Forged valve types are very reliable in tough places. They work well in places with high pressure and heat. Oil & gas and power plants use forged valves a lot. Butterfly valves and ball valves are common types. These valves are used for about 30% of hard jobs. Forged valves are strong and last longer than cast valves. They do better when strength is important. Forged valves also resist problems inside the valve. People use electric valve actuators for better control. This helps keep important systems working right.

Forged steel valves handle tough conditions better than cast steel valves. They help keep things safe and working well.

| Industry | Valve Type | Approximate Usage Percentage | Reason for Use |

|---|---|---|---|

| Oil & Gas | Forged & Cast Steel Gate Valves | 30% | Control gas flow when pressure is high |

| Power Generation | Forged & Cast Steel Gate Valves | 30% | Control systems with high pressure |

Key Takeaways

- Forged valves are stronger than cast valves. They last longer too. This makes them good for high-pressure jobs. They also work well in high heat.

- There are many forged valve types. These include gate, globe, ball, check, needle, butterfly, bellows sealed, cryogenic, and extended body valves. Each type helps with control or safety in different ways.

- Picking the right valve material is important. You can choose carbon steel, alloy steel, stainless steel, duplex, or nickel alloys. The choice depends on pressure, temperature, and how well it resists rust.

- Forged valves work better in tough places. They do not leak or crack easily. They also do not wear out fast. This means less fixing and less time when machines stop.

- It is important to follow rules and guides from makers. This keeps valves safe and working for a long time.

- Picking the right valve pattern helps a lot. Y-pattern, T-pattern, and angle pattern can make flow better. They also lower pressure loss and repair costs.

- Forged valves are used in many industries. These include oil & gas, chemical, power, water treatment, and HVAC. People use them because they are safe and reliable.

- Checking and taking care of forged valves often is smart. This stops problems and helps valves last longer.

Forged Valve Types

Gate Valves

Features

Gate valves are a common forged valve in factories. They work by being fully open or fully closed. This lets liquid flow straight through with little pressure lost. The strong seal keeps leaks from happening. Gate valves are good for stopping flow when needed. Forged gate valves are tough because of their tight grain structure. They meet API and ISO rules, so they work well in hard places. Their simple design makes them easy to put in and fix. But, they are bigger and heavier than some other valves.

Gate valves let liquid move both ways with little resistance. They are good for pipes that carry thick liquids.

- Little pressure is lost because flow is not blocked

- Made for turning flow on or off, not for slowing it down

- They open and close slowly, which stops water hammer

- They seal better than other shutoff valves

- Forged steel makes them strong against rust and heat changes

Applications

Factories use forged gate valves to stop flow in important spots. Oil and gas plants use them to control flow in pipes with high pressure and heat. Power plants use gate valves to keep systems safe and working. Chemical plants, water plants, and HVAC systems also use them. These valves work well where no leaks and tight shutoff are needed.

| Industry | Application Example | Reason for Use |

|---|---|---|

| Oil & Gas | Pipeline isolation | Handles high pressure and temperature |

| Power Generation | Boiler feedwater isolation | Reliable shutoff under extreme conditions |

| Chemical Processing | Process line isolation | Corrosion resistance and durability |

| Water Treatment | Main line isolation | Minimal leakage and easy maintenance |

Features

Globe valves are another popular forged valve in many industries. They have a moving disk and a fixed ring seat. This helps control how much liquid flows through. Forged globe valves are strong and last long in hot and high-pressure places. Their seals stop leaks, which keeps things running smoothly. There are different shapes like T-pattern, Y-pattern, and angle pattern. This lets people pick the best one for their system.

Globe valves give good control and stop leaks, even in tough places.

- They control flow very well

- They seal tightly to stop leaks

- Many designs fit different jobs

- Forged steel makes them last longer

- Good for fluids that are hot, dangerous, or can cause rust

Applications

Forged globe valves are used in many fields because they control flow and handle tough jobs. Refineries and chemical plants use them for controlling dangerous or fast-moving liquids. Power plants use globe valves for steam and water systems. Chemical, drug, and food factories use them for clean and careful flow control. Mining and gas companies also use globe valves because they are strong and reliable.

- Refineries: Control of dangerous liquids

- Power Plants: Steam and water flow control

- Chemical Processing: Dosing and cooling

- Pharmaceuticals: Batch fluid control

- Food & Beverage: Steam and cleaning

Forged Ball Valve

Features

Forged ball valves are stronger than cast ball valves. Forging lines up the steel grains, making them tough and hard to break. These valves have a round ball inside that turns to open or close the flow. This lets them shut off quickly and well. They have smooth surfaces at the seals, so leaks are less likely. The tight grain structure keeps cracks and holes from forming. This makes them work well under high pressure and heat.

Forged ball valves can handle sudden pressure changes and do not crack easily, so they are good for important jobs.

- Work well with high pressure and heat

- Resist damage from heat and rust

- Open and close quickly for fast shutoff

- Smooth seals help stop leaks

- Work well in hard and busy places

Applications

People pick forged ball valves for jobs with high pressure and heat. Oil and gas plants use them in pipes where safety matters. Power and chemical plants like them for tough liquids and hard jobs. Water plants and HVAC systems use them because they last long and work fast. These valves help stop leaks and keep things running safely.

| Industry | Application Example | Reason for Use |

|---|---|---|

| Oil & Gas | Pipeline shutoff | High pressure and temperature resistance |

| Power Generation | Steam and water control | Quick operation and durability |

| Chemical Processing | Process isolation | Corrosion resistance and reliability |

| Water Treatment | Main line shutoff | Leak prevention and easy maintenance |

Check Valves

Features

Check valves let fluid move in just one way. They stop flow from going backward. This keeps pumps and other equipment safe. Forged check valves are made with strong materials. Their small size helps them work well in tough places. The main parts are the disc, seat, and body. The disc moves to let fluid pass. It closes when the flow stops. This stops fluid from going the wrong way.

Check valves often work in hard conditions. The most common ways they fail are:

- The disc lifting part can break. This can happen if drain holes are blocked, parts are worn, or if the valve is put in wrong.

- The swing rocker part can get damaged. Pressure changes or putting it together wrong can cause it to break or not line up.

- If the non-return part does not work, fluid can go backward. This can happen if the seal is damaged or dirt builds up.

Checking and taking care of check valves helps stop these problems. Picking the right material and putting the valve in the right way also helps them last longer.

- Stops backflow and keeps equipment safe

- Works by itself without needing someone to control it

- Handles high pressure and heat

- Small and strong forged body

- Needs to be checked often to stop problems

Applications

Industries use forged check valves in pipes to stop backflow. Oil and gas plants use them to keep pumps and compressors safe. Power plants put them in steam and water pipes. Chemical factories use check valves to keep dangerous fluids moving the right way. Water plants use them to stop dirty water from going backward.

| Industry | Application Example | Reason for Use |

|---|---|---|

| Oil & Gas | Pump discharge lines | Stops reverse flow and protects equipment |

| Power Generation | Boiler feedwater systems | Stops backflow in high-pressure pipes |

| Chemical Processing | Process safety systems | Stops dangerous fluid from going backward |

| Water Treatment | Main water supply lines | Keeps water moving the right way and safe |

Needle Valves

Features

Needle valves give very careful control of fluid flow. They use a long, thin needle that fits into a seat. Turning the stem moves the needle slowly. This lets you make small changes to the flow. Needle valves are good for high pressure and heat when you need to be exact.

| Feature | Description |

|---|---|

| Pressure Capability | Can handle up to 45,000 psig (3100 bar) |

| Leak Detection | Some have small holes to find leaks early |

| Packing System | Special packing keeps the seal tight even under stress |

| Temperature Range | Works at temperatures up to 600°F |

| Flow Control Precision | Lets you make small changes for labs and research |

Needle valves are made from strong materials like stainless steel. The slow movement of the needle stops sudden pressure changes. This helps stop leaks and keeps the system steady.

Needle valves are best when you need careful flow control and no leaks.

- Gives careful flow control for small or sensitive jobs

- Strong build for high pressure and heat

- Tight seal with strong parts

- Easy to adjust for small changes

- Used in labs, instruments, and process control

Applications

Forged needle valves are used where exact flow control is needed. Labs use them for tests and experiments. Oil and gas companies use them in pressure control systems. Power plants use them for steam and water samples. Chemical plants use them for mixing and dosing. Water plants use them for adding chemicals and checking flow.

| Industry | Application Example | Reason for Use |

|---|---|---|

| Oil & Gas | Pressure control panels | Careful adjustment and no leaks |

| Power Generation | Steam sampling systems | Exact flow control |

| Chemical Processing | Dosing and mixing lines | Fine control of chemical flow |

| Water Treatment | Chemical injection systems | Reliable and careful flow control |

Butterfly Valves

Features

Butterfly valves use a disc that turns to control flow. The disc spins inside the valve to open or close it. Forged butterfly valves have strong bodies and discs made from stainless steel or carbon steel. The seat and packing use rubber or PTFE for a tight seal. These valves can handle many pressures and temperatures.

- Valve body is strong against stress and rust

- Disc and shaft are tough for high pressure

- Sealing ring and packing stop leaks

- Can use electric, air, hydraulic, or hand actuators

- Good for big pipes and quick shutoff

Process industries pick forged butterfly valves because they work well. These valves do well when pressure and temperature change. They also fight rust from harsh chemicals or saltwater. The design makes them easy to use and simple to take care of.

Butterfly valves work fast and seal well, even in hard places.

Applications

Forged butterfly valves are used in many industries. Oil and gas plants use them in big pipes for quick shutoff. Chemical factories use them for moving harsh fluids. Power plants use butterfly valves in cooling and water systems. Water plants put them in main supply lines. These valves are also used in HVAC systems for air and water flow.

- Oil & Gas: Main pipe shutoff and flow control

- Chemical Processing: Moving harsh or rough fluids

- Power Generation: Cooling water and extra systems

- Water Treatment: Main line shutoff and flow control

- HVAC: Air and water balancing

| Industry | Application Example | Reason for Use |

|---|---|---|

| Oil & Gas | Main pipeline valves | Fast use and fights rust |

| Chemical Processing | Acid and alkali handling | Fights chemicals and lasts long |

| Power Generation | Cooling water systems | Big size and easy to use |

| Water Treatment | Main supply line control | Tight seal and easy care |

| HVAC | Air and water flow control | Quick changes and works well |

Bellows Sealed Valves

Features

Bellows sealed valves use a metal bellows to seal the stem. The bellows is flexible and welded, so it stops leaks. This design works well in places with high pressure or dangerous chemicals. The bellows keeps harmful gases from escaping. These valves are important for handling toxic or hazardous fluids.

- Welded bellows stop leaks, even with dangerous substances.

- Double seals give extra safety from leaks.

- They work well when pressure or temperature changes.

- Strong parts help the valve last a long time.

- You do not need to fix them often, which saves money.

- They follow rules that help protect the environment.

Bellows sealed valves are very important for safety and protecting the environment.

Applications

Industries use bellows sealed valves for dangerous or sensitive liquids. These valves are found in petrochemical, drug, nuclear, and cold gas systems. They stop leaks of harmful things like hydrogen, ammonia, and chlorine. Workers use them in pipes that carry toxic or flammable fluids. Their strong design also works for vacuum systems and places where leaks must not happen.

- Petrochemical plants: Shut-off for toxic and flammable fluids.

- Nuclear power: Controls radioactive liquids.

- Drug factories: Stops contamination and keeps products pure.

- Cold gas systems: Keeps low-temperature gases safe.

- Vacuum and electronics: Makes sure there are no leaks.

Cryogenic Valves

Features

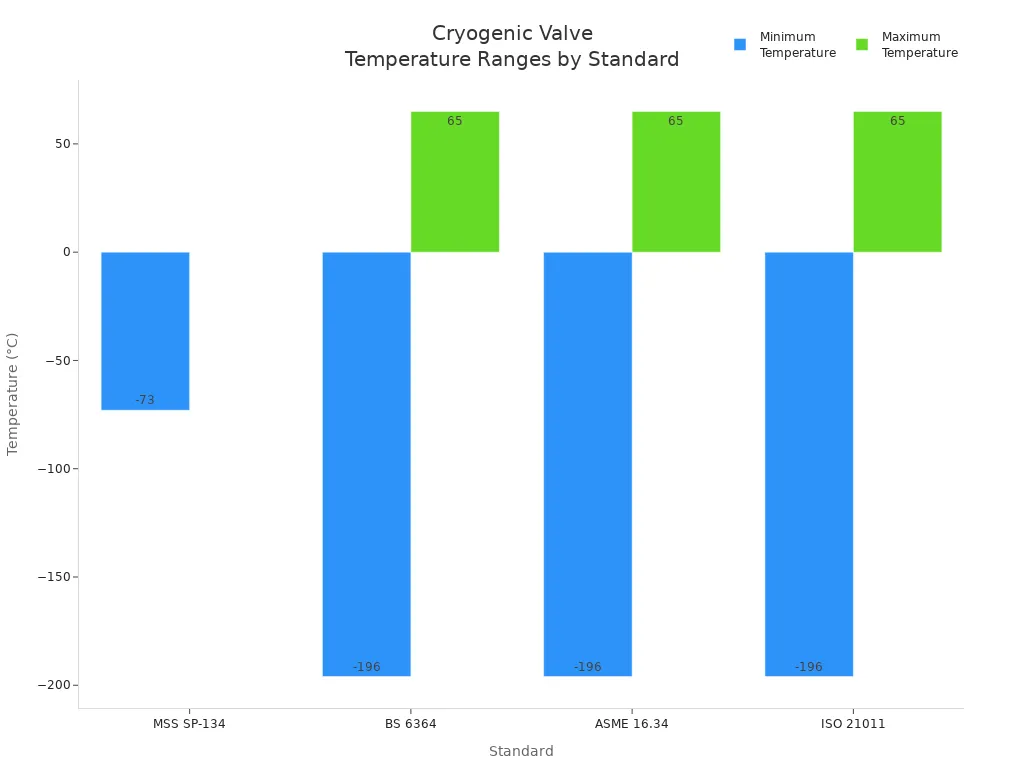

Cryogenic valves work at very cold temperatures, down to -196°C. They have long bonnets to keep the stem packing away from cold fluids. This helps the valve seal well. Makers use stainless steel, Inconel, and Monel because they do not break in cold or stress. The design has low-emission seals, blowout-proof stems, and ways to let out extra pressure.

| Standard | Key Design and Temperature Range Requirements |

|---|---|

| MSS SP-134 | Materials must work below -73°C; long bonnets keep stem packing safe. |

| BS 6364 | Needs long bonnets, pressure relief, and special tests for cold use. |

| ASME 16.34 | Works from cold up to 65°C; needs pressure tests. |

| ISO 21011 | Works from -196°C to 65°C; needs tough materials and long bonnets. |

- Long bonnets protect seals from cold.

- Careful machining keeps leaks from happening.

- Fire-safe and electric designs stop fire and static problems.

- Pressure relief helps with warming fluids.

Cryogenic valves keep liquefied gases and cold fluids safe and under control.

Applications

Workers use cryogenic valves for liquefied natural gas, liquid nitrogen, and other cold fluids. These valves are needed for gas making, storing, and moving. They are also used in hospitals, space, and labs where cold gases are common.

- LNG plants: Controls and stops liquefied gases.

- Gas factories: Handles oxygen, nitrogen, and argon safely.

- Hospitals: Stores and gives out medical gases.

- Space: Manages rocket fuel and oxidizer.

- Labs: Controls cold fluids for experiments.

Extended Body Valves

Features

Extended body valves have a longer body. This lets them join pipes of different sizes. The design helps fluids move smoothly and lowers resistance. The longer body makes it easier to put the valve in tight or tricky places.

- Long body joins pipes with different diameters.

- Less pressure loss and less fluid turbulence.

- Good for small spaces like ships or tall buildings.

- Easier to fix or change parts.

- Can be put in sideways, straight, or at an angle.

- Forged parts make them strong and able to handle pressure and heat.

Extended body valves help pipelines work better and fit in many places.

Applications

Industries use extended body valves when pipes are different sizes or space is tight. These valves are used in petrochemical, drug, and food factories. Workers also use them in water systems, oil pipes, and places with lots of pipes.

- Petrochemical and chemical plants: Joins pipes and helps with high flow.

- Food and drink factories: Keeps things clean and flowing well.

- Water treatment: Lowers pressure loss in long pipes.

- Ships and tall buildings: Saves space and fits special pipe layouts.

- Underground places: Makes putting in and fixing pipes easier.

Common Forged Valve Steel Grades

Carbon Steel Grades

A105: Widely used for ambient and high-temperature service, offering good mechanical properties and weldability.

A105 carbon steel is a popular choice for forged steel valves. It is strong and can handle both normal and hot temperatures. Many oil, gas, and power plants use A105 because it is reliable and easy to weld. The forging process makes the steel tough and helps stop leaks. This grade has high tensile and yield strength, so it works well in many places.

| Carbon Steel Grade | ASTM A105 | ASTM A350-LF2 |

|---|---|---|

| Tensile Strength (min) | ~485 N/mm2 (70,000 psi) | 485-655 N/mm2 (70,000-95,000 psi) |

| Yield Strength (min) | 250 N/mm2 (36,000 psi) | 250 N/mm2 (36,000 psi) |

| Elongation (%) | 22% | 22% |

| Reduction of Area (%) | 30% | 30% |

| Hardness (max) | 187 HB | 15/12 ft-lbs (impact toughness) |

| Impact Toughness (CVN) | N/A | 20/16 joules at -50℉ |

A105 forged steel valves are trusted in pipelines and systems where strength and heat resistance are needed.

LF2: Low-temperature carbon steel, suitable for cryogenic and subzero applications due to its enhanced toughness.

LF2 carbon steel is made for very cold places. It is tough, so it does not break easily in the cold. Cryogenic plants and cold storage use LF2 forged steel valves. These valves stay strong and bendy even when it is freezing. Forging makes the steel dense and helps stop cracks.

Alloy Steel Grades

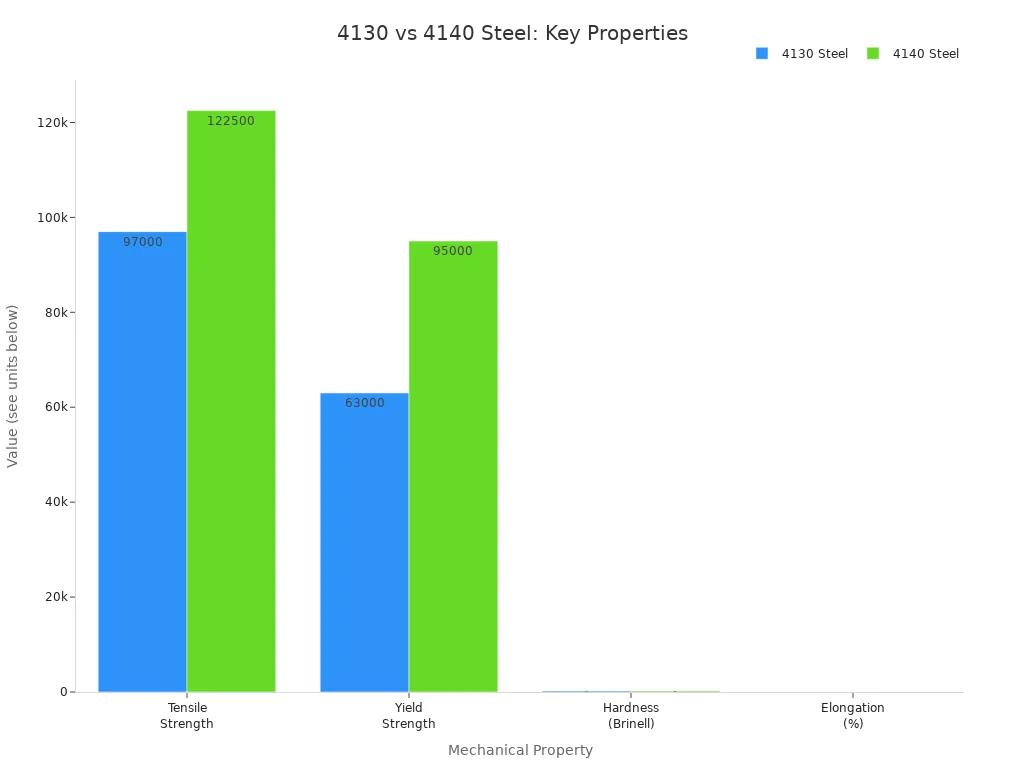

4130: Chromium-molybdenum alloy steel, known for high strength and toughness, often used in high-pressure environments.

4130 alloy steel has chromium and molybdenum. These make it strong and tough. This steel is used for forged steel valves in high-pressure systems. It is easy to weld and shape. 4130 valves are used in oil, gas, airplanes, and big machines.

4140: Similar to 4130 but with higher carbon content, providing greater hardness and wear resistance.

4140 alloy steel has more carbon than 4130. This makes it harder and better at resisting wear. 4140 is picked for forged steel valves in tough and hot places. The extra carbon helps these valves last longer and handle more pressure.

| Property/Aspect | 4130 Steel | 4140 Steel |

|---|---|---|

| Carbon Content | ~0.28% – 0.33% | ~0.38% – 0.43% |

| Tensile Strength | ~97,000 psi | ~95,000 – 150,000 psi |

| Yield Strength | ~63,000 psi | ~60,000 – 130,000 psi |

| Hardness (Brinell) | ~197 HB | ~217 HB |

| Elongation (%) | ~25% | ~20% |

| Weldability | Excellent | Good |

4140 forged steel valves are best for jobs that need both strength and long life.

Stainless Steel Grades

410 / F6A: Martensitic stainless steel, offering moderate corrosion resistance and high strength, commonly used for trim parts.

410 and F6A stainless steels are martensitic types. They are strong and resist some rust. These steels are used for trim parts in forged steel valves, like stems and seats. Their hardness helps them last longer in moving parts.

F304: Austenitic stainless steel, excellent corrosion resistance, suitable for a wide range of media.

F304 stainless steel is an austenitic type. It resists rust and has good strength. F304 works well in water, steam, and mild chemicals. Forged steel valves made from F304 are used in food, water, and factories. But F304 can get small holes in salty places.

F316: Enhanced corrosion resistance compared to F304, especially in chloride environments.

F316 stainless steel has molybdenum, which helps it fight rust better than F304. F316 is used for forged steel valves in marine, chemical, and drug factories. It works well in very hot or cold places. F316 resists pitting and crevice rust much better than F304.

Forged steel valves made from F304 and F316 stainless steel last a long time and work well, even in harsh or rusty places.

Precipitation Hardening and Duplex Grades

17-4PH: Precipitation hardening stainless steel, combining high strength and good corrosion resistance, ideal for demanding applications.

17-4PH stainless steel is special because it is strong and fights rust. It gets stronger from a heat treatment called precipitation hardening. Many companies use 17-4PH for forged steel valves in tough places. These valves work in aerospace, chemical plants, and power stations. The material does not rust and stays strong for a long time. Maintenance teams see that these valves last longer and break less often. 17-4PH works well in wet and dry places. This makes it useful for many systems.

17-4PH forged steel valves are strong and reliable. They help control flow where strength and rust resistance are needed.

F51: Duplex stainless steel, offering superior strength and resistance to stress corrosion cracking.

F51 is called duplex stainless steel. It mixes two steel types: ferrite and austenite. This mix makes F51 almost twice as strong as regular stainless steel. Forged steel valves made from F51 do not crack easily from stress or chlorides. These valves are used in chemical plants, oil pipes, and desalination systems. F51 valves also fight pitting and crevice rust better than normal grades. F51 costs less than super duplex grades. This makes it a smart pick for many projects. Operators trust F51 forged steel valves for their strength, rust resistance, and good price.

F53: Super duplex stainless steel, providing exceptional corrosion resistance and mechanical properties for aggressive environments.

F53 is called super duplex stainless steel. It has more chromium and molybdenum than F51. This helps F53 fight pitting, crevice rust, and stress cracks even better. Forged steel valves made from F53 work in very harsh places like offshore oil rigs and underwater pipes. These valves are very strong, up to 100 ksi, and stay safe under high pressure and chemicals. F53 forged steel valves protect systems in tough places like desalination plants and marine jobs, where failure is not allowed.

| Property / Feature | Duplex Stainless Steel (F51) | Super Duplex Stainless Steel (F53) |

|---|---|---|

| Microstructure | Ferrite + Austenite (biphasic) | Optimized biphasic structure |

| Mechanical Strength | Nearly double that of austenitic | Even higher (up to ~100 ksi) |

| Corrosion Resistance | Good (pitting, crevice, SCC) | Superior (higher Cr, Mo, N content) |

| PREN (Pitting Resistance) | 28-38 | 38-45+ |

| Typical Applications | Oil & gas, chemical, desalination | Offshore, subsea, desalination |

| Cost | Moderate | Higher |

Duplex and super duplex forged steel valves are both strong and fight rust. Duplex grades like F51 work well in tough places. Super duplex F53 is best for the hardest jobs. Picking the right grade helps forged steel valves stay safe and last a long time.

Forged Valve Materials and Pressure Ratings

Common Materials

Carbon Steel

Carbon steel is used a lot for forged valves. It is strong and easy to weld. Carbon steel valves work well with medium pressure and heat. Many companies pick carbon steel because it is cheap and works well.

Alloy Steel

Alloy steel has things like chromium and molybdenum in it. These make the steel stronger and tougher. Alloy steel forged valves can handle more pressure and heat than carbon steel. They are used in power plants, oil refineries, and chemical factories.

Stainless Steel

Stainless steel does not rust or corrode easily. It is good for water, steam, and chemicals. Forged stainless steel valves last longer in rough places. They stay strong in both hot and cold conditions.

Duplex Stainless Steel

Duplex stainless steel mixes ferrite and austenite. This makes duplex valves strong and hard to crack from stress. People use duplex valves in seawater, chemical, and oil and gas systems.

Nickel Alloys

Nickel alloys can handle very high heat and tough chemicals. These forged valves work well in harsh places like chemical plants and offshore platforms.

Picking the right forged valve material helps keep things safe and working for a long time.

Material Selection Considerations

Corrosion Resistance

Engineers choose materials that do not rust from the fluid. Stainless steel and nickel alloys protect best against rust and chemicals.

Temperature Resistance

Some materials do better with heat than others. Alloy steels and nickel alloys stay strong when it is hot. LF2 carbon steel is good for cold jobs because it does not get brittle.

Mechanical Strength

Forged valves need to be strong for high pressure. Alloy steel and duplex stainless steel have high strength. This keeps the valve safe and tough.

Cost and Availability

The price and supply of materials matter for projects. Carbon steel is cheap and easy to get. Special alloys cost more but are needed for hard jobs.

- The most used materials for forged valves are:

- Carbon steel

- Stainless steel

- Alloy steel

- Duplex and nickel alloys

People pick these based on pressure, heat, and rust resistance. Forging makes valves stronger and safer for high-pressure jobs.

Pressure Ratings Overview

ASME Pressure Classes (150, 300, 600, 900, 1500, 2500)

ASME pressure classes show how much pressure a valve can take at a certain heat. Bigger numbers mean the valve can handle more pressure. Engineers pick the class that fits the system.

PN Ratings (PN10, PN16, PN25, PN40, etc.)

PN ratings are used in Europe. They show the pressure a valve can take. The PN number is the max pressure in bars. PN40 means the valve can take up to 40 bar.

Relationship Between Material and Pressure Rating

The material of a forged valve changes its pressure rating. Stronger materials let valves handle more pressure. ASME rules say engineers must:

- Find the highest pressure and heat in the system.

- Pick a material group that works for those needs.

- Use ASME tables to choose the right pressure class for that material.

The right material and pressure rating keep systems safe and working well.

Selecting the Right Material and Pressure Rating

Matching Material to Service Conditions

Engineers need to pick the right valve material for each job. Every system is different and has its own needs. The fluid in the pipe might be hot, cold, or able to cause rust. Some fluids can damage the inside of pipes. Carbon steel is good for water and oil jobs. Stainless steel does not rust and is used in chemical plants. Alloy steel is strong for high pressure and heat. Nickel alloys are best for strong chemicals and very hot or cold places.

The valve material must also match the system’s pressure and temperature. If the pressure is high, the metal must be strong. If it is very cold, the metal should not crack. ASTM A105 carbon steel is used for normal jobs. Stainless steel 304 and 304L are picked for places with rust or chemicals. Forged steel valves last longer because they are made with tight grains.

Tip: Always check what fluid, pressure, and temperature you have before picking a valve material.

Ensuring Compliance with Industry Standards

Industry standards help keep systems safe and working well. Engineers must follow rules from groups like API, ASME, and ISO. These rules say how strong a valve should be and what materials to use. Valves must meet the pressure and temperature ratings in these rules. If a valve does not meet the rules, it could break and cause trouble.

Some important steps for following the rules are:

- Know the valve type and job to pick the right one for no leaks.

- Pick the material based on if the fluid is rusty, hot, or under pressure.

- Check the pressure and temperature ratings to fit the system.

- Make sure the ends and sizes match the pipes.

- Choose valves for the right flow, like globe valves for slow flow or ball valves for fast shutoff.

- Pick seals that fit the job, like soft seats for liquids or metal seats for hot or rough fluids.

- Think about how easy it is to fix the valve to keep downtime low.

- Always follow API, ASME, and ISO rules for safety and good work.

Note: Following the rules helps stop leaks, breaks, and expensive fixes.

Consulting Manufacturer Guidelines

Manufacturers give helpful advice for picking valves. Their guides show which materials are best for each job. They list pressure ratings, temperature limits, and sealing choices. Engineers should read these guides before buying valves. The guides help match the valve to what the system needs.

Manufacturers also tell how to put in and take care of valves. They show how to check for leaks and change parts. Using these tips helps valves last longer and work better. If you are not sure, ask the manufacturer for help.

| Step | Why It Matters |

|---|---|

| Read product specs | Makes sure you pick the right material |

| Check pressure class | Keeps the system safe |

| Follow care tips | Helps valves last longer |

| Ask questions | Fixes problems before they start |

Tip: Manufacturer help can stop mistakes and keep systems working well.

Forged Valve Manufacturing

Forging Methods

Forged valves are made using strong methods. These methods help the valves work well and last long. Forging shapes metal with heat and pressure. This makes the valve stronger and tougher. There are three main ways to forge valves.

Rolled Ring

Rolled ring forging makes round parts from hot metal rings. The metal is shaped between two rollers. This way, the rings are strong and have a smooth grain. Valves made this way can handle high pressure and heat. Rolled ring forging is used for valve bodies and flanges. It also helps save material and lower costs.

Closed Die

Closed die forging is also called impression die forging. It uses two dies to press hot metal into a shape. This method makes complex valve parts with little extra metal. Closed die forging gives valves a smooth finish and exact size. The metal fibers follow the part’s shape, making it stronger and less likely to leak. This method is used for small and medium valves that need to be very exact.

Closed die forging helps make detailed valve shapes that are always the same and high quality.

Open Die

Open die forging shapes metal between flat or simple dies. It works well for big or special valve parts. This method gives the metal an even structure and removes bad spots. Open die forging can make many sizes and shapes. But it is not as exact as closed die forging. People use open die forging for big valves or custom shapes.

- Open die forging is good for making big, strong valve parts.

- This method lets workers change the shape during forging to fit special needs.

Forging methods change how good a valve is by making the inside metal better. Hot forging above 800°C lines up the metal grains. This makes the valve harder and tougher. Controlling the heat, speed, and pressure helps the valve last longer and work better.

Materials

How well a valve works depends on what it is made from. Each material has its own good points for different jobs.

Carbon Steel

Carbon steel is often used for forged valves. It is strong and easy to weld. Carbon steel valves work well with medium pressure and heat. The material is easy to shape and helps keep costs low for many companies.

Alloy Steel

Alloy steel has things like chromium and molybdenum in it. These make the steel stronger and better with heat. Alloy steel forged valves are good for high pressure and heat. The tough steel is used in power plants and refineries.

Stainless Steel

Stainless steel does not rust or corrode. Forged stainless steel valves are used in chemical plants, water plants, and food factories. The material stays strong in hot and cold places. Stainless steel valves last a long time and do not need much fixing.

Picking the right forging way and material helps valves do their job well and last a long time.

Applications

High Pressure

Forged valves are very important for high pressure jobs. Their strong design helps them handle a lot of pressure. They do not leak or break easily. Workers use forged globe valves to control flow in oil and gas pipes. Water plants use them to keep pressure steady during cleaning. Power plants use forged valves for steam that is very hot and under pressure. Chemical plants pick forged valves for moving hot and harsh liquids. These valves have a moving plug and seat. This helps control flow exactly, which is needed for important work.

- Oil and gas sites use forged valves to control pipe flow.

- Water plants use them to manage pressure when cleaning water.

- Power plants use forged valves for steam with high heat and pressure.

- Chemical plants use them for hot and harsh fluids.

Tests show forged valves work better after fixing worn seals. New seals help valves last longer by half. Workers say they have less downtime and better efficiency. Chemical plant surveys show most workers care about the total cost. Forged valves are picked because they save money over time. Forged globe valves seal better and control flow more exactly than gate or ball valves. They last longer and need less fixing in high pressure places. Their strong build and good seals stop leaks and lower costs.

Forged valves work well and save money in high pressure jobs. They are needed for safe and good work.

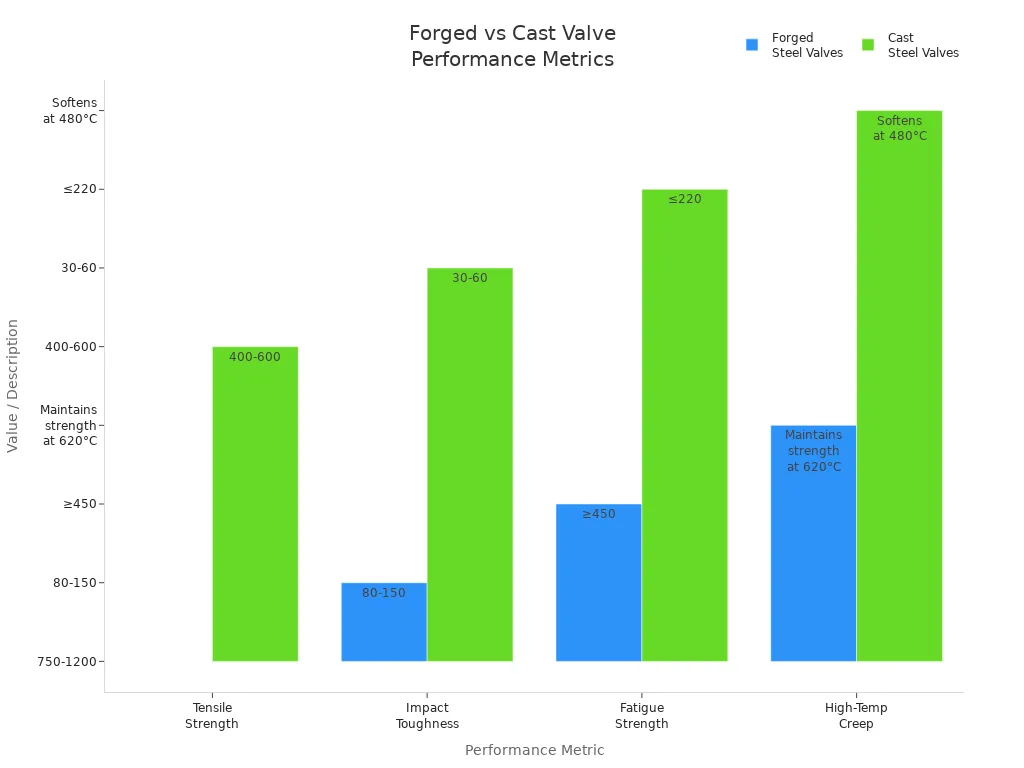

High Temperature

Forged valves are great for high heat jobs where others may fail. They are made by pressing metal hard, which makes the inside grains smaller and stronger. This makes the valves tough and free from weak spots. Forged steel valves stay strong up to 620°C. Cast steel valves get soft at 480°C.

| Performance Metric | Forged Steel Valves | Cast Steel Valves | Performance Advantage of Forged Valves |

|---|---|---|---|

| Tensile Strength (MPa) | 750 to 1200 | 400 to 600 | 40% to 100% higher tensile strength |

| Impact Toughness (J/cm2 at 25°C) | 80 to 150 | 30 to 60 | Up to 150% better toughness |

| Fatigue Strength Limit (MPa) | ≥450 (10? cycles) | ≤220 (10? cycles) | Approximately double fatigue life |

| High-Temperature Creep Performance | Maintains strength at 620°C | Softens significantly at 480°C | Operates reliably at temperatures 140°C higher |

Forged valves are used in power plants for super hot steam. They are also used for hydrogen filling at high pressure. Their small grains and good seals help them last through many uses. Makers test these valves with water and sound to make sure they are safe. Other valves like stainless steel, plastic, or ceramic can be good for some jobs. But forged steel valves are best for very high heat and pressure because they are so strong.

Forged valves last longer, work better, and are more reliable in high heat jobs.

Corrosive Media

Forged valves work very well with harsh chemicals and rough fluids. They are picked for places with acids, strong bases, or hard bits in the liquid. Workers use forged valves in acid places like hydrogen sulfide and sulfuric acid. They also use them in bases like sodium hydroxide. For fluids with hard bits, forged valves with special coatings last longer.

- Acid places: Forged valves made from Hastelloy C276, titanium alloy, or Inconel 625 do not rust and stay strong.

- Bases: Monel 400 and 316L stainless steel forged valves fight off strong bases.

- Rough fluids: Metal seals with tungsten carbide or silicon carbide stop wear.

Some forged valves have special gates to seal better when pressure changes. Forged valves stay strong, do not change shape, and need less fixing. They are the best choice for tough chemical and dirty jobs.

Forged valves keep things safe and working in harsh chemicals. They help protect equipment and lower repair costs.

Industry Sectors

Oil & Gas

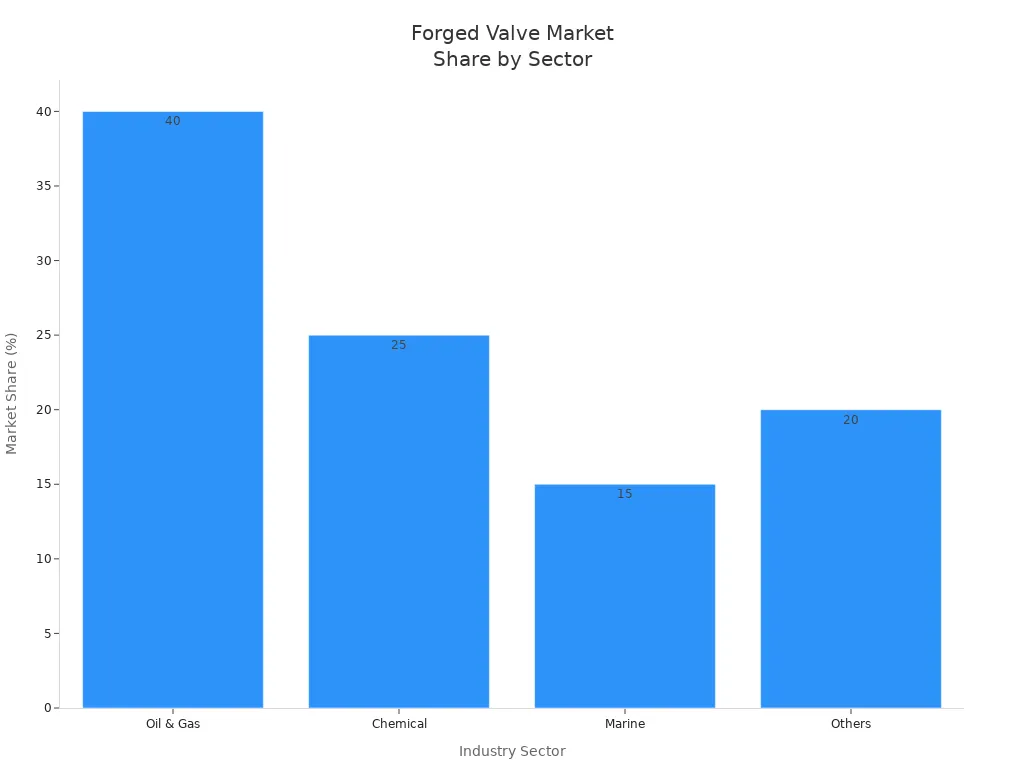

Oil and gas companies use forged valves more than other industries. These valves control flow in pipelines and refineries. They are also used on offshore rigs. Engineers pick forged valves because they work with high pressure and heat. They also handle strong chemicals. Offshore drilling and shale gas need valves that resist saltwater and chemicals. LNG plants use forged valves to stay safe at very cold temperatures. Some smart valves have sensors to watch flow and stop leaks fast.

| Industry Sector | Market Share (%) | Main Drivers for Adoption |

|---|---|---|

| Oil & Gas | 40 | Need for valves that withstand high pressures and extreme low temperatures in LNG production, transportation, and liquefaction; increasing global demand for natural gas as a cleaner energy source; expanding LNG infrastructure; stringent regulatory standards. |

Operators change valves to follow new safety rules. They also do this for carbon capture needs. Oil and gas companies use forged valves for new jobs and repairs. These valves help keep systems safe and working in hard places.

Chemical

Chemical plants use forged valves for acids, bases, and other strong fluids. These valves do not rust and last longer in tough places. New rules make companies use valves that stop leaks and lower pollution. Many chemical factories use smart valves to control flow and keep people safe. Forged valves help meet strict environmental rules.

| Industry Sector | Valve Demand Share / Role | Main Drivers for Adoption and Trends |

|---|---|---|

| Chemical & Petrochemical | Significant demand | Corrosion resistance for acid processing; sustainability mandates (EU Green Deal, China’s carbon targets); adoption of IoT-enabled smart valves to optimize dosing and reduce emissions. |

Chemical companies pick forged valves because they are safe and work well with dangerous fluids. These valves help plants run safely and smoothly.

Power

Power plants need forged valves for steam, water, and fuel. These valves work in hot and high-pressure places. Hydrogen and LNG storage need cryogenic valves that stay strong in the cold. Renewable energy projects use smart valves to control flow and add new systems. Desalination plants and city water systems also use forged valves to work safely.

| Industry Sector | Valve Demand Share / Role | Main Drivers for Adoption and Trends |

|---|---|---|

| Power Generation & Water Management | Growing demand | Use of cryogenic valves for hydrogen and LNG storage; smart valves for renewable energy integration; valves for desalination and urban water infrastructure. |

Power companies choose forged valves for their strength and safety. These valves help energy systems work without problems.

Water Treatment

Water treatment plants use forged valves to control flow and stop leaks. These valves handle cleaning chemicals in water. Operators pick forged valves because they last long and do not rust. City water and desalination projects use forged valves to move lots of water safely.

| Industry Sector | Market Share (%) | Main Drivers for Adoption |

|---|---|---|

| Others | 20 | Various other industrial applications requiring forged valves under extreme conditions. |

Forged valves help water plants meet health and safety rules. They make sure cities and factories get clean water.

HVAC

HVAC systems use forged valves to balance air and water in buildings. These valves work in heating, cooling, and air systems. Engineers pick forged valves because they last long and handle changing pressure and heat. Hospitals, schools, and offices use forged valves to keep air and water safe.

Forged valves are important in many industries. They help oil and gas, chemical, power, water, and HVAC systems work safely and well.

Key drivers for forged valve adoption include:

- New ways to get energy and changing needs

- Rules for safety and the environment

- New technology for better and smarter valves

Forged valves do great in hard jobs. They help companies meet safety, green, and work goals.

Forged Valve Patterns

Y-Pattern

Y-pattern forged valves have a stem that moves at a 45-degree angle. The body shape lets fluid move in a straighter line. This design makes the flow smoother and lowers pressure drop, sometimes by half compared to T-pattern valves. Operators get better flow and can control the valve more exactly. The small and light body is easier to put in, even in tight spots. Maintenance workers like that the inside parts are easy to reach, so checking and fixing is faster. The valve and pipes do not wear out as fast, so they last longer.

- The stem moves at a 45-degree angle for smooth flow.

- Pressure drop is lower and flow works better.

- Small size makes putting in and fixing easier.

- Best for high-pressure, high-heat jobs that need exact control.

- Easier to fix because parts wear less and are easy to reach.

Y-pattern valves work well in tough places. Their shape helps keep systems running and cuts down on repairs.

T-Pattern

T-pattern forged valves have a stem that sits straight up and down. This makes the fluid turn quickly and sharply. The zigzag path makes the flow rougher and causes more pressure drop. The bigger body can be hard to fit in crowded pipes. It is harder to fix because the inside parts wear out faster. T-pattern valves cost less and are good for jobs with lower pressure where exact control is not needed.

- The stem is straight up and down, making sharp turns.

- More pressure drop and rougher flow.

- Bigger body makes putting in and fixing harder.

- Inside parts wear out faster and need more care.

- Cheaper for simple jobs that do not need perfect control.

T-pattern valves are a good choice when you want to save money. They work for basic flow jobs where you do not need high efficiency.

Angle Pattern

Angle pattern forged valves are a special kind of Y-pattern valve. The body turns the flow by 90 degrees. This keeps the flow smooth like a Y-pattern but lets the pipe turn a corner. These valves are good for pipes that need sharp turns but still want good flow. Operators see less pressure drop and smoother flow, even when the pipe changes direction. Fixing these valves is easy, just like with Y-pattern valves.

- The body turns the flow at a 90-degree angle.

- Flow stays smooth and does not get rough.

- Good for pipes that need sharp turns.

- Easy to fix because the inside is easy to reach.

| Valve Pattern | Defining Characteristics | Effect on Flow and Pressure Drop | Maintenance Implications |

|---|---|---|---|

| Y-pattern | 45-degree angled stem; streamlined flow path | Reduced turbulence and pressure drop | Less wear; easier maintenance; longer life |

| T-pattern | Perpendicular stem; abrupt flow direction change | Higher pressure drop and turbulence | More wear; maintenance more complicated |

| Angle pattern | 90-degree flow redirection; variant of Y-pattern | Efficient flow with directional change | Maintenance similar to Y-pattern |

Picking the right valve pattern helps engineers make flow better, lower repair costs, and keep systems working well. Each pattern has its own job, so choosing the right one is important for good results.

Cast vs Forged Valves

Mechanical Strength

Forged valves are much stronger than a cast ball valve. The forging process lines up the metal grains. This makes the valve tougher and better at handling hits. Forged valves can take more pressure and sudden force without breaking. Cast ball valves can have tiny holes or cracks from how they are made. These weak spots make them less safe in high pressure or heat.

Engineers pick forged valves for pipes with high pressure, especially if the pipe is smaller than DN50. Forged valves keep their shape even when hit or squeezed. Cast ball valves are used more for bigger pipes and lower pressure. Because forged valves are stronger, people use them where safety is very important. Cast ball valves are fine when the pressure is not as high.

Forged valves stop leaks better because they have fewer weak spots inside. This makes them safer for tough jobs.

Durability

Forged valves last longer than a cast ball valve. Forging makes the metal dense and even, with almost no holes. This gives forged valves higher strength. They can take more hits before breaking and do not wear out as fast. Cast ball valves have random grain patterns, so they can crack after being used a lot.

The table below shows the main differences in how long they last:

| Property/Aspect | Forged Valves | Cast Valves |

|---|---|---|

| Tensile Strength | Up to 26% higher because grains are lined up | Not as strong, grains go in random directions |

| Yield Strength | Can take 50% more stress before bending | Bends at about 66% of forged steel’s strength |

| Fatigue Resistance | 37% better at handling repeated stress | Can crack from inside flaws |

| Defect Susceptibility | Almost no holes or cracks inside | Can have holes, cracks, or other weak spots |

| Impact Resistance | Takes 3 times more energy before breaking | Breaks easier if hit hard |

| Ductility | Can stretch 58% before breaking | Only stretches 6%, breaks easier |

| Maintenance & Lifespan | Lasts longer, needs less fixing | Wears out faster, needs more repairs |

| Ideal Applications | Good for high pressure and safety jobs | Good for simple, low-stress, or tricky shapes |

A cast ball valve costs less and is easier to make in odd shapes. But it does not last as long because of weak spots inside. Forged valves are stronger, last longer, and need less fixing in hard jobs.

Thermal Fatigue

Thermal fatigue happens when valves get hot and cold over and over. Forged valves handle this better than a cast ball valve. Their thin walls and neat grain pattern help them heat up and cool down fast. This stops stress and keeps cracks from starting.

Forging gets rid of common casting problems like holes and thick spots. So, forged valves stay strong even after many hot and cold cycles. Cast ball valves have thicker walls and can hide flaws inside. This makes them more likely to get weak and break when the temperature changes a lot.

Forged valves work better and last longer in hot and high-pressure places than a cast ball valve. They are best for important jobs because they do not crack from heating and cooling.

Choosing Between Cast vs Forged Valves

Picking the right valve is important for safety and how well things work. Engineers often have to pick between cast or forged valves. Each one has its own good points and is best for certain jobs.

Key Factors to Consider:

- Pressure and Temperature:

Forged valves can take more pressure and heat. Cast valves are fine for medium jobs. - Valve Size:

Forged valves are best for small pipes, under DN50. Cast valves are used for bigger pipes because they are easier to make. - Mechanical Strength:

Forged valves are strong because their grains are packed tight. This means they do not crack as easily. Cast valves might have weak spots inside that make them less strong. - Corrosion Resistance:

Both types can use materials that fight rust. Forged valves usually last longer in rough places. - Cost:

Cast valves cost less money. Forged valves cost more but work better for hard jobs. - Complex Shapes:

Cast valves can be made in more shapes and bigger sizes. Forged valves are simpler because of how they are made.

| Selection Criteria | Forged Valves | Cast Valves |

|---|---|---|

| Pressure/Temperature | High | Moderate |

| Size Range | Small (DN50 and below) | Medium to Large |

| Strength | Superior | Good (may have weak spots) |

| Cost | Higher | Lower |

| Shape Complexity | Simple | Complex |

| Lifespan | Longer in tough conditions | Adequate for standard service |

Tip: Always pick the valve that fits your system. Think about pressure, heat, and what flows through the pipe before you choose.

When to Choose Forged Valves:

- For high pressure or heat

- When safety is very important

- If the job has lots of heating and cooling

- When you want the valve to last a long time

When to Choose Cast Valves:

- For big pipes

- When pressure and heat are not too high

- If you need to save money

- When you need a special shape

Engineers should look at what the system needs and read the maker’s advice. They should also check the rules for each job. Picking the right valve helps things work well and saves money on repairs.

Selection Guide

Criteria

Picking the right forged valve for a factory job takes careful thought. Engineers need to make sure the valve type and size fit the system. The material must not rust or get damaged by the chemicals in the pipes. The valve’s pressure and temperature ratings should be as high or higher than what the system needs. For check valves, how fast they work and how they are put in matters. Planning for repairs is important too, because easy fixes mean less time stopped.

Key criteria for forged valve selection include:

- Valve Size and Type: Pick a valve that matches how much flow and control the system needs.

- Material Compatibility: Make sure the valve material does not rust or wear out from the fluid.

- Performance Requirements: Check that the valve can handle the highest pressure and heat in the system.

- Application and Function: Decide if the valve will start, stop, control, or protect the flow.

- Connection Type: Choose ends and fittings that fit the pipes.

- Maintenance Needs: Pick valves that are easy to clean, check, and fix.

- Delivery and Availability: Think about how fast you can get the valve and if the supplier is reliable.

Tip: Always check that the valve’s pressure class and material are right for the hardest job in your system.

Common Mistakes

Many companies make expensive mistakes when picking forged valves. Not following rules like API or ISO can cause leaks, rust, or even dangerous pressure problems. Accepting unclear or missing details from suppliers can lead to accidents and legal trouble. Forgetting to ask for test papers or proof of quality can mean insurance will not pay and projects get delayed. Picking suppliers who do not show their certificates or quality checks can hurt a company’s name.

Frequent mistakes include:

- Not using API or ISO rules when picking valves.

- Accepting unclear or missing valve details.

- Forgetting to ask for test papers or outside checks.

- Not checking if the supplier is honest and has good quality.

- Ignoring the need for the right size and material.

These mistakes can cause leaks, pressure problems, and long stops. They can also get companies in trouble with the law and cost a lot of money.

Expert Tips

Experts have some good advice to help forged valves work well in tough places. Always pick valves that fit the exact needs for fluid, pressure, and heat. Ask engineers or trusted valve sellers to help you choose. Use forged valves made from strong materials like alloy or stainless steel for longer life. Check valves often and fix leaks early to help them last.

- Pick forging instead of casting for high-pressure or important jobs because it is stronger.

- Use valves designed with computers for a better fit and best results.

- Use heat treatment and coatings to make valves stronger and stop rust.

- Ask for strong testing and quality checks, like pressure tests, before using the valve.

- Follow the maker’s care plan to keep downtime low and valves working longer.

Note: Careful picking and regular care keep forged valves safe, working well, and saving money for a long time.

Summary Table

Valve Types vs Applications

Picking the right valve type for each job helps engineers keep things safe and working well. The table below shows which forged valve types work best in different jobs and places.

| Valve Type | Best Applications | Key Strengths | Typical Industries |

|---|---|---|---|

| Gate Valve | On/off isolation, pipeline shutoff | Low pressure drop, tight seal | Oil & Gas, Power, Water |

| Globe Valve | Flow regulation, throttling | Precise control, leak resistance | Chemical, Power, Pharma |

| Ball Valve | Quick shutoff, emergency isolation | Fast operation, minimal leakage | Oil & Gas, Water, HVAC |

| Check Valve | Preventing backflow | Automatic operation, equipment safety | Power, Chemical, Water |

| Needle Valve | Fine flow adjustment, sampling | High accuracy, small flow control | Labs, Oil & Gas, Chemical |

| Butterfly Valve | Large diameter flow control, HVAC | Lightweight, easy to operate | Water, HVAC, Chemical |

| Bellows Sealed Valve | Toxic or hazardous media, zero leakage | Emission control, safety | Chemical, Nuclear, Pharma |

| Cryogenic Valve | Low temperature, LNG, liquid gases | Cold resistance, long bonnet | LNG, Medical, Space |

| Extended Body Valve | Tight spaces, pipe transitions | Easy installation, space saving | Petrochemical, Water, Marine |

Engineers need to pick the right valve for each job. This stops leaks and helps machines last longer.

Quick Tips for Valve Selection:

- Use gate valves to shut off main pipes.

- Pick globe valves when you need to control flow.

- Choose ball valves for fast shutoff jobs.

- Put in check valves to stop flow from going backward.

- Select needle valves for careful flow changes.

- Use butterfly valves in big pipes or HVAC systems.

- Pick bellows sealed valves for dangerous fluids.

- Choose cryogenic valves for very cold jobs.

- Use extended body valves when space is tight.

This table makes it easy to see the differences. It helps people compare valve types and choose the right one for their needs.

Forged valve types are very strong and last a long time. They work well in tough places where things can go wrong. Engineers pick gate, globe, ball, or butterfly valves based on how they need to control flow and what the system needs. If the job has high pressure, harsh chemicals, or is very important, picking the right forged valve keeps things safe and helps the valve last longer.

For tricky systems, talking to valve experts helps things work better and follow the rules.

FAQ

What makes forged valves stronger than cast valves?

Forged valves have grains packed close together. This makes them strong and tough. Engineers use forged valves where pressure and heat are high.

Which industries use forged valves most often?

Oil and gas, chemical plants, power plants, water plants, and HVAC systems use forged valves. These places need valves that work well in hard jobs.

How do engineers select the right forged valve material?

Engineers pick materials based on what flows inside, the heat, and the pressure. They look at guides from makers and follow rules. Stainless steel, carbon steel, and alloy steel are used a lot.

Can forged valves handle corrosive chemicals?

Yes. Forged valves made from stainless steel, duplex, or nickel alloys fight rust. Chemical plants and offshore rigs use these valves for strong chemicals.

What is the difference between gate and globe forged valves?

Gate valves shut off flow tightly and do not slow it down much. Globe valves let you control flow very exactly. People use gate valves to stop flow and globe valves to adjust it.

Are forged valves suitable for cryogenic applications?

Forged cryogenic valves have long bonnets and special metals. They work well in very cold places. LNG plants and hospitals use them for cold liquids.

How often should forged valves be maintained?

Checking and caring for valves helps them last longer. Workers look at seals, seats, and moving parts. Makers give advice on how often to check and fix valves.

Tip: Always use the maker’s instructions to stay safe and keep valves working well.