You can find a non return valve and a check valve in many systems. These systems move liquids or gases. Both valves let things flow in just one direction. They stop backflow and keep your equipment safe. People often talk about non return valve vs check valve. Most industries use them as the same kind of valve. You may also hear about butterfly valve or ball valve. These valves work in a different way. They do not stop backflow.

Knowing about these valves helps you keep your systems safe. It also helps your systems work well.

Non-Return Valve

Definition

You use a non-return valve when you want fluid or gas to move in only one direction. This valve blocks flow from going backward. In engineering, people call it a one-way valve, retention valve, reflux valve, or foot valve. The main job of a non-return valve is to protect your equipment, like pumps and pipes, from damage caused by backflow. You do not need to control it by hand or use electricity. The valve works automatically. When the pressure on one side gets higher than the other, the valve opens. If the flow tries to reverse, the valve closes quickly. This action keeps your system safe and running smoothly.

How It Works

Mechanism

A non-return valve uses a simple but smart design. When fluid or gas pushes from the correct direction, the valve opens. If the flow tries to go the other way, the valve shuts. This quick response stops problems like water hammer, which can harm your pipes. You do not need to do anything—the valve reacts on its own. The automatic operation makes it very reliable for many uses.

Types

You can find different types of non-return valves for many needs. Some common types include:

- Swing check valves: These use a hinged disc that swings open with flow and closes if flow reverses.

- Lift check valves: These use a disc that lifts up when fluid flows in the right direction and drops down to block reverse flow.

- Ball check valves: These use a ball that moves to let flow pass and seals against a seat to stop backflow.

- Foot valves: These are placed at the end of a pipe, often in a well or tank, to keep the pump primed.

Each type works best in certain situations. For example, swing check valves fit well in low-pressure systems, while ball check valves handle small flows and vertical pipes.

Common Uses

You see non-return valves in many places. Here are some typical uses:

- Air compressors: The one-way valve lets air flow into the tank but stops it from flowing back. This protects the compressor pump and keeps the air tank pressurized. It also helps save energy and keeps moisture or debris out of the compressor.

- Vacuum systems: Non-return valves help create and keep a vacuum. They stop air from coming back into the chamber. You find them in roughing valves, vent valves, and holding valves. These valves protect pumps and keep the vacuum strong.

- Gas lines: The one-way valve prevents gas from flowing backward in pipelines. This protects equipment and keeps the system safe. Special check valves can handle pulsing pressures and reduce wear.

You often use a non-return valve in low-pressure and vertical piping. The automatic, one-way flow makes it perfect for these setups. You can trust it to keep your system safe and efficient.

Check Valve

Definition

You use a check valve to control the direction of flow in a pipe. This valve has two ports—one for entry and one for exit. When you install a check valve, you make sure that liquid or gas can only move forward. If the flow tries to reverse, the check valve closes. You do not need to operate it by hand. The check valve works automatically. Major engineering standards, such as ASME, API, ISO, and EN, focus on safety and durability for check valves. These standards guide the design, pressure ratings, and materials so that the check valve prevents backflow in a reliable way.

How It Works

Mechanism

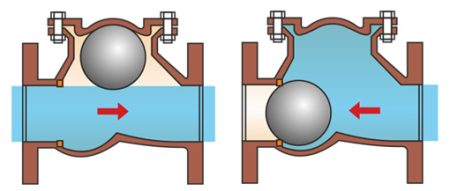

A check valve opens when the pressure on the entry side, called upstream pressure, gets high enough. This pressure must reach a certain level, known as the cracking pressure. When the flow stops or tries to go backward, the check valve closes. This action keeps your system safe from damage. You do not need to adjust anything—the check valve responds to changes in pressure and flow on its own.

Types

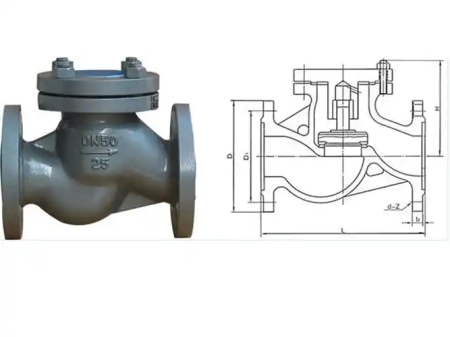

You can find many types of check valves. Each type uses a different mechanism to open and close:

- Swing check valve: This type uses a disc that swings on a hinge. When flow moves forward, the disc swings open. If flow reverses, the disc swings shut.

- Ball check valve: This type uses a ball that lifts off its seat when flow moves in the right direction. The ball drops back to block reverse flow.

- Resilient hinge check valve: This type uses a flexible hinge that helps the disc close softly and quickly, reducing noise and water hammer.

- Diaphragm check valve: This type uses a flexible diaphragm that bends to let flow pass and returns to block backflow.

- Wafer check valve: This type fits between two pipe flanges and uses a thin disc or plate to control flow.

You choose the type of check valve based on your system’s needs, such as pressure, flow rate, and installation space.

Tip: Always install a check valve in the correct direction. Look for the arrow on the valve body to guide you.

Common Uses

You see check valves in many places, both at home and in factories. In homes, you use a check valve in water heaters, dishwashers, and washing machines to stop dirty water from flowing back. In industrial systems, you use a check valve to protect pumps, compressors, and pipelines. The check valve keeps pressure steady and prevents leaks or contamination. You also find check valves in HVAC systems, fire suppression systems, and chemical plants.

Here are some common uses:

- Prevent backflow in pump systems for water, gas, or steam.

- Stop reverse flow in oil and gas pipelines.

- Keep wastewater from re-entering clean water lines.

- Maintain pressure in home water heaters and pump systems.

- Control coolant flow in large building HVAC systems.

- Protect equipment in manufacturing, chemical, and power plants.

- Prevent water hammer by slowing fluid when the valve closes.

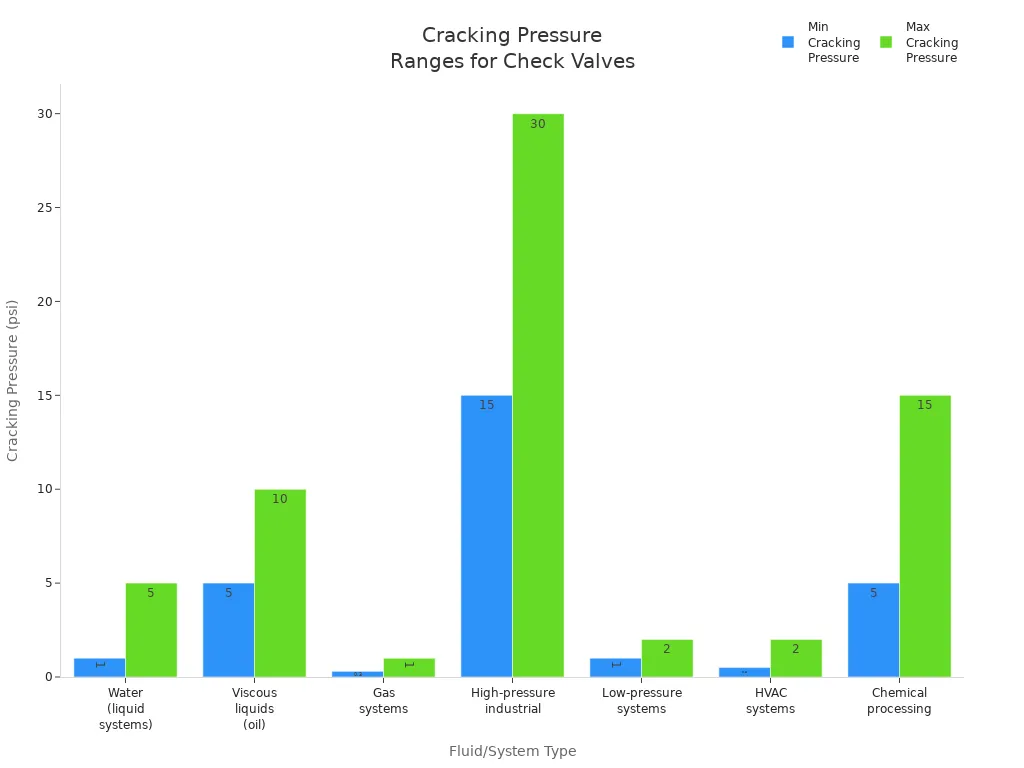

Check valves work in both liquid and gas systems. You often install a check valve in horizontal piping, but some types, like the swing check valve and resilient hinge check valve, also work in vertical pipes. The cracking pressure for a check valve depends on the system. For example, gas systems need a lower cracking pressure than oil or water systems.

| Fluid/System Type | Typical Cracking Pressure Range (psi) |

|---|---|

| Water (liquid systems) | 1 – 5 |

| Viscous liquids (e.g., oil) | 5 – 10 |

| Gas systems | 0.3 – 1 |

| High-pressure industrial | 15 – 30 |

| Low-pressure systems | 1 – 2 |

| HVAC systems | 0.5 – 2 |

| Chemical processing systems | 5 – 15 |

A check valve helps you keep your system safe, clean, and efficient. You can trust a check valve to protect your equipment and prevent costly problems.

Non Return Valve vs Check Valve

Similarities

When you compare non return valve vs check valve, you notice they have many things in common. Both valves stop fluid from going backward. They help protect your system from damage. You do not need to turn them on or off by hand. They work by themselves. Fluid can only move one way through these valves. You see them used with water, gas, and air. Their main job is to keep equipment safe and prevent problems.

Here is a table that shows how non return valve and check valve are alike:

| Similarity Aspect | Non-Return Valve | Check Valve |

|---|---|---|

| Primary Function | Prevents fluid backflow to protect systems | Prevents fluid backflow to protect systems |

| Operation | Automatic, relies on fluid pressure and mechanical forces | Automatic, relies on fluid pressure and mechanical forces |

| Flow Direction | Allows fluid flow in one direction only | Allows fluid flow in one direction only |

| Application Purpose | Used to stop backflow and maintain system safety | Used to stop backflow and maintain system safety |

| Industry Standards | Rarely covered by formal standards | Recognized and regulated by standards like API, ASME, ISO |

| Design Complexity | Simpler design, fewer parts (flaps, balls) | More complex design, multiple parts (springs, discs, seats) |

| Pressure Handling | Suitable for low-pressure systems | Suitable for high-pressure and industrial systems |

Both valves help keep your system safe. They block reverse flow and help you avoid expensive repairs.

Differences

You might wonder what makes non return valve and check valve different. The biggest difference is inside the valve and how you put it in your system. A check valve often uses a spring and a disc, ball, or poppet. It opens when pressure is high enough. It closes when pressure drops or goes backward. Check valves have springs, plates, or poppets that seal tightly. This design works well for strong pressure and big machines.

A non-return valve also lets fluid go one way. It may use gravity or a simple hinged disc to close. You see swing, clapper, flap, duckbill, and ball non-return valves. Swing check valves have a disc that swings open or shut. Ball check valves use a ball to block flow. Non-return valves are simpler and have fewer parts. You use them in low-pressure or vertical pipes.

Here are some main differences:

- Check valves use springs for quick closing.

- Non-return valves may use gravity or a swinging disc.

- Swing check valves and lift check valves go in horizontal pipes.

- Spring-assisted axial flow check valves work in vertical or slanted pipes.

- Check valves follow strict rules like API, ASME, and ISO.

- Non-return valves do not usually have official standards.

Tip: Always look for the arrow on the valve. It shows which way the fluid should go.

You should know about official rules. Plumbing codes do not allow a simple check valve or non-return valve for drinking water backflow prevention. You must use special devices like Double Check Valve assemblies or Reduced Pressure Zone devices. These use two check valves or add a relief valve for extra safety. Local rules say you must test and take care of these devices often.

Interchangeability

People sometimes use non return valve and check valve as if they mean the same thing. In many cases, you can use either one to stop fluid from going backward. The names are mixed up a lot. But you need to pay attention to details. The way they are made, the rules, and how you install them can be different. For example, you cannot use a simple check valve or non-return valve as a certified backflow preventer for drinking water. You need a device that meets official rules.

When you pick between non return valve and check valve, think about what your system needs. If you need to follow strict rules or handle strong pressure, choose a check valve that meets API, ASME, or ISO standards. If you want something simple for low pressure or vertical pipes, a non-return valve might be best. Always check the arrow and make sure the valve fits your system.

Note: Do not mix up dual check valves with Double Check Valve assemblies. Only the assemblies meet the rules for backflow prevention in fire, irrigation, and boiler systems.

Non return valve and check valve can mean the same thing in some places. But you need to know the differences in how they are made, the rules, and official approval. This helps you pick the right valve and keep your system safe.

Applications

Residential

Check valves and non return valves are used in many places at home. These valves help keep your house safe and clean. Here are some ways you use them:

- Washing machines and dishwashers have a check valve. It stops dirty water from going back into the machine. This keeps your water clean and protects your appliances.

- Fish tanks use a check valve in the air pump line. It stops water from flowing out if the power goes out. This keeps the pump safe.

- Floor drains and sinks use a check valve. It stops sewer water from coming back into your house. This protects your floors and keeps your home healthy.

- Hot tubs and swimming pools use check valves. They control water flow between different parts. This stops water from going where it should not.

- Your home’s HVAC system has a check valve. It stops refrigerant from moving backward. This helps your air conditioner work better and last longer.

Tip: Always look for the arrow on the valve before you install it. This makes sure the valve will stop backflow and protect your home.

Industrial

Factories and big buildings need check valves and non return valves. These valves help systems work well. You find them in pumps, compressors, and pipelines. They stop backflow, which can hurt machines or cause safety problems. Chemical plants use a check valve to keep chemicals from mixing the wrong way. Oil and gas pipelines use these valves to stop leaks and protect nature. Fire suppression systems use check valves. They make sure water or foam only goes toward the fire. Using the right valve saves money and helps avoid breakdowns.

Water Systems

Check valves and non return valves help keep water clean and safe. These valves let water move in one direction only. This stops dirty water from mixing with clean water. Swing check valves use a swinging disc to block water that tries to go backward. This works well in water treatment plants. The valves close fast when pumps stop. This helps avoid water hammer and keeps pressure steady. Ball check valves, diaphragm check valves, and wafer check valves are used for different jobs. These valves need little care and work without electricity, even in emergencies. Picking the right valve and checking it often helps keep water good and protects people’s health. In places like hospitals and food factories, a backflow preventer is very important for safety rules.

HVAC

Check valves help keep HVAC systems safe and working well. These valves make sure air, water, or refrigerant only goes one way. If you put in a check valve, you stop back-flow. This keeps your system from getting damaged.

You find check valves in pumps, chillers, boilers, and cooling towers. They help control how fluids and air move. Without a check valve, water or air could go backward. This might break pumps, waste energy, or even stop the system from working.

HVAC system

- They stop dirty water or air from getting into clean parts.

- They keep pumps and compressors safe from reverse flow.

- They hold system pressure steady by letting flow go one way.

- They help stop water hammer, which can break pipes or valves.

- They let you work on one part of the system without turning off everything.

- They help you save energy and money by needing less extra equipment.

There are different check valves for HVAC systems. Swing check valves are used a lot. They open when fluid moves forward and close fast if flow goes back. This helps save energy because the valve does not block flow much. Ball check valves and lift check valves also work in some HVAC setups.

Check valves help your system run smoothly. Using a check valve stops problems like weird temperatures or wasted air. It also stops big changes in pressure. These problems can make your HVAC system work too hard and use more energy. By stopping back-flow, you help your system last longer and work better.

Here is a table that shows where check valves go in an HVAC system:

| HVAC Component | Purpose of Check Valve |

|---|---|

| Pump | Stops water from flowing backward |

| Chiller | Prevents mixing of chilled and warm water |

| Boiler | Keeps hot water moving in one direction |

| Cooling Tower | Blocks air or water from reversing |

| Air Handler | Prevents loss of conditioned air |

Choosing the Right Valve

Fluid Type

When you choose a valve, you need to think about the type of fluid in your system. Some valves work best with water, oil, or gas. Others are made for special fluids like food products or chemicals. You want to pick a valve that matches your fluid’s needs. The material of the valve and the seal must be safe for your fluid. For example, stainless steel and FDA-approved seals are good for food and drink systems. If you use chemicals, you need a valve that can handle strong liquids without breaking down.

Here is a table that shows how sanitary non-return valves fit different fluid types:

| Aspect | Details |

|---|---|

| Valve Type | Sanitary check valve (also called non-return valve) |

| Typical Applications | Food, beverage, pharmaceutical, chemical industries (sanitary/hygienic fluids) |

| Valve Body Material | Stainless Steel SS304 or SS316L |

| Seal Materials | EPDM, NBR, FPM, PTFE (FDA-compliant) |

| Certifications | FDA, CE |

| Suitable Fluid Types | Liquid products, especially sanitary or food-grade fluids |

| Max Working Pressure | 10 Bar |

| Max Working Temperature | 120°C |

| Operation | Automatic, no external control needed; prevents backflow and pipe-hammering |

| Connection Types | Clamp, Weld, Thread |

You should also look at the flow rate and temperature of your fluid. Some valves work better with thick liquids, while others are made for thin fluids or gases. Always check the valve’s label and make sure it matches your system.

Tip: Pick a valve with the right material and seal for your fluid. This helps your system last longer and keeps it safe.

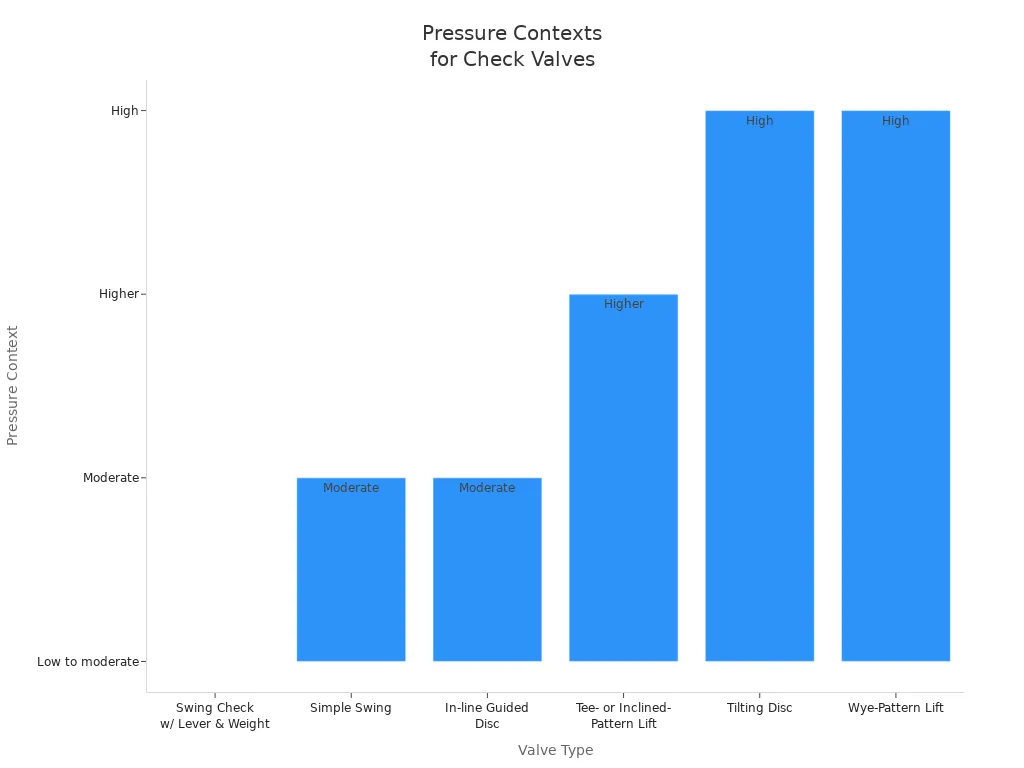

Pressure

Pressure is another key factor when you select a valve. Each valve has a minimum pressure needed to open, called the cracking pressure. If your system does not reach this pressure, the valve will stay closed. You need to know your system’s pressure range before you buy a valve. Some valves work at low pressure, while others are made for high-pressure jobs.

The chart below shows how different valve types fit different pressure levels in industrial systems:

You see that swing check valves with a lever and weight work at low to moderate pressure. Tilting disc and wye-pattern lift valves handle high pressure. Always match the valve’s cracking pressure to your system. If you use a spring-loaded valve, make sure the spring fits your pressure needs. If your system has sudden changes in pressure, pick a valve that closes quickly to stop backflow.

Note: If your system runs at high pressure, choose a valve designed for those conditions. This keeps your equipment safe and working well.

Installation

How you install your valve matters a lot. You need to pick a valve that fits your pipe size and shape. Some valves work best in horizontal pipes, while others fit vertical pipes. Always look for the arrow on the valve. This shows you the right direction for flow.

Follow these steps for a good installation:

- Choose the right valve for your fluid, pressure, and pipe layout.

- Make sure your pipes are clean and lined up. Remove any dirt or old fluid.

- Use the right tools and sealants. Tighten bolts evenly and check for leaks.

- Align the valve with the flow arrow. This helps the valve work as it should.

- For swing check valves, install them in horizontal pipes so gravity helps them close. For lift check valves, use them in vertical pipes with upward flow.

- Ball and diaphragm valves can go in different positions, but always check the manufacturer’s guide.

- After you install the valve, slowly add pressure and watch for leaks.

Tip: Always make sure you can reach the valve for future checks and repairs. Good installation helps your valve last longer and keeps your system safe.

Maintenance

You need to take care of your check valves and non return valves to keep your system safe and working well. Good maintenance helps your valves last longer and prevents problems like leaks or backflow. If you ignore maintenance, you may face costly repairs or even system failure.

Here are the main steps for valve maintenance:

- Keep the area clean. Dirt and debris can build up around the valve. Clean the valve and the pipes nearby. This stops blockages and keeps the valve working.

- Inspect the valve often. Look for leaks, rust, or mineral deposits. Check if the valve opens and closes the right way. Use tools like inspection cameras or pressure gauges to help you see inside.

- Disassemble if needed. Sometimes, you need to take the valve apart to clean inside. Check for damage or rough spots on the parts. If you see worn or broken pieces, replace them.

- Lubricate moving parts. Some valves need oil or grease on the outside parts. This helps the valve move smoothly and last longer. Most internal parts use the system fluid for lubrication.

- Check installation. Make sure the valve sits in the right direction. The arrow on the valve should match the flow. Pipes should be straight before and after the valve to reduce turbulence.

- Document your work. Write down each inspection, cleaning, or repair. This record helps you track the valve’s health and plan future maintenance.

- Troubleshoot common issues. If the valve sticks open or closed, clean it or replace damaged parts. If you hear noise or see leaks, check for debris or worn seals. Fix problems quickly to avoid bigger issues.

- Monitor high-stress valves more often. Valves in high-pressure or high-temperature systems need extra attention. Inspect these valves more frequently.

Tip: Most non return valves last 10 to 15 years if you take care of them. High heat or pressure can shorten their life. About half of valve failures happen because of dirt or poor installation.

If you work with high-pressure systems or welded valves, call a professional for help. Use the right tools and wear safety gear when you do maintenance. Good care keeps your valves working and your system safe.

Design and Manufacturing Standards

Knowing the standards for non return valves and check valves helps you pick safe products. These rules tell you how to make valves, what materials to use, and how to test them. If you choose a valve that follows these rules, your system stays safe and you follow the law.

Key International and U.S. Standards

Many groups make rules for how valves should work. These groups help make sure valves are safe and strong. They also make sure valves fit well in different systems. Here is a table that lists the main standards you should know:

| Standards Organization | Relevant Standards for Non-Return and Check Valves | Scope and Focus |

|---|---|---|

| ASME (American Society of Mechanical Engineers) | ASME B16.34, ASME B16.10, ASME B16.24 | Safety, durability, design, dimensions, and manufacturing requirements for valves in mechanical engineering. |

| API (American Petroleum Institute) | API 6D, API 607, API 609 | Safety, performance, and testing standards for valves in oil and gas industries. |

| ISO (International Organization for Standardization) | ISO 6002, ISO 1721, ISO 10631 | International standards for quality, safety, compatibility, and efficiency of valves. |

| EN (European Norm) | EN 593, EN 1349, EN 1983 | European standards for design and safety, ensuring valves work well across Europe. |

ANSI

ANSI helps make rules in the United States. ANSI works with groups like ASME and API. These rules make sure valves are safe and work well. ANSI standards help you know a valve will fit your system.

ASME (American Society of Mechanical Engineers)

ASME standards, like ASME B16.34, tell how to build valves. They say what size and strength a valve should have. These rules help you pick valves that last and keep your system safe.

API

API standards, such as API 6D and API 607, focus on valves for oil and gas. These rules make sure valves can handle high pressure and tough jobs. API also has rules for fire safety and testing.

ISO

ISO standards help valves from different countries work together. ISO rules cover how to make, test, and label valves. If you see an ISO mark, the valve meets global safety and quality rules.

Tip: Always check if your valve meets one or more of these standards. This helps you avoid problems and keeps your system safe.

Material and Performance Requirements

The material in your valve is very important. Standards tell you which materials are best for each job. They also set rules for how much pressure and heat a valve can take.

Material compatibility and durability

You need to choose a valve made from the right material for your fluid and system. Here is a table to help you see which materials fit different uses:

| Material Type | Applications & Performance Requirements | Key Features & Limitations |

|---|---|---|

| Stainless Steel 304 | Food processing, brewing, water treatment | Good corrosion resistance; not for salty environments |

| Stainless Steel 316 | Marine, chemical, pharmaceutical | Better corrosion resistance; higher cost |

| Steel | Oil & gas, power plants, steam | Strong; needs coating in corrosive places |

| Brass (Standard) | Water, HVAC, low pressure | Easy to machine; not for high pressure or harsh chemicals |

| Brass (Red) | Drinking water | More corrosion resistance; more expensive |

| Plastic (PVC) | Water, pools, irrigation | Light, resists rust; not for high heat or pressure |

| Plastic (Nylon) | Automotive, industry | Tough; absorbs water, which can change its strength |

| Plastic (Polypropylene) | Chemicals, labs, food | Resists acids and bases; lower impact strength |

Seal materials are important too. For example, EPDM is good for water and steam. PTFE (Teflon) works with strong chemicals and high heat. Always match the seal to your fluid and temperature.

Pressure and temperature ratings

Every valve has a limit for pressure and temperature. Standards like API 6D and ISO 5208 set these limits. You must check that your valve can handle your system’s highest pressure and temperature. If you use a valve outside its limits, it might leak or break.

Testing and certification procedures

Valves must pass tests before you use them. Standards like API 598 and ISO 5208 require tests for leaks, strength, and safety. These tests make sure the valve will not fail when you need it most. Certified valves come with papers that show they passed all tests.

Note: Always ask for test certificates when you buy valves for important jobs. This gives you proof that the valve meets safety rules.

Importance of Compliance

Following standards is not just about rules. It helps you keep your system safe, reliable, and legal.

Ensuring safety and reliability

When you use valves that meet standards, you lower the risk of leaks, fires, and breakdowns. Standardized valves use strong materials and safe designs. They also pass tough tests for pressure, temperature, and fire resistance. This means your system will work well, even in harsh conditions.

- You avoid leaks and spills that can harm people or the environment.

- You reduce the chance of fires or explosions in risky places.

- You keep your equipment running longer, with fewer repairs.

Meeting regulatory and industry requirements

Many places require you to use valves that meet certain standards. If you do not follow these rules, you may face fines or have to shut down your system. Using certified valves also helps you get insurance and pass safety checks.

- You meet local and national laws for safety.

- You avoid legal problems and costly shutdowns.

- You make it easier to get approvals for your projects.

Facilitating global trade and system integration

When you use valves that meet international standards, you can buy and sell them anywhere. This helps you find parts faster and at better prices. It also means your system can work with equipment from other countries.

- You can replace valves easily, even if you buy from different suppliers.

- You save money by choosing from more options.

- You make your system ready for upgrades or changes in the future.

Remember: Valves that meet standards may cost more at first, but they save you money and trouble over time. Always choose certified products for the best safety and performance.

Installation and Maintenance

Installation Tips

You want your non return valves and check valves to work well from the start. Good installation helps you avoid leaks, noise, and early failure. Here are some tips to help you:

- Always remove any packaging or storage materials from the valve before you install it.

- Check that the valve’s moving parts, like the disc or flapper, move freely. Nothing should block their movement.

- Clean the pipes and the valve area. Dirt or debris can stop the valve from closing and cause leaks.

- Use Teflon tape correctly on threaded connections. Too much or too little tape can cause leaks.

- Make sure you install the valve in the right direction. Look for the arrow on the valve body.

- For vertical pipes, install the valve so the flow goes upward. For horizontal pipes, keep the valve cover on top.

- Leave enough space around the valve for future checks and repairs.

- Tighten bolts evenly and check for leaks after installation.

Tip: Always follow the manufacturer’s instructions and use valves from trusted brands. This helps you avoid problems like worn hinge pins, misaligned discs, or loose connections.

Troubleshooting

If your valve does not work as expected, you can fix many problems with a few simple steps. Here is a step-by-step guide to help you find and solve common issues:

- Inspect the valve for debris or dirt. Clean the valve and pipes to remove any blockages.

- Check if the valve disc or flapper moves freely. If it sticks, lubricate or realign the parts.

- Make sure the valve is installed in the correct direction. Reverse installation can cause backflow.

- Look for leaks at the connections. Tighten bolts and replace gaskets if needed.

- Test the valve by running water or air through it. Listen for unusual noises like banging or vibration. These sounds may mean water hammer or loose parts.

- If you see slow valve closure, check for worn hinge pins or excessive friction. Lubricate or replace parts as needed.

- For industrial systems, ask a qualified professional to inspect and test the valve.

Note: Always test-run the valve after installation or repair to make sure it works properly.

Maintenance Best Practices

Regular care keeps your valves working for years. You can prevent most problems by following these best practices:

- Inspect your valves often for signs of wear, leaks, or dirt buildup.

- Clean the valves by taking them apart and removing any deposits. Use the right cleaning solutions for your system.

- Lubricate moving parts like stems and bearings with the correct lubricant.

- Store spare valves in a clean, dry place to avoid rust or damage.

- Replace worn or damaged seals and gaskets right away to stop leaks.

- Fix valve sticking by cleaning debris and making sure all parts line up correctly.

- Tighten any loose bolts or connections to stop noise and vibration.

- After maintenance, reassemble the valve carefully and test it to make sure it works.

Tip: Train your team on how to inspect, clean, and maintain valves. Good training helps you spot problems early and keeps your system safe.

You now know that non return valves and check valves work in similar ways. Most experts agree that both types let fluid flow in only one direction and stop backflow. You do not need to operate them by hand. They protect your system from damage and contamination.

- Both valves open and close based on pressure changes.

- You find them in many designs, like swing, ball, or spring-assisted types.

- Their main job is to keep your equipment safe and your fluid clean.

Choose the right valve by thinking about your system’s needs. Both names often mean the same thing, so focus on the function and standards that fit your application.

FAQ

What is the main job of a non return valve?

You use a non return valve to let fluid or gas flow in only one direction. This valve stops backflow. It protects your equipment from damage and keeps your system safe.

Can you use a check valve for drinking water?

You cannot use a simple check valve for drinking water backflow prevention. You need a certified device, like a Double Check Valve assembly, that meets plumbing codes.

How do you know which way to install the valve?

You look for the arrow on the valve body. The arrow shows the correct flow direction. Always match the arrow with your system’s flow.

What happens if you install the valve backward?

If you install the valve backward, fluid will not flow as needed. The valve will block flow or let backflow happen. This can damage your system.

How often should you check or clean your valve?

You should inspect and clean your valve every six months. If your system runs at high pressure or with dirty fluids, check it more often.

What is cracking pressure in a check valve?

Cracking pressure is the minimum pressure needed to open the valve. You must know your system’s pressure to pick the right valve.

Can you use non return valves in vertical pipes?

You can use non return valves in vertical pipes. Ball and lift types work well for upward flow. Always check the manufacturer’s guide.

What materials work best for valves in chemical systems?

You should choose valves made from stainless steel or plastic like PTFE. These materials resist strong chemicals and high temperatures.