Efficient steam system management relies on the precise regulation of flow and pressure, making a control valve an essential component in various industrial processes. A control valve designed for slow opening and closing plays a critical role in maintaining system integrity by preventing abrupt changes that could lead to hammering or operational inefficiencies. The ability to modulate steam flow with precision ensures optimal performance, energy savings, and safety throughout the system. Selecting the right control valve for specific applications is vital, as it significantly impacts overall functionality and reliability. we’ll examine the types of control valves that excel in steam flow regulation, their features, and why slow actuation is key to maintaining process stability.

Introduction to Control Valve

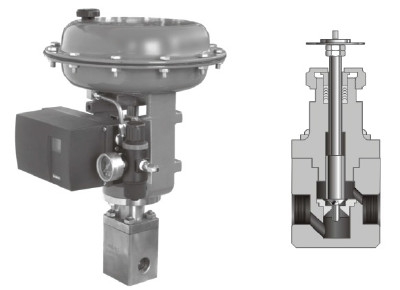

Control valves are indispensable in industrial systems where the regulation of steam flow is critical for maintaining efficiency, safety, and operational precision. These valves, designed to modulate the rate of flow or pressure, are tailored to meet specific industrial needs. Renowned pressure regulating valve manufacturers produce advanced solutions to handle demanding conditions, ensuring system reliability. Among the most effective types, a temperature regulating valve excels in maintaining consistent thermal levels, while a Pneumatic diaphragm control valve ensures precise modulation for varied applications. Similarly, the Pneumatic globe valve stands out for its robust design and performance in controlling steam flow. By facilitating slow opening and closing, these valves prevent system disruptions and ensure smooth, seamless operation.

Types of Control Valve Used for Steam Flow

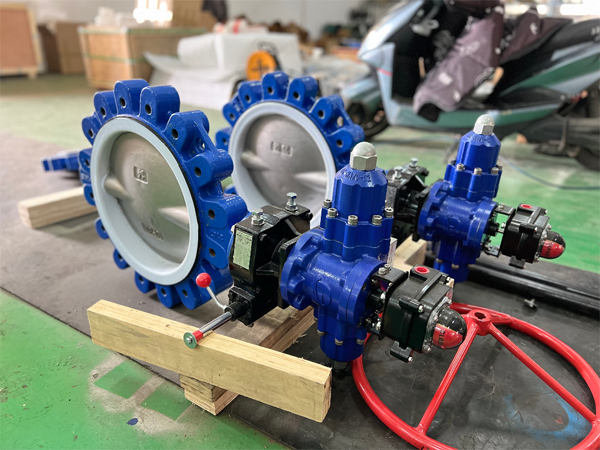

Control valves designed for steam applications must combine precision and durability to regulate flow effectively. Among the most suitable options are globe valves, renowned for their accuracy in modulating steam flow due to their linear movement and robust sealing. Butterfly valves, with their compact and lightweight design, offer quick response and reliable control, especially in larger systems. Ball valves, equipped with a rotary mechanism, provide smooth operation and excellent flow shutoff capabilities. Each of these valves allows for slow opening and closing, preventing pressure surges and steam hammering. Selecting the appropriate control valve is essential to maintaining operational efficiency and protecting system integrity.

Overview of different types of control valves commonly used with steam systems, such as globe valves, butterfly valves, and ball valves.

Control valves in steam systems are essential for regulating flow and maintaining system efficiency. Globe valves are a popular choice due to their precise throttling capabilities, offering exceptional control over steam flow by allowing gradual opening or closing. Butterfly valves, valued for their compact design and lightweight structure, provide reliable flow restriction in systems where space-saving solutions are required. Ball valve, with their simple quarter-turn operation, excel in applications demanding both durability and quick actuation. Each of these valves can be adjusted incrementally, ensuring steam flow is controlled smoothly to meet specific operational demands while protecting system components from pressure surges.

Explanation of which control valve types are best suited for slow opening and closing to ensure accurate steam flow regulation.

Globe valves are the top choice for slow opening and closing in steam systems due to their precise throttling capabilities. Their design allows for fine control over steam flow, making them ideal for applications demanding accuracy and stability. Butterfly valves, known for their lightweight structure and smooth rotation, offer controlled adjustments that are well-suited for gradual opening or closing in compact systems. Ball valves, though primarily designed for quick operation, can still be modulated slowly to regulate flow effectively. Using these valve types ensures accurate steam flow control, minimizes pressure surges, and protects system components from undue stress.

Highlight specific features of these valves that make them ideal for steam applications.

Globe valves, with their precise flow control and robust design, are perfectly suited for steam applications requiring accurate regulation. Their fine throttling capabilities ensure smooth and stable adjustments, even under varying pressure conditions. Butterfly valve, valued for their compact and efficient design, excel in systems where space and weight are critical factors, offering reliable flow modulation with minimal resistance. Ball valves bring unmatched durability and are ideal for high-stress environments, providing quick operation while still allowing controlled modulation when needed. These features collectively enhance steam flow management, boost system efficiency, and ensure reliability, reducing pressure surges and maintaining operational stability in industrial settings.

Benefits of Using Control Valves for Steam Flow

Control valves, including globe, butterfly, and ball valves, offer significant benefits for managing steam flow in industrial systems. Their ability to provide precise flow regulation ensures consistent system performance and prevents dangerous pressure surges, safeguarding critical components. The slow opening and closing capabilities of these valves enable gradual adjustments, reducing stress on the system and extending the lifespan of equipment. By optimizing steam flow, these valves enhance overall efficiency, minimize energy waste, and lower operational costs. Their reliable operation contributes to safer environments and ensures smooth, uninterrupted processes, making them indispensable for effective steam system management.

Improved accuracy in steam pressure and temperature control.

Control valves, such as globe, butterfly, and ball valves, play a crucial role in achieving precise steam pressure and temperature control. Globe valves, with their fine throttling abilities, allow incremental adjustments to stabilize pressure and temperature effectively. Butterfly valves, compact yet efficient, support smooth flow modulation, ensuring reduced fluctuations in system parameters. Ball valves, when operated slowly, enable controlled steam flow adjustments critical for maintaining consistent operating conditions. These capabilities prevent sudden spikes or drops, promoting optimal performance, improved energy efficiency, and dependable process reliability. By enhancing control accuracy, these valves ensure long-term stability in demanding industrial applications.

Enhanced system performance by preventing sudden pressure surges or steam hammering.

Control valves, including globe, butterfly, and ball valves, are essential for enhancing system performance by preventing sudden pressure surges or steam hammering. Globe valves offer precise throttling, enabling smooth flow adjustment to reduce pressure spikes. Butterfly valves, with their efficient modulation, excel in stabilizing flow and minimizing turbulence. Ball valves, when operated gradually, ensure controlled steam distribution, effectively mitigating the risk of hammering. The slow opening and closing capabilities of these valves protect critical components, maintain system stability, and prevent damage. These features lead to smoother operations, decreased maintenance demands, and increased longevity of industrial steam systems.

Reduced energy consumption and improved operational efficiency.

Control valves, such as globe, butterfly, and ball valves, play a pivotal role in reducing energy consumption and boosting operational efficiency in steam systems. Their precise flow control capabilities ensure steam is delivered at optimal rates, minimizing energy waste and avoiding unnecessary overuse. The gradual operation of these valves prevents abrupt changes, maintaining consistent system performance and reducing strain on equipment. By optimizing steam distribution, these valves enhance productivity, lower operational costs, and contribute to sustainable practices. Their ability to streamline energy use while ensuring reliable operation makes them indispensable for achieving cost-effective and efficient industrial processes.

How Control Valve Work

Control valves function by precisely regulating steam flow through gradual adjustments to the valve’s position. Comprised of key components like the actuator, valve body, and control element, these valves work in harmony to manage flow rates accurately. The actuator, driven by signals from a control system, moves the valve’s internal element — such as a plug, disc, or ball — to either increase or restrict steam flow. This controlled movement prevents abrupt pressure changes, safeguarding system stability and equipment integrity. By ensuring smooth, steady flow modulation, control valves play an essential role in optimizing efficiency and ensuring reliable performance in industrial steam systems.

Detailed explanation of the functionality of a control valve in controlling steam flow.

Control valves are designed to precisely regulate steam flow by adjusting the valve’s position using components like the actuator, valve body, and control element. The actuator receives commands from a control system, initiating movement of the control element—such as a plug, disc, or ball—within the valve body. This modulation either increases or restricts the flow rate based on system requirements. The gradual opening and closing capabilities of control valves are critical in mitigating pressure surges and preventing steam hammering, protecting the system and its components. These features ensure consistent flow regulation, contributing to efficient steam distribution and dependable operation in industrial environments.

Description of the components, like actuators and positioners, and their roles in achieving precise regulation.

Control valves rely on critical components like actuators and positioners to achieve precise regulation of steam flow. Actuators convert control signals from the system into mechanical motion, adjusting the valve’s internal element—such as a plug or disc—to modulate flow rates. Positioners enhance accuracy by continuously comparing the control signal to the valve’s actual position, making fine corrections to ensure precise alignment. This dynamic interaction between actuators and positioners allows for highly responsive and reliable flow control, minimizing fluctuations and maintaining system stability. Together, these components play an integral role in optimizing efficiency and ensuring dependable performance in industrial steam systems.

Overview of how control valves modulate flow based on input signals from control systems.

Control valves modulate steam flow by responding to input signals from control systems, which specify the desired flow rate. Upon receiving these signals, the valve’s actuator converts them into mechanical motion, adjusting the position of the valve’s internal component—such as a plug, disc, or ball. Feedback mechanisms, such as positioners, monitor the valve’s actual position and compare it to the control system’s command. If discrepancies arise, the positioner makes adjustments to ensure accurate alignment. This process allows precise regulation of steam flow, maintaining efficiency and stability while preventing pressure surges or energy waste, which are vital for industrial system performance.

Maintenance Tips for Control Valve

Regular maintenance is essential for ensuring control valves in steam systems operate effectively and reliably. Establish a routine inspection schedule to identify potential issues early, such as leaks or wear and tear in critical components. Check the actuator and positioner regularly to confirm their responsiveness and accuracy. Clean valve components thoroughly to prevent buildup and corrosion, which can compromise performance, and apply proper lubrication to all moving parts to maintain smooth operation. Consistent, proactive maintenance not only extends the valve’s lifespan but also optimizes system efficiency, reduces downtime, and prevents costly, unexpected failures in demanding industrial environments.

Importance of regular inspection and servicing to maximize the lifespan of control valves.

Regular inspection and servicing are crucial for maximizing the lifespan of control valves in steam systems. Routine checks enable early detection of wear, leaks, or potential malfunctions, ensuring timely corrective action before issues escalate. Servicing plays a key role in maintaining the valve’s optimal performance, preventing unexpected breakdowns that can disrupt operations or compromise safety. Proper maintenance practices keep components clean, lubricated, and functioning efficiently, which not only extends the valve’s life but also improves system efficiency. By reducing the risk of failures and minimizing downtime, consistent servicing significantly lowers operational costs and supports reliable performance in demanding industrial environments.

Key maintenance practices such as lubrication, cleaning, and calibration.

Proper maintenance of control valves is essential to ensure dependable performance in steam systems. Regular lubrication is critical for smooth operation, reducing friction, and preventing wear on moving parts such as actuators and internal valve components. Cleaning the valve thoroughly removes debris and prevents corrosion, which can hinder functionality and compromise the system’s efficiency. Calibration is equally important, ensuring the valve’s position aligns accurately with control system signals, maintaining precision and responsiveness. Together, these practices enhance the valve’s reliability, extend its lifespan, and uphold the efficiency of industrial steam systems, minimizing unplanned downtime and optimizing operational performance.

How to identify and address common issues affecting control valves in steam systems.

To identify and address common issues affecting control valves in steam systems, start by watching for signs like leaks, unusual noises, or erratic valve movements. Regular inspections are vital for detecting these issues before they escalate. Leaks often stem from loose connections or worn seals, so tightening fittings or replacing seals can resolve the problem. Unusual noises may indicate debris or damage inside the valve, which cleaning or component replacement can fix. Erratic movement usually points to calibration issues or faulty actuators, requiring recalibration or part replacement. Addressing these problems promptly prevents further damage, ensuring system efficiency and reliability.

FAQ control valve

Question 1:What makes an electric globe valve suitable for controlling steam flow in industrial applications?

An electric globe valve is ideal for precise steam flow control due to its linear motion design, which allows for fine adjustments to flow rates. Powered by an electric actuator, this valve provides accurate and consistent modulation in response to control system signals. The electric globe valve is especially valuable in high-temperature steam systems, where its sturdy construction and precise operation ensure reliable performance over time.

Question 2:How does a pneumatic control valve operate to regulate steam flow effectively?

A pneumatic control valve uses air pressure to adjust the valve’s position, ensuring smooth and responsive control of steam flow. Its actuator translates input signals from a control system into mechanical motion, allowing gradual opening or closing of the valve. Pneumatic control valves are often preferred in steam systems for their reliability, quick response times, and the ability to operate without requiring an external power source.

Question 3:Why is an electric control valve a reliable choice for slow and precise steam flow modulation?

An electric control valve offers accurate and gradual steam flow modulation, thanks to its motorized actuator, which converts electrical signals into precise movements. The advanced design of an electric control valve ensures optimal positioning, even under fluctuating operating conditions. These valves are highly versatile, integrating seamlessly with automated control systems for enhanced efficiency and real-time adjustments in industrial steam applications.

Conclusion control valve

Control valves play a critical role in regulating steam flow to ensure precision and efficiency in industrial systems. Among these, the self-operated pressure regulating valve, self-operated regulating valve, and self-operated control valve are standout solutions for maintaining stable pressure and flow control. These valves operate without external power sources, offering simplicity and reliability in demanding applications. Their ability to adjust automatically to fluctuations enhances system safety and ensures consistent performance. By incorporating self-operated designs, industries benefit from reduced operational complexity, improved system efficiency, and minimized downtime, making them indispensable tools for effective steam system management.