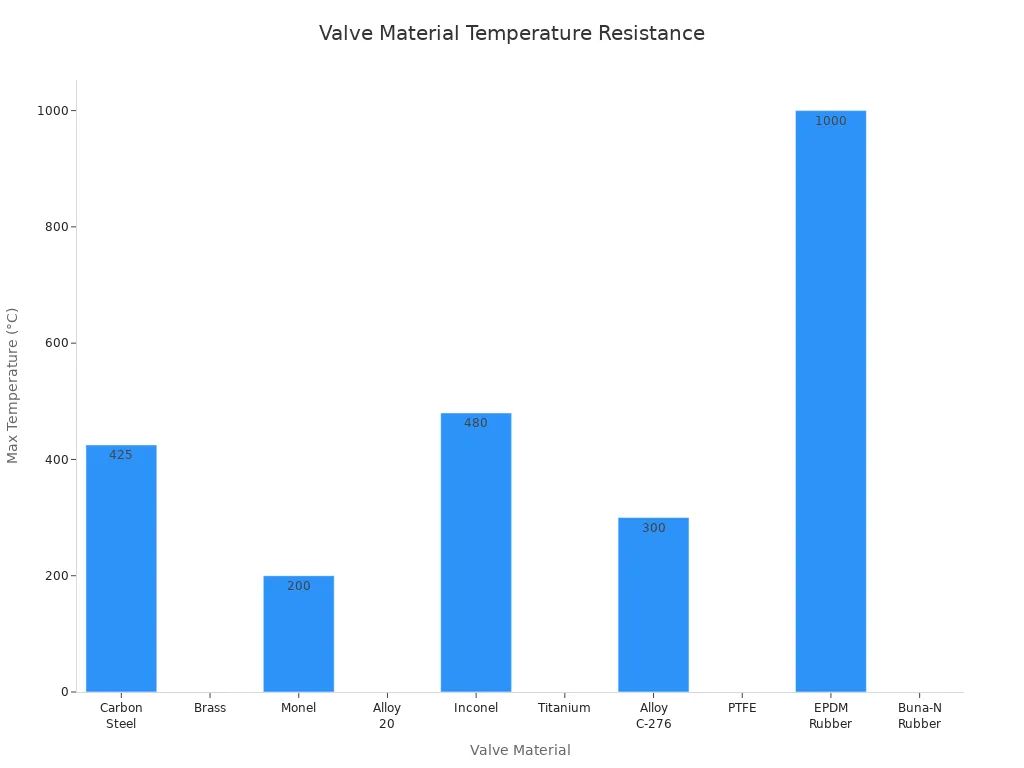

Metal

Metal valves are strong in high heat. Some metals, like stainless steel and titanium, work above 500°F. Special alloys, like Inconel or Alloy C-276, go even higher. You find these valves in power plants and refineries. Heat is a big problem in these places.

| Valve Material | Temperature Resistance | Key Characteristics |

|---|---|---|

| Carbon Steel | Satisfactory heat resistance (moderate to high) | Improved abrasion resistance due to extra carbon |

| Brass | Lower heat resistance than stainless steel, higher than carbon steel | Good for fuels, air, water, oils |

| Monel | High heat and corrosion resistance | Nickel superalloy, excellent in saline and corrosive environments |

| Alloy 20 | High corrosion resistance, less expensive than superalloys | Stainless steel-superalloy hybrid |

| Inconel | Very high resistance to oxidation and heat | Nickel-chromium alloy, withstands extreme heat and pressure |

| Titanium | Can withstand extremely high temperatures | Highly corrosion resistant, used in nuclear plants |

| Alloy C-276 | Exceptional corrosion resistance | Nickel-molybdenum-chromium alloy for harsh chemical environments |

Pick metal valves for the highest heat. Metal valves stay strong under pressure. This is important for many jobs. But not all metals resist chemicals like PTFE. Always check if the metal is safe for your chemicals.

Rubber

Rubber valves work best at normal temperatures. EPDM rubber works from -40°C to 130°C (266°F). Buna-N rubber works in a similar range but not as high. If you use rubber valves above their limit, they can crack or leak. This can cause problems.

- Silicon rubber seals can go up to 300°C, but most rubber valves fail sooner.

- Rubber cannot seal well at very high heat.

- For high heat, use metal or graphite seals.

Rubber valves do not handle heat like PTFE or metal. Use rubber valves for water, air, or weak chemicals at normal heat. Do not use rubber valves for high heat.

Note: Rubber valves get old and stiff with heat. Always check the temperature rating before you pick a rubber valve.

Durability

PTFE

PTFE valves last a very long time. They do not wear out or get damaged by chemicals. PTFE keeps its shape and strength for years. You can use PTFE valves in tough places where others break. PTFE does not soak up water or react with most chemicals. This means PTFE works well for a long time. You do not have to replace PTFE valves often, so you save money. PTFE keeps sealing tight and does not crack or fall apart. PTFE is a great pick for chemical plants, labs, and places with very hot or cold temperatures.

PTFE valves work well for a long time, even in hard jobs. You do not need to fix them often or worry about leaks.

- PTFE valves do not scratch or rust.

- You can use PTFE valves for many years and they still work.

- PTFE stays strong in both hot and cold places.

Metal

Metal valves are strong and last a long time. You see metal valves in places with high heat and pressure. Stainless steel and alloys do not rust easily and last for years. Metal valves can take hits and rough use. They work well in oil, gas, and water systems. But strong acids or bases can hurt metal valves. Sometimes you need special coatings or alloys to make them last longer. Metal valves usually last longer than rubber valves, especially in factories.

| Valve Type | Durability Rating | Longevity | Common Issues |

|---|---|---|---|

| Stainless Steel | High | Long | Rust with strong acids |

| Cast Iron | Moderate | Medium | Breaks if hit hard |

| Alloy | Very High | Very Long | Costs more, needs care |

You should check where you will use the metal valve. Metal valves work well for a long time, but you must watch out for rust in chemical places.

Rubber

Rubber valves bend easily and seal well, but they do not last as long as PTFE or metal. You see rubber valves in water pipes and low-pressure jobs. Rubber can get old, crack, or swell after some time. Rubber valves often fail because they get old, break, or are not put in right. These problems cause leaks and make them not last long. You have to fix or change rubber valves more often.

1. Bad design, like uneven seals, makes leaks and lowers how long they last. 2. Using the wrong rubber makes it get old and lose its seal fast. 3. Problems from making the valve, like cracks or bubbles, make it not last. 4. Putting the valve in wrong or using it in bad places makes it wear out faster.

You can help rubber valves last longer by picking the right rubber, putting them in right, and checking them often. Rubber valves are good for easy jobs, but they do not last long in tough places.

Tip: Always check what kind of rubber you need for your system. Good design and care help rubber valves work better and last longer.

Cost

PTFE

You might notice that PTFE valves often cost more than rubber valves when you first buy them. The price comes from the special material and the way manufacturers make these valves. PTFE stands out because it resists chemicals and lasts a long time. You pay more at the start, but you save money later. PTFE valves do not rust or break down with harsh chemicals. You do not need to replace them as often as rubber valves.

PTFE valves are also much lighter than metal valves. You can install them faster and with less effort. Sometimes, you spend only half as much time and money on installation compared to metal valves. This lighter weight means you do not need heavy equipment or extra workers. Over time, PTFE valves need less maintenance because they do not corrode. You avoid many repair costs that come with metal valves in tough chemical settings.

Tip: If you want to save money on installation and avoid frequent repairs, PTFE valves give you good value over their lifetime.

Metal

Metal valves usually have the highest upfront cost. You pay more for the raw materials, like stainless steel or special alloys. Making metal valves takes longer and needs more steps, such as grinding and hardening. This adds to the price. Metal valves are heavy, so you need more people and tools to install them. The installation process takes longer and costs more than PTFE or rubber valves.

| Aspect | Metal Valves | PTFE Valves |

|---|---|---|

| Material Cost | High | Moderate to High |

| Installation | Heavy, complex, expensive | Light, simple, less costly |

| Maintenance | Expensive, more frequent | Lower, less frequent |

Metal valves last a long time, especially in high-pressure or high-heat jobs. However, if you use them with strong chemicals, you might face rust or corrosion. This leads to higher maintenance costs. You may need to buy special coatings or replace parts more often.

Note: Metal valves work best where you need strength and can handle the higher costs.

Rubber

Rubber valves cost the least when you buy them. You see these valves in places where budgets matter most. The materials, like EPDM or Buna-N, are cheaper than PTFE or metal. Making rubber valves is simple and fast. You do not need special tools or long production times.

You can install rubber valves quickly because they are light. You do not need many workers or machines. However, rubber valves do not last as long as PTFE or metal. They can crack, swell, or wear out faster, especially with strong chemicals or heat. You might need to replace them more often, which adds to the total cost over time.

If you want to save money now and use the valve for water or weak chemicals, rubber valves are a smart choice. For tough jobs, you may spend more in the long run by replacing them often.

Maintenance

PTFE

You will find that PTFE valves need less maintenance than other types. PTFE resists most chemicals, so you do not see much corrosion or buildup. You should still check your PTFE valves often to keep them working well. Look at seals and gaskets for cracks or leaks. Test the actuator to make sure it moves smoothly. Watch the stem packing for signs of wear. Inspect the valve body and trim for any damage. Use lubricants that match PTFE to avoid sticky movement.

Here are some important steps for PTFE valve care:

- Keep the temperature below 120°C for regular use. Short peaks up to 150°C are safe, but higher heat can soften the PTFE lining.

- Avoid negative pressure. This helps prevent the lining from bulging or peeling.

- Control the pressure and differential pressure. This protects the bellows, especially in PTFE-bellows sealed valves.

- Do not let hard particles or impurities enter the valve. Abrasive media can damage the inside.

- Size your valve correctly. If you use a valve at a low opening for a long time, it may vibrate or break.

You should also use routine visual and functional inspections. Open and close the valve fully to check for smooth operation. Use sensors to watch for vibration, pressure changes, or temperature spikes. Schedule maintenance based on how the valve looks and works, not just on a fixed calendar. Store spare PTFE valves in a clean, dry place. Protect the seats and seals when not in use.

Tip: PTFE valves last longer if you watch for leaks, noise, or sticky movement. Early checks help you avoid bigger problems.

Metal

Metal valves need regular care to stay strong and safe. You should inspect for rust, especially if you use the valve with water or chemicals. Look at the body and trim for signs of corrosion or pitting. Check the seals and gaskets for leaks. Test the actuator and controls to make sure they work well. Lubricate moving parts to prevent sticking and wear.

You may need to clean metal valves more often if you use them in dirty or corrosive places. Remove any buildup or deposits inside the valve. If you see rust, use special cleaners or coatings to protect the metal. Replace worn seals and gaskets right away. Watch for vibration or noise, which can mean loose parts or damage.

Note: Metal valves last longer if you keep them clean and fix small problems quickly. Regular checks help you avoid costly repairs.

Rubber

Rubber valves need more frequent checks because rubber can wear out faster. You should look for cracks, swelling, or hard spots in the rubber. Check the seals and seats for leaks. Test the valve by opening and closing it to see if it moves easily. Clean the valve to remove dirt or buildup. Replace any worn or damaged rubber parts as soon as you see problems.

Rubber valves do not like high heat or strong chemicals. If you use them in tough places, inspect them more often. Store spare rubber valves in a cool, dry spot. Protect the seats and seals from sunlight and heat.

| Valve Type | Maintenance Frequency | Common Issues | Key Actions |

|---|---|---|---|

| PTFE | Low | Leaks, sticky motion | Inspect, lubricate, monitor |

| Metal | Medium | Rust, corrosion | Clean, coat, replace seals |

| Rubber | High | Cracks, swelling | Replace, clean, inspect |

Tip: Rubber valves work best when you check them often and replace worn parts quickly. Regular care keeps your system safe and leak-free.

PTFE and PFA Comparison

Chemical Compatibility

If you need a valve for hard jobs, you want strong chemical resistance. Both ptfe and pfa protect well against harsh chemicals. You can use them with acids, bases, and strong solvents. These materials do not react with most chemicals. This means you do not have to worry about leaks or damage. PTFE is well known for its chemical resistance in clean and tough places. PFA is just as good as ptfe for chemical resistance. You can use either one for most chemical jobs.

Here is a quick look at how they compare:

| Property/Characteristic | PTFE (Polytetrafluoroethylene) | PFA (Perfluoroalkoxy copolymer) |

|---|---|---|

| Chemical Resistance | Handles aggressive chemicals like aqua regia and organic solvents | Equal to ptfe; safe for most chemicals |

| Application Preference | Best for high temperature and very corrosive environments | Good when you need easy processing or special shapes |

Tip: You can trust both ptfe and pfa for chemical resistance in labs, factories, and water treatment plants.

Temperature

You need a valve that works in hot and cold places. PTFE and pfa both handle high heat up to about 260°C (500°F). This means you can use them in most labs and factories. PTFE has a higher melting point, but both work the same for daily use. PFA also resists cracking better if the temperature changes fast.

| Property | PTFE | PFA |

|---|---|---|

| Maximum Continuous Use Temperature | About 260°C (500°F) | About 260°C (500°F) |

Note: You can pick either ptfe or pfa for high heat jobs. PFA may last longer if your system heats up and cools down a lot.

Flexibility

Flexibility is important if your valve needs to move or fit in small spaces. PTFE bends a little, so it works for simple valve shapes. PFA bends more and can fit into tricky shapes. This makes pfa better for valves that move a lot or need special designs. PFA is also stronger, so it handles pushing and pulling better than ptfe.

| Property | PTFE Valve Characteristics | PFA Valve Characteristics |

|---|---|---|

| Flexibility | Moderate; less bendy; good for simple designs | High; more bendy; fits complex shapes and frequent movement |

| Mechanical Strength | Tensile strength 20-30 MPa | Tensile strength 25-35 MPa; more durable |

| Durability | Good for chemical resistance | Lasts longer under stress and pressure |

If you need a valve that bends or moves a lot, pfa is the better pick. PTFE is best for simple and steady jobs.

Application Scenarios

Corrosive Chemicals

It is hard to pick the right valve for strong chemicals. Many factories and water plants use liquids that can harm valves fast. You need a valve that does not get damaged by chemicals. PTFE valves are great because they do not react with most chemicals. They also do not rust or corrode. You often see PTFE-lined butterfly valves and diaphragm valves where acids, bases, and solvents move every day.

PTFE valves keep working well even with strong acids, bases, steam, and solvents. Rubber valves like Viton or EPDM work with weak chemicals but break with strong ones. Metal valves can rust or lose their strength in acid or base. PTFE valves help stop rust and lower repair costs. This makes them the best pick for chemical factories.

Here are some chemicals that need PTFE valves instead of metal or rubber:

- Strong acids like sulfuric acid, hydrochloric acid, nitric acid

- Strong bases like sodium hydroxide, potassium hydroxide

- Organic solvents like acetone, methanol, toluene

- Chlorine and other cleaners

- Steam in chemical plants

Tip: Pick PTFE butterfly valves or diaphragm valves for strong chemicals. You get better safety, chemical resistance, and longer life.

High Temperature

You need valves that work well in high heat, like in steam pipes and big machines. Metal valves such as stainless steel, carbon steel, and nickel alloys are strong in hot places. Stainless steel butterfly valves and diaphragm valves do not rust and stay strong in heat. Brass and bronze valves also work well when it is hot.

PTFE valves can handle very cold and very hot temperatures, up to 260°C (500°F). You use PTFE-lined butterfly valves and diaphragm valves for steam and hot chemicals. PTFE seals keep their strength and chemical resistance even when the temperature changes fast. Rubber valves like EPDM work in warm places but fail in high heat. Do not use NBR and FKM for steam because they stop working when it gets too hot.

Good valve materials for high heat and steam:

- Stainless steel (304 and 316)

- Carbon steel

- Bronze

- Alloy steel (Inconel, Hastelloy)

- PTFE (for seals and linings)

- Graphite (for sealing in high heat)

Note: For steam and hot chemicals, pick stainless steel or PTFE-lined butterfly valves and diaphragm valves. You get strong performance and long life.

Water Systems

Valves are used everywhere in water systems, like city water plants and factories. PTFE and rubber valves are important in these jobs. PTFE-lined butterfly valves and diaphragm valves resist chemicals and last long when used with water treatment chemicals like chlorine. Rubber valves such as EPDM and Buna-N seal well and absorb shocks in water systems.

PTFE valves work well and last long in chemical dosing and cleaning jobs. Rubber-lined butterfly valves and diaphragm valves are good for acids, bases, or rough liquids at normal heat. Metal parts give strength, while PTFE or rubber linings stop rust and leaks. These valves help you follow safety rules for water systems.

Main benefits of PTFE and rubber valves in water jobs:

- Stop leaks and keep the system safe

- Resist chemicals in treated water

- Handle changes in pressure and heat

- Meet rules like AWWA, NSF, and EPA

Tip: Use PTFE-lined or rubber-lined butterfly valves and diaphragm valves for water systems. You get safe, strong, and long-lasting valves.

Food & Pharma

When you work in food or pharmaceutical plants, you need valves that keep your products safe and clean. You must follow strict rules to avoid contamination and protect your brand. PTFE, stainless steel, and special rubbers like EPDM and silicone are the top choices for these jobs.

Food and pharma valves must meet many standards. These rules make sure your equipment does not add harmful chemicals or bacteria to your products. You need valves with smooth surfaces, no cracks, and materials that do not react with food or medicine.

Here is a table showing the main standards and what they mean for you:

| Compliance Standards | Description |

|---|---|

| FDA 21 CFR 177.2600 | Rules for rubber seals in food contact applications |

| EC 1935/2004 | European law for food contact materials |

| 3-A Sanitary Standards | Used in dairy for clean equipment design |

| WRAS & NSF | Standards for safe drinking water |

You need valves made from materials that do not rust or react with your products. Stainless steel (316 or 316L) is common because it resists corrosion and cleans easily. PTFE is also popular because it does not stick, does not react, and handles cleaning chemicals well. For seals and gaskets, you use food-grade rubbers like EPDM, silicone, or NBR. These materials stay safe in hot and cold places and do not add taste or smell.

Here are key properties of valve materials for food and pharma:

| Material Type | Key Properties |

|---|---|

| PTFE | Nonstick, chemically inert, resists high and low temperatures, easy to clean |

| Stainless Steel (316/316L) | Corrosion resistant, smooth finish, strong, supports steam cleaning |

| Silicone | Non-toxic, odorless, biocompatible, good for seals and gaskets |

| EPDM | Safe for seals, resists chemicals and heat |

| NBR | Good for oily foods, strong and cost-effective |

Compatibility Checklist

Key Questions

When you pick a valve, you should ask smart questions. These questions help you know if the valve will work well. You want your butterfly valve or diaphragm valve to last and be safe. Here are some important questions to think about:

- What will go through the valve?

- Does the valve material stand up to the chemicals you use?

- Can the valve handle the heat and pressure in your system?

- Will the butterfly valve or diaphragm valve meet rules like ASTM, ANSI, or ISO?

- Is the valve tough enough for stress?

- Are the seals and elastomers good for your media and conditions?

- Does the valve come from a trusted company with good parts?

You should answer these questions before you choose a valve. This helps you stop leaks, rust, and bad performance.

Tip: Always check how well the valve resists chemicals and heat. This keeps your system safe and helps your work go smoothly.

Here is a table to help you see how common valve materials match up:

| Material | Advantages | Limitations | Typical Applications |

|---|---|---|---|

| Brass | Strong, lasts long, does not rust, low cost | Not good for high heat or pressure | Air, diesel, vacuum, safe gases |

| Carbon Steel | Handles high pressure | Not good with many chemicals, lower heat | Hydraulic systems |

| Stainless Steel | Very strong, does not rust, handles high heat | Costs more | Food, drinks, high pressure or heat |

| Thermoplastic | Does not rust, good for clean jobs | Not good for high pressure or heat | Drinking water, drinks |

Decision Steps

You need simple steps to help you pick the best valve. Follow these steps to check if your butterfly valve or diaphragm valve will work well:

- Know the media

Write down what will go through the valve. Is it water, steam, acid, or solvent? - Check chemical resistance

Look at charts for butterfly valve and diaphragm valve materials. Make sure the material will not rust or break. - Check heat and pressure limits

Find the highest and lowest heat and pressure in your system. Make sure the valve can handle these numbers. - Check strength

Make sure the valve is tough enough for your job. See if it will face shaking, stress, or lots of use. - Check rules and standards

See if the valve meets rules like ASME, ANSI, ASTM, or NACE. This keeps your system safe and legal. - Check supplier quality

Pick valves from companies you trust. Good valves work better and have fewer problems. - Test seal and elastomer fit

Make sure the seals and gaskets work with your media and heat. This stops leaks and keeps your butterfly valve or diaphragm valve working well.

Note: If you follow these steps, you get better compatibility and top performance. You avoid mistakes and keep your system safe.

Here is a table of key things to check for compatibility:

| Factor | Description |

|---|---|

| Media Compatibility | Make sure valve materials match what flows in your system. |

| Chemical Resistance | Pick materials that do not rust or wear out from chemicals. |

| Temperature Tolerance | Choose valves that work in your system’s heat range. |

| Pressure Tolerance | Make sure the valve can handle your system’s pressure. |

| Mechanical Strength | Check if the valve is tough enough for stress and movement. |

| Compliance & Standards | Use valves that meet safety and quality rules for good performance. |

You can use this checklist every time you pick a butterfly valve or diaphragm valve. This helps you get the right fit and great performance for all your jobs.

Common Mistakes

Chemical Compatibility Errors

Some people think any valve works with any fluid. This is not true. Many people pick the wrong valve for chemicals. If you do not check what is in your process, you can get leaks. Small chemicals not listed can hurt your valve. These hidden things can make your valve fail early.

- You might not look at chemical charts or ask for help.

- You may forget to check the temperature for the valve and chemicals.

- Sometimes, you think the valve is safer than it really is.

- You may not think about all the chemicals or changes in your system.

If you miss these details, you can get leaks, rust, and safety problems. You might have to stop work and pay a lot to fix things. Always check what is in your fluids and talk to experts before you choose.

Temperature Oversights

Temperature is important for how long your valve lasts. Many valves break because they are used in the wrong heat or cold. If your system gets too hot or cold, seals can get weak. High heat makes seals wear out faster. Cold makes fluids thick and hard to move. This puts stress on the valve.

You need to pick the right size and material for your valve. If you ignore heat limits, your valve can break and need more fixing. Big changes in temperature can also change how chemicals act. This can hurt your valve. Always check the heat rating for your valve and chemicals.

Good heat control helps your valves last longer. It also helps you avoid expensive repairs.

Maintenance Neglect

Checking and cleaning your valves keeps them safe. If you skip this, you can have problems. PTFE valves can get scratches that make them leak. Metal valves can rust or get stuck if not cleaned. Rubber valves can crack or swell if you do not change old parts.

- You might see leaks, hard handles, or weird sounds if you skip care.

- Dirt can make your valve wear out faster.

- Without oil, moving parts can break quickly.

- If you do not check bolts or seals, your valve can fail fast.

- If you skip pressure tests, you might miss leaks or other problems.

One real example shows that skipping care at an LNG plant caused leaks and lost money. You should check, clean, and change old parts often to stop these problems.

Taking care of your valves saves money, keeps things safe, and helps valves last longer.

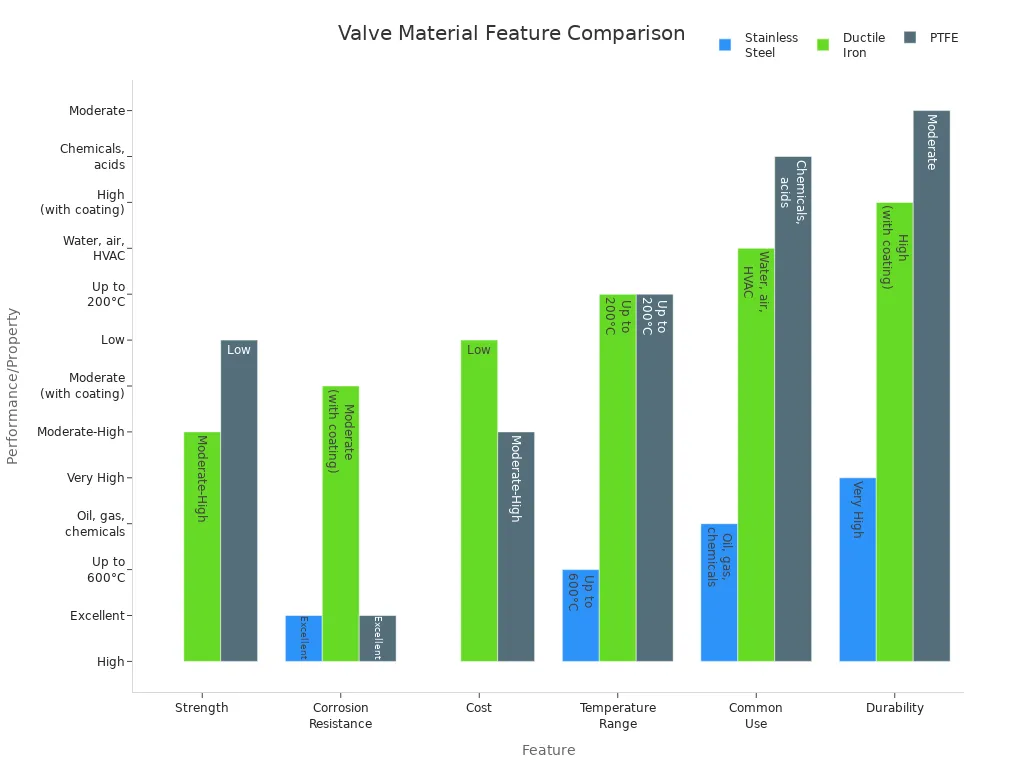

You can pick the best valve by thinking about what you need. Think about how strong it should be, if it needs to resist chemicals, and how much you want to spend. The table below helps you see the differences:

| Feature | Stainless Steel | Ductile Iron | PTFE |

|---|---|---|---|

| Strength | High | Moderate-High | Low |

| Corrosion Resistance | Excellent | Moderate (coated) | Excellent |

| Cost | High | Low | Moderate-High |

| Temperature Range | Up to 600°C | Up to 200°C | Up to 200°C |

| Common Use | Oil, gas, chemicals | Water, air, HVAC | Chemicals, acids |

| Durability | Very High | High (coated) | Moderate |

Always make sure the valve works with your chemicals and heat. Use the checklist and examples to help you choose. For the best choice, look at datasheets or ask a valve expert.

FAQ

What makes PTFE valves better for chemical resistance?

PTFE valves resist almost all chemicals. You can use them with acids, bases, and solvents. PTFE does not react or corrode. This keeps your system safe and reduces leaks.

Can you use PTFE valves for food and drinking water?

Yes, you can. PTFE is non-toxic and does not add taste or smell. Many PTFE valves meet FDA and NSF standards. You often see them in food, beverage, and water systems.

How do PTFE valves compare to metal valves for high temperatures?

PTFE valves handle high heat up to 500°F. Metal valves can go even higher, depending on the alloy. You should pick PTFE for chemical resistance and metal for extreme heat or pressure.

Are rubber valves safe for strong acids or bases?

No, rubber valves do not resist strong acids or bases well. They can swell, crack, or leak. You should use PTFE valves for strong chemicals. Rubber works best with water or weak chemicals.

How often should you check or maintain PTFE valves?

You should inspect PTFE valves regularly. Look for leaks, cracks, or sticky movement. PTFE needs less maintenance than metal or rubber. Early checks help you avoid bigger problems.

Can you use PTFE valves outdoors or in freezing weather?

Yes, you can use PTFE valves in very cold places. PTFE stays strong down to -328°F. You should still protect the valve from physical damage and dirt.