Electric actuator control valves help control flow very accurately. They use less energy and do not need much upkeep. These valves work well with new automation and remote monitoring systems. Many modern buildings use them. The world market for electric actuator control valves was $2.8 billion in 2023. It may grow to $4.9 billion by 2032. Asia Pacific is growing fastest because of more automation and building projects.

| Metric | Value | Notes |

|---|---|---|

| Global Market Size (2023) | USD 2.8 billion | This is the market size for electric valve actuators in 2023. |

| Projected Market Size (2032) | USD 4.9 billion | This is the expected market size by 2032. |

| Compound Annual Growth Rate | 6.5% | This is the yearly growth rate for electric valve actuators from 2023 to 2032. |

People pick electric actuator control valves when they need accuracy. These valves work better than a pneumatic ball valve or pneumatic valve in some cases. Electric valves are reliable and safe. They are good for places that need to be safe and efficient. Many industries now use electric actuator control valves for automated ball valve systems. This is because of Industry 4.0 and new safety rules.

Key Takeaways

- Electric actuator control valves give very accurate flow control. This helps things work better and makes products higher quality.

- These valves use power only when they move. This saves energy, lowers costs, and cuts down on pollution.

- They need less fixing because they have fewer moving parts. They also do not need oil or air to work.

- Electric actuators fit well with new automation systems. This lets people control and watch them from far away.

- They make things safer because workers can control valves from a safe distance. They also have backup power choices.

- Electric valves are used in many fields like water treatment, power, oil and gas, and food making.

- Picking the right valve means matching flow, pressure, media type, and the place where it will be used.

- Electric actuators cost more at first but save money later. This is because they use less energy and last longer.

What Are Electric Actuator Control Valves?

Basic Function

Electric actuator valves are important in fluid control systems. They use an electric actuator to move the valve to a set spot. The main job is to control how liquids or gases flow. They do this by opening, closing, or changing the valve’s position. In factories, these valves have many key uses:

- They control the valve’s position with sensors and feedback.

- They can make small changes or just open and close.

- They work with automation systems like PLCs, DCS, and SCADA.

- They can use communication protocols like Modbus and Profibus.

- People can operate and watch them from far away, which is safer.

- They help save money and make things run better and safer.

Electric actuator valves take signals from a control system. They turn these signals into exact valve movements. This helps control flow in many different jobs.

Key Components

Each electric actuator control valve has three main parts. These are the actuator, the valve body, and the control system.

- The actuator uses a motor or solenoid. It changes electrical energy into movement. This movement opens, closes, or moves the valve for good flow control.

- The valve body holds the inside parts that guide the flow. It connects to pipes and must handle the fluid and pressure. It is often made of stainless steel, carbon steel, or special alloys.

- The control system sends signals to the actuator. It also gets feedback about where the valve is. This feedback helps keep the flow steady and correct.

The materials used for the valve body and other parts help it last longer. They also protect it from tough conditions. All these parts work together for fast response and easy use with automation.

How They Work

Electric actuator valves change electrical signals into movement. This happens in a few steps:

| Aspect | Description |

|---|---|

| Operation Principle | Electric actuators use motors and gears to move valves. |

| Control Signals | Inputs like 4-20mA or 0-10VDC move the valve to the right spot. |

| Modulating Control | Circuit boards help the valve move to the right position based on signals. |

| Fail-Safe Options | Some valves have battery backup to keep them safe if power goes out. |

| Protection Ratings | NEMA standards help the valve work in many places, even dangerous ones. |

| Speed and Torque | These valves give strong force and good control, but may move slower than pneumatic valves. |

| Installation & Sizing | Picking the right size and torque helps the valve work well. |

Electric actuator valves use fast motors and gears. This lets them control big or high-pressure valves. Newer valves have smart features like position feedback and built-in controllers. These features help keep the valve in the right spot and control flow smoothly, even in tough places. Their small size and low upkeep make them a good pick for many automated systems.

Applications and Benefits

Applications of Electric Actuator Control Valves

Electric actuator valves are used in many industries. They help control liquids and gases very well. Water treatment, power plants, oil and gas, chemical factories, and food production use these valves often. Each industry has its own reason for using them. All of them like how accurate and reliable the valves are.

| Industry | Primary Applications of Electric Actuator Control Valves |

|---|---|

| Power | Used for turning on and off and controlling steam in plants. They handle tough cycles, heat, and pressure. Gate, globe, and ball valves are common. |

| Water Works | Used for moving water with low-pressure valves. Rubber seals help keep water from leaking. Most valves work below 200 psi, but some go up to 300 psi in dams. |

| Offshore | Used in oil and gas pipes on platforms and rigs. Ball, check, and API 6D gate valves help move gas, water, and oil. |

| Wastewater | Used in pipes for cleaning sewage. Check valves and iron gate valves are built to AWWA standards. |

| Oil and Gas Production | Used for wellhead equipment that handles high pressure. Special globe valves and gate valves help control flow. Other valves are used for lower pressure. |

| Pipelines | Used for controlling flow and safety in underground and underwater pipes. These valves are marked for safety and repairs. |

Electric actuator valves are also found in ships, paper mills, drug factories, mines, and HVAC systems. These valves help control machines automatically. They help companies follow safety and environmental rules. In water plants, they control flow and pressure to keep things working well. Power plants use them for steam and cooling water. This makes the plants safer and more efficient. Chemical plants use them for mixing and dosing. This stops accidents and keeps products good.

The market for electric actuator valves is getting bigger. Water, power, and chemical industries use them more because of automation, saving energy, and new rules. North America uses these valves the most. Asia-Pacific is growing fast because of new factories and smart buildings.

Note: Electric actuator valves help save energy and cut waste. They help companies follow environmental laws. These valves work with modern automation and make it easy to watch and control things from far away.

Advantages of Electric Valve Actuators

Electric valve actuators have many good points over pneumatic and hydraulic types. These benefits make them popular for new automation projects.

Precision Control

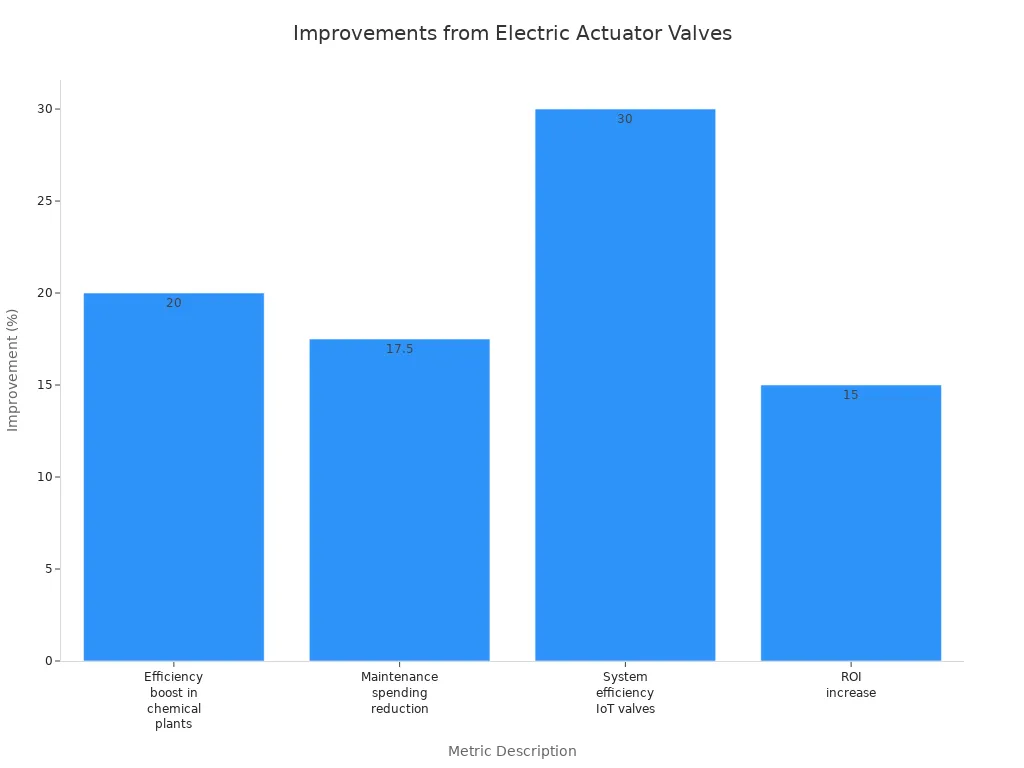

Electric actuator valves give better control of flow. They move to exact spots and stay there. This is important when tight control is needed. Chemical plants work better by about 20% after switching to these valves. Car factories save lots of money each year by using them for better fluid control. Good control helps cut waste and make products better.

Energy Efficiency

Electric actuator valves use less energy than other types. They do not need pumps or compressors. This lowers energy bills. The valves only use power when moving. This helps companies save money and lower pollution. Saving energy is a big reason why many pick these valves.

Low Maintenance

Electric actuator valves need less fixing than other types. They have fewer parts that move and do not need oil. This means less time stopped and cheaper repairs. Smart tools using AI and IoT help find problems early. This can cut repair costs by up to 20%. These tools also stop machines from breaking and keep things running.

Automation Integration

Electric actuator valves work well with new automation systems. They use digital protocols like Modbus and Profibus. This makes it easy to connect to PLCs, DCS, and SCADA. Remote control and watching improve safety and efficiency. Automated systems can change valve positions quickly. This helps companies react fast to changes.

Safety

Safety matters most in oil, gas, power, and chemical industries. Electric actuator valves lower risks by letting workers control valves from far away. Some valves have battery backups to keep them safe if power goes out. These features help stop accidents and keep people safe.

Reliability

Electric actuator valves are very reliable. They last longer because they have fewer moving parts. They do not leak or break as much. Many industries see up to 30% better system efficiency after switching. Companies also get about 15% more return on investment each year because of better reliability.

Remote Monitoring

Remote monitoring is another big benefit. Electric actuator valves send live data to control rooms. Operators can check performance and find problems early. This helps with smart repairs and stops expensive breakdowns. Remote monitoring also helps manage big or tricky places.

Compact Design

Electric actuator valves are small and easy to install. They fit in tight spaces and can be put in different ways. This makes it easier for companies to upgrade old systems.

Tip: When picking valve automation, think about what your job needs. Electric actuator valves give good control, save energy, and work well with new automation.

Electric actuator valves are a smart choice for companies. They help improve efficiency, safety, and sustainability. Their benefits include better control, less fixing, and easy use with automated systems. As more industries use automation and smart repairs, electric actuator valves will become even more important.

How to Select the Right Electric Actuator Control Valve

Assessing Application Requirements

Flow Rate and Pressure Needs

Engineers need to match the valve to the system’s flow and pressure. The actuator should give 1.2 to 1.5 times more torque than needed. This extra power helps the valve work safely and last longer. The valve must handle the highest flow and pressure in the system. If it is too weak, it could break or leak. Operators should check the motor power, current, and control voltage. These things help the valve work well in tough jobs.

Type of Media (Liquid, Gas, Slurry)

The kind of media in the valve matters a lot. Liquids, gases, and slurries all need different things. Slurries can wear out valves faster, so strong materials are best. Chemical plants use stainless steel to stop rust. Water plants may use coated metals or plastic. The media’s heat and chemicals also matter. Some valves work better with clean water. Others can handle harsh chemicals or thick slurries.

Control Precision

Many jobs need very exact control. Electric actuator valves can move to set spots. This keeps flow steady and products the same. Advanced systems use sensors to check where the valve is. Operators can set the valve for on/off or small steps. Small steps help mix chemicals or control steam. The actuator’s speed should fit the job. Fast moves can cause shocks. Slow moves may not keep up with what is needed.

Tip: Pick electric actuator valves with extra torque and speed. This helps stop problems and keeps the valve working well for a long time.

Evaluating Environmental Conditions

Temperature and Humidity

Heat and moisture can hurt electric actuator valves. High humidity can make them rust. Very hot or cold weather can break seals and motors. Some valves work from -40°C to +85°C. Operators should pick valves with good seals and high IP ratings. These ratings show how well the valve keeps out dust and water. Checking valves often and fixing them early helps stop damage from heat and wetness.

Corrosive or Hazardous Environments

Some places have harsh chemicals or are dangerous. These need special electric actuator valves. Stainless steel and anodized aluminum do not rust easily. Coatings and sealed cases keep out water and chemicals. Salt and strong chemicals can make valves rust faster. Operators should check valves often and fix problems early. Valves in risky places must meet safety rules like NEMA or UL.

Indoor vs. Outdoor Installation

Indoor and outdoor valves need different protection. Outdoor valves face rain, dust, and changing weather. High IP ratings and strong cases help protect them. Indoor valves may not need as much protection but still must resist wetness and chemicals. Operators should look at the space and how to mount the valve before picking one.

Integration and Compatibility

Control System Compatibility

Electric actuator valves must work with the control system already in place. Most factories use PLCs, DCS, or SCADA. The valve should take signals like 4-20mA or 0-10VDC. Working with advanced systems makes setup easier. Feedback tools like potentiometers or encoders help operators watch the valve’s spot.

Communication Protocols

Communication protocols link valves to control networks. Modbus, Profibus, and Ethernet/IP are used a lot. These let people control and watch valves from far away. Operators should pick valves that use the same protocol as their system. This saves money and helps with early repairs.

Power Supply Considerations

Electric actuator valves need steady power. Most use AC, but some use DC. Operators must check what voltage and current the valve needs. Battery backup or fail-safe options keep valves working if power goes out. Good power supply helps the valve last longer and saves energy.

Note: Making sure the valve works with control systems and has good power helps it run smoothly and makes repairs easier.

Maintenance and Support

Availability of Spare Parts

Spare parts are important for keeping electric actuator control valves working. Companies should make sure spare parts are easy to find before buying a valve. Getting parts like gaskets, seals, and bearings quickly helps stop long delays. Many suppliers sell kits with the most needed parts. This makes fixing things faster and keeps systems running.

Technical Support and Service

Good technical support helps fix problems quickly. Many makers offer help like checking, fixing, and testing valves. Trained workers can test actuators, clean and swap out old parts, and even rebuild the actuator if needed. Some companies can also update old valves with new parts. These services help valves last longer and work better.

Regular support includes cleaning, removing grease, changing seals, and testing how the valve works close up or from far away. These steps help keep valves working well.

Ease of Maintenance

Electric actuator control valves need less care than other types. They have fewer moving parts, so they break less often. Maintenance jobs often include checking for leaks, looking at bolts, and making sure the motor works right. Many systems use smart tools to watch how the valve is doing. These tools can find problems early, which helps stop big breakdowns. Doing regular checks and using smart sensors can make products better and save money.

- Common maintenance steps:

- Look at surfaces and control knobs

- Check oil and tighten bolts

- Test handwheel and valve movement

- Check wires for water or damage

- Change seals and cover screws if needed

Tip: A good maintenance plan helps stop expensive repairs and keeps things working well.

Cost and Total Value

Initial Investment

Electric actuator control valves usually cost more at first than pneumatic or hydraulic ones. The table below shows a comparison:

| Actuator Type | Initial Investment Cost | Notes |

|---|---|---|

| Electric | Higher upfront cost | Gives accurate, energy-saving control |

| Pneumatic | Lowest upfront cost | Good for medium jobs, quick payback |

| Hydraulic | Costly to set up | Strong force, pays off over time if used right |

Operating Costs

Electric actuators use more power because they need steady electricity. But they save money over time since they need less fixing. Pneumatic actuators cost less to run at first but need more repairs, especially for seals. Electric actuators also help cut hidden costs by giving better control and breaking down less. Companies often see that electric actuators lower total costs over time.

Long-Term Reliability

Electric actuator control valves last longer because they have fewer moving parts and can handle dust and rust. Their main parts, like bearings, can be made to last a long time and often come greased for life. Pneumatic actuators need new seals more often and do not like dirty air. Electric actuators also give better data for watching how things work, which helps find problems early and keeps systems strong. Many companies pick electric actuators because they last longer and cost less to own in the end.

Electric Valve Actuators in Industry

Water and Wastewater

Electric actuator valves are important in water treatment plants. They help move water and chemicals at each step. Operators use them to automate jobs like filtering and adding chemicals. They also help with air mixing and cleaning sludge. This makes work faster and needs fewer workers.

At the Marselisborg plant in Denmark, these valves control water leaving machines. They send it to tanks that clean out phosphorus. This saves energy and stops dirt from blocking pipes. The Milano San Rocco plant in Italy uses these valves to control air in tanks. This helps clean harmful stuff from water. These valves work well in tough places. They can handle bad weather and strong chemicals because they are built strong.

Electric actuator valves link to control systems for different jobs. Their design lets people upgrade them easily. Digital tools like fieldbus and Bluetooth help watch and control them live. Operators can change settings fast. This helps keep things running well and costs less to fix. Electric valve actuators make water treatment safe, efficient, and good for the environment.

Power Generation

Power plants use electric actuator valves to stay safe and work well. These valves control steam, water, and other fluids. This keeps the plant at the right heat and pressure. Electric actuators give exact control. This stops unsafe problems and protects machines and people.

They help control steam pipes, cooling water, and fuel. Electric actuator valves work with control systems like PLC and SCADA. This lets workers watch and change things from far away. Safety features like battery backup and manual controls help in emergencies.

These valves have strong cases and do not rust easily. Sensors inside check how the valve moves and how fast. If something is wrong, safety steps start. These valves also help keep computer systems safe from hackers. They break less often and help fix problems before they get big. Electric valve actuators help power plants be safe and reliable.

Tip: Electric actuator valves make power plants safer and help with new automation. They are very important for making energy today.

Oil, Gas, and Pipelines

Oil, gas, and pipeline jobs need strong flow control. Electric actuator valves do this well. They work smoothly in hard places. They handle high pressure, heat, and bad chemicals without stopping.

Operators use them for quick shutdowns and to control the process. Workers can control these valves from far away. This means fewer people in risky spots. If power goes out, the valves move to safe positions. This helps stop accidents and protect nature.

Electric actuator valves work with digital control systems. This lets people watch them live and fix problems early. The valves use strong seals, so they last longer and need less fixing. They do not leak gas or oil like other systems. This helps companies follow strict rules for the environment.

Chemical and Pharmaceutical

Chemical and pharmaceutical plants must control things very carefully. Electric actuators help by moving valves exactly right for mixing and dosing. Workers use them to manage how chemicals and liquids move. These actuators act fast, so there are fewer mistakes and steady work.

Many plants pick electric actuators because they save energy. They do not need oil or air, so leaks and spills are less likely. This makes them safer for handling dangerous stuff. Their tough build lets them work in places with heat, dust, or chemicals.

Electric actuators work well with new automation systems. They let workers watch and control valves from far away. This keeps workers safe and lets them fix things quickly. These actuators do not need much fixing, so plants save money and avoid stopping work.

Key benefits in chemical and pharmaceutical jobs include:

- Exact valve moves for mixing and dosing

- Quick action that helps stop mistakes

- Little fixing needed and no oil, so less mess

- Easy to use with automation and control systems

- Work well in hard places

- Can be watched and controlled from far away

Tip: Electric actuators help companies follow safety rules and stop leaks, which is important for handling chemicals safely.

Food and Beverage

Food and drink factories must keep products clean and safe. Electric actuators are important in these jobs. They use strong materials like stainless steel to stop rust and handle strong cleaners. Their smooth shapes make them easy to wash and keep clean.

These actuators do not leak, so they help stop germs from spreading. They work well for long hours and many cleanings. Workers trust electric actuators to open and close valves at the right time. This helps machines run by themselves and keeps food making smooth.

Some electric actuators have high protection ratings like IP67 or IP69K. This means they can handle water, steam, and cleaning sprays. Many types meet food safety rules, so they are good for strict places.

Main advantages in food and drink jobs:

- No leaks, so less chance of germs

- Can handle strong cleaning and washing

- Do not rust and last a long time

- Move valves exactly for good automation

- Easy to clean and take care of

Note: Electric actuators help factories use machines and keep food safe for everyone.

Mining and Nuclear

Mining and nuclear jobs need strong safety and control. Electric actuators help by moving valves just right every time. In mining, they control water, chemicals, and dust in tough places. Workers use them for jobs like filling water trucks or running water plants. These actuators do not need air, so they cost less and are easier to use far away.

Electric actuators in mining have smart tools and safety features. They can move valves to a safe spot if power goes out. This keeps workers and machines safe. Their strong build fights off dust, heat, and chemicals, so they work well in hard places.

Nuclear plants use electric actuators for important flow control. These actuators meet tough safety and reliability rules. They work well under high pressure and heat. Workers trust them to last a long time with little wear. The actuators also connect easily to automation, so workers can watch and react fast.

Key roles in mining and nuclear jobs:

- Move valves exactly and control force

- Can shut down safely if needed

- Need less fixing and cost less over time

- Meet tough safety and strength rules

- Work easily with automation and monitoring

Safety and control get better when companies use electric actuators in these tough jobs.

Electric vs. Pneumatic and Hydraulic

Performance

Electric, pneumatic, and hydraulic actuators all work in different ways. Pneumatic actuators are the fastest. They can move a valve in just 0.1 seconds. This is because compressed air moves very quickly. But pneumatic actuators are not as accurate. The air can squish, so the valve might move a little bit by itself. Their accuracy is only about 1-2 millimeters.

Electric actuators move slower than pneumatic ones. They take between 0.3 and 1 second to move. But they are much more exact. Electric actuators can move a valve to within 0.01 millimeters. This makes them great for jobs that need perfect control. Hydraulic actuators are in the middle. They are slower than pneumatic but move smoothly. Hydraulic actuators are good for heavy loads and keep a steady force.

| Actuator Type | Response Time | Accuracy | Description |

|---|---|---|---|

| Pneumatic | Fast (~0.1 s) | Moderate (1-2 mm) | Fastest response due to rapid air pressure application but less precise because of air compressibility. Suitable for fast, repetitive valve operations. |

| Electric | Slower (0.3-1 s) | High (0.01 mm) | Slower response due to motor torque development but offers highest precision and repeatability. Ideal for precise valve control. |

| Hydraulic | Slower than pneumatic | High (better than pneumatic) | Provides smooth, stable motion with excellent load control but slower response time. Best for heavy load applications requiring stable force. |

Note: Electric actuators are best when you need things to be very exact. Pneumatic actuators are good for quick, simple moves. Hydraulic actuators are strong and steady for big jobs.

Energy Use

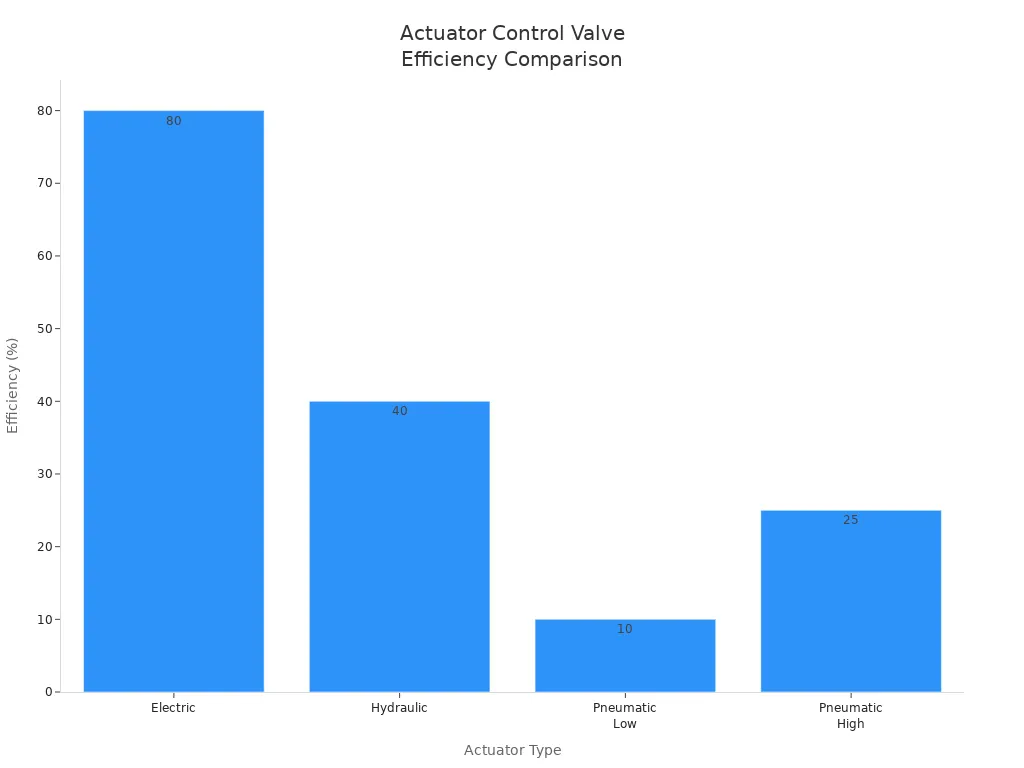

How much energy each actuator uses is very different. Electric actuators are the best at saving energy. They turn electricity right into movement. This makes them about 80% efficient. Because of this, they cost less to run and fix over time.

Pneumatic actuators use much more energy. They only use about 10-25% of the energy given to them. Most energy is lost when making and moving the air. These systems need compressors that run all the time, which uses lots of power. Hydraulic actuators are about 40% efficient. They use pressurized fluids and can hold a spot without extra energy. But they still lose energy from pumping and leaks.

| Actuator Type | Typical Efficiency | Energy Consumption Characteristics |

|---|---|---|

| Electric | ~80% | Most energy-efficient due to direct energy conversion; lower operating and maintenance costs despite higher initial cost. |

| Hydraulic | ~40% | Moderate efficiency; uses pressurized fluids; can hold position without continuous energy input; moderate maintenance complexity. |

| Pneumatic | 10-25% | Least efficient; requires continuous air compression which is energy-intensive; suffers high energy losses due to compression and leaks. |

Electric actuators save the most energy. Pneumatic systems lose a lot of energy in the air and pipes. Hydraulic systems lose less than pneumatic but still use more than electric actuators.

Maintenance

Each actuator type needs different care. Hydraulic actuators need the most attention. Oil leaks can happen and are messy and expensive. These systems also need pumps, hoses, and new fluid often. This makes them cost more to set up and run.

Pneumatic actuators need checks for air leaks and worn seals. Compressors and air lines add to the work. They do not leak oil, but fixing leaks and using energy can get expensive.

Electric actuators are the easiest to take care of. They have fewer moving parts and no fluids. This means they break less and cost less to fix. Electric actuators are also better for the environment. They do not leak oil or waste much energy. Over time, electric actuators save the most money for many companies.

| Actuator Type | Initial Purchase Cost | Installation Cost | Operation Cost | Maintenance Requirements | Environmental Impact | Long-term Cost Effectiveness |

|---|---|---|---|---|---|---|

| Hydraulic | Lower than electric | Higher (due to hydraulic power units and equipment) | Higher (energy inefficiency) | Frequent maintenance due to leaks and seal wear | High (oil leaks cause costly cleanup) | Moderate to high (due to maintenance and environmental costs) |

| Pneumatic | Moderate | Moderate (requires compressed air source) | Higher (energy inefficiency in air compression) | Frequent maintenance due to air leaks and wear | Moderate (no oil leaks but energy inefficiency) | Moderate (balance of costs and maintenance) |

| Electric | Highest | Low (only electrical connection needed) | Low (high energy efficiency) | Minimal (fewer moving parts, no fluids) | Minimal (no fluid leaks, energy efficient) | Most cost-effective long term (low maintenance and operational costs) |

Tip: Picking electric actuators can help companies save money and lower risks to the environment over time.

Suitability

Picking the right actuator depends on what the job needs. The environment and system needs also matter. Electric actuator control valves are used in many new systems. They give very exact control and save energy. These valves are good for places that must be clean and quiet. They also work well where smart automation is needed.

Electric actuators are most suitable for:

- HVAC systems in buildings that need accurate temperature and airflow control.

- Automated water treatment plants that require steady and reliable flow adjustments.

- Food and beverage factories where cleanliness and quiet operation matter.

- Pharmaceutical production lines that demand strict hygiene and precise dosing.

- Power generation facilities that need reliable and low-maintenance valve control.

- Packaging, CNC machinery, and robotics, where closed-loop control and compact size are important.

Electric actuators do not use air or fluid power. This makes them cleaner and simple to set up. They do not make exhaust, so the air stays clean. Their small size lets them fit in tight spots. Many engineers pick electric actuators for machines that can grow or change. These valves work with smart automation and Industry 4.0 systems. They give live feedback and help workers check how things are working and plan repairs.

Hydraulic actuators are better for very big valves or jobs needing strong force. Pneumatic actuators are good for fast, simple jobs but are not as exact as electric types. Electric actuators might cost more at first, but they save money later because they need less fixing and use less energy.

Electric actuators are best where clean air, saving energy, and smart systems are important. They help companies follow strict safety and environmental rules.

There are some limits for electric actuators. They must have steady power. They may not be safe in places with fire or explosions. Hydraulic actuators are better for very hard jobs and tough places. Pneumatic actuators are good for easy, quick jobs when money matters.

The table below shows which actuator works best for each job:

| Actuator Type | Best Use Cases | Key Advantages | Main Limitations |

|---|---|---|---|

| Electric | HVAC, water treatment, food, pharma, robotics | High precision, energy efficient, clean, easy automation | Needs reliable power, higher initial cost, not for explosive areas |

| Pneumatic | Fast, repetitive tasks, basic automation | Quick response, low cost | Less precise, needs compressed air, more maintenance |

| Hydraulic | Large valves, heavy loads, outdoor or harsh sites | Strong force, steady motion | Bulky, needs fluid power, risk of leaks, more maintenance |

Electric actuator control valves are best for new, smart, and clean places. They help companies work better, safer, and collect more data. As more companies use smart systems, these valves will be used even more.

Selection Factors

Application Needs

Choosing the right electric actuator control valve starts with knowing what the job is. Every job has its own needs. Engineers check what kind of fluid will go through the valve. They also look at how much pressure and heat the fluid has. They need to know if the valve will stop flow, control it, or keep a pump safe. The valve must fit the system’s flow and pressure. If the valve is too weak or small, it could break or leak.

Key things to think about are:

- How much force is needed to move the valve. This depends on the valve’s size, shape, and pressure.

- How fast the actuator needs to move. Fast moves help when things change quickly.

- What kind of control signal the system uses, like relay, solenoid, or 4-20mA.

- If feedback is needed to show where the valve is.

- How important safety and reliability are. Some systems need the valve to move to a safe spot if power goes out.

- The total cost, including buying and fixing the valve over time.

Tip: Talking to valve makers helps make sure the actuator is right for the job and meets all needs.

Environment

Where the valve is used changes how well it works and how long it lasts. Electric actuators need steady power, usually 110 VAC, but some use DC or other AC power. If there is no power, another actuator type might be better.

Temperature is important. Most electric actuators work from -40°F to 150°F. Very hot or cold places can make them not work as well. In dangerous places with flammable gases, electric actuators must meet strict safety rules like NEMA VII. Pneumatic actuators are often used in these places, but electric ones can work if they have the right safety features.

The table below shows how different things affect which electric actuator to pick:

| Environmental Condition | Influence on Selection and Performance |

|---|---|

| Power Source Availability | Needs steady electricity; no power may mean using other actuator types |

| Temperature Range | Works best from -40°F to 150°F; very hot or cold can limit use |

| Hazardous Areas | Must meet explosion-proof rules; extra safety may be needed |

| Sizing and Force | Fluid temperature and valve force change sizing and how well it works |

| Fail-Safe Options | Might need battery backup or special systems for safe shutdown |

Picking the right size and safety features helps stop damage and keeps things working well.

Integration

How the actuator fits with the control system is very important. The actuator must work with the plant’s control signals and feedback needs. Many systems use 4-20mA or digital signals. The actuator should read these signals and move the valve to the right spot every time.

Engineers also check if the actuator is easy to put in and use. It should be simple for people to use the controls and see feedback. Good integration means the actuator fits into the system without problems.

- Make sure the actuator works with the control system’s signals.

- Check that feedback devices show where the valve is.

- Look for easy setup and clear controls for workers.

Note: Good integration helps workers control the process better and makes mistakes less likely.

Support

Support is very important when picking electric actuator control valves. Good support helps companies keep things working and avoid long stops. Many people check support before they buy.

Types of Support to Think About:

- Technical Support:

Makers help by phone, email, or chat. Quick answers fix problems fast. Some companies help all day and night for emergencies. - Training:

Training teaches workers how to use and care for valves. Some suppliers give classes, videos, or easy guides. Trained workers find problems early and fix them before they get worse. - Documentation:

Manuals and diagrams help with setup and repairs. Good papers have tips, part numbers, and safety steps. Many companies give digital manuals and video guides now. - Spare Parts Availability:

Getting spare parts fast keeps valves working. Suppliers with local stores ship parts quickly. Some companies sell kits with seals, gaskets, and motors. - After-Sales Service:

After-sales service means repairs, upgrades, and check-ups. Some suppliers send workers to check and fix valves at your site. This service helps valves last longer and keeps things safe.

Tip: Ask about support before you buy. Good support saves time and money while using the valve.

Support Comparison Table

| Support Feature | Why It Matters | What to Look For |

|---|---|---|

| Technical Support | Fixes problems quickly | 24/7 help, expert staff |

| Training | Stops mistakes and long stops | Classes, online, easy guides |

| Documentation | Makes setup and fixing easier | Clear manuals, videos, diagrams |

| Spare Parts | Keeps valves working | Local stores, quick shipping |

| After-Sales Service | Makes valves last, keeps things safe | On-site visits, regular checks |

A company with good support helps customers fix things fast. This support also helps with upgrades and keeps systems new. Many buyers pick suppliers with a good history of support.

Note: Good support is as important as the valve. It helps companies avoid costly stops and keeps work safe.

Picking a supplier with strong support gives peace of mind. It also helps companies get the most from their electric actuator control valves.

Addressing Concerns

Cost

Many people worry about how much electric actuator control valves cost. These valves can cost three to five times more than manual valves at first. The higher price makes some buyers unsure, especially if the budget is tight. Manual valves look cheaper and work for simple jobs that do not need automation.

But electric actuator valves give more value over time. They control flow very accurately, often within ±1%. Workers can use them from far away, which saves time and labor. These valves move fast and use less energy when working. In places where valves open and close a lot, electric actuators mean workers do not need to be there all the time. This lowers labor costs and makes things safer.

Electric actuators help companies save money by making work more efficient. They cut waste and help keep products the same. Over many years, saving money from better control and less manual work can be more than the higher starting cost. Still, electric actuators need steady power. If power is not always there, backup systems may be needed, which adds to the cost.

Note: Electric actuator control valves cost more at first, but they often save money later by lowering labor and making process control better.

Reliability

Reliability is another thing people worry about. Some think about electrical failures, parts wearing out, or tough environments. Electric actuators can stop working if there is a short circuit or power surge. Good grounding and surge protection help stop these problems. Parts like gears and bearings can wear out after a while. Regular care, like oiling and changing old parts, keeps the actuator working well.

Very hot or cold weather and rust can also hurt reliability. Strong cases and materials that do not rust help actuators last longer. Companies often make schedules for regular care. These include checking, cleaning, oiling, and setting up the actuator. By doing these steps, workers can find problems early and stop big breakdowns.

- Common reliability worries:

- Electrical failures like short circuits and surges

- Parts wearing out like gears and bearings

- Problems from temperature and rust

- Need for regular care

- Ways to help:

- Surge protection and grounding

- Preventive care

- Strong cases

- Materials that do not rust

Tip: Regular checks and good protection help electric actuators stay reliable for many years.

Compatibility

Compatibility is important when adding electric actuator control valves to old systems. These valves must work with the plant’s control systems like PLCs or SCADA. Most electric actuators use common signals like 4-20mA or digital protocols. This makes it easier to connect them to new automation systems.

Sometimes, old systems do not work with new electric actuators. In these cases, adapters or upgrades may be needed. Power supply is also important. Electric actuators need steady electricity. In far away or unstable places, companies may need backup power or a different actuator type.

A simple checklist for compatibility:

- Check what kind of control signal is used

- Make sure the power supply fits the actuator

- See if communication protocols match

- Plan for any adapters or upgrades needed

Making sure everything matches before installing helps stop delays and extra costs.

Support and Maintenance

Support and maintenance are important for electric actuator control valves. Companies need these valves to work safely and efficiently. If a valve stops, the whole system can slow down or stop. Good support helps stop problems and keeps things working.

Manufacturers give lots of help for installing and caring for valves. They offer manuals, training, and expert advice. Workers use these tools to fix problems fast and avoid long delays. Regular maintenance helps valves last longer and work better.

Experts say workers should follow steps for support and compatibility. These steps help workers put in valves the right way and keep them working for years.

- Follow the manufacturer’s rules for electrical connections. This makes sure the actuator connects to power and control systems correctly.

- Check that the actuator and power source have matching voltage. This stops damage or problems.

- After installing, set rotation limits and control signals as the manufacturer says.

- Test the actuator by opening and closing it. This checks if it works right.

- Use mounting interfaces like ISO 5211. These help the actuator and valve fit together well.

- Use couplings that are the right size and lined up. This helps the actuator move the valve smoothly.

- Set position indicators and limit switches. These show where the valve is and stop it from moving too far.

- Do regular maintenance with manuals and expert help.

- Get expert support from the manufacturer for setup, fixing, and help any time. This keeps the valve working well.

Workers should check valves often and fix small problems early. Many companies use smart sensors to watch how valves work. These sensors send alerts when something needs fixing. Quick fixes help stop big repairs and keep things safe.

The table below lists important support resources for electric actuator control valves:

| Support Resource | Purpose | Benefit |

|---|---|---|

| Manuals | Show how to install and care for valves | Fewer mistakes |

| Training | Teach workers to use and fix valves | Faster problem solving |

| Expert Assistance | Help with hard problems and troubleshooting | Reliable operation |

| Spare Parts Availability | Give quick access to needed parts | Less downtime |

| 24/7 Service | Offer help any time | Peace of mind |

Tip: Companies that do regular maintenance and get expert help have fewer breakdowns and longer valve life.

Support and maintenance help electric actuator control valves stay reliable. Workers who follow good steps and use manufacturer help keep systems running better and safer. Good support means less downtime and more value from every valve.

Electric actuator control valves help many industries in big ways. They make work faster, safer, and easier to control with machines. These valves are used in places like water plants, power stations, and food factories.

- They control flow very exactly.

- They do not need much fixing.

- They let workers watch and control them from far away.

Companies should think about what they need and ask experts before picking a valve. These valves are good for the future because they are easy to add to new systems and help work run smoothly.

FAQ

What is an electric actuator control valve?

An electric actuator control valve uses electricity to move a valve. It helps control how liquids or gases move in pipes. Many industries use these valves for automatic and exact control.

How does an electric actuator improve valve control?

The electric actuator moves the valve to the right spot. It gets signals from a control system. This helps make flow changes more accurate and keeps things working better.

Where do companies use electric actuator control valves?

Companies use these valves in water plants, power stations, chemical factories, food making, and oil and gas pipes. These valves help machines work by themselves and make things safer.

What are the main benefits of electric actuator control valves?

Electric actuator control valves give exact control and save energy. They do not need much fixing and work well with automation. They also let people watch and control them from far away and help keep workers safe.

Do electric actuator valves need a lot of maintenance?

These valves need less fixing than pneumatic or hydraulic types. They have fewer moving parts and do not use oil or air. Checking and cleaning them often helps them last longer.

Can electric actuator valves work in harsh environments?

Yes, many electric actuator valves have strong cases and special coatings. They can handle dust, water, chemicals, and very hot or cold places. Always check the product’s rating to make sure it fits your job.

How do electric actuator valves support automation?

Electric actuator valves connect easily to control systems like PLCs and SCADA. They use digital signals and feedback. This lets workers control and watch valves from far away.

Are electric actuator control valves safe to use?

These valves make things safer because people can use them from a distance. Some have backup batteries to keep them safe if power goes out. This helps stop accidents and keeps everyone safe.