Isolation valves help stop or let fluids move in pipes. This lets you control the system and keep it safe during repairs or emergencies. You must pick the right isolation valve to stop leaks and protect machines. The right valve also helps things run well. Many industries use different types of valves. These include gate valves, ball valves, butterfly valves, globe valves, and diaphragm valves. Each valve type is made for a special job. For example, a ball valve can shut off flow fast. A butterfly valve is small and controls flow well. Some systems use electric valves or pneumatic valves for automatic control. As you read, think about what your system needs. Think about how each valve type could work for you.

Key Takeaways

- Isolation valves let fluids move or stop to keep systems safe when fixing things or in emergencies. Different valve types like gate, ball, butterfly, plug, globe, diaphragm, needle, knife gate, and penstock each have special uses and work with certain fluids. Picking the right valve depends on pressure, temperature, fluid type, size, and how easy it is to take care of. Some common mistakes are mixing up valve types, not checking if materials match, and forgetting to look at pressure or flow needs. Ball valves shut fast and seal tight but do not control flow well; gate valves can handle high pressure but open slowly. Butterfly valves save space and money but block some flow; diaphragm valves are good for thick fluids and are simple to clean. Always check valve safety ratings and rules, especially for oil, gas, and chemical jobs, to stop leaks and accidents.

Isolation Valves Overview

What Is an Isolation Valve

An isolation valve stops liquids or gases from moving in a pipe. It makes a wall that keeps fluid on one side. The other side stays blocked. If you need to fix part of your system, you close this valve. This lets you shut off flow and work safely. You can repair or check equipment without worry. Regulating valves are different. They control how much fluid moves. Isolation valves are made to stop flow all the way.

Tip: Pick an isolation valve that fits your system’s pressure and fluid type. This helps stop leaks and keeps everything safe.

Here is how isolation valves are not like other valves:

- Isolation valves seal tight and keep fluid on one side.

- Their main job is to stop flow and block off parts of your system.

- Regulating valves only control flow and may not stop it fully.

- Isolation valves must seal well, especially with dangerous fluids.

- The main reason for an isolation valve is to give a strong shutoff.

Why Isolation Valves Matter

You need isolation valves for safety, repairs, and control. These valves keep your team and equipment safe. When you fix a pump or test a system, you use an isolation valve to block flow. This stops dangerous fluids or gases from getting out. In emergencies, these valves cut off harmful or flammable stuff and protect your building.

| Primary Function / Requirement | Description |

|---|---|

| Isolate piping sections | Lets you work on parts of your system without shutting everything down. |

| Emergency flow cut-off | Stops flow of dangerous materials during emergencies. |

| Prevent release or ingress | Blocks release of harmful substances or entry of gases in sensitive areas. |

| Protect equipment | Shields pumps and valves during maintenance or testing. |

| Location and accessibility | Should be easy to reach and operate safely. |

| Operability | Must work both manually and remotely. |

| Fire safety rating | Needs to work even during fire conditions. |

| Visual indication | Shows you if the valve is open or closed. |

| Compliance with standards | Meets rules from groups like API, NFPA, and ASME. |

You find isolation valves in many places. In nuclear plants, they keep radioactive stuff inside. In firewater systems, you use manual isolation valves to remove pumps or test flow. Some valves show if they are open or closed. This helps you not make mistakes. Always put isolation valves in safe, bright places where you can reach them fast.

Isolation valves do more than just shut off flow. They help you stay safe, follow rules, and keep your system working well.

Types of Isolation Valves

Gate Valves

Mechanism

Gate valves have a flat or wedge-shaped gate inside. The gate moves up or down when you turn the handwheel. If the gate is up, fluid can flow through. If the gate is down, it blocks the fluid. The path for the fluid is straight when open, so it moves easily. There are rising stem and non-rising stem types. Rising stem types let you see if the valve is open or closed.

Best Uses

Gate valves are used when you need to stop flow completely. They work best in systems that stay open or closed for a long time. You find them in oil and gas, water treatment, chemical plants, and power plants. Gate valves can handle high pressure and heat. They are good for hot water, steam, and other tough jobs.

Tip: Gate valves should not be used to control flow. If you try to do this, the gate can wear out quickly.

Here is a table that shows where you use gate valves and their pressure ratings:

| Valve Class | Pressure Rating (PSI @ 100°F) | Typical Applications |

|---|---|---|

| Class 150 | ~285 PSI | General purpose |

| Class 300 | ~740 PSI | Medium pressure |

| Class 800 | ~1975 PSI | High pressure: steam, petroleum, power |

Pros and Cons

Pros:

- Fluid moves straight through, so there is little pressure drop.

- Good for shutting off big pipelines.

- Can handle high pressure and heat.

- Used in many industries.

Cons:

- Takes a long time to open or close.

- Not good for controlling flow.

- Big and heavy, especially in large sizes.

- Needs more room to put in.

Gate valves are found in oil refineries, water plants, and chemical factories. They help you block off parts of a system for repairs or emergencies.

Ball Valves

Mechanism

Ball valves have a round ball with a hole in the middle. When you turn the handle, the hole lines up with the pipe and lets fluid pass. Turn the handle again, and the ball blocks the flow. This quarter-turn makes it fast to shut off. Ball valves seal tightly and work with many fluids.

Best Uses

Ball valves are used when you need to stop flow quickly. They are found in HVAC systems, water pipes, and gas lines. Ball valves work in both low and high-pressure systems. You see them in oil and gas, chemical plants, and water treatment. They are small, so they fit in tight spaces.

Ball valves are about 19.5% of all industrial valves. People like them because they work fast, seal well, and need little care.

Here is a table that compares common valves and their uses:

| Valve Type | Common Applications | Key Characteristics and Notes |

|---|---|---|

| Ball Valves | HVAC, chilled water, domestic water | Quarter-turn, tight seal, sizes 15-50mm, minimal turbulence, not for throttling, hand or actuator operated |

| Butterfly Valves | HVAC, space-limited, chilled water | Compact, quarter-turn, on-off and some throttling, elastomer liners, good for higher pressure and temperature |

| Gate Valves | Chemical, pharmaceutical, hot water | Rising/non-rising stem, straight flow, low pressure drop, not for throttling |

| Globe Valves | Isolation and throttling | Spherical body, high resistance, effective throttling, less common for isolation |

Pros and Cons

Pros:

- Turns 90 degrees for fast shutoff.

- Seals tightly to stop leaks.

- Needs little care and is easy to fix.

- Works with many fluids.

- Small and fits in tight spots.

Cons:

- Not good for controlling flow; can wear out.

- Can trap fluid inside when closed.

- Some types do not handle very high heat.

Ball valves are used for water, oil, gas, and chemicals. They are good in emergencies because you can close them fast.

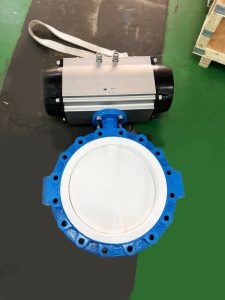

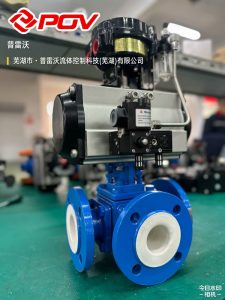

Butterfly Isolation Valve

Mechanism

Butterfly isolation valves have a disc on a rod. When you turn the handle, the disc turns a quarter turn to open or close. The disc stays in the flow path, even when open. This makes the valve light and easy to put in.

Best Uses

Butterfly valves are used in big pipes where space and weight matter. They are found in HVAC systems, water pipes, and places with little room. Butterfly valves are good for turning flow on or off and for some flow control. You see them in chilled water, hot water, and home water systems.

Here is a table that compares butterfly valves and gate valves in big pipes:

| Factor | Butterfly Isolation Valves | Gate Valves |

|---|---|---|

| Size & Weight | Smaller, lighter, easier to install | Larger, heavier, more complex installation |

| Operation Speed | Faster operation, quick open/close | Slower, requires multiple turns |

| Cost | Lower cost, especially in large sizes | Higher cost, particularly for large diameters |

| Flow Obstruction | Disc remains in flow path causing some obstruction | Straight-through flow path, minimal obstruction |

| Pressure Drop | Higher pressure drop due to disc in flow | Minimal pressure drop when fully open |

| Throttling Capability | Good throttling and flow regulation | Not suitable for throttling, only on/off |

| Suitability | Good for space-limited, moderate pressure and temperature | Best for high pressure and temperature, tight shutoff |

| Durability Concerns | Possible cavitation, vibration at some flows | More durable under tough conditions |

| Maintenance | Simpler due to fewer parts | More complex maintenance |

Pros and Cons

Pros:

- Small and light.

- Opens and closes quickly.

- Costs less for big pipes.

- Good for some flow control.

Cons:

- Disc stays in the flow, so there is some pressure drop.

- Does not shut off as tightly as ball or gate valves.

- Seals and seats can wear out over time.

- May have problems with cavitation or vibration.

Butterfly valves can fail if the stem leaks, if there are leaks inside, or if they do not seal well. You should check for dirt, rust, and worn seals when you do maintenance.

Note: Butterfly valves are a good choice if you need to save space and money, but they may not work well for high pressure or high heat.

Plug Valves

Mechanism

Plug valves have a plug with a hole in the middle. The plug is shaped like a cylinder or a cone. When you turn the handle, the plug spins inside the valve. If the hole matches the pipe, fluid can move through. If you turn the plug, it blocks the flow. This makes it easy to turn on or off fast. Some plug valves have special coatings or liners. These help them work with strong or dangerous fluids.

Best Uses

Plug valves are used in chemical plants and refineries. They work with many fluids, even ones that are dangerous or can burn. Plug valves can control flow both ways and handle tough jobs. You can use them to turn flow on or off or slow it down. Their simple shape makes them useful in many places.

- Plug valves help control chemicals in factories.

- They can handle strong materials, which is important for safety.

- You can use them to mix chemicals and keep products safe.

- Plug valves work well with different flow needs in factories.

Pros and Cons

Pros:

- Simple shape with not many moving parts.

- Easy to clean and fix. You can take out the plug to clean it.

- Works with many fluids, even strong chemicals.

- Turns off flow quickly.

Cons:

- Not good for big pressure drops.

- Can be hard to turn if not oiled.

- May wear out faster with rough fluids.

| Feature | Plug Valve | Ball Valve |

|---|---|---|

| Maintenance | Easier to fix because it has fewer parts. You can take out the plug and clean it. The inside is easy to reach for cleaning. | Harder to fix because the ball is deep inside. Dirt can get stuck inside, making cleaning hard. Most ball valves are replaced, not fixed. Only 3-piece ball valves can be fixed easily. |

Plug valves are special because they are easy to fix and work with many fluids. You find them where you need fast shutoff and easy cleaning.

Globe Valves

Mechanism

Globe valves have a round body and a moving disc. When you turn the handwheel, the disc goes up or down. This opens or closes the path for fluid. The fluid must turn inside the valve, which lowers the pressure. Globe valves let you control flow very well. You can change how much the disc lifts to adjust flow.

Best Uses

Globe valves are good when you need to control flow and pressure. You see them in cooling water, fuel oil, and steam lines. They are used in power plants, chemical factories, and water plants. Globe valves can slow down flow without getting damaged.

- Cooling water systems

- Fuel oil systems

- Chemical feed systems

- Boiler and steam vents and drains

- Turbine oil systems

You also find globe valves in:

- Oil refineries

- Chemical plants

- Power plants

- Steam stations

- Thermal power plants

Globe valves are common for stopping and slowing flow. They help you control flow and shut off tightly.

Pros and Cons

Pros:

- Great for careful flow control.

- Can handle high pressure, up to about 1500 psi.

- Good for stopping and slowing flow.

- Shuts off well.

Cons:

- Makes pressure drop because of the S-shaped path.

- Bigger and heavier than some other valves.

- Costs more than gate or ball valves of the same size.

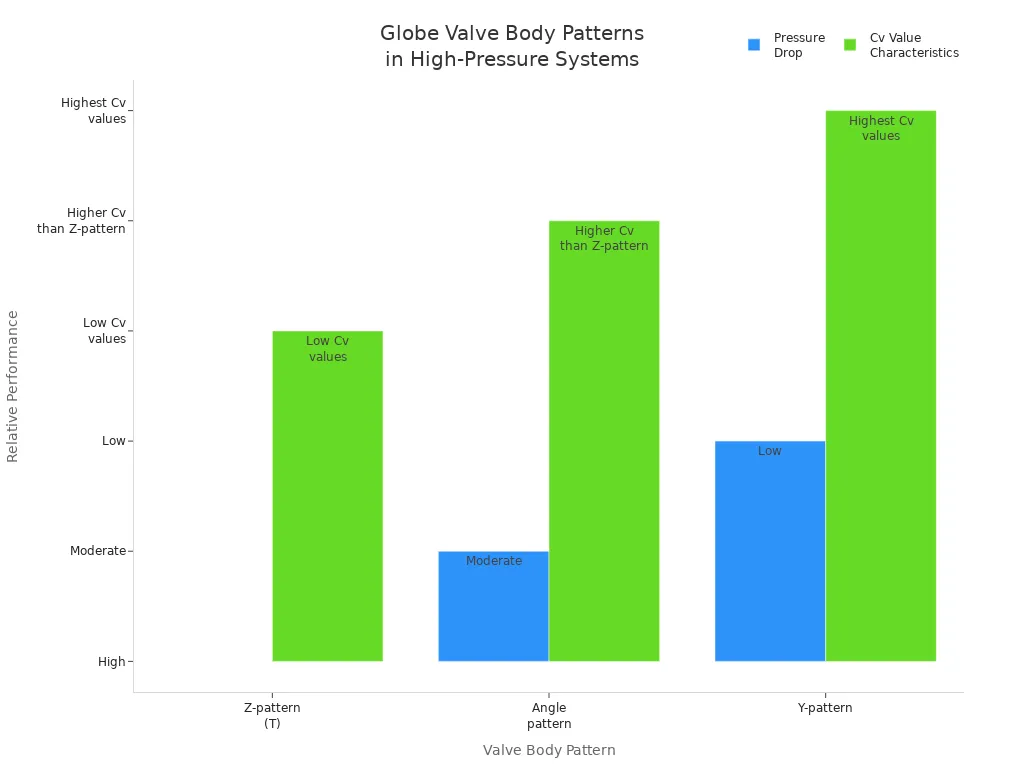

| Valve Body Pattern | Flow Path Description | Pressure Drop | Cv Value Characteristics | Suitability for High Pressure |

|---|---|---|---|---|

| Z-pattern (T) | S-shaped with two sharp turns | High | Lower Cv values | Used often but higher pressure drop |

| Angle pattern | One sharp turn | Medium | Higher Cv than Z-pattern | Better than Z-pattern |

| Y-pattern | Slanted, straighter flow | Low | Highest Cv values | Best for high pressure |

Globe valves let you control flow very well. You can pick from Z-pattern, angle, or Y-pattern globe valves. These types of isolation valves are important when you need both control and shutoff.

Diaphragm Valves

Mechanism

Diaphragm valves use a soft diaphragm that pushes down to stop flow. When you turn the handle, the diaphragm lifts up and lets fluid move. The valve and diaphragm can be made from special materials to stop rust or damage. The design keeps the fluid away from moving parts, so leaks are less likely.

Best Uses

You see diaphragm valves in water plants, chemical factories, and mines. They work well with fluids that can damage other valves. Diaphragm valves are also used in medicine and food factories. They are easy to clean and do not trap dirt.

- Diaphragm valves do not rust or wear out fast.

- The design lets fluid drain out, so there is less dirt.

- Sealed parts keep out dust and dirt, so they last longer.

- You can use them to control flow carefully, which is important in labs and medicine.

- They react fast to changes, so you waste less and keep things safe.

- Their simple shape means less fixing and longer life.

Pros and Cons

Pros:

- Great for strong or rough fluids.

- Simple shape with few moving parts.

- Easy to clean and fix.

- Good for careful flow control.

- Lasts a long time if you take care of it.

Cons:

- Not good for very high pressure or heat.

- The diaphragm can wear out and need changing.

- Only comes in certain sizes and flow rates.

To keep diaphragm valves working well, you should:

- Check the diaphragm for damage and change it if needed.

- Clean the valve and parts often to stop buildup.

- Make sure the actuator is lined up right.

- Look for leaks at the seals and fix them.

- Make sure the valve moves smoothly.

- Oil moving parts if needed.

- Change diaphragms and seals on a schedule.

- Watch for changes in flow that could mean trouble.

Diaphragm valves are a type of isolation valve that works well in tough places. You can trust them for clean work and easy care, especially in water and chemical plants.

Needle Valves

Mechanism

Needle valves have a long, sharp needle inside. The needle fits into a matching seat. When you turn the handle, the needle moves up or down. This opens or closes a tiny gap for fluid. The sharp tip and tight fit help you change flow in small steps. The valve body has fine threads. This lets you control the needle very carefully.

Best Uses

You use needle valves when you need careful flow control. These valves are best when small changes matter a lot. You see them in:

- Laboratory equipment

- Medical devices

- Fuel lines in engines

- Hydraulic and pneumatic systems

- Chemical processing plants

Needle valves help you:

- Set flow rates with high accuracy

- Keep pressure steady and stop sudden jumps

- Balance pressure in different parts of a system

- Change flow and pressure quickly if needed

Needle valves are used in aerospace, cars, and medicine. Their design lets you make tiny changes, which is important for safety and good results.

Tip: Needle valves work with actuators. You can use them by hand or with a motor for remote or automatic control.

Pros and Cons

| Pros | Cons |

|---|---|

| Lets you make small flow changes | Not good for high flow rates |

| Keeps pressure steady and stops sudden jumps | Can clog if fluid has dirt or solids |

| Works well in high-pressure systems | Costs more than simple shutoff valves |

| Can be used with actuators for automation | Slower to open or close |

| Tight seal stops leaks | Not good for thick or sticky fluids |

Needle valves give you the control you need for careful jobs. You can trust them when you must set exact flow rates and keep your system safe.

Knife Gate Valves

刀閘閥-3-450x450.jpg)

Mechanism

Knife gate valves have a flat, sharp blade inside. The blade moves up or down to open or close the valve. When you turn the handle or use an actuator, the blade slides through the fluid. The sharp edge cuts through thick or solid-filled fluids. The valve body is made from strong metals like stainless steel. Seals around the blade stop leaks.

Best Uses

You use knife gate valves for thick or solid-filled fluids. These valves work best with:

- Slurries (water mixed with solids)

- Pulp in paper mills

- Wastewater with debris

- Mining sludges

- Food processing with bulk materials

Knife gate valves are found in:

- Chemical plants

- Mining and mineral processing

- Pulp and paper factories

- Power plants

- Water and wastewater treatment

You pick knife gate valves to block off parts of a system with tough or sticky fluids. The sharp blade keeps the valve from getting stuck and helps it seal well.

Knife gate valves are easy to use and fix. You can use them by hand, with air, or with electric actuators.

Pros and Cons

| Pros | Cons |

|---|---|

| Cuts through thick and solid-filled fluids easily | Not good for high-pressure jobs |

| Simple design means low fluid resistance | Not good for careful flow control |

| Good sealing stops leaks | Can wear out with very rough fluids |

| Light and easy to put in | May leak if not checked often |

| Works well in harsh, corrosive places | Not good for gases or clean fluids |

Knife gate valves help you handle tough jobs in your plant. You can count on them to keep your system working, even with thick or dirty fluids.

Penstock Valves

Mechanism

Penstock valves work like sliding gates. You move a flat or curved plate up or down to control water flow. You can do this by hand, with a motor, or with automatic controls. The frame and gate are made from strong metals like stainless steel. Seals along the edges stop water from leaking. Some penstock valves use rollers or guides to help the gate move smoothly, even with high water pressure.

Best Uses

You use penstock valves to control lots of water. These valves are made for big jobs where you need to start, stop, or change water flow. You find penstock valves in:

- Water treatment plants

- Dams and reservoirs

- Irrigation systems

- Hydroelectric power plants

- Flood control systems

- Stormwater and wastewater plants

Penstock valves help you:

- Control water levels in tanks and channels

- Manage flow during floods or heavy rain

- Move water for farming or industry

- Block off parts of a water system for repairs

Penstock valves are built for tough jobs. Their strong seals and frames keep them working with high water pressure and in harsh places.

Pros and Cons

| Pros | Cons |

|---|---|

| Handles very large amounts of water | Big and heavy, needs strong supports |

| Strong seals stop leaks, even with high pressure | Costs more than smaller valve types |

| Made from metals that do not rust for long life | Not good for small pipes or low flows |

| Can be used by hand or with machines | Needs regular checks to keep seals working |

| Good for careful control in water management | Slow to open or close compared to other valves |

Penstock valves give you strong control over water in big systems. You can trust them for safety and good results in water projects.

Selecting the Right Valve

Key Selection Factors

When you pick a valve, you need to look at a few important things. First, check the highest pressure your system can reach. The valve must handle this pressure, even if it only happens sometimes, like when a pump shuts off. Next, think about how hot or cold your system gets. The valve should work safely at these temperatures.

You also need to make sure the valve material matches the fluid in your pipes. Some fluids need special materials like stainless steel, Monel, or Inconel. These materials work well with strong chemicals or high-pressure fluids. If you use the wrong material, you could get leaks or rust, and your system might break.

Think about how the valve connects to your pipes. Welded ends stop leaks in high-pressure systems, but you cannot take them apart easily. Flanged ends are easier to take off for repairs. Make sure the valve comes in the size you need. Some valves only fit certain pipe sizes.

If you work with dangerous fluids, you need a valve that does not leak. Look for valves that meet safety rules for leaks. You should also think about how easy it is to clean or fix the valve. Some valves, like plug valves, are easier to clean than others.

Here are some tips to help you pick a valve:

- Make sure the valve can handle your system’s pressure and temperature.

- Check that all parts touching the fluid are safe for it.

- Pick a connection type that makes repairs easy for you.

- Make sure the valve size fits your pipe.

- Think about how often you will need to clean or fix the valve.

Note: Always check these important things before you choose a valve. This helps you avoid problems and keeps your system safe.

Common Mistakes

People often make mistakes when picking isolation valves. One mistake is mixing up valve types and what they do. For example, you might use a pressure regulator when you need a backpressure regulator. Or you might use a solenoid valve without checking if it is safe when power goes out.

Another big mistake is not checking if the valve material works with your fluid. If you skip checking charts or temperature ratings, you could get leaks, rust, or even safety problems. Some people just match the valve size to the pipe size without checking if it can handle the pressure or flow. This can make the valve fail.

Other mistakes are not thinking about how fast the fluid moves or how quickly the valve closes. If you forget these, you might get water hammer or break your system. Some people do not check if the actuator voltage or cover is right, which can cause overheating or fire.

Here is a quick list of mistakes you should not make:

- Mixing up valve types and what they do.

- Not checking if the valve material works with your fluid or temperature.

- Picking a valve size without checking pressure or flow needs.

- Forgetting about how fast the fluid moves or how fast the valve closes.

- Not checking if the actuator voltage or cover is right.

Tip: If you are not sure how to pick a valve, ask an expert or the company that makes valves. They can help you avoid these mistakes and choose the best valve for your system.

Decision Guide for Purchasing Isolation Valves

Picking the right valve can be tricky. You want your system to be safe and last long. This guide helps you compare valves fast. It shows you how to pick the best one for your needs.

Comparison Table

This table helps you look at the most important features. Engineers check these things before they choose a valve.

| Parameter Category | Examples / Details |

|---|---|

| Conveyed Fluid | Liquid, Gas, Slurry, Solids |

| Nature of Fluid | Neutral, Corrosive, Hygienic, Abrasive |

| Valve Function | On/Off, Control/Modulating |

| Type of Disc | Gate, Rotary Ball, Plug, Diaphragm, Butterfly, Needle, Pinch, Squeeze, Spiral Sock |

| Material and Build | Stainless steel, brass, plastic, corrosion resistance |

| Port Design | Standard port, full port |

| Connection and Mounting | Threaded, flanged, welded, actuator compatibility |

| Cost and Lifecycle | Initial cost, maintenance needs |

| Flow and Pressure | System flow rate, pressure drop |

| Installation Conditions | Space, pipeline layout, automation plans |

| Maintenance Objectives | Cleaning, repair frequency, energy loss |

| Operational Needs | Manual or automated operation |

Tip: Always pick a valve material and design that matches your fluid and system pressure. This stops leaks and keeps your system safe.

Selection Checklist

Use this checklist to help you pick a valve. Each step helps you focus on what is most important.

- Identify the fluid

What will move through the valve? (water, gas, slurry, chemicals) - Check fluid properties

Is the fluid rough, does it cause rust, or must it stay clean? - Define the valve function

Do you need just on/off or do you want to change flow? - Choose the valve type

Pick from gate, ball, butterfly, plug, globe, diaphragm, needle, knife gate, or penstock. - Select the right material

Make sure the valve and seals can handle your fluid and heat. - Decide on port and connection

Choose standard or full port. Pick the right way to connect (threaded, flanged, welded). - Check pressure and flow needs

Make sure the valve can take your system’s highest pressure and flow. - Plan for installation

Check if you have enough space and if you want manual or automatic use. - Think about maintenance

Pick a valve that is easy to clean and fix in your system. - Review cost and lifecycle

Balance the first cost with how often you will need to fix or replace the valve.

Note: Use this decision guide every time you build or upgrade a system. Picking the right valve now saves you time and money later.

Isolation Valve Applications

Industrial Systems

You find isolation valves in many industrial systems. These valves help you control flow and keep your equipment safe. In factories, you often need to stop fluids quickly for repairs or emergencies. You see many application scenarios in power plants, food processing, and manufacturing lines. For example, you might use a gate valve to shut off steam in a power plant. Ball valves work well when you need fast shutoff in chemical mixing tanks. Plug valves help you handle strong chemicals in refineries. Each of these application scenarios needs a valve that matches the fluid and pressure. You must pick the right valve to avoid leaks and keep your team safe. In these settings, you often use valves with strong seals and easy operation. You also need to check valves often to make sure they work well.

HVAC and Plumbing

You use hvac valves in heating, ventilation, and air conditioning systems. These valves help you control water, steam, or air in pipes. You find many application scenarios in large buildings, schools, and hospitals. For example, you might use ball valves to shut off water to a cooling tower. Butterfly valves work well in big air ducts because they are light and easy to turn. Globe valves help you control flow in hot water lines. You also see hvac valves in home plumbing. In these application scenarios, you want valves that open and close fast. You also want valves that do not leak. Good hvac valves help you save energy and keep rooms comfortable. You should check your valves often to stop problems before they start.

Tip: Always label your hvac valves. This helps you find the right one fast during repairs.

Water and Wastewater

You see isolation valves in every municipal water system. These valves help you control water flow to homes, schools, and factories. You find many application scenarios in water treatment plants, pumping stations, and sewer lines. For example, you might use knife gate valves to handle thick sludge in wastewater plants. Penstock valves help you control water levels in reservoirs. Diaphragm valves work well with clean water and chemicals used for treatment. In these application scenarios, you need valves that last a long time and do not rust. You also want valves that are easy to open and close, even if they are big. Good valves help you stop leaks and keep water safe for everyone.

Note: Always test your valves in a municipal water system. This keeps water clean and stops waste.

Oil, Gas, and Chemical

Isolation valves are very important in oil, gas, and chemical plants. These places use many dangerous fluids. You must pick valves that keep everything safe and working well. In oil and gas, you work with fuels like fuel oil and natural gas. Here, you can use standard isolation valves with soft seats. These valves work for most jobs with normal heat and pressure. They are good for fuel storage, moving fuel, and shutting off flow for safety.

In refineries and chemical plants, things get harder. You deal with flammable fluids like petrochemicals, plant gas, and alcohols. These jobs need special isolation valves made just for them. The valves must handle higher heat, more pressure, and strong chemicals. For example, you use metal-seated valves when it gets hotter than 260°C (500°F). This helps stop leaks and keeps the plant safe.

Chemical and refinery jobs also have strict safety rules. Many plants need valves that meet high safety levels, like SIL2 or SIL3. These levels mean the valve must work even if there is an emergency. Some valves have special tests and extra solenoids. These help you check if the valve works without stopping the whole plant. Refineries often use valves built to ANSI 300 rules. These are stronger than ANSI 150 valves used for easier jobs.

Choosing valves in these plants is more complicated. You must think about the fluid, the pressure, and the heat. You also need to make sure the valve meets all safety and environmental rules. In many cases, you cannot use regular valves. You must work with engineers to design the right valve for your job.

Tip: Always check the safety rating and material of your isolation valve before you put it in oil, gas, or chemical systems. This helps you stop leaks, fires, and shutdowns.

Here is a table to help you compare what you need:

| Industry | Typical Fluids | Valve Type Needed | Safety Level | Common Standards |

|---|---|---|---|---|

| Oil & Gas | Fuel oil, natural gas | Standard soft-seated | Moderate (SIL1) | ANSI 150 |

| Refinery/Chemical | Petrochemicals, alcohols | Custom metal-seated | High (SIL2/SIL3) | ANSI 300 |

Each industry has its own jobs. You must pick the right valve to keep your system safe and working well.

Picking the right isolation valve helps your system stay safe and work well. Always choose a valve that fits your job. Use the checklist and table to help you decide. If you are not sure, ask a valve expert for help. Before you buy a valve, think about what your system needs:

- Look at the pressure and temperature

- Find out what kind of fluid you have

- Think about how you will take care of the valve

Remember: Planning ahead helps you save money and keeps your system working without problems.

FAQ

What is the main job of an isolation valve?

You use an isolation valve to stop or allow flow in a pipe. This helps you work on your system safely. You can also use it to block dangerous fluids during emergencies.

How do you know which isolation valve to choose?

You look at your fluid type, pressure, temperature, and how often you need to clean or fix the valve. You also check the size and connection type. Use the checklist in this blog to help you decide.

Can you use a ball valve for flow control?

You should not use a ball valve for flow control. Ball valves work best for quick shutoff. If you try to control flow, the valve can wear out faster.

How often should you check your isolation valves?

You should check your valves at least once a year. If you use them with dangerous or dirty fluids, check them more often. Look for leaks, rust, and worn parts.

What happens if you pick the wrong valve material?

If you pick the wrong material, your valve can rust, leak, or break. This can cause safety problems. Always match the valve material to your fluid and temperature.

Are isolation valves safe for drinking water?

Yes, if you pick valves made from safe materials like stainless steel or approved plastics. Always check that the valve meets drinking water safety standards.

Do isolation valves need special tools for installation?

Most isolation valves use simple tools like wrenches. Some large or automated valves may need special equipment. Always follow the instructions from the valve maker.

Can you automate isolation valves?

Yes, you can add electric or pneumatic actuators to many isolation valves. This lets you open or close them from a control room or with a remote system.