You want your valve to last and perform well, whether it’s a butterfly valve or a diaphragm valve. Choosing the right rubber, such as understanding the differences in epdm vs nbr, makes a big difference. For water systems, EPDM works best, especially in a butterfly valve or diaphragm valve, while NBR stands out for oil and fuel applications. Each rubber type faces stress and can develop cracks over time, particularly at the seal where pressure builds up. Small flaws in the rubber or mixing process can cause early failure. Selecting the right material for your valve environment helps you avoid these problems and ensures reliable performance.

Key Takeaways

- Pick EPDM rubber for valves that use water or steam. It is also good for outdoor use. EPDM does not get damaged by sun, ozone, or weather.

- Use NBR rubber for valves that touch oil or fuel. It also works well with petroleum fluids. NBR does not swell or wear out fast in these places.

- Make sure the rubber matches what the valve carries. This helps stop leaks, cracks, and early breaks.

- EPDM can handle more temperatures and stays bendy. It is great for hot, cold, or changing weather.

- NBR is stronger when there is a lot of pressure. It is better for parts that move a lot. But NBR does not last long outside.

- Look for certifications like FDA, NSF, and REACH. These show the rubber is safe for food, water, and clean valves.

- Think about costs over time. EPDM may cost more at first. But it lasts longer and needs less fixing, so you save money later.

- Do not mix EPDM and NBR parts in one valve. Mixing them can cause uneven wear and make the valve break sooner.

Quick Answer

Picking EPDM or NBR rubber for valves depends on what the valve will touch. EPDM rubber is best for water, steam, and outside use. NBR rubber, also called nitrile, works well with oil, fuel, and things made from petroleum. You need to pick the right rubber for your valve’s job. This helps your valve work better and last longer.

Key Differences

The table below shows how EPDM and NBR rubber are different. It helps you see which one is better for your valve.

| Performance Aspect | EPDM Characteristics | NBR Characteristics |

|---|---|---|

| Temperature Resistance | Works in a wide range: about -40°C to 120-150°C; good for changing or extreme heat | Works in a smaller range: about -30°C to 100-120°C; good for mild heat |

| Chemical Resistance | Great against water, acids, alkalis, ozone, UV; good for water treatment, HVAC, and chemicals | Great against oils, fuels, and petroleum; not good with acids, alkalis, or water |

| Mechanical Properties | Softer, bends easily, seals well; can wear out faster if stressed | Stronger, resists wear and pressure; good for high stress and pressure |

| UV and Ozone Resistance | Very good; great for outside and sunlight | Not good; not for outside or sunlight |

| Application Suitability | Water treatment, HVAC, chemical jobs, outside use | Cars, oil and gas, places with petroleum fluids |

You can also look at their chemical resistance and how tough they are:

| Property | EPDM | NBR |

|---|---|---|

| Oil Resistance | Not good (gets bigger in oil) | Very good (does not swell in oil or fuel) |

| Ozone/Aging Resistance | Very good (stays strong in sun and weather) | Not good (breaks down in sun and ozone) |

| Temperature Range | Wide: -50°C to 150°C (can go up to 180°C with special types) | Medium: -30°C to 100°C (can go to -55°C for some types) |

| Mechanical Properties | Bends well, not as tough against wear | Stronger, lasts longer with lots of rubbing and pressure |

| Typical Applications | Water treatment, car cooling, chemical machines | Fuel systems, hydraulic machines, food machines |

Tip: Use EPDM rubber for valves that see sun, ozone, or water. Use NBR rubber for valves that touch oil, fuel, or petroleum fluids.

When to Use EPDM

Pick EPDM rubber for valves that touch water, steam, or weak chemicals. EPDM rubber stands up to heat, sun, ozone, and weather. It works well outside and in places that get cleaned a lot or get hot. EPDM rubber is good for:

- Water treatment valves

- HVAC systems

- Steam valves

- Irrigation systems

- Food, drink, and medicine valves

EPDM rubber seats can handle hot water, steam, and cleaning chemicals. They resist weak acids, alkali, and some chemicals that clean. EPDM rubber is not good for oil or petroleum products. It gets bigger and breaks down if it touches them.

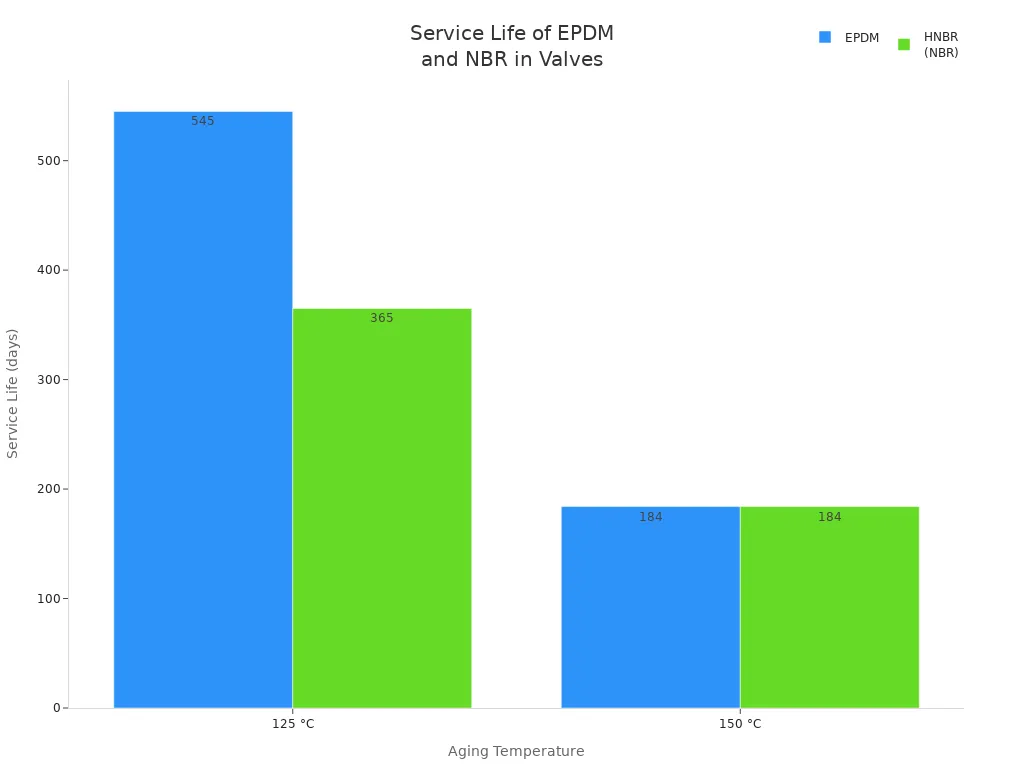

You can see how EPDM rubber lasts in valves by looking at the chart below:

EPDM rubber keeps leaks away longer at lower heat. This makes it a good pick for valves in cool water or steam systems.

When to Use NBR

Pick NBR rubber, or nitrile, for valves that touch oil, fuel, or petroleum fluids. NBR rubber does not swell or break down with these. It is strong and resists wear, so it is good for high pressure and moving parts. NBR rubber is good for:

- Car fuel valves

- Hydraulic machine valves

- Air valves

- Valves for oil and gas

- Food machines that use oil

NBR rubber does not stand up to sun, ozone, or weather. It is not good for outside valves or ones in sunlight. NBR rubber also does not resist many chemicals and breaks down in high heat. Do not use NBR rubber for valves with brake fluid, strong cleaners, or strong acids and alkalis.

| Property | Details |

|---|---|

| Sensitivity | Gets damaged by weather |

| Temperature Resistance | Handles up to about 75°C |

| Chemical Resistance | Does not resist many chemicals; not for brake fluid or strong cleaners |

| Compatibility | Works with oil, some cleaners, and alcohol |

| Comparison | Not as good as EPDM, FKM, or PTFE for chemicals and heat |

NBR rubber works better than EPDM at higher heat because of how it ages. But EPDM rubber lasts longer at lower heat.

EPDM vs NBR

Chemical Resistance

EPDM rubber and NBR rubber are different in chemical resistance. EPDM rubber is good with water, steam, weak acids, alkalis, and cleaning chemicals. It does not get damaged by ozone or sunlight. You can use EPDM in valves for water treatment, HVAC, and chemical jobs. EPDM rubber works well where there is moisture or cleaning agents.

NBR rubber is strong against oil, fuel, and petroleum fluids. It does not swell or break down with these. NBR rubber is used in valves for hydraulic systems, fuel lines, and machines with oil. But NBR rubber does not resist acids, alkalis, or water as well as EPDM. If you use NBR rubber in water or chemical valves, it may wear out faster.

Note: The best rubber depends on what goes through your valve. EPDM rubber is better for water and chemicals. NBR rubber is better for oil and fuel.

Temperature Range

Temperature range is important when picking EPDM or NBR. Both rubbers can handle hot and cold, but there are differences. EPDM rubber works in very hot and very cold places. You can use EPDM from -70°F to 250°F. This makes EPDM good for steam valves, outdoor valves, and places with big temperature changes.

NBR rubber also works in hot and cold, but not as much. Standard NBR rubber works from -30°F to 250°F. Some special NBR types can go lower, but most should not be in extreme cold. EPDM rubber can handle up to 257°F (125°C). NBR rubber can handle up to 220°F (104°C). If your valve gets very hot or has steam, EPDM rubber is safer.

| Material | Standard Temperature Range (oF) | Maximum Continuous Operating Temperature (oF) |

|---|---|---|

| EPDM | -70 to 250 | 257 |

| NBR | -30 to 250 | 220 |

EPDM rubber is better for high heat and steam. NBR rubber is best for medium heat and oil.

Weather and UV

Outdoor valves need to handle weather, sunlight, and ozone. EPDM rubber is great for these tough conditions. It stays strong and flexible after lots of sun and ozone. Tests show EPDM gaskets keep 75% strength after 1,000 hours of sun and ozone. This means EPDM rubber is good for outdoor valves, irrigation, and sunny places.

NBR rubber does not do well outside. Sun and ozone make NBR rubber crack and get weak. If you use NBR rubber outside, it may fail early. EPDM rubber has few problems outdoors, but NBR rubber has clear limits.

| Property | Description | Benefit |

|---|---|---|

| Weather & UV Resistance | Great resistance to sunlight and ozone | Lasts long outside |

| Elasticity | Very flexible and stretches well | Seals well |

| Temperature Range | -50°C to +150°C | Works in very hot or cold places |

Always pick the right rubber for your valve’s environment. EPDM rubber is good for weather and ozone. NBR rubber is best for inside or away from sun.

Mechanical Properties

When you choose a rubber for your valve, you want to know how strong and flexible it is. The mechanical properties of EPDM and NBR rubber help you decide which one fits your needs. These properties show how the material will handle pressure, stretching, and bending inside a valve.

EPDM rubber is known for its great flexibility. You can stretch it a lot before it breaks. This makes EPDM a good choice for seals that need to bend or move. NBR rubber is tougher and can handle more pressure. It works well in places where the seal faces a lot of force or rubbing.

Here is a table that shows the typical tensile strength for each rubber:

| Rubber Type | Typical Tensile Strength Range (MPa) |

|---|---|

| EPDM | 7 – 14 |

| NBR | 12 – 20 |

Tensile strength tells you how much pulling force the material can take before it snaps. NBR rubber has a higher range, so it is stronger under tension. This makes NBR rubber a good pick for high-pressure valves or moving parts.

You should also look at how much the rubber can stretch before it breaks. This is called elongation at break. Both EPDM and NBR rubber can stretch a lot, but EPDM rubber can stretch even more. Here is another table that compares these properties:

| Material | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|

| EPDM | ≥ 15.2 | ≥ 400 |

| NBR | ≥ 15.2 | ≥ 350 |

You can see that both materials have strong tensile strength, but EPDM rubber can stretch a bit more before breaking. This extra stretch helps EPDM rubber keep a tight seal, even if the valve moves or shakes.

- EPDM rubber stays soft and flexible, even in cold weather.

- NBR rubber is more resistant to wear and pressure, so it lasts longer in tough jobs.

- Both rubbers can handle bending and stretching, but EPDM rubber is better if you need more flexibility.

Tip: If your valve needs to handle a lot of movement or vibration, EPDM rubber is a smart choice. If your valve faces high pressure or heavy use, NBR rubber gives you more strength and durability.

When you compare epdm vs nbr, think about what your valve will face. The right mechanical properties help your valve last longer and work better.

Applications

Water Valves (EPDM)

EPDM rubber is used a lot in water valves. It works well where water, steam, or weak chemicals move through the valve. EPDM rubber does not get damaged by water or steam. This helps it last longer in wet places. You can find EPDM rubber in butterfly valves and diaphragm valves. It is also in check valves at water plants, irrigation, and HVAC systems. These valves need seals that do not break when they touch water or cleaners.

EPDM rubber also stands up to ozone and weather. This makes it good for outdoor water valves. You can use EPDM rubber in food and drink factories. It does not react with most cleaning products. When you pick EPDM rubber for water valves, you get a seal that stays soft and does not crack. This helps your valve work well for many years.

Tip: Pick EPDM rubber for water valves if you want strong protection from water, steam, and cleaning chemicals.

Oil and Fuel Valves (NBR)

NBR rubber is great for oil and fuel valves. You need a seal that does not get bigger or break when it touches oil or fuel. NBR rubber does not swell or fall apart with these fluids. You can find NBR rubber in ball valves, gate valves, and butterfly valves. These are used in oil pipes, car fuel systems, and hydraulic machines.

NBR rubber is also used in air valves and low-pressure gas valves. These valves use NBR O-rings and diaphragms. The material does not get hurt by gasoline, hydraulic oil, or grease. NBR rubber is good for valves that have oil or fuel inside. But do not use NBR rubber outside. Sunlight and ozone can damage it.

Note: NBR rubber is best for oil and fuel valves because it does not swell and keeps its shape in petroleum fluids.

Chemical Valves

Chemical valves need the right rubber for safety. EPDM rubber and NBR rubber are both used, but you must match the rubber to the chemicals. EPDM rubber works well with water and steam. You see EPDM rubber in diaphragm valves and gaskets for chemical jobs with water-based liquids.

NBR rubber is used in chemical valves that handle oil, some hydrocarbons, and hydraulic fluids. You find NBR rubber in ball valves and gate valves in chemical plants with petroleum products. But NBR rubber does not resist some chemicals like chlorinated hydrocarbons, ketones, or esters. These can break down the rubber and cause leaks.

Here is a table to help you pick the right rubber for chemical valves:

| Rubber Type | Chemicals That Cause Damage | Chemicals That Are Safe |

|---|---|---|

| EPDM | Petroleum-based products, nonpolar hydrocarbons | Water, steam, mild chemicals |

| NBR | Chlorinated hydrocarbons, ketones, esters | Oils, gasoline, hydraulic fluids |

You should always check if the rubber matches the chemicals before you choose EPDM or NBR for chemical valves. This helps stop leaks and keeps your system safe.

Outdoor Valves

When picking rubber for outdoor valves, think about sun and rain. Weather can be hard on some rubbers. EPDM rubber is great for outdoor valves. It stays strong and flexible after years in the sun.

- EPDM resists UV rays and ozone. You can use it for outdoor water, irrigation, and rooftop valves.

- EPDM keeps a tight seal when temperatures change.

- EPDM stays bendy and does not crack, even after lots of sun and weather.

- NBR does not last long outside. Sun and ozone make it crack and lose its seal.

- NBR works best indoors or in places with oil or fuel.

Here is a table to help you compare EPDM and NBR for outdoor valves:

| Property/Feature | EPDM Rubber | NBR (Nitrile Rubber) |

|---|---|---|

| UV Resistance | Excellent; resists cracking and degradation | Poor; prone to cracking outdoors |

| Ozone Resistance | High; does not degrade in ozone | Low; cracks in ozone-rich air |

| Outdoor Durability | Lasts 10+ years in sun and weather | Limited; not ideal for outdoor use |

| Typical Applications | Outdoor valve seals, irrigation, roofing | Oil and fuel seals, indoor use |

Tip: Use EPDM rubber for valves that face sun, rain, or weather. It helps your valve last for years without leaks or cracks.

You see EPDM in outdoor valves like water plants, irrigation, and rooftop HVAC units. NBR is not good for these jobs. It cannot handle sun or ozone. Always pick the right rubber for the place your valve will be.

Food and Sanitary Valves

Food and sanitary valves need special care. You want food, drinks, and medicine to stay safe and clean. EPDM and NBR can be used, but they must follow strict safety rules.

EPDM and NBR must pass REACH certification. This means the rubber is safe and clean. REACH checks that the rubber will not hurt people or the earth. You also need other approvals like FDA, USP, and NSF. These rules make sure the rubber is safe for food and sanitary use.

- EPDM is common in food and drink valves. It does not react with cleaning chemicals or water. You find EPDM in dairy, drink, and medicine valves.

- NBR is used in food valves where oil or grease is present. It works well in machines that use oil or fat.

- Both rubbers must stay clean and not change the taste or smell of food or drinks.

Note: Always check that your valve’s rubber meets REACH, FDA, USP, and NSF rules before using it for food or sanitary jobs.

You can trust EPDM and NBR for food and sanitary valves if they have the right safety marks. This keeps your products safe and your valves working well.

Nitrile vs EPDM

Valve Seals

When you choose a rubber for valve seals, you want to make sure it matches your needs. Nitrile rubber and EPDM rubber both work well, but they shine in different places. Nitrile rubber stands out in oil and fuel systems. You see nitrile in car engines, fuel pumps, and hydraulic valves. The properties of nitrile rubber include strong resistance to petroleum-based fluids and good abrasion resistance. This means nitrile rubber seals last longer in oily or greasy environments.

EPDM rubber works best in water, steam, and outdoor valves. It resists weather, UV, and many chemicals. If your valve faces sun, rain, or cleaning agents, EPDM rubber gives you a reliable seal. Nitrile vs EPDM comes down to what flows through your valve. If you need sealing for oil or fuel, nitrile rubber is the right choice. For water or outdoor use, EPDM rubber wins.

Tip: Always match the rubber to the media in your valve. This helps you avoid leaks and early failure.

O-Rings and Gaskets

O-rings and gaskets keep valves tight and leak-free. Nitrile rubber O-rings work well in oil, fuel, and hydraulic systems. The benefits of nitrile rubber include strong sealing in oily places and good wear resistance. You find nitrile O-rings in fuel lines, pumps, and compressors. The properties of nitrile rubber make it a top pick for petroleum-based fluids.

EPDM rubber O-rings shine in water, steam, and outdoor jobs. EPDM rubber has a low compression set. This means it bounces back after being squeezed, keeping its shape and sealing power over time. You want this in valves that open and close often. Nitrile rubber also offers durability, but EPDM rubber’s elasticity gives it an edge in dynamic sealing application.

Here is a quick table to help you compare:

| Feature | Nitrile Rubber | EPDM Rubber |

|---|---|---|

| Oil/Fuel Resistance | Excellent | Poor |

| Water/Steam Resistance | Poor | Excellent |

| Compression Set | Good | Very Low (Better) |

| UV/Ozone Resistance | Poor | Excellent |

| Typical Use | Oil, fuel, hydraulics | Water, steam, outdoor |

If you need O-rings or gaskets for oil or fuel, pick nitrile rubber. For water, steam, or outdoor valves, EPDM rubber is the better choice.

Stem Seals

Stem seals stop leaks where the valve stem moves. You want a rubber that can handle movement and pressure. Nitrile rubber stem seals work well in engines, pumps, and hydraulic systems. The advantages of nitrile rubber include strong resistance to oil and good wear life. Nitrile rubber keeps its shape under pressure, so it works well in moving parts.

EPDM rubber stem seals fit best in water and steam valves. EPDM rubber stays flexible in hot and cold weather. It resists cracking from sun and ozone. If your valve sits outside or handles water, EPDM rubber gives you a long-lasting seal.

Note: Nitrile rubber is not good for outdoor use. The disadvantages of nitrile rubber include poor UV and ozone resistance. EPDM rubber is better for valves exposed to weather.

When you compare nitrile vs epdm for stem seals, think about what your valve faces every day. Nitrile rubber is best for oil and fuel. EPDM rubber is best for water, steam, and outdoor use. Both rubbers help you get a tight seal, but each one fits a different job.

Selection Guide

Media Compatibility

You need to match the valve rubber to what flows through your system. This step is the most important part of the selection process. If you pick the wrong material, your valve may leak or fail early. EPDM and NBR each work best with certain fluids.

Here is a table to help you compare:

| Material | Recommended Media Compatibility | Temperature Range | Not Suitable For |

|---|---|---|---|

| EPDM | Acids, alkalis, salts, drinking water | Up to 90°C | Oils, petrochemicals, concentrated acids |

| NBR | Oils, petroleum | 60-90°C | Ozone, strong acids, oxidizing media |

EPDM works well with water, steam, and mild chemicals. It does not affect the taste of drinking water. NBR is best for oil, fuel, and petroleum products. It also offers good wear resistance. You should avoid using EPDM with oils or hydrocarbons. NBR does not last long with ozone or strong acids.

Tip: Always check what media your valve will handle before making your selection. This helps you get the best sealing and longest valve life.

Temperature Needs

Temperature can change how rubber works in your valve. You must know the highest and lowest temperatures your valve will face. EPDM and NBR have different temperature limits.

– EPDM works well from -20°F to 230°F. Some types can go up to 130°C (266°F).

- NBR works best between -40°F and 212°F. It handles cold better but does not like high heat.

If you use a material outside its range, it may swell, harden, or crack. This can cause leaks or even valve failure. High heat can weaken rubber and lower its chemical resistance. Cold can make rubber brittle and break.

Note: Always match the temperature range of your selection to your process. This keeps your valve safe and avoids costly repairs.

Compliance

You must also check if your valve rubber meets safety rules. Many jobs need special certifications. For drinking water, look for NSF 61 certification. This shows the material is safe for pipes, gaskets, and seals in water systems.

Other important certifications include:

- FDA 21 CFR 177.2600 for food contact

- EC 1935/2004 for European food safety

- 3-A Sanitary Standards for dairy

- WRAS and NSF for potable water

- API 609 and API 607 for fire safety and traceability

These rules make sure your selection is safe for food, water, and medicine. EPDM is known for chemical resistance and weather durability. NBR is strong against oil and fat. Both can meet strict standards if you choose the right grade.

Always ask your supplier for proof of compliance before you buy. This protects your system and keeps you in line with the law.

Cost and Maintenance

When you choose a rubber for your valve, you need to think about more than just the price tag. The cost of your selection includes what you pay upfront and what you spend over time to keep your valve working. EPDM and NBR have different strengths that affect how much you pay for maintenance and replacements.

EPDM rubber usually costs a bit more at the start. You might wonder if it is worth it. Over time, EPDM saves you money because it lasts longer in tough environments. EPDM stands up to water, steam, acids, alkalis, ozone, and aging. This means you do not have to replace seals as often. You spend less time fixing leaks or calling for repairs. For example, some users found that switching to EPDM extended diaphragm life from three months to over a year. Fewer replacements mean less downtime and lower total cost of ownership.

NBR rubber often costs less when you buy it. If your valve handles oil or fuel, NBR is a smart choice. It resists swelling and works well in dynamic sealing jobs. However, NBR does not like high heat or ozone. When temperatures go above 100°C, NBR can harden and crack. Sunlight and ozone also make NBR break down faster. You may need to replace NBR seals more often, which adds to your maintenance costs. Over time, the money you save upfront can disappear if you have to fix or replace your valve too many times.

Here is a table to help you compare the cost and maintenance of EPDM and NBR:

| Rubber Type | Upfront Cost | Maintenance Frequency | Typical Service Life | Best For |

|---|---|---|---|---|

| EPDM | Medium | Low | Long | Water, steam, outdoor |

| NBR | Low | Medium to High | Medium | Oil, fuel, indoor use |

Tip: If you want your valve to last and need fewer repairs, EPDM is often the better investment for water, steam, and outdoor jobs. NBR works well for oil and fuel, but you should plan for more frequent maintenance.

When you make your selection, think about where your valve will work and what it will handle. The right choice helps you avoid surprise costs and keeps your system running smoothly. Always balance the upfront price with the long-term savings from lower maintenance and longer service life.

Common Misconceptions

Oil Resistance

Many people think all rubbers have the same oil resistance. This is not true. You need to know that EPDM and NBR act very differently when they touch oil. NBR gives you strong oil resistance. It keeps its shape and does not swell when oil or fuel touches it. EPDM does not have good oil resistance. If you use EPDM in oil or fuel valves, the rubber can swell, get soft, and break down fast. You should always check the type of rubber before you use it with oil. If you want a seal that lasts in oil, pick NBR. EPDM works better for water and steam, not oil.

Remember: NBR is your best choice for oil resistance. EPDM will fail in oil or fuel.

Water Resistance

Some people believe NBR works well with water. This is a mistake. EPDM gives you the best water resistance. It stands up to water, steam, and cleaning chemicals. NBR does not have strong water resistance. Over time, water can make NBR seals hard and crack. If you use NBR in water valves, you may see leaks or seal failure. EPDM keeps its strength and flexibility in water. You should use EPDM for water, steam, and outdoor valves. NBR fits best in oil and fuel systems.

Here is a quick table to help you remember:

| Rubber Type | Water Resistance | Oil Resistance |

|---|---|---|

| EPDM | Excellent | Poor |

| NBR | Poor | Excellent |

Tip: Always match the rubber to the media. EPDM for water, NBR for oil.

Lifespan

You might think all valve rubbers last the same amount of time. This is not correct. The lifespan of a rubber seal depends on the type of media and the environment. EPDM lasts longer in water, steam, and outdoor use because it has strong resistance to weather, ozone, and UV. NBR lasts longer in oil and fuel because of its oil resistance. If you use the wrong rubber, the seal will wear out fast. For example, EPDM in oil will break down quickly. NBR in water will crack and fail. You should always choose the right rubber for your valve’s job. This helps you get the longest service life and the best resistance to leaks.

Note: The right rubber gives you better resistance and a longer lifespan. Always check your valve’s needs before you choose.

Other Comparisons

EPDM vs Viton

When you pick between EPDM and Viton for valves, you should think about heat, chemicals, and pressure. EPDM works in cold and hot places, from -40°C to 150°C. It bends well and does not get hurt by sun or rain. People use EPDM in water pipes and outside valves.

Viton is also called fluorocarbon elastomer. It can take more heat, from -30°C to 200°C. Viton stands up to many chemicals, like oils and fuels. You see Viton in oil valves, car fuel parts, and places with strong chemicals.

Here is a table to help you compare:

| Material | Temperature Range | Chemical Resistance | Flexibility | Pressure/Strength | Notable Limitations | Best Use |

|---|---|---|---|---|---|---|

| EPDM | -40°C to 150°C | Weak to oils and fuels | Good | Moderate | Not for oils or fuels | Water, weather, general sealing |

| Viton | -30°C to 200°C | Strong, especially oils and fuels | Moderate | Good | Not for steam | Oil, gas, fuel systems |

Tip: Pick EPDM for water and outside valves. Choose Viton if your valve has oil, fuel, or gets very hot.

Teflon vs EPDM

Teflon, also called PTFE, is not like EPDM. Teflon can handle very hot and very cold, from -200°C to 260°C. It does not get damaged by almost any chemical. Teflon is not as bendy as EPDM, but it lasts a long time.

EPDM bends better and works well for water and outside jobs. Teflon does not bend much, so it can break if you twist it. Teflon costs more than EPDM. Use Teflon if your valve needs to handle super hot, super cold, or strong chemicals.

Key points:

- EPDM is good for water, steam, and outside jobs.

- Teflon is good for very hot, cold, or strong chemicals.

- Teflon does not bend much and costs more.

| Material | Temperature Range | Chemical Resistance | Flexibility | Pressure/Strength | Notable Limitations | Best Use |

|---|---|---|---|---|---|---|

| EPDM | -40°C to 150°C | Weak to oils/fuels | Good | Moderate | Not for oils/fuels | Water, weather, general sealing |

| Teflon | -200°C to 260°C | Excellent | Low | Limited (unless reinforced) | High cost, can crack | Extreme temperature, harsh chemicals |

Note: Pick Teflon for the hardest jobs. Use EPDM for most water and outside valves.

Viton vs PTFE

Viton and PTFE (Teflon) both work with strong chemicals, but they are different. Viton works from -30°C to 200°C. It stands up to oils, fuels, and many chemicals. Viton bends more than PTFE, so it seals better when parts move.

PTFE works in even colder and hotter places, from -200°C to 260°C. It does not get hurt by almost any chemical. PTFE does not bend much, so it can break if you twist it. PTFE costs more and does not handle high pressure unless it is made stronger.

Comparison Table:

| Material | Temperature Range | Chemical Resistance | Flexibility | Pressure/Strength | Notable Limitations | Best Use |

|---|---|---|---|---|---|---|

| Viton | -30°C to 200°C | Strong, especially oils/fuels | Moderate | Good | Not for steam | Oil, gas, fuel systems |

| PTFE | -200°C to 260°C | Near-universal | Low | Limited (unless reinforced) | High cost, can crack | Extreme temperature, harsh chemicals |

Tip: Use Viton for oil, fuel, and chemical valves that need to bend a bit. Pick PTFE for valves in very hot, cold, or strong chemical places.

Viton vs Teflon

When you choose between Viton and Teflon for valve applications, you need to look at how each material handles chemicals, temperature, and movement. Both materials work well in tough environments, but they have different strengths.

Viton is a type of fluorocarbon rubber. You find it in places where oil, fuel, and many chemicals flow through valves. Viton stays flexible and keeps its shape when you use it with oils and fuels. It also works well in high heat, up to 200°C (392°F). You can use Viton in car engines, fuel systems, and chemical plants. It seals well when parts move or shake.

Teflon is also called PTFE. It is not a rubber, but a plastic. Teflon stands out because it resists almost every chemical. You can use Teflon in places with acids, bases, and strong cleaners. It works in very hot and very cold places, from -200°C to 260°C (-328°F to 500°F). Teflon does not bend much, so it can crack if you twist or stretch it. You see Teflon in valves for chemical plants, labs, and food factories.

Here is a table to help you compare Viton and Teflon:

| Property | Viton (FKM) | Teflon (PTFE) |

|---|---|---|

| Type | Rubber (elastomer) | Plastic (fluoropolymer) |

| Temperature Range | -30°C to 200°C | -200°C to 260°C |

| Chemical Resistance | Excellent (oils, fuels, many chemicals) | Near-universal |

| Flexibility | Good | Low |

| Pressure Resistance | Good | Limited (unless reinforced) |

| UV/Ozone Resistance | Good | Excellent |

| Cost | High | Higher |

| Best Use | Oil, fuel, chemical valves | Extreme chemicals, high/low temp valves |

FAQ

What is the main difference between EPDM and NBR in valves?

EPDM works best with water, steam, and outdoor use. NBR handles oil, fuel, and petroleum products. You should choose based on what flows through your valve.

Can I use EPDM rubber for oil or fuel valves?

No, you should not use EPDM for oil or fuel. Oil and fuel make EPDM swell and break down. NBR is the better choice for these fluids.

Is NBR rubber safe for drinking water valves?

NBR does not work well with water, especially drinking water. It can crack and fail over time. EPDM is the safer option for water and food applications.

How do I know which rubber to pick for my valve?

Check what flows through your valve and the temperature range. Use EPDM for water, steam, and outdoor jobs. Use NBR for oil, fuel, and indoor use.

Does EPDM rubber last longer outdoors than NBR?

Yes, EPDM lasts much longer outside. It resists sun, rain, and ozone. NBR breaks down quickly in sunlight and outdoor weather.

Are both EPDM and NBR approved for food and sanitary valves?

You can use both if they have the right certifications, like FDA or NSF. Always check with your supplier for proof before you buy.

What happens if I use the wrong rubber in my valve?

Using the wrong rubber can cause leaks, swelling, or cracks. Your valve may fail early. Always match the rubber to your valve’s job for best results.

Can I mix EPDM and NBR parts in the same valve?

You should not mix them. Each rubber reacts differently to fluids and temperatures. Mixing can cause one part to fail faster than the other.