When picking valve actuators for automation, electric ball valves and pneumatic valve actuators both have strong points. Pneumatic valve actuators work fast and move quickly. They are good for places that need quick changes and are tough. Electric ball valves are great for exact control. They are easy to set up and cost less to run. The table below shows their main good and bad points:

| Factor | Pneumatic Valve Actuators | Electric Ball Valve |

|---|---|---|

| Speed | Fast (1–6 seconds) | Slower (5–15 seconds) |

| Reliability | Strong, not much affected by weather | Can be hurt by wet or hot places |

| Cost | Cheaper at first, costs more later | Costs more at first, cheaper later |

| Control | Simple on/off | Exact movement |

Pneumatic actuators are best for places that need speed or are dangerous. Electric actuators are better when you need things to be exact and want less fixing. The best valve depends on what your automation needs.

Key Takeaways

- Pneumatic ball valves move quickly and are good for fast jobs. They give strong action when needed. Electric ball valves let you control them very exactly. They work well with digital automation systems. Pneumatic actuators are cheaper to buy at first. But they can cost more later because air systems need care. Electric actuators cost more at the start. But they save energy and need less fixing over time. Pneumatic valves last longer in hard places. They are safer in dangerous areas. Electric valves are easier to hook up to new control systems. They also give real-time data. You should pick a valve based on speed, control, safety, price, and where you use it. Doing regular care helps both types last longer and work well.

Overview

Quick Comparison

Valve actuators are important in automation. Electric and pneumatic valve actuators have different good points. The table below shows how they are not the same in many ways:

| Factor | Electric Ball Valve Actuators | Pneumatic Valve Actuators |

|---|---|---|

| Energy Source | Uses electricity; does not need compressed air | Uses compressed air; needs an air supply |

| Precision | Very exact and steady; good for careful moves | Not as exact; speed is harder to control |

| Maintenance | Costs more to buy and fix | Cheaper to buy and fix; strong and lasts long |

| Cost | Costs more at first; costs less to use | Costs less at first; costs more to use because of air |

| Speed | Works slower | Works faster |

| Noise | Makes little noise | Can be loud |

| Size and Space | Usually smaller and takes up less room | Small actuator but needs space for air system |

| Environmental Suitability | Best where power is steady; not good if power goes out | Good for rough, dirty, or very hot or cold places |

| Integration | Easy to connect to digital systems; can be watched closely | Harder to connect; simpler controls |

| Application Examples | Used in watering, water pipes, and heating | Used in engines, factories, and transport machines |

Valve actuators should fit what each job needs. Electric ball valve actuators use electricity to move motors and gears. They are very exact, do the same thing every time, and are easy to connect to digital systems. Pneumatic valve actuators use air to move. They work fast, are good in tough places, and cost less at first. But pneumatic actuators always need air and can be noisy.

Main Differences

Tip: Pick the actuator that matches what your job needs.

Electric ball valve actuators are best for being exact and doing the same thing over and over. They control how fluids move very well and can talk to digital systems. They do not need air or oil systems, so they are easier to set up and take care of. They also use less energy, which saves money later.

Pneumatic valve actuators are great for being fast and strong. They work quickly and can handle hard places, like very hot or dirty spots. These actuators are good when you need things to move fast and not break. Pneumatic systems need more room for air equipment and may need more fixing because of air leaks.

Valve actuators connect to automation in different ways. Electric actuators are easy to hook up to new control systems and can use digital signals. Pneumatic actuators can also connect, but they need more equipment and care. Electric ball valve actuators are best where power is steady and you need careful control. Pneumatic valve actuators are better where things must move fast and be tough.

Choosing a valve depends on how exact you need to be, the place it will be used, how much room you have, how much you can spend, and how you want to control it. Electric ball valve actuators are easy to connect and save energy. Pneumatic valve actuators are fast and strong for hard jobs.

Performance

Precision Control

Electric Ball Valve

Electric ball valves are very accurate in automated systems. They use electric motors to move the valve. These motors can work in different ways, like on-off or modulating. You can control the flow very closely. This makes them good for jobs that need exact amounts of liquid. You can use them for mixing or batch jobs. Electric actuators let you control the valve from far away. They are easy to connect to digital systems. Some have energy-saving motors and strong parts. This helps them last a long time.

You can also change electric ball valves to fit your needs. You can pick different sizes, connections, and controls. This helps you get the right accuracy for your job. Electric ball valves react fast to signals. They keep the flow, pressure, and temperature steady. Digital systems like HART or Fieldbus make them even more flexible and exact.

Note: Electric actuators give steady and repeatable control. This is important for safety and remote pipeline work.

Pneumatic Valve Actuators

Pneumatic actuators use air to move valves. They change the valve by changing air pressure. Pneumatic ball valves move fast. But their accuracy depends on how steady the air is. If the air leaks or changes, they lose accuracy. Sometimes, they need extra parts to be more exact.

The table below shows how electric and pneumatic actuators compare for precision:

| Aspect | Pneumatic Valve Actuators | Electric Ball Valves |

|---|---|---|

| Precision Control | Uses air pressure to control. Leaks or changes in air can make it less exact. May need extra parts for high accuracy. | Can move the valve to any spot between open and closed using electric signals and circuit boards. |

| Modulating Control | Cannot always control flow well by itself. | Can move the valve to any spot between open and closed using electric signals and circuit boards. |

- Both types can control valves at partly open spots.

- Pneumatic actuators often need more equipment for high accuracy.

- Electric actuators are more exact because they use electric signals.

Repeatability

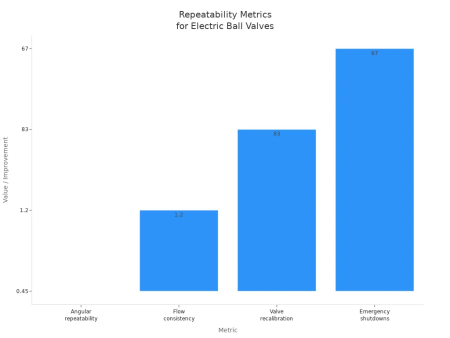

Repeatability means doing the same thing the same way every time. Electric actuators are better at this. They use special motors and sensors to check their position. They can move very small amounts, less than half a degree. They keep flow steady within about half a percent, even after many uses. This helps in jobs like adding chemicals or making batches.

The chart below shows how electric ball valves do in repeatability:

| Metric | Value/Improvement | Context/Duration |

|---|---|---|

| Angular repeatability | 0.45° | Used for precise catalyst dosing |

| Flow consistency | ±1.2% | Over 8 months (plant audit 2023) |

| Valve recalibration | 83% reduction | Annual maintenance records |

| Emergency shutdowns | 67% reduction | Safety reports T1-T3 2024 |

Electric actuators hold their spot without moving by accident. This makes them more reliable and means less fixing. Pneumatic ball valves are not as repeatable. Air pressure can change, so they are less steady. Their controls are simpler, so they are not as good for very exact jobs. Pneumatic ball valves are strong and not too expensive. But they need extra sensors and programming to be as repeatable as electric ones.

Tip: Repeatability affects how reliable and exact a valve is. It also changes how much fixing is needed. Electric actuators usually work better for exact jobs over time.

Speed

Actuation Time

Pneumatically Actuated Ball Valves vs Electrically

Speed is very important in automation. Pneumatic and electric ball valves move at different speeds. Pneumatic valve actuators use air to move the valve fast. Most pneumatic actuators finish moving in less than one second. Air pressure gives them instant power. Big pneumatic valves might take up to thirty seconds. Most are much faster.

Electric ball valves use motors and gears to move. These motors need more time to work. Small electric valves take two or three seconds. Big electric actuators can take up to ninety seconds. Electric motors can get hot and need breaks. This makes them slower.

The table below shows how long each type takes:

| Actuation Type | Average Cycle Time |

|---|---|

| Pneumatic Valve Actuators | 0.5 to 1 second |

| Electric Ball Valve Actuators | About 6 seconds (can be 25 seconds or more) |

Fast valve actuators help systems work better. Pneumatic ball valves are best when speed is needed. Electric actuators are good for slow, careful moves. Pick the right valve for how fast your system needs to work.

Tip: Fast valves help automation work quickly. Pneumatic actuators help systems change fast.

Fast Cycling

Some jobs need valves to open and close many times. Pneumatic actuators are great for this. Pneumatic ball valves open or close in about one second. They can do up to one million cycles. This makes them good for lots of use. They are small and do not get hot easily.

Electric ball valves move slower. Most electric actuators need about six seconds to open or close. Some take up to twenty-five seconds. Electric actuators can do about 250,000 cycles. They might get too hot if used too much.

The table below shows how fast each type cycles:

| Actuator Type | Fastest Cycling Rate (Open/Close) |

|---|---|

| Pneumatic | 0.5 to 1 second |

| Electric | About 6 seconds (Gemini Valve) to 25+ seconds (other brands) |

Fast cycling helps factories work better. Pneumatic ball valves are good for jobs that need lots of fast moves. Electric actuators are better for careful moves and fewer cycles.

The next table shows features for high-speed jobs:

| Feature | Pneumatic Ball Valves | Electric Ball Valves |

|---|---|---|

| Cycle Time | Fast: 0.5 to 1 second | Slow: about 6 seconds or more |

| Durability | High: up to 1,000,000 cycles | Medium: about 250,000 cycles |

| Size | Small: up to 70% smaller than electric actuators | Bigger size |

| Operating Environment | Good against heat and wet places | Can get hot; works in fewer places |

| Power Source | Needs air (60-125 PSI) | Needs electricity; no air needed |

| Failsafe Options | Has spring-return and double-acting failsafe | Not many failsafe choices |

| Cost | Cheaper at first; costs more to run with air | Costs more at first; cheaper to run |

Valve actuators should fit what the system needs. Pneumatic actuators are fast and last long for many cycles. Electric actuators are exact but not as good for fast, repeated moves. Pneumatic ball valves are best for quick, repeated jobs.

Note: Fast cycling helps factories and plants work well. Pneumatic actuators keep systems working fast and strong in busy jobs.

Cost

Initial Cost

Electric Ball Valve

Electric ball valves cost more to buy than other types. They can cost from $200 up to $1,500. The price depends on how big and fancy they are. Big projects with many valves will pay more at first for electric actuators. This is because they have special electronics and motors inside. Many companies use electric ball valves for their accuracy. They also like that these valves work well with digital systems.

Pneumatic Valve Actuators

Pneumatic valve actuators are cheaper to buy at first. Most cost between $50 and $500. Some big or special ones can cost up to $2,000. Pneumatic actuators use air, so they are less expensive at the start. Factories often pick pneumatic actuators for big jobs to save money. The table below shows the usual price ranges:

| Actuator Type | Typical Initial Cost Range |

|---|---|

| Pneumatic Actuators | $50 to $500 |

| Electric Actuators | $200 to $1,500 |

Tip: Pneumatic actuators help save money when you need lots of valves.

Operating Cost

How much it costs to run a valve actuator is important. Electric actuators need power all the time. This can make your electric bill go up, especially if they run all day. Sometimes, electric actuators need new parts, which adds to the cost.

Pneumatic actuators use air to work. They do not need electricity, but the air system uses energy. You need compressors, filters, and other parts for the air. These things need care and can cost more over time. At first, pneumatic actuators seem cheaper, but running the air system can get expensive.

Maintenance

Electric and pneumatic actuators need different kinds of care. Electric ball valves have more parts, like wires and motors. These need to be checked often and sometimes fixed. Repairs can be harder because of the electronics.

Pneumatic actuators have fewer moving parts, so they are easier to fix. But the air system needs a lot of care. Compressors and filters must stay clean and work right. Seals in pneumatic actuators wear out faster and need to be changed. Pneumatic actuators can last a long time, but the air system means more work.

| Aspect | Electric Ball Valves | Pneumatic Valve Actuators |

|---|---|---|

| Power Requirement | Needs constant electricity | Needs compressed air |

| Maintenance Needs | More complex, more parts to check | Fewer parts, but air system needs care |

| Operating Costs | Higher energy and part costs | Lower at first, but air system adds cost |

| Durability & Longevity | Durable, fewer moving parts | Durable, but seals wear out faster |

Note: Taking care of your valve actuators helps them last longer and keeps them working well.

Reliability

Longevity

Valve actuators need to last a long time in machines. How long electric ball valves and pneumatic actuators last depends on how they are made and used. The table below shows how long they usually last and what can change that:

| Component | Expected Lifespan | Key Factors Affecting Lifespan |

|---|---|---|

| Electric Ball Valves | About 8-10 years | Material, media, corrosion, wear from turning, maintenance |

| Pneumatic Actuators | Longer than ball valves | Usually last longer, need fewer replacements |

Pneumatic actuators often last longer than the ball valves they move. They have fewer parts that can wear out. Ball valves may need to be changed sooner, especially if used a lot or under high pressure. Turning on and off all the time can make both types wear out faster. Cleaning and checking for leaks helps both types last longer.

Picking the right actuator and putting it in the right way helps them last. Using the best materials for the job stops rust and damage. Not switching the valve too much helps both types last longer. Checking and fixing things on time keeps the system working for years.

Note: Good care and the right setup make actuators last longer. Pneumatic actuators usually last longer, but both need care to work their best.

Common Issues

Electric ball valves and pneumatic actuators can have problems in machines. The most common problems are leaks, things getting stuck, and actuator failures. The table below lists these problems and what causes them:

| Reliability Issue | Description and Causes |

|---|---|

| Air Leaks | Old seals, loose parts, or cracked tubes cause leaks in pneumatic systems. |

| Mechanical Blockages | Dirt, rust, or debris can block the ball or seats, causing sticking or failure to shut off. |

| Actuator No Response | Lack of air supply, missing control signals, or broken actuator parts stop movement. |

| Slow or Erratic Actuator | Low air pressure, clogged filters, or worn parts cause slow or jerky movement in pneumatic actuators. |

| Sticking or Partial Movement | Debris, corrosion, or misalignment can prevent full movement. |

| Electrical Component Issues | Solenoids, limit switches, wiring, or control circuits can fail in electric ball valves. |

Some common problems are:

- Air supply problems, like broken compressors or pipes, make pneumatic actuators work badly.

- Valves can stick if dirt or stuff builds up inside.

- Bad seals cause leaks and loss of control.

- Actuators can break from rust or worn parts.

- Putting in the wrong size or installing it wrong can make it not work.

Checking actuators often helps find problems early. Looking at seals, connections, and air lines stops leaks and keeps things working. Calibrating actuators and keeping air pressure right also helps. Using good parts and following care plans makes actuators last longer and break less.

Tip: Fixing small problems fast stops bigger ones and helps both electric and pneumatic valves last longer.

Safety

Hazardous Environments

Pneumatic Valve Actuators

Pneumatic valve actuators are important in dangerous places like chemical plants. They use air to work, so they do not make sparks. This makes them safer where there are explosive gases or dust. These actuators react fast and keep working when things get tough. Many companies pick pneumatic actuators because they last a long time and do not need much fixing. Their simple build helps stop problems in hard places.

Pneumatic actuators must follow strict safety rules. Certifications like ATEX and IECEx show they are safe for explosive areas. Other important safety marks are NEC, CSA, and fire-safe rules like API 607. All parts, like solenoid valves and positioners, must be safe for these places too. People often choose pneumatic valve actuators for important safety jobs. They do not need electricity, which can be risky in explosive spots.

Tip: Pneumatic actuators work fast and do not cause explosions. This makes them a top pick for safety in dangerous places.

Electrically Actuated Ball Valves

Electrically actuated ball valves give exact control and connect easily to digital systems. In dangerous places, these valves need special designs to stop sparks or getting too hot. Makers use explosion-proof covers and high IP ratings like IP67 or IP68 to keep out dust and water. These valves must also have safety marks like ATEX, IECEx, and NEMA to be safe.

Picking the right materials, like stainless steel and PTFE, helps them stand up to chemicals and heat. Electrically actuated ball valves often have fire-safe seals and emergency shutoff features. People must put these valves in the right way, ground them, and check them often. With the right safety steps, these valves work well in oil, gas, and chemical jobs.

Failsafe Features

Failsafe features keep systems safe if power or air stops. Pneumatic valve actuators often use springs to move the valve to a safe spot if air is lost. Some pneumatic actuators use both double-acting and spring action for extra safety. These features work without needing electricity, which is good in emergencies.

Electrically actuated ball valves can have springs too, but not as often. Many electric actuators have handles so people can move the valve by hand if power goes out. Switches help check if the valve is in the right spot and keep things safe. Some electric actuators have heaters and controls to stop freezing or water damage.

| Actuator Type | Failsafe Feature | Description |

|---|---|---|

| Pneumatic Actuators | Spring-Return Failsafe | Spring moves valve to safe position if air fails. |

| Pneumatic Actuators | Double-Acting with Failsafe | Combines double-acting use with automatic spring for emergencies. |

| Electric Actuators | Spring-Return Electric Actuator | Mechanical spring returns valve to safe spot during power loss. |

| Electric Actuators | Manual Override Handle | Lets operator move valve by hand if power fails. |

| Electric Actuators | Position Detection Switches | Monitors valve position for safe operation. |

| Electric Actuators | Environmental Features | Heaters and controls prevent freezing and moisture problems. |

Pneumatic valve actuators give strong failsafe action in emergencies. Their spring-return design works even if power or air stops. Electrically actuated ball valves need power and special covers, so they need more features for safety. Both types help keep people and machines safe, but pneumatic ones are often faster and more reliable in tough times.

Integration

Automation Systems

Electrically Actuated Ball Valves

Electrically actuated ball valves work well with new automation systems. Many factories use PLCs and SCADA to control machines. These electrical actuators can connect right to these systems. They use common ways to talk, like Modbus or Profibus, so setup is easy. Operators can see where the valve is and how it works right away. This live information helps fix problems before they get big and keeps machines working.

Smart electrical actuators let workers control valves from far away. People can open or close valves from a safe control room. This means fewer trips to dangerous places and keeps workers safe. Electrical actuators save energy because they only use power when moving. Picking actuators that match the system makes sure everything works well and is quick to install.

Note: Electrical actuators make it easy to add more valves to digital systems. This helps companies grow and update their machines without stopping work for long.

Pneumatic Valve Actuators

Pneumatic actuated ball valves are also important in automation. These valves use air to move, and many factories already have air systems. Pneumatic valve actuators can connect to PLCs and SCADA, but they need extra parts like solenoid valves and positioners. These parts help change digital signals into air pressure.

Pneumatic systems work well in tough places. They handle dust, heat, and wet better than some electrical actuators. But connecting pneumatic actuated ball valves to digital controls can be harder. The air system must stay clean and steady for the valves to work right. When set up well, pneumatic actuated ball valves move fast and work well in automated jobs.

Control Compatibility

Control compatibility is important when picking between electrical actuators and pneumatic actuated ball valves. Electrical actuators work with many digital signals and ways to talk. They fit into most automation systems easily. Operators can use one control panel to run many valves, which saves time.

Pneumatic actuated ball valves need more parts to connect to digital controls. Solenoid valves and feedback devices help connect air power to electronic signals. This setup is good in big plants with air systems already there. But it may need more care and careful setup.

| Feature | Electrical Actuators | Pneumatic Actuated Ball Valves |

|---|---|---|

| Digital Protocol Support | Wide (Modbus, Profibus, etc.) | Limited, needs extra components |

| Integration with PLC/SCADA | Direct and simple | Needs solenoids and positioners |

| Real-Time Monitoring | Yes, with live data | Possible, but less detailed |

| Ease of Expansion | High | Medium, depends on air system |

Tip: For easy setup and advanced control, electrical actuators are best for modern automation. Pneumatic actuated ball valves are good where air systems are already used and speed matters most.

Applications

Industrial Automation

Factories and plants use electric ball valves and pneumatic valve actuators. These actuators help control liquids and gases in many machines. Electric ball valves are used in water plants and for controlling heat or cooling. They also help in making things in factories. Pneumatic actuators run machines, move conveyor belts, and help build things on assembly lines. The table below shows where each actuator is used:

| Actuator Type | Common Industrial Automation Applications |

|---|---|

| Electric Ball Valves | Automated water plants, process control in manufacturing, HVAC systems, oil and gas pipeline flow control |

| Pneumatic Valve Actuators | Operating machinery, controlling conveyor systems, automating assembly lines, food and beverage packaging |

Pneumatic actuators are picked for their speed and power. Electric ball valves are chosen when exact control is needed. Both types help factories work better and keep workers safe.

Tip: Picking the right actuator helps machines work well and stops long breaks in work.

Building Automation

Building automation uses actuators to control heating, cooling, water, and fire safety. Electric ball valves are important in these systems. They open and close to move fluids without people needing to help. This makes them good for HVAC, water, and watering plants. These valves come in many sizes and are made from PVC, brass, or stainless steel. They work for small pipes and big water lines.

| Feature/Aspect | Details |

|---|---|

| Operation | Electric actuator opens/closes valve for precise fluid flow control |

| Common Applications | HVAC, water and wastewater management, fire protection, irrigation |

| Sizes Available | 1/4″ to 8″ diameter valves |

| Advantages | Reliable, durable, easy integration, precise control |

Pneumatic actuators are also used in buildings, but electric ball valves are easier to add and make less noise. For example, the Series HBAV HVAC Electrical Ball Valve controls hot and cold water well. It has a manual handle for backup, which makes it more useful and safe.

Process Control

Process control is used in oil, gas, chemical, and food factories. The job decides if you need electric or pneumatic actuators. Pneumatic actuators are strong and fast, so they are good for big valves or high pressure. They last longer and can be used many times. Electric actuators are used when there is no air supply. They give exact control but are slower.

- Pneumatic actuators are best for fast, tough jobs and places with hot or cold weather.

- Electric actuators are good when you need quiet or special movement.

- How easy it is to fix and what power is there also matters.

Ball valve automation makes jobs safer and helps keep quality high. Picking the right actuator keeps things running and means less fixing is needed.

Electric ball valves and pneumatic actuators are both good for automation. Pneumatic actuators work fast and are safe and strong. They are best for jobs that need quick moves and tough places. Electric ball valves give exact control. They are easy to connect to computers and digital systems.

| Factor | Best Choice |

|---|---|

| Speed | Pneumatic Actuator |

| Precision | Electric Ball Valve |

| Safety | Pneumatic Actuator |

| Integration | Electric Ball Valve |

Picking the right actuator depends on what the job needs. People should think about torque, how often it will be used, safety, and where it will be used. Asking automation experts helps you choose the best one for your project.

FAQ

What is the main difference between electric and pneumatic ball valves?

Electric ball valves use motors and gears that run on electricity. Pneumatic ball valves move because of compressed air. Each type works best for different jobs and places.

Which actuator is better for fast operation?

Pneumatic actuators move valves much faster than electric ones. They are good for jobs that need quick opening and closing.

Are electric ball valves easier to integrate with digital systems?

Yes. Electric ball valves can connect right to most digital systems. They work with digital signals and let you watch them in real time.

Can pneumatic actuators be used in hazardous environments?

Pneumatic actuators are safe for dangerous places. They do not make sparks and follow safety rules for explosive or dusty areas.

How do maintenance needs compare between electric and pneumatic actuators?

Pneumatic actuators need checks for air leaks and worn seals. Electric actuators need their motors and wires checked. Both types last longer with regular care.

Which actuator is more cost-effective over time?

Electric ball valves cost more at first but save energy and need fewer repairs. Pneumatic actuators are cheaper to buy but can cost more later because of air system upkeep.

Can both types handle control valves in industrial automation?

Both electric and pneumatic actuators can run control valves in factories. The best one depends on how fast, exact, and tough the job is.

What safety features do these actuators offer?

Pneumatic actuators often have spring-return failsafe features. Electric actuators may have handles for manual use and switches to check position. Both types help keep people and machines safe.