Selecting the right valves keeps steam and oil systems safe. Globe valves, angle seat valves, and stainless steel valves are important for high temperature jobs. Many industries use safety valves, check valves, and butterfly valve designs to control flow and pressure. Valve products like the pneumatic ball valve and pneumatic control valve help with accurate operation. Safety needs the right material, correct valve size, and regular maintenance. Operators rely on safety valves to stop too much pressure. Valve material, like carbon steel or stainless steel, should fit system needs for best safety. Safety valves and regular checks help stop failures. Safety is always the most important thing when picking any high temperature valve.

Safety valves keep equipment and people safe by letting out extra pressure, so safety is always needed in every valve design.

Valve Types

Globe Valves

Control Applications

Globe valves are very important in steam and oil systems. They help control how much fluid moves through pipes. Engineers pick globe valves because they can control flow very well. These valves have a moving plug and a fixed seat inside a round body. There are three main shapes: Z-body, Y-body, and Angle. The Y-body shape helps lower pressure loss, so it works well for tough jobs. The angle body lets fluid turn once at a right angle. This helps the fluid move better and stops damage inside the valve. In hot steam systems, globe valves are set up with pressure above the disk. This stops the stem from shrinking and keeps the seal tight. Good sealing is needed to keep things safe.

Note: Globe valves work well and last long if you take care of them. They only let fluid go one way, which stops backflow and keeps the system safe.

Some good things about globe valves are:

- They control flow very well when you need it.

- They close tightly to stop leaks or backflow.

- They work in places with high pressure and heat.

- They last a long time if you take care of them.

But globe valves also have some problems:

- They make fluid lose more pressure, which can waste energy.

- They are big and heavy, so they are hard to put in.

- They open and close slower than other valves.

- They do not let as much fluid through as some other valves.

High Pressure/Temperature

Globe valves are strong and work well in hot and high-pressure places. Their tough build lets them handle heat and pressure changes. Y-body and angle shapes help stop swirling and damage inside the valve. This makes the valve work better and keeps it safe. Globe valves are used in steam pipes and chemical lines. Safety valves and pressure relief valves must work well in these places. Globe valves are heavy and big, so you need to plan before putting them in.

| Valve Type | Function & Mechanism | Application in High Temperature Environments | Key Advantages & Limitations |

|---|---|---|---|

| Globe Valve | Round body with moving plug and fixed seat; controls flow; starts and stops fluid | Used in steam and chemical systems that need good flow control and no leaks | Great at controlling flow and closing tight; causes more pressure loss and swirling; heavy; not good for thick or dirty fluids |

Angle Seat Valves

Steam Flow Regulation

Angle seat valves let a lot of fluid move with little pressure loss. They have a piston that moves with air and a seat set at an angle. This design lets fluid move straight through and lowers resistance. These valves can handle hot and thick fluids. They are good for controlling steam in hard jobs. People use angle seat valves in steam cleaning, oil recovery, and steam heating. The simple path inside the valve does not clog easily. This helps keep the valve safe and working well.

- Angle seat valves keep high flow even with thick or dirty fluids.

- They do not need much care because they are simple and strong.

- Air power makes them work fast and well, which is important for safety in machines.

Durability

Angle seat valves last a long time and are very tough. They can work over 10 million times before wearing out. They are made strong and use PTFE seals, so they can handle heat up to 200°C (392°F). These valves do not clog or wear out fast. This lowers the chance of breaking and keeps things safe. They work with liquids, gases, and harsh fluids. This makes them a good choice where safety valves and pressure relief valves must always work.

Tip: Angle seat valves work better than ball and solenoid valves with thick steam. They are more efficient and reliable.

Ball Valves

High Temperature Construction

Ball valves use a ball with a hole to control flow. In hot places, metal-seated ball valves are strong and seal tightly. They do not wear out or rust easily. This makes them good for chemical plants, fire systems, and pipes with flammable fluids. Metal seats can take heat up to 1000oF (538oC). This keeps the valve safe and working well in tough spots. Stainless steel and carbon steel bodies are strong and do not rust. But if they get too hot, they can swell and leak if not made right.

| Valve Type | Temperature Resistance | Durability and Leakage Performance | Application Notes |

|---|---|---|---|

| Metal-seated Ball Valves | Up to 1000oF (538oC) | Very strong; do not wear out or rust; seal tightly; good for harsh fluids. Leaks are rare because the seals are hard and smooth. | Best for very hot and high-pressure jobs; used in chemical plants, fire systems, and pipes with flammable fluids. |

Overheating Risks

Ball valves can have trouble sealing tight when very hot. Getting a perfect seal many times at 600oF is hard without oil and clean fluid. A less perfect seal with more leaks is more likely. Soft-seat ball valves break down fast in heat, so they leak more and work worse. When parts get hot, they can swell and stick or leak unless the valve has special springs. Safety valves and pressure relief valves must be picked carefully to work well in these hot places.

- Stainless steel and carbon steel valves get bigger with heat, which can cause leaks if not made just right.

- Plastic and rubber seals get soft or break down in heat, so leaks can happen.

- Heat makes hydraulic fluid thinner, which causes more rubbing and wear. This can hurt how the valve works and make it less safe.

Safety is always most important when picking ball valves for hot jobs. Pick the right materials and check safety valves and pressure relief valves often to stop problems and keep the system safe.

Butterfly Valves

Efficiency

Butterfly valves are important in steam and oil systems. They work well when things get very hot. The disc lines up with the flow when open. This makes it easier for fluid to move. It also helps save energy. People pick butterfly valves because they work under high heat and pressure. These valves use strong metals like stainless steel and carbon steel. These metals help the valve last in tough places.

- Butterfly valves lower pressure drops, so the system works better.

- You can turn them a quarter way to change flow fast. This is good for quick safety actions.

- Their small and simple shape makes them easy to put in and fix.

- Power plants use butterfly valves to make more steam and need less fixing.

- Oil refineries use these valves for steady flow, less energy, and saving money.

The table below shows how butterfly valves do compared to other valves:

| Valve Type | Efficiency at High Temp | Maintenance Needs | Typical Use Cases |

|---|---|---|---|

| Butterfly Valve | High | Low | Power plants, oil refineries |

| Globe Valve | Medium | Medium | Steam lines, chemical systems |

| Ball Valve | Medium | Medium | Fire systems, chemical plants |

Note: Butterfly valves are simple, so it is easy to check and fix them. This helps keep safety valves and pressure relief valves working well.

Versatility

Butterfly valves work in many steam and oil jobs. They can handle steam, oil, and chemicals. They work in places with low or high pressure. Their small size lets them fit in tight spots.

- Butterfly valves fit lots of pipe sizes and can turn flow on or off.

- They help keep things safe by shutting off fast in emergencies.

- You can use them with hand, electric, or air power.

- Their design makes it easy to use safety valves and pressure relief valves.

Butterfly valves help safety valves and pressure relief valves do their job. They work fast and seal well to stop accidents in hot systems.

Check Valves

Backflow Prevention

Check valves keep steam and oil systems safe by stopping backflow. Backflow can hurt pumps, compressors, and pipes. Metal valves like stainless steel or brass work best in hot places. These metals do not rust and last longer.

- Spring-loaded and lift check valves close fast to stop backflow, even if flow changes.

- Picking the right metal keeps the valve safe and working longer.

- Checking valves often helps, but picking the right one means less fixing.

- Duckbill, diaphragm, and stop check valves stop backflow in tough places, even with heat and bad fluids.

- Lift and nozzle check valves are used in high-pressure steam and oil pipes. Springs help them close fast and stop water hammer.

Here is a table that shows what check valves do best:

| Valve Type | Best Use Case | Key Safety Feature | Material Options |

|---|---|---|---|

| Lift Check Valve | High-pressure steam/oil | Fast closure, prevents backflow | Stainless steel, brass |

| Nozzle Check Valve | High-velocity flow | Spring-assisted, reduces water hammer | Stainless steel |

| Duckbill Valve | Corrosive/high-temp fluids | Flexible, resists clogging | Rubber, reinforced |

Tip: Always pick a check valve that matches the system’s pressure and heat. This helps safety valves and pressure relief valves work right.

Check valves help keep equipment safe and the system running well. They work with safety valves and pressure relief valves to stop danger. Picking the right valve and checking it often keeps steam and oil systems safe when things get hot.

High Temperature Valve Design

Bonnet Design

The bonnet is very important for how well a high temperature valve works and keeps people safe. The bonnet covers the valve stem and inside parts. It keeps them safe from heat, pressure, and things that can cause rust. Engineers pick different bonnets depending on how hot, how much pressure, and what kind of fluid is in the system. This helps keep things safe and makes fixing easier.

There are a few types of bonnets for high temperature valves:

- Bolted bonnets are easy to take off for cleaning or fixing. You can remove them to check inside. But bolts can get weak if it gets hotter than 600°F (315°C). This can make the seal less safe.

- Welded bonnets do not let leaks happen. They work well when it is very hot or under a lot of pressure. Welded bonnets are harder to fix, but they help stop leaks and make things safer.

- Pressure-seal bonnets use the system’s own pressure to make the seal tighter. These are used a lot in hot steam systems. They help stop leaks and make safety valves work better.

- Extended bonnets keep the valve stem and packing away from the hottest parts. This helps stop heat damage and makes the valve last longer.

| Bonnet Design Aspect | Impact on Reliability and Maintenance |

|---|---|

| Extended (Long) Bonnets | Keep the valve stem and packing cooler, so they last longer and work better. |

| Pressure-Seal Bonnets | Seal better as pressure goes up, which is important for hot, high-pressure steam; helps keep things safe. |

| Connection Methods | Bolted bonnets are easy to fix, but bolts can get weak above 600°F; welded bonnets stop leaks but are harder to fix. |

| Material Selection | Carbon steel, stainless steel, and special alloys are picked to handle heat and rust, so the valve lasts longer and needs less fixing. |

| Sealing Performance | The bonnet helps keep the valve sealed tight, so nothing leaks out and the valve works well. |

| Protection of Components | The bonnet keeps the inside parts safe from heat, rust, and damage, so the valve works longer and needs less fixing. |

Materials

Stainless Steel

Stainless steel is a great material for high temperature valve bodies in steam and oil systems. Grades like 304 and 316 can take heat up to 1700°F (925°C). Stainless steel does not rust and stays strong even when it is very hot. This helps stop leaks and rust, which is very important for safety valves. Stainless steel valves work in places with or without things that cause rust. They last a long time and help stop safety valves from breaking.

Carbon Steel

Carbon steel valves, like ASTM A216 WCB, work up to 800°F (425°C). These valves are strong and cost less. Carbon steel is best for medium or high pressure systems with less stuff that causes rust. For even hotter jobs, engineers use low alloy steels with chromium or molybdenum. These can take heat up to 1200°F (650°C). Carbon steel valves often use stainless steel seats and stems to work better and be safer.

- Carbon steel globe valves: -20°C to +400°C, up to 40 bar pressure.

- Carbon steel ball valves: -40°C to 425°C, good for steam and oil.

- Stainless steel valves: up to 925°C, best for very hot and rusty places.

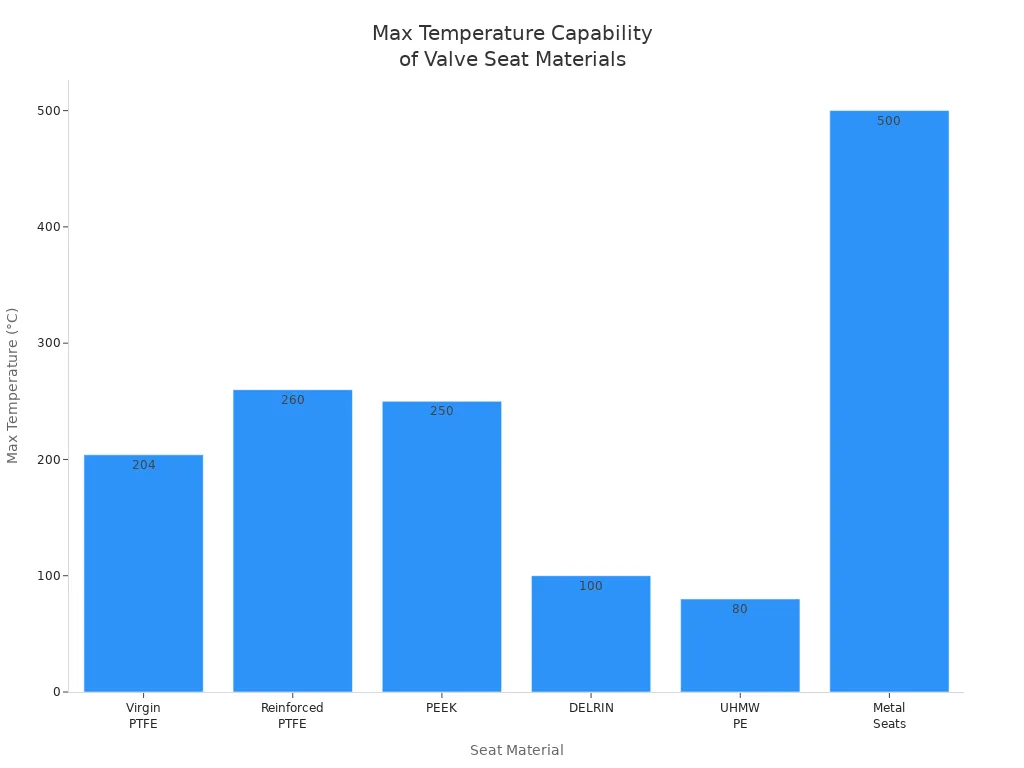

Seat Materials

Seat materials help the valve seal tight and last longer. The right seat keeps leaks away and makes safety valves work well. Engineers pick seat materials by looking at how hot, how much pressure, and what chemicals are in the system.

| Seat Material Type | Examples | Temperature Resistance | Pressure Suitability | Mechanical Strength | Chemical Compatibility | Wear Resistance | Typical Applications |

|---|---|---|---|---|---|---|---|

| Soft Seats | PTFE, TFM1600, C-RPTFE, UHMW PE | Up to 260°C | Low to Medium | Not as strong, but better with fillers | Very good | Medium | Chemical, food, pharma |

| Hard Seats | DELRIN, DEVLON, PEEK | Up to 250°C | High | Strong | Good | Strong | Oil & gas, aerospace |

| Metal Seats | Stainless steel, TCC, CCC | Very High | Very High | Very strong | Good | Very strong | High temp/pressure |

Metal seats, like stainless steel or tungsten carbide coated, work best when it is very hot and under a lot of pressure. These seats are very tough and last a long time. Soft seats like PTFE are good for lower heat but break down fast if it gets too hot. Hard plastic seats like PEEK are good when you need both chemical resistance and strength for safety valves.

Tip: For safety valves in really tough places, metal seats seal best and last longest. Always pick a seat material that matches the system’s heat and pressure for the safest valve.

Construction

刀閘閥-3-450x450.jpg)

Metal Seats

Metal seats are needed for high temperature valves. They can take a lot of heat and pressure, so they are good for safety valves in steam and oil systems. Metal seats do not wear out fast and keep a tight seal, even after being used many times. Alloys like Stellite, tungsten carbide, and chromium carbide coatings make them even harder and last longer. These materials help stop leaks and make safety valves work well.

- Metal seats can take very high heat and pressure.

- They do not rust or get damaged easily.

- Coated metal seats last longer and need less fixing.

Stem Design

Stem design is important for how well a high temperature valve works and stays safe. The stem connects the actuator to the valve plug or disc. In hot places, the stem must not bend, stretch, or get longer from heat. Engineers use stainless steel or alloy stems because they are strong and do not rust. Extended stems keep the packing and seals away from the hottest parts, which keeps safety valves safe from heat.

- A strong stem stops leaks and helps the valve work well.

- Extended stems help keep heat away from seals, making things safer.

- Good stem materials and design help safety valves last longer.

Note: High temperature valve design means every part, from the bonnet to the seat and stem, must be picked carefully. Each part helps keep things safe and makes sure the valve works well in tough places.

Ratings

Pressure

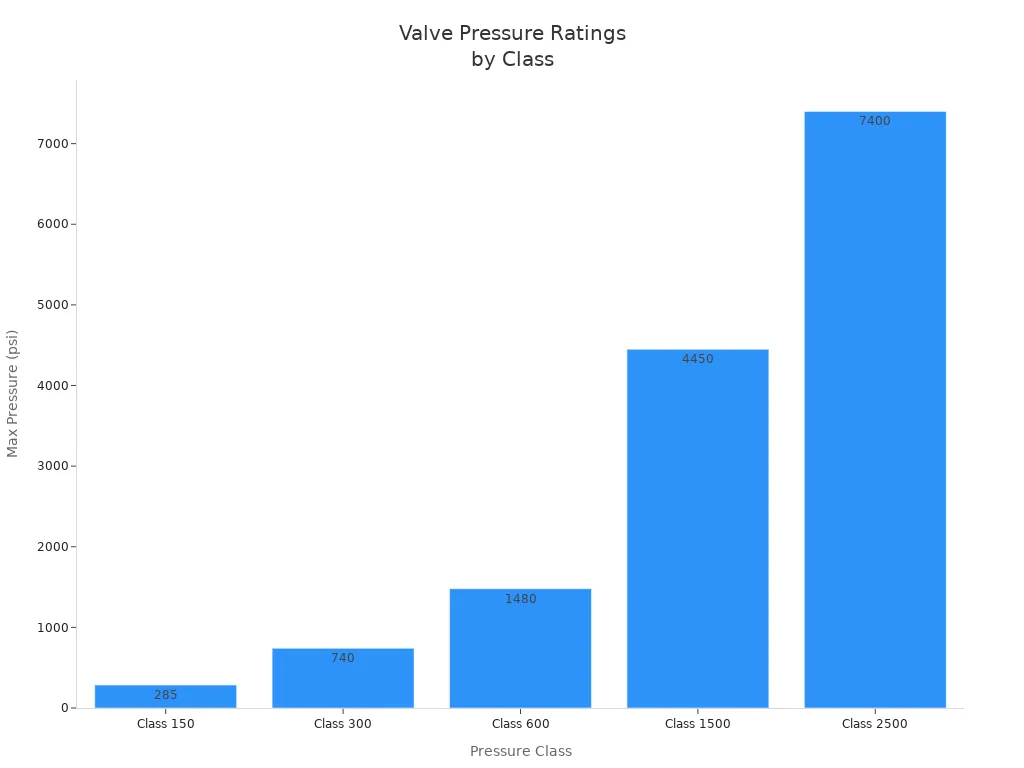

Pressure ratings are very important when picking high temperature valves. Every valve must hold the highest pressure in the system. This stops leaks and keeps things safe. Engineers use rules like API 6D and ASME B16.34 to sort valves by pressure class. These rules help keep steam and oil systems safe and working well.

- Pressure classes show the most pressure a valve can take at a certain heat.

- High temperature valves often have double block and bleed, fire-safe parts, and anti-blowout stems for more safety.

- Safety valves must be as strong or stronger than the system’s highest pressure to protect people and equipment.

The table below lists common pressure classes and their ratings for high temperature valves:

| Pressure Class | Temperature Range (°F/°C) | Max Pressure (psi/bar) |

|---|---|---|

| Class 150 | -20°F to 450°F (-28°C to 232°C) | Up to 285 psi (19.6 bar) |

| Class 300 | -20°F to 450°F (-28°C to 232°C) | Up to 740 psi (51 bar) |

| Class 600 | -20°F to 450°F (-28°C to 232°C) | Up to 1480 psi (102 bar) |

| Class 1500 | -20°F to 450°F (-28°C to 232°C) | Up to 4450 psi (307 bar) |

| Class 2500 | -20°F to 450°F (-28°C to 232°C) | Up to 7400 psi (510 bar) |

Pressure ratings change based on what the valve is made of and how it is built. Stainless steel, duplex stainless steel, and special alloys like Inconel or Hastelloy can take more pressure and are safer in tough places. Checking valves often and testing for leaks helps safety valves work well under high pressure.

Tip: Always pick a high temperature valve with a pressure rating higher than your system’s top pressure. This makes things safer and helps the valve last longer.

Temperature

Temperature ratings matter just as much as pressure ratings for high temperature valves. The valve must handle the hottest part of the system without getting weak or leaking. Safety valves help by letting out extra pressure if things get too hot.

- Most steam and oil systems run between 150°C and 300°C, but some go up to 649°C (1200°F) with special alloys.

- Carbon steel valves work up to 537°C (1000°F), and stainless steel can go up to 649°C (1200°F).

- Special seal materials like PTFE and PEEK are used in safety valves, but only up to their own heat limits.

The chart below shows the highest pressure ratings for valve pressure classes by API 6D:

Heat affects every part of the valve. High heat can make metal weaker, hurt seals, and cause leaks. Safety valve design must think about these dangers. Engineers pick materials and ways to build that keep the valve safe even when it is very hot.

- Checking valves often and doing regular care helps find problems like heat damage or bad seals early.

- Safety valves should be tested a lot to make sure they open at the right heat and pressure.

Note: Never go over the temperature rating for a high temperature valve. Too much heat can make the valve break fast and put people in danger.

Having the right pressure and temperature ratings is key for safe valve design. By following the rules and picking good materials, engineers make sure safety valves and all high temperature valves work well in tough steam and oil systems.

Valve Standards

High temperature steam and oil systems must follow strict rules for safety. These rules help keep people and equipment safe and working well. Engineers and buyers need to know about ASME, API, and ISO standards. These standards tell how to design, test, and check every valve, including safety valves and pressure relief valves. Following these rules helps stop accidents and keeps things running safely.

ASME

ASME standards are the main rules for valves in the United States and other places. ASME B16.34 talks about valves with flanged, threaded, or welded ends for tough jobs. ASME B31.1 and B31.3 are for pipes in power plants and chemical factories. These rules say how to build a valve, what materials to use, and how to test for leaks. The ASME Boiler and Pressure Vessel Code (BPVC) also covers safety valves and pressure relief valves in steam and oil systems. ASME changes these rules every two years, so engineers should always check for new updates to keep things safe.

Tip: Always look for new ASME updates and go to industry events to learn about the latest safety rules for every valve.

API

API standards are for the oil and gas industry, where heat and pressure are big problems. API puts safety and emissions rules right into valve design. For example, API 622 and API 624 test valve packing for leaks at high heat. API 607 and API 6F make sure valves pass fire safety tests, including safety valves and pressure relief valves. API 6D and its extra parts test how valves work under pressure and with gas. API rules say every valve must be certified to meet tough safety and performance rules.

| Challenge / Requirement | API Standard / Solution | Description |

|---|---|---|

| High temperature and pressure sealing | API 622 | Tests valve packing for leaks under set conditions. |

| Low emissions over valve lifecycle | API 624 | Tests rising stem valves with graphite packing for leaks. |

| Quarter-turn valve emissions control | API 641 | Tests quarter-turn valves for low leaks over many uses. |

| Fire safety and certification | API 607, API 6F | Tests valves for fire safety in oil and gas jobs. |

API rules also say safety valves and pressure relief valves must pass hard leak and fire tests. These tests make sure every valve works even when things get really tough, so safety always comes first.

ISO

ISO standards are worldwide rules for valve safety and how well they work. ISO 15848 has strict rules for testing leaks, which is important for safety valves and pressure relief valves in hot jobs. ISO 23632 checks if the valve design works by testing it with heat and movement. ISO rules often need more tests and cover more heat than API or ASME. ISO 10497 matches API 607 for fire safety, so valves can get both certifications for use around the world.

- ISO 15848-1: Checks and measures leaks for safety valves.

- ISO 23632: Tests valve design with heat and movement.

- ISO 10497: Tests fire safety for valves, including pressure relief valves.

- ISO certification is not required, but many global customers want it for safety and the environment.

Note: ISO rules help companies show their safety valves and pressure relief valves are safe everywhere.

By following ASME, API, and ISO rules, engineers make sure every valve, safety valve, and pressure relief valve is safe, works well, and helps protect people, equipment, and the environment in hot steam and oil systems.

Innovations in Valves

Smart Technologies

Smart valve technology has changed steam and oil systems. Engineers use IIoT automation instead of manual work. These systems watch pressure, temperature, and valve movement all the time. Operators see what is happening and keep things safer. Predictive maintenance uses valve data to find problems before they happen. This helps stop breakdowns and saves money.

Plant managers connect smart valves to IIoT platforms for better control. Remote shutdowns and automatic reports make things safer. Smart steam traps use venturi designs for strong and efficient work. Some companies give a 20-year warranty, fast shipping, and full service. Customers get site checks, setup, and long service plans. Guarantees and free trials let users test safety valves in real steam systems.

Applied Control gives digital zone valve control for steam systems. Their solutions help heat spread and save energy. Advanced valves and actuators make things safer and stop extra maintenance on steam traps. Operators get help any time and support for setup. Case studies show smart valves cut downtime by 30% and make products better by 25%. Power plants get 5% more energy and 10% less emissions. New analytics will help with predictive maintenance and make things even safer and more efficient.

Smart valve technology helps operators find problems early, act fast, and follow safety rules.

Advanced Materials

Valve makers use new materials to make valves work better in hot places. Ceramic coatings made by 3D printing protect valves from quick heat changes. These coatings lower heat transfer by conduction, convection, and radiation. Valves last longer and need less fixing.

Noble metal plating on gaskets stops rust and keeps them strong in heat. Better gasket materials seal well and lower leaks. These things are very important for safety in hydrocracking and other hot jobs. Engineers pick these materials so safety valves work well in tough conditions.

| Material Type | Benefit | Application |

|---|---|---|

| Ceramic Coatings | Lower heat transfer, last longer | Thermal sleeves, valve bodies |

| Noble Metal Plating | Stop rust, stay strong | Gaskets, seals |

| Improved Gaskets | Seal better, fewer leaks | High temperature valves |

Advanced materials help safety by making valves stronger and more reliable in hard steam and oil jobs.

Maintenance Kits

Maintenance kits help high temperature valves last and work well. Swagelok kits have all the parts and easy instructions. Technicians fix valve parts like packing, seats, O-rings, and stems quickly. These kits let people do repairs and care without changing the whole valve, so valves last longer.

Swagelok valves are easy to open and fix inside. Special kits and clear steps help stop leaks and problems. The company gives a Limited-Lifetime Warranty for strong parts. Regular care with these kits finds wear early and stops leaks and downtime.

Technicians check all valve parts for damage or wear. They fix bad parts with seal kits and do not need to change the whole valve. Tags and signs show what each valve does and when to check it, making care easier. These steps keep safety valves working well in hot places.

Maintenance kits help quick repairs, keep things safe, and make valves work well in steam and oil systems.

Valve Maintenance

Testing

Testing high temperature valves helps keep systems safe. It also makes sure valves work well in steam and oil jobs. Technicians use different ways to look for leaks, damage, or problems. Each test follows strict rules to check if safety valves work right. The table below shows common tests and what they check:

| Testing Method | Description | Conditions/Standards Referenced |

|---|---|---|

| Valve Shell Test | Looks for leaks with the valve partly open. Uses water pressure 50% higher than normal. | Water temp 41°F-122°F; stainless steel chloride <100 ppm |

| Valve Seat Leak Test | Valve is closed tight. Water is pushed in to see if it leaks. | Pressure ≥110% max allowed at 100°F; 1-minute test |

| Pressure Safety Valve Inspection | Checks pipes and valve parts for rust, cracks, or damage. | Visual and hands-on check of all parts |

| Backseat Valve Test | Valve is opened all the way, ends are closed, and pressure is added. | Checks if the seal holds under pressure |

| API 598 | Rule for testing metal and soft seated valves for leaks and pressure. | No leaks allowed |

| ANSI-API 607 | Rule for fire testing soft-seated quarter-turn valves. | Checks how valves work in fire |

| API SPEC 6D | Rule for ball, check, plug, and pipeline valves. Covers design, making, testing, and paperwork. | For oil and gas pipes |

| BS 759-1 | Rule for valves and safety parts in boilers and pipes. | Boiler valve rules |

Testing safety valves and other valves often helps stop sudden problems and keeps everyone safe.

Failure Modes

High temperature valves can have many problems that hurt safety and how well they work. Knowing these problems helps engineers and workers fix things before safety valves stop working.

Thermal Fatigue

Thermal fatigue happens when valves get hot and cold over and over. This makes the metal grow and shrink. Cracks or bends can form. Over time, this makes the valve body and moving parts weak. This problem is common in steam systems where heat changes a lot. Workers need to look for signs of thermal fatigue to keep things safe and working.

Seal Degradation

Seal degradation is a big problem for safety valves in hot places. Heat makes rubber seals hard or cracked. Chemicals and rough bits can also hurt seals. When seals break down, leaks start and safety valves cannot hold pressure. This makes the valve work worse and can be unsafe. Checking and changing seals often helps stop this problem.

Stem Wear

Stem wear happens from rubbing, parts not lining up, or turning too hard. In high temperature valves, the stem links the actuator to the plug or disc. If the stem wears out, leaks, sticking, or odd movement can happen. If the stem breaks, safety valves may not open or close right. Lining up parts and using oil helps stop stem wear and keeps valves working.

| Failure Mode | Root Cause(s) |

|---|---|

| Leakage (internal & external) | Broken seals, worn seats, rubbing, bubbles, rust |

| Erosion | Fast flow or rough stuff in the fluid |

| Cavitation | Pressure drops make bubbles that pop and hurt the valve |

| Corrosion | Chemicals or wrong materials cause rust |

| Stem Failure | Turning too hard or parts not lined up |

| Packing Failure | Tightening too much or packing breaking down |

| Thermal Expansion/Contraction | Heat changes make parts move or bend |

| Elastomer Degradation | Heat makes seals hard or cracked |

| Seat Wear or Damage | Rubbing or bubbles hurt the seat |

Workers should fix these problems fast to keep things safe and valves working well.

Preventive Practices

Taking care of valves helps safety valves and other valves last longer in hot systems. These steps help stop problems and make valves work better:

- Check valves often for damage, leaks, or rust.

- Clean valves with safe cleaners, not harsh ones.

- Oil moving parts with the right kind of oil.

- Watch how valves work by checking flow, pressure, and heat.

- Follow the maker’s rules for care, like how tight to make things and when to change parts.

- Teach workers how to use and care for valves the right way.

- Write down all care and repairs for each valve.

- Use the right tools so you do not break anything during care.

- Pick the right size and type of valve for the job.

- Use sensors to find problems early before they get bad.

Doing these care steps all the time keeps things safe, helps valves last longer, and makes sure valves work well in steam and oil systems.

Selection and Sizing

Sizing

Getting the right size valve is very important for safety. Engineers pick a valve size that matches flow, pressure, and temperature. If the valve is too small, it blocks flow and drops pressure. If the valve is too big, it can shake or not control well. Sizing charts and flow coefficients (Cv) help pick the best valve. Always check the highest pressure and temperature the valve will see. These things change how the valve works when stressed and keep it safe. Valves that are too big can leak or break early. This makes the valve work worse and can be unsafe.

Specification

Picking the right specification makes sure the valve is safe and works well. Engineers look at many things:

- Media compatibility: The valve material must not rust or get damaged by the fluid. Stainless steel, monel, and Inconel are good for tough jobs.

- Pressure ratings: The valve must handle the highest pressure, even in bad cases.

- Temperature impact: High heat can lower how much pressure the valve can take. Always check both ratings together.

- End connections: Use flanged or welded ends for high heat and pressure. These ends help stop leaks and keep things safe.

- Leakage tolerance: Some jobs need no leaks. Standards like MSS SP-61 say what is okay.

- Size availability: High-pressure valves are usually smaller. Make sure the size you need is easy to get.

Note: Never use a valve above its design pressure or temperature. This keeps everyone safe and helps the valve last longer.

Installation

Putting in valves the right way is very important for safety. Technicians should clean the system before putting in a valve. Dirt can hurt the valve and make it less safe. Put safety valves straight up with the spindle over the pipe center. This helps keep the right pressure and makes the valve work better. Use inlet pipes that are as big or bigger than the valve inlet. Do not put shut-off valves between the safety valve and the system.

Never block safety valve drains or vent holes. These parts are needed for safety and good valve work. Put drip pan elbows on safety valve outlets to send discharge away and lower stress. Make vent pipes as big or bigger than the valve outlet. Keep vent pipes short and point them away from people. Always follow ASME codes and local rules for safety.

Certified technicians should install valves to make sure they line up and connect right. This lowers leaks and helps the valve work better. Pick places for valves that are easy to reach for checks and care. Good position and support stop stress and help the valve last longer.

Tip: Check valves often after installing them. This helps find problems early and keeps safety high.

Cost Considerations

Picking the right valve for steam and oil systems needs careful thinking about money. Engineers must look at the first price, how much it costs to fix, and how safe it is. If a valve costs too much or too little, it can cause trouble. A pricey valve might not make things safer if you do not need it. A cheap valve might break early, which can be unsafe and cost more later.

The table below shows important cost points:

| Aspect | Explanation |

|---|---|

| Cost vs Suitability | Picking a valve that costs too much or too little can cause safety problems, more fixing, less flow, wasted energy, and higher bills. |

| Process Requirements | The valve and its main material must match what the fluid is like. |

| Operating Conditions | You need to know the heat and pressure to pick the right size and type of valve, so things work right. |

| Common Materials for High Temp/Oil/Steam | Stainless steel and cast steel valves are best for hot and high-pressure jobs because they last long and do not rust. |

| Cost Management Strategies | Do not use costly materials unless needed; only use coated valves when you must; pick cheaper valve types that still keep things safe. |

| Optional Features | Skip extra features you do not need to save money (like stainless steel handles if not needed). |

| Repair vs Replacement | Fixing a valve can save money instead of buying a new one if you can. |

FAQ

What is the best material for high temperature valves?

Stainless steel is the top choice for most hot jobs. It does not rust and stays strong when it gets hot. Carbon steel works well too, but only for lower heat. Always pick a material that fits what your system needs.

How often should high temperature valves be inspected?

Engineers say to check valves every six months. If the system is used a lot or has harsh fluids, check more often. Regular checks help stop leaks and keep valves from breaking.

Can ball valves handle steam applications?

Metal-seated ball valves can work with steam and high heat. Soft-seated ball valves might not work in hot steam. Always pick the right seat material for the job.

Why do valves fail in high temperature systems?

Valves can break from heat, bad seals, or worn stems. High heat makes metal grow and seals get weak. Doing regular care helps lower these risks.

How do I size a valve for steam or oil?

Engineers use charts and Cv numbers to pick the right size. The valve must fit the flow, pressure, and heat of the system. If the valve is too big or small, it can cause trouble.

Are smart valves worth the investment?

Smart valves give live data and help plan repairs. They help find problems early and cut down on downtime. Many plants are safer and spend less money with smart valves.

What is the role of a safety valve?

A safety valve keeps people and equipment safe. It lets out extra pressure if it gets too high. This stops accidents and keeps the system safe.