Engineers and plant managers use electric actuator valve solutions for automation. The top 10 choices for industrial automation have rotary and linear types. These include the Rotork IQ3 Series, Emerson Bettis XTE3000, Schneider Electric EasyPact TVS, Flowinn K Series, ABB EDP300, Siemens SIPART PS2, Honeywell HercuLine 2000, Belimo PR Series, AUMA SA Series, and SAMSON Series 300.

Electric actuator valves give high positioning accuracy. They need little maintenance. They are quiet when working. They are easy to connect with digital control systems. These features make them popular in many uses. People use them in water treatment and oil and gas. They work with butterfly valve, electric ball valve, ball valve, and can replace pneumatic ball valve designs.

Electric Actuator Valve Overview

What Is an Electric Actuator Valve

An electric actuator valve uses electricity to make things move. This movement can open, close, or change a valve’s position. Engineers use these valves to control how liquids or gases move in pipes. The electric actuator gets signals from control systems. It moves the valve to the right spot. This helps control the valve very accurately. It also makes it easy to use with automation. Electric actuators do not need air or fluid like other types. They only need electricity. This makes them easier to set up and take care of.

The table below shows how electric, pneumatic, and hydraulic actuators are different:

| Feature | Electric Actuators | Pneumatic Actuators | Hydraulic Actuators |

|---|---|---|---|

| Operation Energy | Use electrical energy to generate mechanical motion | Use compressed air to provide force and motion | Use hydraulic fluid to provide very high force |

| Precision | High precision, suitable for automation | Moderate precision, less than electric | Low precision |

| Force | Moderate force, limited for large valves | High force, suitable for medium to large valves | Very high force, suitable for heavy-duty valves |

| Speed | Fast operation | Fast response and rapid movement | Moderate speed |

| Energy Efficiency | More energy-efficient | Moderate energy efficiency | Low energy efficiency |

| Noise | Cleaner and quieter operation | Can be noisy due to air exhaust | Generally quieter but complex system |

| Control | Easy integration with modern control systems | Controlled via air supply and solenoid valves | Requires pumps, reservoirs, and complex controls |

| Maintenance | Low maintenance | Moderate maintenance due to air leaks | High maintenance due to fluid leaks and complexity |

| Power Source | Electricity | Compressed air | Hydraulic fluid |

Benefits in Industrial Automation

Electric actuator valves have many good points for factories. They are very precise. You can program them to move to exact spots and control how fast they move. Operators can set them to be very accurate, even to tiny amounts. These valves do not need much care. They have fewer parts that move and do not need oil. This means less chance for things to get dirty and less time fixing them.

Electric actuators work well with digital control systems. This lets people check on them and fix problems from far away. Operators can change settings and see how things are working without being there. This makes things safer and more reliable. Electric actuators do not leak, so they help keep things clean and safe for the environment. You can program them for different jobs. This makes them great for new ideas in many industries.

Main Applications

Many industries use electric actuator valves to control machines and processes. These valves are used where accuracy, trust, and digital control are important. The table below shows some industries and how they use these valves:

| Industry | Primary Applications in Sector |

|---|---|

| Manufacturing | Process control requiring precise valve position control |

| Water Treatment | Automated water plants |

| HVAC Systems | Heating, ventilation, and air conditioning systems |

| Aerospace | Landing gear, engine control, fluid transfer, safety systems |

Engineers pick electric actuator valves for jobs like controlling flow, closing off parts of a pipe, or keeping systems safe. These valves help make modern factories work better by giving strong and steady control.

Top Manufacturers

Rotork

Rotork is a top company for electric actuator technology. It started in the United Kingdom. Now, Rotork works in more than 170 countries. Rotork cares about new ideas and being dependable. Many businesses use Rotork for exact valve control. Rotork has ISO 9001 and ISO 14001 certifications. These show Rotork cares about quality and the environment.

Rotork’s electric actuators are used in oil and gas, water treatment, and power plants. Their products connect with digital systems and can be checked from far away. Rotork’s actuators are very accurate and last a long time. Engineers like Rotork because it gives good technical help and has service everywhere.

Rotork keeps improving its electric actuators by doing lots of research.

Emerson

Emerson is one of the best companies for electric actuators. It is strong in North America, Europe, and Asia Pacific. Emerson’s actuators are used in oil and gas, chemicals, and water systems. Emerson’s products meet ISO 9001 and other world standards. This means they are safe and high quality.

Emerson’s electric actuator valves work well in tough places. Emerson uses smart technology for digital control and checking problems. Their actuators help factories work better and stop problems. Many engineers pick Emerson because it has many products and a good history.

The table below shows how much of the market top electric actuator valve companies have:

| Category | Details |

|---|---|

| Top 5 Companies Market Share | About 60% of the global electric valve actuator market |

| Leading Companies | Emerson, Rotork, Auma, Flowserve, SCHIEBEL, ABB Ltd, others |

| Regional Market Shares | North America: ~24%, Asia Pacific: ~23%, Europe: ~23% |

| Largest Product Segment | Multi-turn electric actuators with over 55% share |

| Major Application | Oil & Gas industry leads, then general industries |

Honeywell

Honeywell is a famous company in industrial automation. It makes many actuator products, including electric actuator valves. Honeywell’s products are used in HVAC, water treatment, and factories. Honeywell has ISO 9001 certification and meets safety and performance rules.

Honeywell’s electric actuator valves are trusted for working well and connecting easily to digital systems. The company makes designs that are easy to use and have smart controls. Honeywell helps customers with good technical support and has stores all over the world.

Honeywell is trusted for quality and new ideas in industrial automation.

Siemens

Siemens is a top company in automation and control. People know Siemens for new ideas and products that work well. Siemens has ISO 9001 certification. This shows Siemens cares about making good products. Its electric actuator valves are used in many places. These include building automation, water systems, and energy plants.

Siemens makes electric actuator valves to control flow well. These valves help keep things comfortable and control water and steam. This helps hydronic systems work better. Siemens has the most globe valves for HVAC jobs. These valves can close very tightly and have a 100:1 rangeability. This means they work well even in tough places.

Engineers pick Siemens because the products always work the same. The electric actuator valves help keep flow right and make boilers and chillers better. Siemens lets people watch and control systems from far away. This saves energy and keeps things safe.

Siemens keeps working on new ideas. The company wants to make products for the changing needs of factories.

ABB

ABB is a big name in industrial automation. The company works in over 100 countries and has a long history. ABB has ISO 9001 and ISO 14001 certifications. This means ABB cares about quality and the environment.

ABB’s electric actuator valves are made to be exact and last long. They are used in oil and gas, power plants, and water treatment. ABB’s actuators have smart controls and can talk to digital systems. This helps people check how they work and find problems early.

ABB is known for always trying new things. The company spends a lot on new technology to make actuators better. ABB helps customers everywhere with technical support.

ABB’s electric actuator valves help companies work better and spend less on repairs.

Schneider Electric

Schneider Electric is a world leader in energy and automation. People trust Schneider Electric for good products. Schneider Electric has ISO 9001 certification. This shows the company cares about quality.

Schneider Electric’s electric actuator valves are used in buildings, water systems, and factories. These actuators are strong and easy to use with digital controls. Schneider Electric makes sure their products are simple to set up and use.

The company’s actuators help save energy and keep systems working well. Schneider Electric gives lots of help and training to customers. This helps engineers and managers get the best from their systems.

Schneider Electric stays ahead by making new actuator products for today’s industry.

Belimo

Belimo is a top company for actuator and valve technology. The company started in Switzerland. Now, it works in over 80 countries. Belimo makes products for heating, ventilation, and air conditioning systems. These products help buildings save energy and stay comfortable.

Belimo has ISO 9001 certification. This means the company cares about quality. It also follows tough rules for the environment. Many engineers trust Belimo because its products last a long time. Belimo’s electric actuator valves are easy to put in and simple to use. The company makes many actuators for different valves, like ball valves and butterfly valves.

Belimo’s electric actuator valves are very accurate and quick. These actuators use smart control technology. They can connect to building automation systems. Operators can check and change settings from far away. This helps managers save energy and money. Belimo also has smart actuators that use digital communication. This makes it easy to work with modern control systems.

Belimo is known for new ideas and helping customers. The company keeps making new products for building automation.

Flowinn Global

Flowinn Global is well known in the electric actuator market. The company has made actuators for over ten years. Flowinn Global works with water treatment, energy, petrochemicals, and marine jobs.

Flowinn Global sells many kinds of electric actuators. Their products include rotary, linear, quarter-turn, and multi-turn actuators. These actuators have different torque levels and can be changed for special needs. Flowinn makes actuators that are precise and last long, even in hard places.

- The product list includes:

- Basic, integral, and smart actuators

- Mechatronics and explosion-proof models

- Spring return actuators for safety

Flowinn Global’s actuators work with many valve types. This makes them good for lots of industrial jobs. The company focuses on saving energy and easy care. Many actuators help lower downtime and make things safer. Flowinn also has choices for digital integration. This lets operators watch and control systems from far away.

Flowinn Global works hard on quality and custom options. This helps industries make their processes better and safer.

The company has international certifications and follows strict quality rules. Flowinn Global keeps adding new products for industrial automation.

Top 10 Electric Valves

Rotary Electric Actuator Valves

Rotork IQ3 Series

Rotork’s IQ3 Series is a strong choice for rotary jobs. This actuator uses smart tools to check itself and save data. It works with both multi-turn and quarter-turn valves. The display shows clear info for control and updates. Engineers use the IQ3 Series in water, power, and oil and gas. Its tough build stands up to rough places and lets people watch it from far away. The actuator can use many voltages and gives lots of power, so it fits big valves.

Emerson Bettis XTE3000

Emerson’s Bettis XTE3000 is great for moving rotary valves. The XTE3000 moves valves with care and works for on/off or changing jobs. It has parts you can swap out, so fixing it is easy. The actuator has smart controls, like analog and digital ways to connect. Engineers use the XTE3000 in oil and gas pipes, chemical plants, and power plants. Its strong build and waterproof case help it work well in tough spots.

Schneider Electric EasyPact TVS

Schneider Electric’s EasyPact TVS is small and good for rotary valves. This actuator works with quarter-turn valves and gives steady power. The EasyPact TVS connects easily to digital control systems. It is simple to put in and does not need much care. Engineers use it in buildings, water systems, and light industry. The actuator’s strong parts and smart motor help it last a long time.

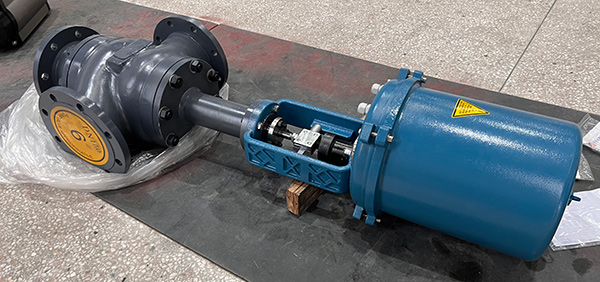

Flowinn K Series

Flowinn’s K Series electric actuator valve works well for rotary jobs. The K Series fits both quarter-turn and multi-turn valves. It can use many voltages and has lots of control choices, like analog and CAN. The actuator’s stainless steel body stops rust, so it is good for ships and chemical plants. Engineers like the K Series for its strong power and settings you can change. Its smart design lets people check it from far away and fix problems before they get big.

ABB EDP300

ABB’s EDP300 is a flexible rotary actuator for factories. The EDP300 fits many valve sizes and types, like stainless steel and cast iron. It uses smart motion control and works with digital systems. The actuator works well in oil and gas, water, and power plants. ABB’s EDP300 saves energy and does not use much power. Its parts are easy to put together and fix.

Many rotary electric actuator valves, like those from Emerson and ABB, are used a lot in oil and gas. These actuators give careful control and last a long time, which is very important for these jobs.

Best Electric Linear Valve Actuators

Siemens SIPART PS2

Siemens SIPART PS2 is one of the best electric linear valve actuators. This actuator uses a brushless servomotor, so it works better and needs less fixing. The SIPART PS2 moves valves to the right spot and fits many sizes. Engineers use it in water, chemicals, and HVAC systems. The SIPART PS2 has smart tools to check itself and can be watched from far away. Its strong build helps it work well in hard places.

Honeywell HercuLine 2000

Honeywell’s HercuLine 2000 is a top electric linear valve actuator. It is known for being exact and working well. The actuator uses a brushless servomotor for good power and long life. The HercuLine 2000 moves smoothly and can stop anywhere along its path. Engineers use it in power plants, refineries, and factories. The actuator’s digital link lets it work with new control systems. Its tough build helps it last in hard factory jobs.

Belimo PR Series

Belimo’s PR Series is a top electric linear valve actuator for buildings. The PR Series uses a brushless servomotor for high accuracy and repeat moves. This actuator reacts fast and can remember many set positions. Engineers use the PR Series in HVAC, water, and energy jobs. Its small size makes it easy to put in tight spaces. Belimo’s PR Series collects data to help fix problems before they start.

AUMA SA Series

AUMA’s SA Series is a strong actuator for moving linear valves. The SA Series fits many valve sizes and types. It has a tough motor and smart motion control. Engineers use this actuator in oil and gas, water, and power plants. The SA Series has many control choices, like analog and digital. Its parts are easy to swap, so fixing and changing it is simple.

SAMSON Series 300

SAMSON’s Series 300 electric linear valve actuator gives careful control for important jobs. The actuator uses a brushless servomotor for good power and feedback. The Series 300 can move heavy things and push with lots of force, so it works in tough places. Engineers use it in chemical plants, power plants, and factories. The actuator’s smart motion control and limit switches keep it safe and protect its parts.

Electric linear valve actuators have some good points over rotary actuators. They can move to the right spot and stop anywhere along their path. Linear actuators turn round motor moves into straight moves, so they are good for moving things and short trips. They can lift heavy things and push hard, which is needed in factories. Using brushless servomotors makes them work better, need less fixing, and move to the same spot every time.

Comparison Table: Key Technical Specifications

| Model | Actuator Type | Voltage Range | Power Output | Valve Size | Materials | Operating Temp | Torque/Force Range | Control Options | Waterproof Rating | Motor Design | Application Suitability |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Rotork IQ3 Series | Rotary | 24V–240V | 50W–500W | 1/2″–48″ | SS316, Cast Iron | -40°C–+70°C | High Torque | Analog, Digital | NEMA 6P | High Reliability | Oil & Gas, Water, Power |

| Emerson Bettis XTE3000 | Rotary | 24V–240V | 50W–400W | 1/2″–36″ | SS304, WCB | -40°C–+80°C | High Torque | Analog, CAN | NEMA 6P | Modular | Oil & Gas, Chemical, Power |

| Schneider EasyPact TVS | Rotary | 24V–240V | 10W–100W | 1/4″–12″ | Brass, PVC | -20°C–+60°C | Moderate Torque | Analog, Digital | IP67 | Compact | Building, Water, Light Industry |

| Flowinn K Series | Rotary | 24V–240V | 20W–300W | 1/2″–24″ | SS316, CF8M | -40°C–+70°C | High Torque | Analog, CAN, Smart | NEMA 6P | Customizable | Marine, Petrochemical |

| ABB EDP300 | Rotary | 24V–240V | 30W–350W | 1/2″–24″ | SS316, Cast Iron | -40°C–+70°C | High Torque | Analog, Digital | NEMA 6P | Modular | Oil & Gas, Water, Power |

| Siemens SIPART PS2 | Linear | 24V–240V | 10W–100W | 1/2″–12″ | SS316, Brass | -40°C–+80°C | High Force | Analog, Digital | IP66 | Brushless Servomotor | Water, Chemical, HVAC |

| Honeywell HercuLine 2000 | Linear | 24V–240V | 20W–150W | 1/2″–16″ | SS304, Cast Iron | -40°C–+70°C | High Force | Analog, Digital | NEMA 4X | Brushless Servomotor | Power, Refinery, Manufacturing |

| Belimo PR Series | Linear | 24V–240V | 10W–80W | 1/2″–8″ | Brass, PVC | -20°C–+60°C | Moderate Force | Analog, Digital | IP66 | Brushless Servomotor | HVAC, Water, Energy |

| AUMA SA Series | Linear | 24V–240V | 30W–300W | 1/2″–24″ | SS316, Cast Iron | -40°C–+70°C | High Force | Analog, Digital | NEMA 6P | Modular | Oil & Gas, Water, Power |

| SAMSON Series 300 | Linear | 24V–240V | 20W–200W | 1/2″–16″ | SS316, CF8M | -40°C–+80°C | High Force | Analog, Digital | IP67 | Brushless Servomotor | Chemical, Power, Process |

Tip: When picking the best electric linear valve actuators, engineers should look at things like voltage, power, materials, and control choices. Brushless servomotors work better and last longer, so they are good for tough jobs.

Comparison Table

Electric Actuator Valve Features

Picking the right electric actuator valve takes careful thought. Engineers compare important features to make sure the actuator works well. They want it to fit the job and be reliable.

- Motion control lets you set position, speed, and force. These features help move the valve to the right spot.

- Force and torque ratings must be strong enough for the job. This keeps the system safe and working, even when things get tough.

- Control options can be simple on/off or more advanced. Modulating control lets you change flow, pressure, or temperature exactly.

- Position feedback and cycle speed control help watch the valve. These features stop problems like water hammer.

- You can connect actuators to control systems like PLCs and HMIs. This helps people check on them and fix things before they break.

- Certifications like ISO 9001 or explosion-proof ratings show safety and quality. These prove the actuator meets industry rules.

- Maintenance needs and reliability matter for long-term costs. They also affect how often the system is running.

The table below shows the top 10 electric actuator valves and their main features:

| Model | Actuator Type | Torque/Force Range | Control Options | Certifications | Best Use Cases |

|---|---|---|---|---|---|

| Rotork IQ3 Series | Rotary | High Torque | Analog, Digital, Modulating | ISO 9001, 14001 | Oil & Gas, Water, Power |

| Emerson Bettis XTE3000 | Rotary | High Torque | Analog, CAN, Modulating | ISO 9001 | Oil & Gas, Chemical, Power |

| Schneider EasyPact TVS | Rotary | Moderate Torque | Analog, Digital, On/Off | ISO 9001 | Building, Water, Light Industry |

| Flowinn K Series | Rotary | High Torque | Analog, CAN, Smart | ISO 9001, Explosion-proof | Marine, Petrochemical |

| ABB EDP300 | Rotary | High Torque | Analog, Digital, Modulating | ISO 9001, 14001 | Oil & Gas, Water, Power |

| Siemens SIPART PS2 | Linear | High Force | Analog, Digital, Modulating | ISO 9001 | Water, Chemical, HVAC |

| Honeywell HercuLine 2000 | Linear | High Force | Analog, Digital, Modulating | ISO 9001 | Power, Refinery, Manufacturing |

| Belimo PR Series | Linear | Moderate Force | Analog, Digital, Modulating | ISO 9001 | HVAC, Water, Energy |

| AUMA SA Series | Linear | High Force | Analog, Digital, Modulating | ISO 9001, 14001 | Oil & Gas, Water, Power |

| SAMSON Series 300 | Linear | High Force | Analog, Digital, Modulating | ISO 9001 | Chemical, Power, Process |

Tip: Engineers should check if the actuator gives position feedback. They should also see if it works with their control systems. These features help keep things running and make fixing easier.

A good table helps engineers and managers pick the right actuator fast. By looking at type, torque, control, certifications, and best uses, they can choose what works best for their project.

Selection Criteria for Electric Actuator Valves

Picking the right electric actuator valve takes careful thinking. Engineers and plant managers need to make sure the actuator fits the job, the place, and the control system.

Key Factors

Valve Type Compatibility

Engineers must check if the actuator fits the valve type. Rotary actuators work best with ball, butterfly, and plug valves. Linear actuators are good for globe, gate, and diaphragm valves. Using the right match helps the valve move well and work every time.

Torque and Power

Every job needs a certain amount of force or torque. The actuator must give enough power to move the valve, even if pressure changes. If the actuator is too big, it wastes energy. If it is too small, it might break. Looking at the valve size and what the process needs helps pick the right one.

Control and Communication

Modern automation needs easy connection to control systems. Actuators should use standard signals like 4-20 mA for steady communication. For batch jobs, AS-Interface (AS-I) networks make wiring simple and more reliable. Limit switches and feedback devices, like potentiometers, tell the control system where the valve is. Manual override options, like a wrench or gear, help keep things working if automation fails.

Environmental Ratings

The place where the actuator works matters a lot. The table below shows important environmental factors and how they affect the actuator:

| Environmental Factor | Rating/Specification | Impact on Selection and Maintenance |

|---|---|---|

| Dust Protection | IP5X, IP54, IP6X | Rod-style actuators with wipers and gaskets keep out dust. At least IP65 is best for dusty places. |

| Moisture Protection | IPX5 and above | Rod-style actuators can reach IP65–IP69K. IP69K is needed for food washdowns. |

| Corrosion Resistance | Type 316 SS, Viton? seals | Helps stop rust and means less fixing. |

| Hazardous Area Compliance | NEMA VII | Needed to stop explosions in dangerous areas. |

| Safety Features | Fail-safe, torque switches, battery backups | Make the actuator safer and lower fixing needs. |

Actuators in dangerous places need NEMA VII cases to stop explosions. Safety features like fail-safe modes and battery backups help the actuator work if the power goes out.

Maintenance and Support

Actuators that need little fixing save time and money. Things like strong parts, torque switches, and good seals help stop damage. Picking actuators from companies with good support means help and spare parts are easy to get.

Application Guidance

Engineers and plant managers can use these tips to put electric actuator valves into automation the right way:

- Use standard signals like 4-20 mA for good communication between sensors, controllers, and actuators.

- Pick limit switches or proximity sensors to show the valve’s position to control systems.

- For dangerous places, choose actuators with safe cases, like NEMA or ATEX-rated models.

- Think about manual override options to keep things running if automation fails.

- Work with skilled automation suppliers to match actuator features to the job, safety, and the environment.

- For always watching the valve, use potentiometers with resistance-to-current transducers to send feedback far away.

Picking and setting up electric actuator valves the right way helps keep automation safe, efficient, and reliable in any factory.

Industrial Automation Trends

Digital Integration

Electric actuator valves are now very important in factories. They help connect machines to computers. These valves work with control systems like DCS, PLC, and SCADA. They use special protocols such as HART, Foundation Fieldbus, and Profibus. This lets workers watch and change settings from control rooms. Operators can see valve position, torque, vibration, temperature, and how much electricity is used. IoT-enabled actuators have sensors and send data to the cloud. This helps fix problems before they get big and keeps workers safe.

| Aspect of Integration | Description | Benefits |

|---|---|---|

| Connectivity with Industrial Control Systems | Valves connect to DCS, PLC, SCADA using protocols like HART, Foundation Fieldbus, Profibus. Data goes both ways. | Workers can watch valves, change settings, and get feedback from control rooms. |

| Advanced Control Algorithms | Valves use smart controls like cascade, feedforward, and model predictive control. | This makes factories work better, saves energy, improves product quality, and needs less manual work. |

| Safety Enhancements | Valves have safety features like fail-safe, backup controls, and automatic shutdowns if sensors find problems. | This helps workers and machines stay safe and records safety events for rules. |

| Industry 4.0 and IoT Integration | Valves send real-time data for digital twin models and smart manufacturing. | This helps factories waste less, make better products, and meet green goals. |

| Data-Driven Analytics | Valves collect data about how they work, when they need fixing, and how much energy they use. Machine learning helps predict problems. | This means less downtime, lower fixing costs, and better factory work. |

| Future-Ready Technologies | Valves are built to work with AI, edge computing, cybersecurity, and new ways to connect. | This keeps them ready for new automation, saves energy, and helps factories grow. |

IoT lets workers control valves from far away, even in dangerous places. This makes factories safer and helps them grow.

Energy Efficiency

Factories want to save energy and money. Electric actuator valves help control fluid flow very well. This makes machines run smoother and use less energy. New actuator designs do not need compressed air. This saves energy and cuts carbon emissions by about 20%. Smart tools like AI and IoT help watch valves and fix them before they break. These tools can lower downtime by 30% and cut fixing needs by 50%. Faster valves also make jobs quicker by up to 40%, so factories work better.

- Electric actuators follow world energy rules like the EU Energy Efficiency Directive.

- Small and light designs fit into soft robots and new machines.

- The market for electric actuators is growing fast and will be worth billions by 2026.

Energy-saving automation helps companies spend less and meet green goals.

Future Developments

Electric actuator valves will keep getting better in the future. Companies are making new designs that use AI, edge computing, and cybersecurity. Modular valves are easy to upgrade and work with new systems. Data and machine learning will help predict problems and make factories work better. Electric actuators will help with digital twin models and smart manufacturing. This will help companies waste less and make better products.

- Smart actuators will collect more data about how they work and when they need fixing.

- Edge computing will help valves make decisions faster.

- Better cybersecurity will keep automation safe from hackers.

- New ways to connect will help valves work with more systems.

Electric actuator valves will keep improving, helping factories save energy and work smarter.

- The top 10 electric actuator valves work well in factories.

- Each valve is good for different jobs and places.

- Engineers should look at the table and tips before picking one.

- Choosing the right features helps the valve work safely and smoothly.

If the job is hard, talking to experts or companies can help get the best results.

FAQ

What is the main difference between rotary and linear electric actuator valves?

Rotary actuators spin valves like ball or butterfly valves. Linear actuators push or pull valves in a straight line, like globe or gate valves. Each kind works best with certain valve shapes and jobs.

How does an electric actuator valve improve automation?

Electric actuator valves help control flow and position very exactly. They connect to digital systems without trouble. Operators can watch and change settings from far away, making things safer and faster.

Can electric actuator valves work in hazardous environments?

Many electric actuator valves have special cases to stop explosions. These cases keep out dust, water, and chemicals. Engineers should look for safety marks like NEMA or ATEX before using them.

What maintenance do electric actuator valves require?

Most electric actuator valves do not need much fixing. Checking for damage, cleaning, and updating software keeps them working well. Good seals and brushless motors mean fewer repairs.

Which industries use electric actuator valves most often?

Industries like oil and gas, water treatment, factories, and HVAC use electric actuator valves a lot. These valves help control machines, make things safer, and support automation.

How do engineers select the right electric actuator valve?

Engineers pick the actuator type that matches the valve shape. They check how much force is needed, control choices, and if it can handle the environment. Looking at company support and safety marks helps make sure it works well.

Do electric actuator valves support digital integration?

Most new electric actuator valves work with digital systems like HART or Profibus. These features let people watch, control, and collect data for smart automation.

Tip: Always make sure the actuator works with your control system before you install it.