When you look at knife gate valve vs gate valve, you see clear differences. Use a knife gate valve if your system moves slurries, thick fluids, or solids. Pick a gate valve for high pressure or clean liquids. The right valve helps things work better and cuts down on stoppages. Some jobs may also need a butterfly valve, ball valve, Pneumatic diaphragm valve, or Pneumatic control valves. Always pick the valve that fits your fluid and system for the best results.

Key Takeaways

- Pick a knife gate valve for thick fluids or solids. It can cut through materials and stops clogs.

- Use a gate valve for clean fluids like water or oil. It seals tightly and works well with high pressure.

- Knife gate valves need little care because they have fewer parts. Check them often to stop leaks and make them last longer.

- Gate valves work best in places with high pressure. They are good for oil pipelines and power plants.

- Always choose the right valve for your fluid. This stops leaks and helps your system work well.

- Think about the pressure and temperature each valve can handle. Knife gate valves are good for low or medium pressure. Gate valves are better for high pressure.

- Both valves need regular care. Clean and oil them to stop blockages and keep them working well.

- Ask a valve expert if you are not sure what to pick. This can help you avoid mistakes and make your system work better.

Knife Gate Valve Overview

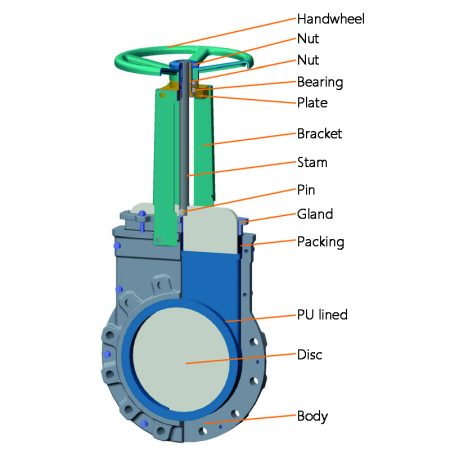

Design

Blade

The blade is the key part of a knife gate valve. It has a sharp edge that can cut thick fluids and solids. When you use the valve, the blade goes down and slices what is in its way. This helps stop clogs and keeps things working well. The tip of the blade can break up material and push it downstream. It does not let anything escape into the air.

Materials

Knife gate valves are made from strong materials. You will see stainless steel, cast iron, or special alloys used. These materials do not rust or wear out fast. If you work in a tough place, you need a valve that lasts long. Picking the right material helps your valve handle chemicals and rough fluids. It will not break down quickly.

Tip: Always look at the material before you buy a knife gate valve. If you pick the wrong one, it might fail early.

| Design Feature | Description |

|---|---|

| Shearing Gate Tip | Cuts and breaks up material, pushing it downstream and stopping leaks to the air. |

| Mechanically Retained Axial Seat | Stops leaks and keeps the gate from bending when it hits solids. |

| Internal Gate Guides | Helps the gate move straight and makes the valve work better. |

| Bi-directional Design | Works with flow in both ways and does not leak. |

| Zero Leakage | Stops all leaks and keeps the environment safe. |

| Suitable for High Solids Slurry | Handles clean fluids and thick solids in many chemical places. |

Operation

Shut-Off

Knife gate valves give you a strong shut-off. The blade goes down and stops the flow. This is good when you need to block thick or solid-filled fluids. The valve is easy to close, even with big particles inside. You can count on it to seal tight and keep your system safe.

Sealing

Knife gate valves use special seats and guides to seal well. The seats hold the blade and stop leaks. Guides help the blade move straight so it does not bend or stick. Some valves seal both ways, so you do not worry about leaks if the flow changes.

Advantages

Slurries

If you move slurries, sludge, or fibers, use a knife gate valve. The sharp blade cuts thick and sticky fluids. This keeps your system clear of clogs. When open, the valve lets fluid pass easily and helps your process work well. Knife gate valves are used in mining, wastewater, and paper plants. These are great places for knife gate valves.

- Strong shut-off for slurry, sludge, or fiber flows

- Low pressure drop when open

- Good resistance to wear and rust

Maintenance

Knife gate valves are simple and small. You will spend less time and money fixing them. There are not many moving parts, so less can break. The valve’s tough materials and tight seal help it last long. You do not need to check or fix it often. This makes knife gate valves a good pick for hard jobs.

- Needs little maintenance

- Built to last

- Simple to check and fix

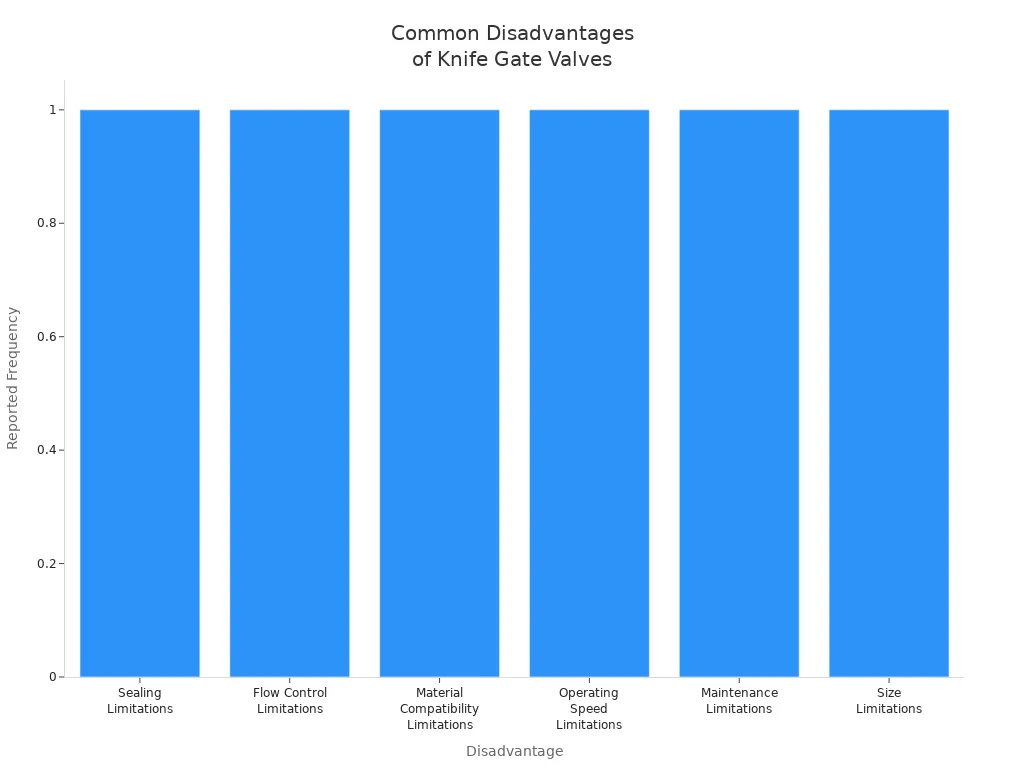

Disadvantages

When you choose a knife gate valve, you need to know its limits. This valve works well for thick fluids, but it does not fit every job. Some problems can happen if you use it in the wrong place.

| Disadvantage | Description |

|---|---|

| Sealing Limitations | You may see leaks, especially when you use the valve in high-pressure systems. |

| Flow Control Limitations | The valve only opens or closes. You cannot control the flow with much detail. |

| Material Compatibility Limitations | Some materials last longer but cost more. Others may rust or wear out faster. |

| Operating Speed Limitations | The valve moves slowly. You cannot use it for fast shut-off needs. |

| Maintenance Limitations | You may need to stop your system to fix the valve. This can slow down your work. |

| Size Limitations | Large valves are hard to make and keep working well. |

Pressure Limits

You should not use a knife gate valve for high-pressure jobs. The seal may not hold tight, and leaks can happen. If your system runs at high pressure, pick a different valve. Knife gate valves work best at low to medium pressure.

Leakage

Leaks are a common issue with knife gate valves. The seal may not stop all fluid, especially if you use the valve for thick or gritty flows. You might see drips or small leaks around the seat. Always check the valve for leaks after you install it. If you need a perfect seal, look for other valve types.

Applications

Knife gate valves help many industries move tough fluids. You will see them in places where thick, solid-filled flows need control.

| Industry | Typical Applications |

|---|---|

| Mining | Slurry transfer, tailings thickeners, cyclone feeds |

| Wastewater | Sewage systems, sludge handling, chamber installations |

Mining

In mining, you often deal with slurry and tailings. These flows have rocks, sand, and water mixed together. A knife gate valve cuts through these solids and keeps your pipes clear. You can use it for cyclone feeds and thickener lines. The valve helps you move heavy fluids without clogging.

Wastewater

Wastewater plants use knife gate valves to handle sludge and sewage. These fluids have solids and grit that can block other valves. The sharp blade slices through the mix and lets you control the flow. You can use the valve in chamber installations and sludge lines. This keeps your system running and stops blockages.

Note: Always match the valve to your fluid type. If you use the wrong valve, you may see leaks or clogs.

Gate Valve Overview

Design

Wedge

The wedge is the main part inside a gate valve. It moves up and down to let fluid pass or stop it. Most wedges are flat or shaped like a rectangle. This shape helps the valve close tightly. Some wedges are solid, and some can bend a little. Flexible wedges work better when the pressure is high. They can change shape to keep the seal strong.

| Feature | Knife Gate Valve | Gate Valve |

|---|---|---|

| Design | Sharp-edged blade for cutting through thick media | Flat or rectangular gate structure |

| Application | Suitable for slurries, powders, and fibrous materials | General-purpose for clean liquids, gases, and steam |

| Sealing Performance | Good when closed, but may leak when open | Good bidirectional sealing in both states |

| Pressure Suitability | Not suitable for ultra-high pressure | Can be used in high-pressure applications |

Body Types

There are different body types for gate valves. The most common are rising stem and non-rising stem. Rising stem valves show if the valve is open or closed. This makes them easy to check. Non-rising stem valves save space. They fit well in small places. You might also see bolted bonnet or pressure seal bonnet shapes. Each type works best for certain jobs.

Operation

Linear Motion

Gate valves open and close in a straight line. You turn the handwheel, and the wedge goes up or down. This lets you control how much fluid moves through. When open, fluid flows easily. When closed, the wedge stops all flow. This design gives a strong shut-off every time.

- Gate valves stop fluid flow completely. This helps prevent leaks in high-pressure places.

- They can block flow in both directions. This means they work well for high-pressure jobs.

- Flexible wedge gate valves are made for higher pressures. They are more reliable in tough spots.

Tight Seal

Gate valves seal very well. The wedge pushes against seats on both sides. This stops leaks from happening. The seal works no matter which way the fluid goes. You can trust the valve to keep your system safe.

Advantages

High Pressure

Gate valves are good for high-pressure systems. They work well where you need a strong seal and tough parts. The design helps them last in hard conditions. You will find gate valves in power plants and oil pipelines. They are reliable and keep things running.

| Advantage | Description |

|---|---|

| Energy Efficiency | Gate valves save energy by lowering resistance, which is beneficial in large operations. |

| Strong Sealing Capabilities | When closed, gate valves seal tightly to prevent leaks, enhancing safety and system performance. |

| Versatility | They can handle various fluids, including liquids, gases, and slurries, making them adaptable. |

| Reliability Under High Pressure | Gate valves are designed to withstand high pressure and perform well in tough conditions. |

| Ease of Maintenance | Their simple design allows for quick repairs and part replacements, minimizing downtime. |

Clean Fluids

Gate valves are best for clean fluids. The inside is smooth, so liquids, gases, and steam move easily. There is not much clogging or buildup. This makes them great for water, chemicals, and steam lines. You can count on them for safe and easy fluid control.

Tip: Pick a gate valve if you need a strong shut-off and good performance with clean or high-pressure fluids.

Disadvantages

Clogging

You may face clogging when you use a gate valve with fluids that contain solids or particles. The inside of the valve is not designed to handle thick or gritty flows. Solids can get stuck between the gate and the seats. This can stop the valve from closing all the way. If you work with fluids that have sand, dirt, or other debris, you might see the gate valve jam or leak. You should avoid using a gate valve in places where the fluid is not clean.

Tip: Always check your fluid before you choose a gate valve. If you see solids or grit, pick a different valve type to avoid clogging and damage.

Slow Action

A gate valve opens and closes slowly. You need to turn the handwheel many times to move the gate up or down. This takes more time than other valves. If you need to stop the flow quickly, a gate valve may not be the best choice. Slow action can be a problem in emergency situations. You might need a valve that reacts faster.

Here is a table that shows the most common disadvantages of gate valves:

| Disadvantage | Explanation |

|---|---|

| Poor Throttling Capability | You cannot use a gate valve to control flow. Partial opening can damage the gate and seats. |

| Susceptibility to Seat Wear | Frequent use or throttling can wear out the seats, causing leaks. |

| Slow Operation | You need many turns to open or close the valve, which makes it slow. |

| Wear in Abrasive Media | Parts can wear out over time, especially with abrasive or corrosive fluids. |

If you use a gate valve with dirty or abrasive fluids, you may see leaks and need more repairs.

Applications

Oil & Gas

You will find gate valves in oil and gas pipelines. These valves help you control the flow of clean liquids and gases. Gate valves work well in high-pressure systems. You can use them to start or stop the flow in large pipes. In oil refineries, gate valves manage the movement of crude oil and natural gas. They also help control pressure in storage tanks and transfer lines.

Power Plants

Gate valves play a big role in power plants. You use them to handle steam, water, and other clean fluids. These valves help you manage high pressure and temperature. In a power plant, gate valves control the flow to boilers, turbines, and cooling systems. You can rely on them for safe and strong shut-off. Gate valves also work in nuclear and hydroelectric plants.

Here is a table that shows where gate valves are used most often:

| Industry | Typical Use Cases |

|---|---|

| Water Treatment | Control of water flow during treatment processes. |

| Energy Production | Managing flow in oil and gas pipelines, handling pressure and corrosive media. |

| Manufacturing | Flow control in food, beverage, pharmaceuticals, and automotive production. |

| HVAC | Control of heating and cooling fluids without significant pressure drop. |

| Marine | Flow management of seawater and fire protection systems on ships. |

| Fire Protection | Swift control of water flow in fire protection systems. |

| Agriculture | Regulation of water supply in irrigation systems for crops. |

Gate valves are a good choice for clean fluids and high-pressure jobs. You should avoid them for thick or dirty flows.

Knife Gate Valve vs Gate Valve

Fluid Type

You need to think about your fluid type. Knife gate valves work with thick fluids and slurries. They also handle solids in the flow. You see knife gate valves in wastewater and pulp plants. The sharp blade cuts tough stuff and keeps things moving. Gate valves are for clean fluids like water, steam, and oil. These valves are used in power and petrochemical plants. Gate valves let fluid move easily when open. If your fluid has sand or grit, use a knife gate valve. If your fluid is clean and under high pressure, use a gate valve.

| Valve Type | Suitable Applications | Key Characteristics |

|---|---|---|

| Knife Gate Valve | Wastewater treatment, paper and pulp | Effective cutting capability, self-sealing function |

| Gate Valve | Petrochemical, power generation | Superior sealing in high-pressure environments |

Tip: Pick a valve that matches your fluid. This helps stop clogs and keeps your system working well.

Sealing

A good seal is important for your system. Knife gate valves have a thin, sharp gate. This gate slices through thick and sticky flows. The seats are made from strong materials. These seats help stop leaks, even with tough fluids. Gate valves use a thick wedge-shaped gate. The wedge pushes against seats to make a seal. This works best with clean fluids. Dirty fluids can wear out the seal and cause leaks. Knife gate valves are great for wastewater and mining. They handle solids and seal well. Gate valves are better for high-pressure and hot jobs.

- Knife gate valves cut solids and seal with tough seats.

- Gate valves use a wedge to seal, best for clean fluids.

- Knife gate valves work well with slurries and sticky flows.

- Gate valves are best for high-pressure, clean fluid systems.

Note: For dirty or thick fluids, pick a knife gate valve. For clean, high-pressure flows, pick a gate valve.

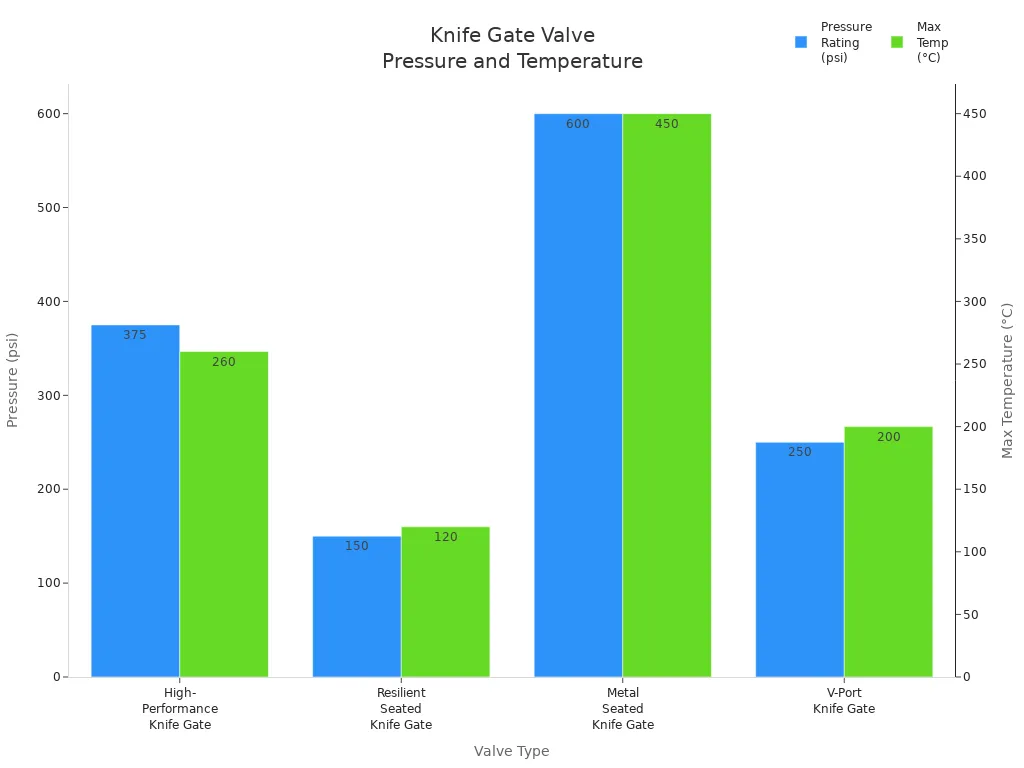

Pressure & Temperature

Pressure and temperature matter when you choose a valve. Knife gate valves come in many types. Each type has its own pressure and temperature limits. Some knife gate valves handle up to 375 psi and 500°F. Metal seated knife gate valves go up to 600 psi and 842°F. These valves are used in chemical and heavy industries. Gate valves are strong in high-pressure systems. You see them in power plants and petrochemical lines. They keep your system safe when pressure and heat are high. Knife gate valves fit low to medium pressure jobs. They are best for thick or dirty fluids. Gate valves fit high-pressure, clean fluid jobs.

| Valve Type | Pressure Rating | Temperature Range | Applications |

|---|---|---|---|

| High-Performance Knife Gate | PN 25 (375 psi) | -29°C to 260°C (500°F) | Chemical, pharmaceuticals, food manufacturing |

| Resilient Seated Knife Gate | PN 10 (150 psi) | Up to 120°C (248°F) | Sewage treatment, water distribution |

| Metal Seated Knife Gate | PN 40 (600 psi) | -40°C to 450°C (842°F) | Power generation, petrochemical, heavy industries |

| V-Port Knife Gate | PN 16 (250 psi) | Up to 200°C (392°F) | Process control in chemical and petrochemical |

| Zero Discharge Knife Gate | PN 25 (375 psi) | Varies | Chemical processing, hazardous waste management |

If your system has very high pressure or heat, use a gate valve. If you need to move thick or dirty fluids at lower pressure, use a knife gate valve.

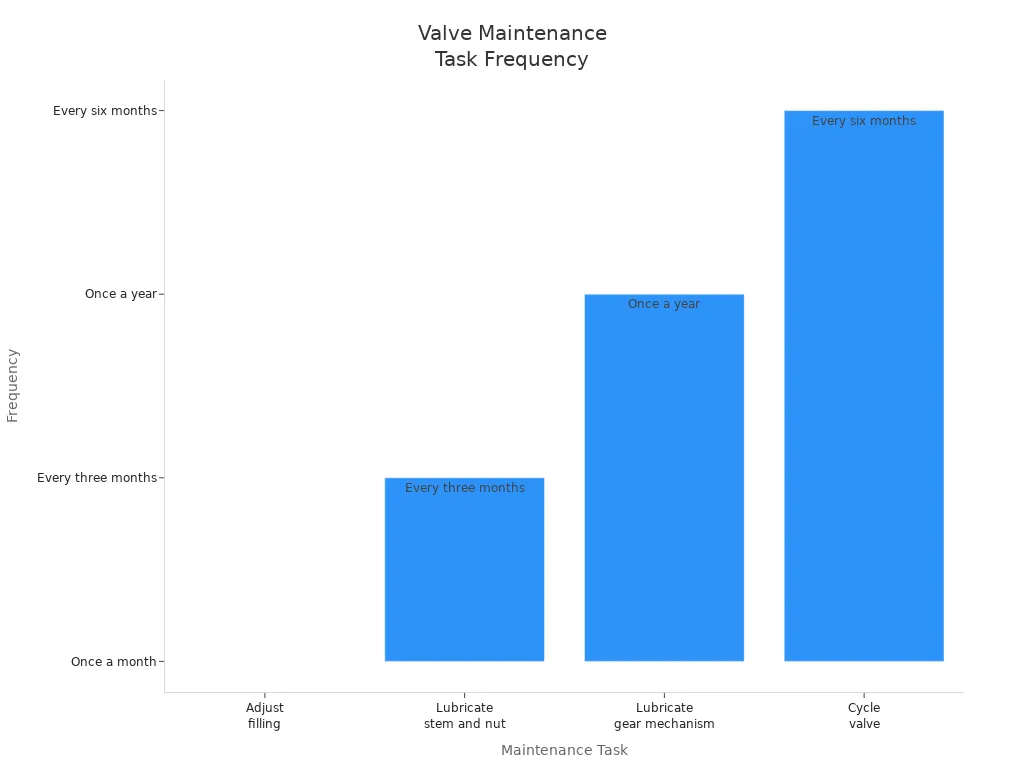

Maintenance

You need to think about maintenance when you choose between knife gate valves and gate valves. Both types need regular care to work well and last long. Knife gate valves have fewer moving parts, but you must handle the gate and packing with care. If you do not check the packing, leaks can happen. Gate valves need more attention to the stem and nut. You must keep these parts clean and lubricated.

Here is a table that shows how often you should do common maintenance tasks for both valves:

| Maintenance Task | Frequency |

|---|---|

| Adjust the filling | Once a month |

| Lubricate the valve stem and nut | Every three months |

| Lubricate the gear operating mechanism | Once a year |

| Cycle the valve (if not used) | Every six months |

You should follow these steps to keep your valves working:

- Adjust the filling to stop leaks.

- Lubricate the stem and nut so the valve moves smoothly.

- Lubricate the gear mechanism to prevent rust.

- Cycle the valve if you do not use it often. This keeps the parts from sticking.

Knife gate valves need special care for the gate and packing. If you do not maintain them, leaks may start. Gate valves need you to check the stem and seats. If you use the valve with dirty fluids, you may see more wear and need more repairs.

Tip: Regular maintenance helps you avoid leaks and keeps your system safe. Always follow the schedule for best results.

Gate Valve vs Knife Gate Valve: Decision Guide

When to Choose Knife Gate Valve

Pick a knife gate valve if your system moves thick fluids or slurries. This valve has a sharp blade that cuts fibers and particles. It helps stop clogs and keeps things working well. Knife gate valves are used in mining, wastewater, and pulp and paper jobs. These places often have tough fluids. The valve is small, so it fits in tight spaces.

Here is a table to help you know when to use a knife gate valve:

| Scenario | Reason for Preference |

|---|---|

| Large flow | Handles big flows without problems |

| Media with suspended solids or fibers | Cuts through solids and fibers easily |

| High installation space requirements | Works well in small or tight spaces |

Tip: If you need low flow resistance and deal with thick or dirty fluids, a knife gate valve helps stop blockages.

When to Choose Gate Valve

Use a gate valve if your system moves clean fluids like water, oil, or steam. This valve works well with high pressure and heat. The wedge inside makes a tight seal to stop leaks. Gate valves are common in oil and gas, power plants, and water treatment. If you want a valve that blocks flow both ways and shuts off strong, this is a good pick.

Gate valves are best when you want little flow resistance. When open, fluid moves easily with almost no pressure drop. This saves energy and keeps your system running well.

Note: If you need a valve for clean, high-pressure fluids and want a strong shut-off, pick a gate valve.

Checklist

Follow this checklist to pick the right valve for your job. It helps you avoid mistakes and match the valve to your system.

- Material selection: Make sure the valve material fits your fluid, temperature, and pressure.

- Proper valve sizing: Check that the valve size matches your flow and pipe.

- Adherence to industry standards: Use valves that meet ANSI, ASME, API, or ISO rules.

- Fluid characteristics: Know your fluid’s thickness, temperature, pressure, and if it can cause rust.

- Flow requirements: Think about pressure drop and how much flow you need.

- Operating conditions: Look at vibration, pressure changes, and temperature in your system.

- Material compatibility: Make sure the valve materials work with your fluids.

- Valve type: Pick the right valve for your job.

- Actuation method: Decide if you want manual or automatic operation.

- Reliability and maintenance: Choose valves from trusted brands.

- Regulatory compliance: Make sure your valve follows all rules.

- Cost considerations: Think about price and long-term value.

- Future expansion and flexibility: Plan for changes in your system.

Remember: Using this checklist helps you avoid mistakes and get the best results from your valve.

If you want to know the difference between gate valve and knife gate valve, look at your fluid, pressure, and space needs. The right valve keeps your system safe and working well. When you compare gate valve vs knife gate valve, think about what your job needs most.

Mistakes to Avoid

Choosing the wrong valve can cause big problems in your system. You need to know the difference between gate valve and knife gate valve before you decide. Many people make mistakes because they do not look closely at their fluid type or pressure needs. Here are some common mistakes you should avoid:

- Using a Gate Valve for Slurries or Thick Fluids

If you use a gate valve in a slurry line, solids can get stuck inside. This can clog the valve and stop the flow. You may need to shut down your system to fix it. Always use a knife gate valve for slurries, sludge, or fluids with lots of particles. - Using a Knife Gate Valve for High-Pressure Jobs

Knife gate valves do not work well with high pressure. If you use them in these situations, leaks can happen. This can lead to safety risks and system damage. Gate valves are better for high-pressure and clean fluid lines. - Ignoring Media and Pressure Requirements

You must know what kind of fluid you have and how much pressure your system uses. If you skip this step, you might pick the wrong valve. This can cause leaks, clogs, or even equipment failure. - Not Asking for Expert Advice

Sometimes, you may not know how to choose the right valve. If you feel unsure, talk to an engineer or valve expert. They can help you match the valve to your system. - Overlooking Maintenance Needs

Every valve needs care. If you forget to check and maintain your valve, it may fail early. Make a schedule for regular checks and stick to it.

Tip: Always match the valve to your fluid and pressure. This helps you avoid costly mistakes and keeps your system safe.

When you compare knife gate valve vs gate valve, remember that each has a special job. The gate valve vs knife gate valve choice depends on your fluid, pressure, and how clean your system needs to be. If you want to know how to choose the right valve, start by looking at your process and asking for help if you need it.

Installation & Maintenance Tips

刀閘閥-3-450x450.jpg)

Installation

You want your valve to work well and last a long time. Start with a careful pre-installation inspection. Look at the valve and make sure it is in good condition. Clean the sealing surfaces and check for smoothness. This helps prevent leaks. Examine all parts for damage or wear. Tighten bolts and nuts securely. This keeps the valve from shifting or leaking.

Align the valve with your pipeline. If you install it crooked, you may see problems later. Follow the manufacturer’s guidelines for orientation. Use the right gaskets to get a tight seal. After you finish, test for leaks. Make sure you can open and close the valve easily. Regular inspections help you catch problems early. Lubricate moving parts to reduce friction. Check bolts from time to time and tighten them if needed. Watch for corrosion, especially if your system runs in a harsh place.

Valve Installation Checklist

| Step | Why It Matters |

|---|---|

| Inspect valve and parts | Prevents early failure |

| Clean sealing surfaces | Stops leaks |

| Tighten bolts and nuts | Avoids misalignment |

| Align with pipeline | Ensures smooth flow |

| Use correct gaskets | Improves sealing |

| Leak test after install | Confirms proper setup |

| Lubricate moving parts | Reduces wear |

| Monitor for corrosion | Extends valve life |

Tip: Careful installation helps you avoid leaks and keeps your valve working for years.

Operation

You want your valve to run smoothly every day. Avoid flow obstructions so fluid moves easily. Pick the right design, size, and material for your job. This helps you get minimal flow resistance and better efficiency. Make sure the valve’s flow rate matches your pipe system. If you mismatch, you may see pressure problems.

Pay attention to temperature and pressure ratings. If you push the valve past its limits, it may fail. Always choose valves that meet your industry’s standards. This keeps your system safe and reliable. When you compare knife gate valve vs gate valve, think about your fluid and pressure needs. This helps you know how to choose the right valve for your job.

- Avoid blockages for smooth operation.

- Match valve size and flow rate to your system.

- Use valves that fit your temperature and pressure needs.

- Follow safety rules and standards.

Note: Good operation starts with smart choices and regular checks.

Maintenance

Routine care keeps your valve working well. Clean the valve often to remove debris. This stops blockages and keeps fluid moving. Lubricate moving parts so the valve opens and closes easily. If you skip lubrication, parts may wear out faster.

Check the alignment of valve components. If parts shift, you may see jamming or leaks. Adjust alignment as needed. Watch for signs of corrosion. If you see rust, clean it off and protect the valve. Regular maintenance helps you avoid big repairs and keeps your system safe.

Maintenance Tips

- Clean valve to prevent blockages.

- Lubricate moving parts for smooth action.

- Inspect and adjust alignment to stop jamming.

- Watch for corrosion and fix it early.

Tip: Set a schedule for cleaning and lubrication. This helps your valve last longer and work better.

Case Studies

Knife Gate Valve Example

Knife gate valves help many industries work better. These valves fix problems with thick fluids and solids. They work where other valves do not.

Here is a table that shows how knife gate valves help:

| Industry/Application | Description | Outcome |

|---|---|---|

| Mining | Used in Chilean copper mines for thick tailings pipelines under high pressure. | Prevents clogs and maintains smooth flow. |

| Paper Manufacturing | Handles thick pulp and fibrous slurries, improving efficiency in paper-making. | Enhances flow control and operational efficiency. |

| Wastewater Treatment | Manages thick sludge and slurry, preventing leaks and clogs. | Ensures smooth operation of slurry systems. |

In mining, tailings can block pipes. Knife gate valves cut through thick mixtures. This keeps the flow steady. You do not need to clean your system as much. In paper plants, pulp and fibers can block regular valves. Knife gate valves slice through these materials. They help you control the flow better. Wastewater plants use knife gate valves for sludge and slurry. These valves stop leaks and clogs. Your system runs smoothly.

Tip: If you work with thick or solid-filled fluids, think about knife gate valves. They help you avoid downtime and keep your process working well.

Gate Valve Example

Gate valves are important in many tough jobs. You use gate valves for strong shut-off and good performance with clean fluids or high pressure.

Here is a table that shows where gate valves work best:

| Application | Description |

|---|---|

| Power Generation | Gate valves are essential for steam control, cooling water systems, and turbine operation in power plants, handling high temperatures and pressures. |

| Chemical and Petrochemical Industry | They control the flow of corrosive fluids and gases, providing tight shut-off and resistance to chemical attack for safe operations. |

| Mining and Manufacturing | Used for slurries and abrasive materials, their robust construction suits demanding industrial environments. |

You can learn from stories in these industries:

- In a refinery, steam isolation valves may leak. This can cause expensive repairs. Engineers switched to gate valves with better sealing to fix this.

- Heavy oil jobs need zero-leakage isolation. Some companies made special gate valves. These valves won big projects because they stopped leaks.

- Chemical plants sometimes have wedge gate valves that leak during turbine isolation. These leaks can shut down the plant. Upgrading to high-quality gate valves helps you avoid shutdowns and keep things running.

Note: Gate valves give you strong shut-off and reliability in high-pressure or clean fluid systems. Pick them when you need tight sealing and safe operation.

Industry-Specific Applications: Knife Gate Valve vs Gate Valve

Mining & Minerals

Knife gate valves are preferred for handling abrasive slurries and thick fluids.

In mining, you deal with rough fluids and thick slurries. These can wear out normal valves fast. Knife gate valves work well because they cut through solids. They keep the flow moving and give a tight shut-off. Even if there is sand or rocks, the valve works. It does not jam easily and can handle pressure changes in mining.

Here is a table to show why knife gate valves are best in mining:

| Valve Type | Suitable Applications | Advantages | Limitations |

|---|---|---|---|

| Knife Gate Valve | Abrasive and corrosive slurries | Resists jamming, handles abrasives, tight shut-off | Higher cost, not needed for clean fluids |

Knife gate valves help stop downtime. They keep your system working, even with tough materials.

Gate valves are rarely used due to clogging risk.

Gate valves are not a good pick for mining. Solids can get stuck inside and cause clogs. The design does not work well with thick or gritty flows. If you use a gate valve, you may get blockages and need more repairs. This can slow down your work and cost more money. For mining, use valves that can handle solids and rough fluids.

Wastewater Treatment

Knife gate valves excel in managing solids-laden and viscous media.

Wastewater plants move sludge, grit, and thick liquids. You need a valve that can handle these tough flows. Knife gate valves have a sharp blade that cuts through solids. This keeps the line clear and stops clogs. They are great for sludge, biosolids, and thick flows. You get a strong shut-off and fewer problems.

Here is a table that compares features in wastewater treatment:

| Feature | Knife Gate Valves | Slide Gates |

|---|---|---|

| Primary Use | Thick liquids and slurries | Dry bulk materials |

| Mechanism | Blade cuts through materials | Flat plate slides to control flow |

| Maintenance | Needs seal replacement | Easier modular maintenance |

| Pressure Limitations | Low-pressure systems | Not for liquids |

| Applications | Wastewater, oil and gas, mining | Powders, pellets, granules |

Knife gate valves help you get fewer clogs and better flow in wastewater.

Gate valves may be used for clean water lines but are less effective with sludge.

You can use a gate valve for clean water in treatment plants. It gives a strong shut-off and works well with clear fluids. But if you use it with sludge or thick flows, it may clog. The design does not handle solids well. For sludge lines, knife gate valves are a better choice.

Oil & Gas

Gate valves are standard for high-pressure, clean fluid pipelines.

In oil and gas, you need to control high-pressure pipes with clean fluids. Gate valves are the main choice here. They give a tight seal and handle high pressure and heat. You can trust them in pipelines, refineries, and storage tanks.

Knife gate valves are occasionally used for specific slurry or sand-laden flows.

Sometimes, oil and gas pipes carry sand or solids. Knife gate valves help in these cases. They cut through particles and stop blockages. Safety and efficiency matter, so knife gate valves are used where regular valves would fail with solids.

Power Generation

Gate valves are common in steam and high-pressure water systems.

You often see gate valves in power plants. These valves help you control steam and water at high pressure. When you need to stop or start the flow, a gate valve gives you a strong shut-off. You can use them in boiler feed lines, turbine isolation, and cooling water systems. The design lets you handle high temperatures and pressure without leaks. If you work in a nuclear or fossil fuel plant, you rely on gate valves for safe operation.

| Application Area | Why Gate Valves Work Well |

|---|---|

| Boiler Feed Lines | Handles high pressure and heat |

| Turbine Isolation | Provides tight shut-off |

| Cooling Water | Resists corrosion and wear |

Tip: Always check the pressure rating before you install a gate valve in a power plant. This helps you avoid leaks and keeps your system safe.

Knife gate valves may be used in ash handling or slurry disposal lines.

You may need a knife gate valve for ash or slurry lines in power generation. These flows often carry solids that can clog regular valves. The sharp blade cuts through thick mixtures and keeps the line clear. You see knife gate valves in ash disposal, bottom ash removal, and slurry transport. If you deal with abrasive or gritty flows, this valve helps you avoid blockages.

- Handles abrasive ash and slurry

- Cuts through solids for smooth flow

- Reduces downtime from clogs

Note: Use a knife gate valve for tough jobs with solids. For clean steam or water, stick with gate valves.

Pulp & Paper

Knife gate valves are ideal for pulp stock, paper slurries, and fibrous materials.

You work with thick pulp and fibrous slurries in paper mills. These materials can block regular valves. A knife gate valve slices through fibers and keeps the flow moving. You use them in stock preparation, recycled fiber lines, and waste handling. The design helps you avoid jams and keeps your process efficient.

| Process Step | Benefit of Knife Gate Valve |

|---|---|

| Stock Preparation | Cuts through fibers and pulp |

| Waste Handling | Handles thick slurries |

| Recycled Fiber Lines | Prevents clogging |

If you want fewer shutdowns and better flow, choose a knife gate valve for pulp and paper jobs.

Gate valves are less suitable due to potential clogging.

Gate valves do not work well with pulp or fibrous materials. The inside can trap fibers and cause jams. You may see leaks or need more repairs if you use them in these lines. For clean water or steam in the plant, gate valves are fine. For thick or dirty flows, avoid them.

- Risk of clogging with fibers

- More maintenance needed

- Not ideal for slurries

Tip: Always match your valve to the fluid. This helps you avoid problems and keeps your system running.

Chemical Processing

Knife gate valves are chosen for corrosive, thick, or particulate-laden chemicals.

You handle many types of chemicals in processing plants. Some are thick, corrosive, or have particles. A knife gate valve works well in these cases. The blade cuts through solids and resists chemical attack. You use them in slurry transfer, waste handling, and mixing tanks. The valve helps you control tough flows and keeps your system safe.

| Chemical Type | Why Knife Gate Valve Works |

|---|---|

| Corrosive Slurries | Resists chemical wear |

| Particulate Flows | Cuts through solids |

| Thick Mixtures | Prevents blockages |

Note: Pick a knife gate valve for tough chemical jobs. It helps you avoid leaks and downtime.

Gate valves are used for clean, non-abrasive chemical flows.

You use gate valves for clean chemical lines. These valves give you a tight seal and strong shut-off. If your chemicals do not have solids or grit, a gate valve works well. You see them in solvent transfer, pure water lines, and non-abrasive flows. The design keeps your system safe and easy to maintain.

- Best for clean, non-abrasive chemicals

- Provides reliable shut-off

- Easy to inspect and repair

Tip: For clean chemical flows, choose a gate valve. For thick or gritty chemicals, use a knife gate valve.

Choosing the right valve boosts your system’s performance. Use a knife gate valve for slurries, thick fluids, or solids. Pick a gate valve for clean, high-pressure flows. Always match the valve to your fluid and job needs.

Tip: Review the decision guide before you buy. If you feel unsure, talk to a valve expert. This helps you avoid costly mistakes and keeps your operation running smoothly.

FAQ

What is the main difference between a knife gate valve and a gate valve?

You use a knife gate valve for thick fluids and solids. You pick a gate valve for clean fluids and high pressure. The blade in a knife gate valve cuts through tough material. The wedge in a gate valve gives a tight seal.

Can I use a knife gate valve for high-pressure systems?

You should not use a knife gate valve for high-pressure jobs. The seal may leak if pressure gets too high. Gate valves work better for high-pressure and clean fluid lines.

How do I know which valve to choose for my application?

You look at your fluid type, pressure, and system needs. If you move slurries or solids, choose a knife gate valve. For clean, high-pressure fluids, pick a gate valve.

Tip: Always match the valve to your fluid and pressure.

Do knife gate valves need more maintenance than gate valves?

You spend less time on knife gate valve maintenance. These valves have fewer moving parts. Gate valves need more care for the stem and seats, especially with dirty fluids.

Are gate valves good for controlling flow?

You should not use gate valves for flow control. They work best fully open or closed. Partial opening can damage the gate and seats.

What materials are best for knife gate valves in corrosive environments?

You pick stainless steel or special alloys for corrosive fluids. These materials resist rust and wear. Always check the chemical compatibility before you buy.

Note: Material choice affects valve life and safety.