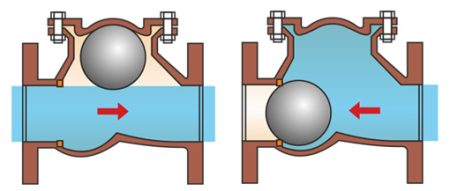

You can see the main difference between a piston check valve and a ball check valve in how they stop backflow. A piston check valve uses a piston that moves to open or close the flow. Ball check valves use a ball that moves to block or let fluid pass. Ball check valves are the most popular in the world. They are worth $1.5 billion in 2024. You often find them in water and wastewater systems. People choose them because they are reliable and not too expensive. Many industries like power generation and chemical processing use piston check valves for better control. The table below shows where piston check valves are used more than other types like butterfly valve, ball valve, and control valve.

| Industry / Sector | Common Use of Piston Check Valves |

|---|---|

| Power Generation | Used in thermal, hydroelectric, and nuclear power plants for good operation and safety in high-pressure places. |

| Oil & Gas | Important for safe and smooth fluid flow, stopping backflow, and lowering leak risks. |

| Chemical Processing | Handles strong chemicals with tight sealing, keeping work safe. |

| Water & Wastewater | Stops backflow in water treatment and pipes, helping follow rules. |

| Food & Beverage Processing | Used for moving different fluids in many conditions, helping the market grow. |

| Pharmaceuticals | Makes sure flow control works well in making medicine. |

| HVAC Systems | Used in big and small buildings for flow control and safety. |

| Industrial Sector | Biggest user group, including factories, processing, and utilities that need strong valves. |

| Commercial Sector | Used in heating, water, and fire safety systems in business buildings. |

| Residential Sector | Used in home plumbing to stop backflow and keep water safe. |

Key Takeaways

- Piston check valves use a piston to control flow. They seal tightly. This makes them good for high-pressure and clean fluid systems.

- Ball check valves use a ball that moves freely. The ball cleans itself. These valves work well with thick, dirty, or solid-filled fluids.

- Piston valves give precise flow control. They seal very well. But they need more maintenance. They work best in horizontal pipes.

- Ball valves have a simple design. They cause low pressure drop. You can put them in vertical or horizontal pipes. They need less upkeep.

- Pick piston check valves for power plants, oil and gas, and chemical factories. These places need safety and control.

- Use ball check valves for wastewater, irrigation, fire safety, and low-pressure systems. These need quick response and easy care.

- The material you pick is important. Stainless steel is good for harsh chemicals and heat. Brass and bronze do not rust in water systems.

- Check valves often to find wear early. Piston valves need checks for piston and seat wear. Ball valves need checks for smooth ball movement.

Piston Check Valve

Operation

Components

A piston check valve has several important parts. You will find a valve body, a piston, a valve seat, and sometimes a spring inside. The piston sits inside the body and moves up or down. The valve seat is where the piston rests to stop flow. Some designs use a spring to help the piston close faster. These parts work together to control the direction of fluid.

Flow Control

When you use a piston check valve, fluid flows in only one direction. As fluid moves forward, it pushes the piston up. This action opens the path and lets the fluid pass through. If the flow stops or tries to go backward, the piston drops down onto the seat. Sometimes, gravity helps the piston close. In other cases, a spring pushes it shut. This quick closing action stops backflow and keeps your system safe. The piston moves smoothly, so you get reliable flow control. This design also helps reduce water hammer, which can damage pipes and equipment.

Tip: Piston check valves work well in high-pressure systems. They protect pumps and other equipment from sudden pressure changes.

Features

Piston check valves stand out because of their unique features.

- The piston moves up with forward flow and seals tightly during backflow.

- You can find a spring or just gravity helping the piston close.

- The internal flow path is not straight. This design can cause a small pressure drop as fluid moves through.

- These valves have several pressure-retaining parts, which means there are more places where leaks could happen.

- You might notice some noise when the valve operates, especially if the pressure changes quickly.

- Over time, the piston and seat can wear out, especially in systems with lots of pressure changes.

These features make piston check valves different from other types of check valves. You get strong sealing and good control, but you should check them regularly for wear.

Materials

You will see piston check valves made from strong materials. Common choices include stainless steel, brass, bronze, and cast iron. These materials help the valve last a long time, even in tough conditions. Stainless steel works well with chemicals and high temperatures. Brass and bronze resist corrosion, making them good for water systems. Cast iron is strong and cost-effective for large industrial setups. You can find piston check valves in many sizes, so you can pick the right one for your job. The tough materials and simple design mean you do not need to do much maintenance. This makes piston check valves a smart choice for many industrial and commercial uses.

Ball Check Valves

Operation

Components

Ball check valves have a simple design. The main parts are the valve body, ball, and seat. The ball sits on a cone-shaped seat inside the valve. Sometimes, a spring holds the ball in place. Many designs let the ball move on its own. The ball often has a metal center with a rubber cover. The rubber helps the ball seal well and absorb shocks. The ball is a little bigger than the seat. This size helps stop leaks and keeps the seal strong.

Flow Control

Fluid pushes the ball off the seat when moving forward. This opens the valve and lets fluid pass. If flow stops or goes backward, the ball drops onto the seat. The ball blocks the way and stops backflow. Gravity can help the ball return to the seat. Some designs use a spring to push the ball back. The ball wipes the seat as it moves. This cleaning action keeps the seat clear of dirt. It works well with thick or dirty fluids. You get one-way flow and less chance of clogging.

Note: The ball cleans itself as it moves. This makes ball check valves good for fluids with solids or thick liquids.

Features

Ball check valves need little care and work well.

- You can put them in horizontal or vertical pipes.

- The ball design gives a smooth path for fluid. This means there is little pressure loss.

- The ball turns as it moves, so it wears evenly and lasts longer.

- The rubber on the ball makes less noise and absorbs shocks. This protects your system.

- You can pick different ball weights to lower water hammer or shaking.

- The cleaning action keeps the seat free from buildup. This makes ball check valves great for wastewater, irrigation, and fire safety systems.

You see ball check valves in drinking water systems, pump stations, factories, and many other places. The design means you do not need to check or clean them often.

Materials

Ball check valves are made from many materials.

- Stainless steel is good for high pressure, heat, or rough fluids.

- PVC and special linings stop rust and handle strong chemicals.

- Brass and bronze last long for water and general use.

- For food or medicine, you can get valves made from safe materials.

The ball can be solid PTFE, polypropylene, or steel with a rubber or plastic cover. This lets you choose the right valve for your job, whether you need strength, chemical safety, or food safety. You find these valves in oil plants, power stations, mines, water plants, and gas systems.

| Component | Common Materials Used |

|---|---|

| Valve Body | Stainless steel, PVC, ductile iron, brass, bronze |

| Ball | Steel core with rubber or polyurethane, PTFE, polypropylene |

| Seat/O-Rings | PTFE-coated Viton, other elastomers |

Tip: Always pick the valve material that matches your fluid and system. This helps your valve work best and last longer.

Check Valve Design Differences

Construction

Moving Parts

When you look inside a check valve, you will see that the moving parts make a big difference. In a ball valve, you find a simple design. The main moving part is a ball that rolls or lifts to open and close the flow. This ball moves freely and does not need guides. The design keeps things simple and strong. You get fewer parts that can break or wear out.

A piston check valve works differently. It uses a piston or disc that moves up and down inside a guide. Sometimes, a spring helps the piston return to its seat. This design gives you more control over how the valve opens and closes. The guided movement keeps the piston in the right spot, so you get a tight seal. However, the extra parts mean more things can wear out over time.

| Feature | Ball Check Valve | Piston (Lift) Check Valve |

|---|---|---|

| Closing Mechanism | Spherical ball seated in conical/spherical chamber | Disc or piston moving vertically within a guide |

| Movement | Rolling action of ball, relies on gravity/backpressure or spring | Vertical lift guided for precise alignment |

| Design Complexity | Simple, robust, few moving parts | More complex due to guided piston/disc movement |

| Self-cleaning Ability | Rolling ball provides self-cleaning, reducing clogging | Sensitive to debris; debris can obstruct piston movement |

You will notice that ball check valves last longer in dirty or debris-filled systems because the ball cleans itself as it moves. Piston check valves give you better sealing but need cleaner fluids to work well.

Body Shape

The shape of the valve body also affects how the check valve works. Ball valves often have a rounded or conical chamber. This shape lets the ball move smoothly and seal tightly. You can install these valves in vertical pipes, and sometimes in horizontal pipes, but you may see limits in performance if you do not follow the right orientation.

Piston check valves have a body that guides the piston straight up and down. This design works best in horizontal pipes. The body shape helps the piston align with the seat, so you get a strong seal. If you use a piston check valve in the wrong position, you may not get the best results.

How They Work

Flow Direction

Both types of check valves let fluid move in only one direction. When you use a ball valve, the ball lifts off the seat when fluid flows forward. If the flow tries to reverse, the ball drops back and blocks the path. This action stops backflow and keeps your system safe.

A piston check valve works in a similar way. The piston lifts when fluid moves forward. If the flow stops or tries to go backward, the piston drops down and seals the seat. This quick action prevents reverse flow and protects your equipment.

Opening and Closing

You will see differences in how fast these valves open and close. Ball check valves use gravity or backpressure to move the ball. The ball responds quickly, but not as fast as a spring-loaded piston. The rolling action of the ball makes the valve reliable and easy to maintain.

Piston check valves often use a spring to help the piston close faster. This spring action gives you a rapid response to changes in flow. If your system needs quick backflow prevention, a piston check valve may work better. The guided movement of the piston also means you get a more precise seal each time the valve closes.

- Ball check valves: Reliable, simple, slower response, self-cleaning.

- Piston check valves: Fast response, precise sealing, more sensitive to debris.

Performance

Sealing

Sealing is one of the most important jobs for any check valve. A piston check valve uses a piston that fits tightly against the seat. This design gives you a very strong seal and helps prevent leaks. You can use piston check valves in high-pressure systems where you need to stop even small amounts of backflow.

Ball check valves use a ball that presses against a seat. The ball makes a good seal, but it may not be as tight as a piston. The ball’s wiping action helps keep the seat clean, which is good for fluids with dirt or solids. If you need a valve for preventing backflow in a system with thick or dirty fluids, a ball valve is a smart choice.

| Valve Type | Sealing Mechanism Description | Effect on Leak Rates and Performance |

|---|---|---|

| Piston Check Valve | Uses a piston that moves vertically to seal against a seat, providing a tight seal. | Superior leakage prevention; suitable for high-pressure and high-velocity applications; generally lower leak rates. |

| Ball Check Valve | Uses a spherical ball that moves freely and seals by being pushed against a seat on flow reversal. | Provides a tight seal with minimal leakage; quick response; effective in high-pressure applications; may be sensitive to debris affecting seal integrity. |

Pressure Drop

Pressure drop means how much the valve slows down the fluid. Ball check valves have a smooth path, so you get a low pressure drop. The ball moves out of the way, and fluid flows easily. This makes ball valves good for systems where you want to keep energy use low.

Piston check valves have a more complex path. The piston and guides can slow the fluid a little more. You may see a higher pressure drop in these valves. If your system needs to save energy, you should think about this difference.

Flow Rate

Flow rate tells you how much fluid can move through the valve in a set time. Ball check valves let fluid move quickly because of their simple design. You get a high flow rate and less resistance. This works well in systems that need to move a lot of water or other fluids fast.

Piston check valves can handle high flow rates, but the extra parts inside may slow things down a bit. You still get good performance, but you may not reach the same flow rates as a ball valve.

Fluid Suitability

You need to match the valve to your fluid. Piston check valves work best with clean, non-viscous fluids like water, gases, or light oils. These valves shine in high-pressure systems where you want to stop backflow completely.

Ball check valves handle a wider range of fluids. You can use them with thick liquids, slurries, and even fluids with solids. The self-cleaning action of the ball keeps the seat clear. You see ball valves in wastewater, chemical plants, and places where fluids are not always clean.

| Valve Type | Recommended Fluid Types | Application Contexts | Material Considerations |

|---|---|---|---|

| Piston Check Valve | Non-viscous fluids such as water, gases, light oils | High-flow and high-pressure applications | Suitable for preventing backflow; often used in moderate to high pressure systems |

| Ball Check Valve | Wide range including viscous liquids, slurries, gases | Industrial applications requiring precise on/off control | Stainless steel for corrosive fluids; brass for water systems; versatile material options |

Tip: Always choose the right check valve for your fluid and system. This helps you get the best performance and longest life from your equipment.

Maintenance

Inspection

You need to check your check valves regularly to keep your system safe. Both piston check valves and ball check valves need inspection, but the process is different for each type.

- For piston check valves, you should look for signs of wear on the piston and seat. Dirt or debris can cause the piston to stick. If the piston does not move freely, you may not get proper backflow prevention.

- For ball check valves, you should check if the ball moves smoothly and seals well. The ball can collect buildup, especially if your fluid has solids. The self-cleaning action helps, but you still need to inspect the seat and ball for damage.

Tip: Schedule inspections based on how often you use the valve and the type of fluid in your system. More frequent checks help you catch problems early.

Durability

You want your check valves to last a long time. The durability of each type depends on the design and the materials you choose.

- Piston check valves use strong metals like stainless steel or bronze. These materials resist corrosion and wear. The guided piston design gives you a tight seal, but the extra moving parts can wear out faster if you have dirty fluids.

- Ball check valves have fewer moving parts. The ball and seat take most of the wear. If you use a ball with a rubber or plastic coating, you get extra protection against damage. Ball check valves often last longer in systems with thick or dirty fluids because the ball wipes the seat clean.

A table can help you compare the durability of both types:

| Valve Type | Durability Factors | Best Use Case |

|---|---|---|

| Piston Check Valve | Strong materials, more moving parts | Clean fluids, high pressure |

| Ball Check Valve | Fewer parts, self-cleaning ball | Dirty fluids, slurries, solids |

Wear Factors

Wear happens over time, but you can slow it down by choosing the right valve for your job. You should know what causes wear in each type.

- In piston check valves, the piston and seat rub against each other every time the valve opens or closes. High pressure and frequent cycling can speed up wear. Dirt or grit in the fluid can scratch the piston or seat, making it harder to stop backflow.

- In ball check valves, the ball rolls and spins as fluid moves. This action spreads out the wear, so the ball lasts longer. The ball also helps keep the seat clean, which lowers the risk of leaks from reverse flow. However, if the ball or seat gets damaged, you may see more leaks.

Note: Always match your valve to your fluid and system needs. This helps you get the best backflow prevention and keeps your valves working longer.

If you want fewer maintenance problems, use ball check valves for dirty or thick fluids. Choose piston check valves for clean fluids and high-pressure systems. Regular inspection and cleaning help both types last longer and keep your system safe from backflow.

Check Valves Applications

Picking the right check valve depends on your fluid, pressure, and control needs. Both piston check valves and ball check valves are used in many industries. Each type works best in certain jobs.

Piston Check Valves

High Pressure

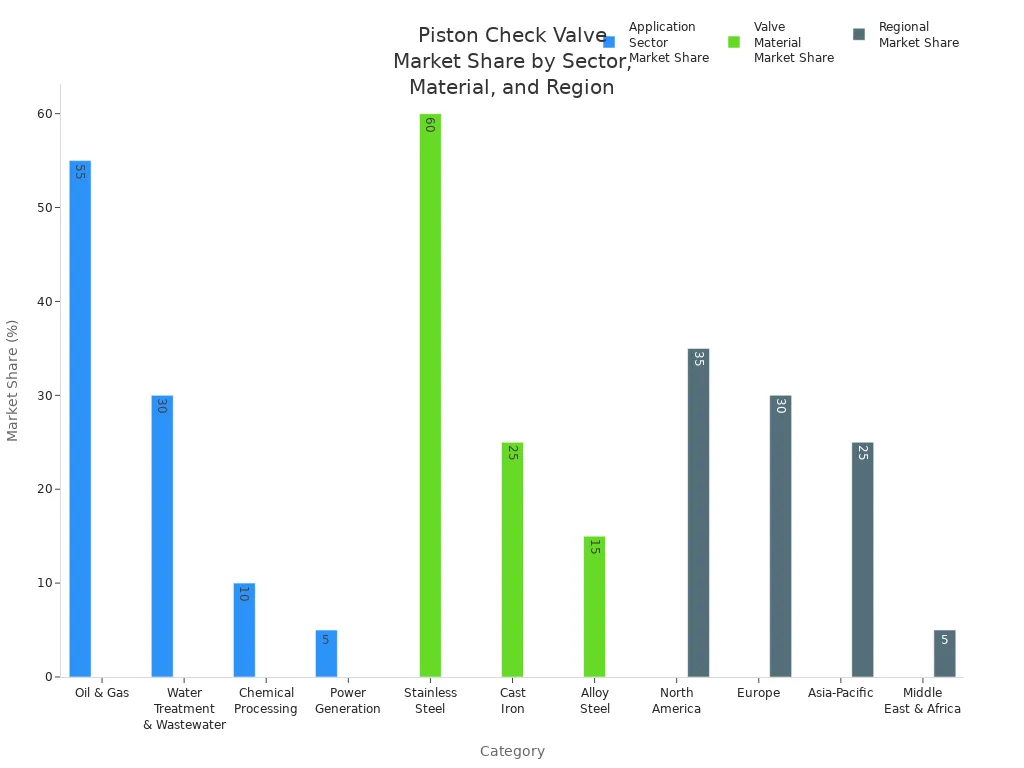

Use a piston check valve if your system has high pressure. These valves can handle strong forces and stop backflow in hard situations. Power plants, oil and gas pipes, and chemical factories use piston check valves for safety. In oil and gas, more than half of pipeline projects use piston check valves. They help stop leaks and keep things safe. AI piston check valves make flow checks and backpressure better by about 20%. This gives you more control and fewer problems.

Precise Control

If you want exact control of fluid, pick a piston check valve. Chemical plants use these valves for hot or harsh fluids. Smart piston check valves make flow control almost 28% more accurate. You can trust them to keep your process safe and working well. Stainless steel piston check valves last longer and need less fixing, even in tough places.

Industrial Use

Piston check valves are used in many jobs. You see them in water treatment, wastewater plants, and city systems. These valves are strong and do not rust, which helps meet rules. Modular valve kits make setup about 18% faster. The table below shows where piston check valves are used most and why they are important:

| Application Sector | Market Share (%) | Key Use Cases and Performance Highlights |

|---|---|---|

| Oil & Gas | 55 | Pipeline backflow prevention, safety systems, improved diagnostics |

| Water Treatment & Wastewater | 30 | Durability, corrosion resistance, faster installation |

| Chemical Processing | 10 | Corrosive fluids, high-temperature, smart flow control |

| Power Generation | 5 | Steam, condensate, boiler feed, high-pressure resistance |

Tip: Pick piston check valves for strong sealing, high pressure, and exact flow control.

Ball Check Valves

Quick Response

A ball check valve reacts fast to changes in flow. You find ball check valves in pump stations, fire safety, and irrigation. The ball moves quickly to stop backflow and protects your equipment. You can put these valves in both flat and upright pipes, so they fit many setups.

Viscous Fluids

If your system has thick or dirty fluids, a ball check valve is a good pick. The ball wipes the seat clean as it moves, so there is less clogging and the valve lasts longer. Wastewater plants, mines, and food factories use ball check valves for slurries and liquids with solids. The simple design means you do not need to clean or fix them much.

Low Pressure

Ball check valves also work well in low-pressure systems. You see them in home plumbing, drinking water, and small business setups. The smooth path means you lose less pressure, which saves energy and keeps things running well.

Note: Ball check valves are easy to use, quick to install, and need little care. Pick them for fast action and tough fluids.

Choosing a Check Valve

Selecting the right check valve for your system can make a big difference in safety, performance, and cost. You need to think about several important factors before you decide. Each type of check valve works best in certain situations. Let’s look at what you should consider.

Factors

Pressure

You must know the pressure in your system. Piston check valves work well in high-pressure places. They give you strong sealing and can handle sudden changes. Ball valves are better for low to moderate pressure. If your system has very high pressure, a piston check valve is usually the safer choice.

Fluid Type

The kind of fluid you move through your pipes matters a lot. Some valves work better with clean fluids, while others handle thick or dirty liquids. The table below shows how fluid type affects your choice:

| Valve Type | Fluid Characteristics Influencing Selection | Applications and Considerations |

|---|---|---|

| Piston Check Valve | Less suitable for fluids containing debris due to risk of sticking | Used in low flow rates and where positive closure is critical; may have higher friction loss; precise control |

| Ball Check Valve | Handles viscous fluids and high flow; suitable for high-pressure systems | Ideal for high flow and viscous media; simple and robust; less suited for fine flow regulation or tight spaces |

If your fluid has a lot of dirt or is very thick, a ball valve is a better pick. If you need tight control and your fluid is clean, a piston check valve will serve you well.

Space

Space in your system can limit your choices. Some valves need more room to fit. Others are compact and fit in tight spots. Here are some tips for space-limited installations:

- Piston check valves are compact and work well in high-pressure spots. You can use them when you need reliable sealing in a small space.

- Ball check valves have a simple design but often need more space. They work best in systems with clean fluids and low pressure.

- Compact valve types, like wafer or piston check valves, fit between flanges and save space.

- Always check the size and shape of the valve before you buy. Make sure it fits your system.

Maintenance

You want a valve that is easy to take care of. Piston check valves have more parts inside. You need to check them often to make sure they do not stick or wear out. Ball check valves are simpler and need less care. If your fluid has a lot of dirt, the ball valve may wear out faster, but it is easy to inspect and replace.

Tip: If you want less maintenance, choose a ball check valve for dirty or thick fluids. Pick a piston check valve for clean fluids and high-pressure systems.

Selection Tips

When to Use Piston

- Choose a piston check valve if you need strong sealing and precise control.

- Use it in high-pressure systems, like power plants or chemical factories.

- Pick this valve when you have clean fluids and need to stop backflow completely.

- If you have limited space and need a compact valve, a piston check valve is a smart choice.

When to Use Ball

- Select a ball valve if your fluid is thick, dirty, or has solids.

- Use it in low to moderate pressure systems, such as wastewater or irrigation.

- Ball check valves are great when you want quick response and easy maintenance.

- If you have more space and want a simple, robust valve, go with a ball valve.

Note: Always match the valve type to your system’s needs. Think about pressure, fluid, space, and how much care you want to give.

Cost

Cost is a big part of your decision. The table below compares the average cost and features of each type:

| Feature | Piston Check Valves | Ball Check Valves |

|---|---|---|

| Cost | More expensive due to robust sealing and suitability for high-pressure applications. | Lower cost due to simpler design. |

| Application | Ideal for high-pressure applications with higher resistance. | Suitable for lower pressure compared to piston valves. |

| Design Complexity | Utilizes a piston mechanism requiring precise alignment. | Simpler design with fewer moving parts. |

You will pay more for a piston check valve, but you get better sealing and control in tough jobs. Ball check valves cost less and work well in many everyday systems. Always balance your budget with your system’s needs.

??? Tip: Spending a little more on the right valve can save you money on repairs and downtime later.

You can pick a piston check valve if you want something strong and easy to fix. It gives good protection from backflow in places with high pressure.

- Piston check valves work by themselves and help save power. They are used in many factories and plants.

- Do not use them if your system has flow that goes up and down a lot or if you worry about water hammer.

Ball check valves are simple and last a long time.

| Ball Check Valve | Good Things | Bad Things |

|---|---|---|

| Uses | Simple to take care of | Not much control over flow |

| Where to Use | Works for water, sewage | Not good for high heat or pressure |

If you are not sure, talk to a valve expert before you begin. This guide can help you choose the best valve for your job every time.

FAQ

What is the main difference between a piston check valve and a ball check valve?

You will see the main difference in the moving part. A piston check valve uses a piston to block flow. A ball check valve uses a ball. Each design works best for certain fluids and pressures.

Can you use ball check valves for thick or dirty fluids?

Yes, you can. Ball check valves work well with thick, dirty, or gritty fluids. The ball wipes the seat clean as it moves. This action helps prevent clogging and keeps the valve working longer.

Do piston check valves need more maintenance than ball check valves?

You may need to check piston check valves more often. The piston and seat can wear out faster, especially with dirty fluids. Ball check valves have fewer parts and usually need less care.

Which valve type is better for high-pressure systems?

You should choose a piston check valve for high-pressure systems. The piston design gives you a tight seal and strong backflow protection. Ball check valves work best at lower or moderate pressures.

Can you install these valves in any position?

You can install ball check valves in both vertical and horizontal pipes. Piston check valves work best in horizontal pipes. Always check the manufacturer’s instructions before you install any valve.

How do I know which material to choose for my valve?

You should match the valve material to your fluid. Use stainless steel for chemicals or high temperatures. Brass or bronze works well for water. PVC is good for many chemicals. Always check compatibility before you buy.