Industrial buyers face challenges selecting a custom valve manufacturer for 2025. The global valve market is valued at approximately $87 billion, featuring both large corporations and numerous specialized smaller firms. Top manufacturers such as Flowserve, Emerson, Velan, Bray, Samson, Severn, and leading Chinese companies offer a wide range of valve options. Buyers should focus on expertise in butterfly valve, ball valve, and pneumatic control valve design. Additionally, it’s important to verify certifications and the manufacturer’s ability to provide customized solutions.

Evaluation Criteria for Custom Valve Manufacturers

Certifications and Standards

API, ISO, NACE, ASTM

Certifications and following rules are very important when picking a custom valve manufacturer. API, ISO, NACE, and ASTM rules help keep valves safe and good quality. API rules are for oil and gas. They need strong checks and tests at the factory. ISO rules work for many industries. They help companies work together on big projects. NACE rules help stop rust. ASTM rules say what materials to use and how to test them. If a manufacturer follows these rules, there are fewer risks. It also helps with getting government approval.

Planning for certifications early can stop delays and failed checks. Manufacturers and buyers should talk about where and how the valves will be used. Doing this early helps pick the right valve and plan for certification time.

The table below shows the most well-known certifications and rules by region:

| Region/Country | Certification / Standard | Issuing Body / Full Name | Scope / Notes |

|---|---|---|---|

| European Union (EU) | PED 2014/68/EU + CE Marking | Pressure Equipment Directive + Notified Bodies | Needed for pressure equipment over 0.5 bar; keeps things safe |

| United States (USA) | ASME Boiler & Pressure Vessel Code | American Society of Mechanical Engineers + NB | For boilers and pressure tanks; needs inspector approval |

| Japan | KHK High Pressure Gas Safety Act | High Pressure Gas Safety Institute of Japan | Needs type or single certification |

| India | IBR Certification | Indian Boiler Regulation | For boiler valves and parts; needs inspection |

| Russia / EAEU | EAC TR CU 032/2013 | Eurasian Conformity (EAC) | For EAEU countries; needs EAC paper or certificate |

| Brazil | NR-13 | Brazilian Boiler and Pressure Vessel Norm | Safety valves must follow rules; local checks needed |

| China | TS License + GB Standards | Chinese National Standards + Special Equipment | Valves must be made in approved places |

| South Korea | KGS Standard | Korea Gas Safety Corporation | Needed for LNG and chemical projects |

| Saudi Arabia | SASO & IECEx/ATEX | Saudi Standards Organization | Needed for places with explosion risk |

| Mexico | NOM-093-SCFI-2020 | Mexican Official Standards | National rule for pressure safety parts |

Application-Specific Certifications

Some certifications are only for certain uses. For example, food and drink valves must meet NSF and FDA rules for cleanliness. Pharmaceutical valves need special papers for cleaning and accuracy. Power and chemical plants need rules for pressure and rust. A custom valve manufacturer should be able to change labels, track parts, and give papers in different languages for global use.

Customization Capabilities

Engineering Support

Good engineering help makes some suppliers stand out. Only about 20% of top manufacturers, like Warren Valve and BMAG Valves, clearly offer help with custom designs. These companies work with customers to fix hard problems and make special valves. Their teams use computer tools to make sure valves work well and are safe.

Tip: Buyers should look for suppliers who offer custom making and advice. This helps make sure the valve fits the project and meets rules.

Material and Sizing Options

Suppliers offer many choices for materials and sizes. First, buyers need to know if the project is new, an upgrade, or just needs spare parts. For upgrades, buyers should find out about the old valve, like who made it, what it is made of, and how it works. Ready-made valves may not work for tough jobs, like very hot or harsh chemicals. Picking the right size and material is important to stop problems and save money.

Suppliers like Williams Valve use strong materials, like carbon steel, bronze, stainless steel, alloy steel, and nickel alloys. They use machines to make sure valves fit pressure and heat needs. The material depends on the job. Oil and gas need strong steel for high pressure and rust. Chemical plants need materials that do not break down in acids. Food and drug companies need clean and leak-free valves.

Product Range and Specialization

Valve Types Offered

A supplier with many products can help more industries. Big custom valve makers sell ball valves, butterfly valves, gate valves, pressure reducing valves, and special valves. They also sell pipe parts and fittings for full systems. The table below shows common product types and materials:

| Product Types | Examples and Categories |

|---|---|

| Valves | Ball, Butterfly, Gate, Pressure reducing, Specialized |

| Pipe Components | Pipe fittings, Plastic tubes |

| Materials Used | Stainless steel, Brass, Carbon steel, Plastic, Bronze, Exotic alloys, Titanium, PTFE, Elastomers |

Industry Focus

Top suppliers help many industries. Flowserve Corporation works with energy, water, and building projects. Neway Valve focuses on chemical, nuclear, and power jobs. Velan Inc. helps mining, oil and gas, ships, chemical, and drug companies. IMI Plc works with gas and power plants. These suppliers make high-quality and custom valves for each industry’s needs.

Note: Buyers should pick a supplier that knows their industry. This helps meet rules and makes sure the valve works well.

Quality and Reliability

Quality Control

Quality control is very important when picking a valve maker. Top suppliers have strong programs to check quality at every step. They watch from the first design to when the valve ships. These programs help stop mistakes and lower accidents. Design errors drop by 82%. Accidents go down by 92%. The best forged steel valve supplier uses special tests. They do water and air tests. They look at the valves closely. They also find out why problems happen. These steps help save energy and cut waste. This makes sure customers get good valves.

The table below shows what top custom valve suppliers do for quality control:

| Quality Control Measure | Description / Impact |

|---|---|

| Industry Certifications | API, ISO, ASME, CE certificates show the valves are safe and good quality. |

| Testing Protocols | Water and air tests, looking at valves, and finding problems help save energy and cut waste. |

| Quality Assurance Programs | Watch the whole process from design to shipping. This cuts mistakes by 82% and accidents by 92%. |

| Material Quality | Using stainless steel, carbon steel, Monel, and Hastelloy makes valves last longer and fight rust. |

| Smart Technologies | IIoT and AI help watch valves all the time and fix problems before they get big. |

| Customer Satisfaction Tracking | Surveys and feedback help keep service good and customers happy. |

Valve-Tech checks valves many times during making. Cla-Val uses smart engineers, good materials, and careful work to make strong valves. Taylor Valve Technology makes sure their products meet API and ASME Code rules. Their valves work for tough jobs. Multivalve Flow Solutions works with partners and has high standards for repairs and tests. They set a high goal for any forged steel valve supplier.

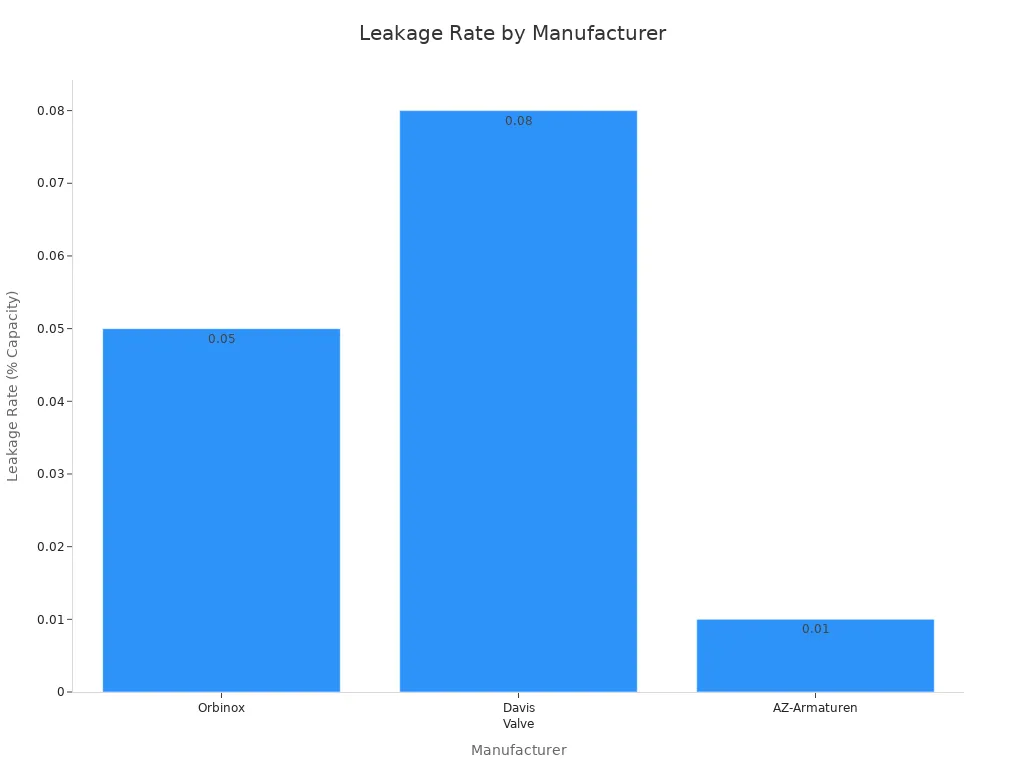

Performance Ratings

Performance ratings give buyers clear facts to compare suppliers. API 598 has strict rules for how much a valve can leak. Gate and globe valves must not leak at all. Ball and plug valves can leak a little, up to 20 bubbles per minute for sizes up to 100mm. The rule says how to test shell, seat, and backseat at certain pressures and times. This makes sure top custom suppliers meet or beat these tough leak rules.

The table below shows how much valves leak and how long the warranty lasts for top brands:

| Manufacturer | Leakage Rate (% Capacity) | Warranty Period |

|---|---|---|

| Orbinox | 0.05 | 5 years |

| Davis Valve | 0.08 | 3 years |

| AZ-Armaturen | 0.01 | 7 years |

AZ-Armaturen has the lowest leak rate and the longest warranty. This shows they are very good at meeting API 598 leak rules. Buyers should always ask for test data from each forged steel valve supplier. This helps make sure the valves will work for their project.

Lead Times and Capacity

Standard vs. Custom Orders

How long it takes to get a valve depends on the order. Standard valves are often in stock. They can ship in hours or a few days. Trimteck ships control valves the same day if you order by 10:00am Eastern Time. Fisher Controls gives QuickShip service. They confirm orders and give shipping times in 24 hours. These fast services show how quickly a valve maker can send standard orders.

Custom valves take more time. The process needs design, engineering, making a sample, testing, and approval. Custom valves usually take 4 to 6 months if the design is simple. Big or hard custom orders can take up to 18 months. Things like special designs, materials, and tests can make it longer. Buyers should plan ahead and talk to their supplier early.

Scalability

Scalability means how well a supplier can handle big or urgent jobs. The best forged steel valve supplier has big factories, lots of stock, and new technology. The table below shows how top makers can make more valves when needed:

| Manufacturer | Scaling Strategy & Capacity Details | Supporting Evidence |

|---|---|---|

| Dombor | Has a huge factory and five lines. Makes over 8000 tons a year. Spends a lot on research for special valves. | Big factory and lots of valves made. Research helps make valves for up to 800°C. Works with 2000 clients worldwide. |

| Velan Inc. | Uses modern machines to meet tough project needs. Has strong engineering help. | New machines and good shop floors. Skilled engineers give support. |

| Warren Valve | Keeps $100 million in stock for fast response. Checks quality better than most. Offers custom solutions. | Big inventory helps keep projects going. Careful checks. Custom valve shop in Houston. |

| Flowserve | Has 206 factories around the world. Uses IoT to watch valves in real time. Follows global rules. | Many factories worldwide. Uses RedRaven tech. Meets ISO 9001 and API rules. |

A scalable valve maker can quickly handle changes in orders. This helps keep projects on track and deliver on time.

After-Sales Support

Technical Assistance

After-sales support is key for long-term project success. Top suppliers help with technical questions and fixing problems. They give papers for certification and help follow industry rules. They also help manage stock so special valves are ready when needed.

Note: A good forged steel valve supplier keeps helping after the sale. They visit and meet with users. This lowers service costs and makes the valves easier to fix.

Suppliers also give full papers, quick help before and after sales, on-site or online advice, and custom engineering help for special jobs.

Maintenance and Training

Maintenance and training programs are different at each top supplier. The table below shows what some leading companies offer:

| Supplier | Customization | Delivery Method | Training Focus | Hands-on vs Theoretical | Additional Features |

|---|---|---|---|---|---|

| Dupill Group | Training fits plant needs | At the plant or their site | Safety and less radiation risk | 70% hands-on | Small classes, Just In Time (JIT) training |

| Sealweld | Site-specific steps | Teacher-led sessions | Troubleshooting from basic to advanced | Balanced | Shares knowledge, 40+ years experience |

| Armour Valve | Custom help from start to training | With maintenance | Safety, better work, always improving | N/A | Extra help like Shutdown Lockbox |

| Emerson | Top performance focus | At their site or online | Real-world use, critical thinking | Multi-day hands-on | Certified teachers, flexible learning paths |

Good maintenance and training help workers use and care for valves safely. Emerson gives hands-on classes with certified teachers and flexible ways to learn. Dupill Group focuses on safety and small classes. Sealweld has over 40 years of experience and teaches both basic and advanced troubleshooting.

A forged steel valve supplier that offers strong maintenance and training helps customers get the best and safest use from their valves.

Top Valve Manufacturers

Flowserve

Flowserve is one of the best valve makers in the world. The company started in 1790. It is known for making strong and new products. Flowserve makes many types of valves, like control, ball, plug, and gate valves. They make custom valves to fit what each customer needs. Their careful work and tough tests make sure the valves last long and work well, even in hard places.

- Flowserve sells more than just valves. They also have pumps, actuation, instrumentation, and seals for moving and controlling fluids.

- Their brands have many special products, so they are a leader around the world.

- Programs like Energy Advantage and RedRaven help customers use their equipment better and stop problems before they happen.

- They help with putting in, fixing, checking, and watching how valves work. They also give advice on saving energy and being green.

- Flowserve makes service plans that fit what each customer wants.

Flowserve cares about making good products and helping customers. This is why many buyers pick them for custom solutions. Their high standards and strong service make them different from other top companies.

Emerson (Fisher)

Emerson (Fisher) is also one of the top custom valve companies. They make many products, like control valves, valve controllers, positioners, pressure relief valves, steam traps, isolation valves, vacuum valves, propane valves, nuclear valves, vent valves, and safety relief valves. Emerson uses new valve technology, like Triple Offset Valve Technology from the Vanessa brand.

- Emerson mixes automation and control with software and IoT. This helps things run better, safer, and more reliably.

- Fisher uses Emerson’s technology to give new and flexible valve choices for many industries.

- They focus on making special valve solutions for oil and gas, chemical plants, and power plants.

Emerson stands out because they have many products, smart technology, and automation. Their skills in automation and digital tools are good for buyers who want smart systems.

Velan Inc

Velan Inc is known for making very exact valves for important jobs, like nuclear power, mining, and oil and gas. They have special non-rotating stem designs that work with actuation, so they are flexible. Velan’s valves meet tough rules, like API 624 and ISO-15848-1. They offer all trim material choices from API 623 and can use custom materials for special jobs.

- Velan makes sure valves close tightly with conical seats and body-guided discs for strong use.

- They offer custom options like hardfaced disc guides, careful machining, and torque arms to make valves last longer and seal better.

- Impactor handwheels help close some valves with more force.

- Velan’s valves follow ASME flange rules and come in many sizes and pressure classes (NPS 2-24, ASME Classes 150-1500).

Velan focuses on quality, strength, and meeting rules. They test their valves to make sure they work well in tough jobs. Their ability to meet special needs makes them a top pick for buyers in Europe and around the world.

Bray International

Bray International is known for making reliable and accurate valves. Their products are also cost-effective. They have a full line of products for many industries. Bray’s V Port Ball Valves can stop flow both ways without leaks. These valves can control small or big changes in flow. They do this with great accuracy. The rangeability is from 300:1 to 2400:1.

Bray’s segmented rotary control valves mix features from knife gate, globe, and ball valves. This design lets them cut through tough stuff and control flow well. They also seal tightly. The segment shape can be changed for dirty or harsh fluids. These rotary valves let more flow through than globe valves. Users can pick smaller valves and actuators. This saves space and money.

Bray’s products include:

- Pneumatic, hydraulic, and electric actuators that work well

- Valve positioners that are easy to set up and use

- Different trims for fire safety, noise, and SIL 3 jobs

- Solutions for leaks and tough places

Bray tests its products to meet global rules like API 607, NACE MR0175, PED, ATEX, and SIL IEC 61508 SC 3. This makes sure the valves work well in important jobs. Bray has over 35 years of experience. They make products around the world and give personal service. Their focus on quality and lower costs makes them a top pick for custom valves.

Samson Control

Samson Control, also called Samson AG, is an expert in control and ball valves. Their valves work well for high pressure and high heat. Samson’s valves use new automation and need little force to work. They shut off tightly with no leaks. The valves can use pneumatic, electric, or hydraulic actuators. This gives users many choices for their systems.

Samson Control is strong because:

- They have accessories like positioners and solenoid valves for better control

- Their valves are made with strong, high-quality materials

- They serve many industries like oil and gas, power, chemicals, drugs, food, and water

- They have ISO 9001 and other special approvals

Samson cares about quality and following rules. This helps buyers trust their valves in tough jobs. Their valves are accurate, last long, and can be customized. These things make Samson a good partner for industrial valves.

Severn

Severn makes special valves for very hard jobs. They are known for solving tough flow problems in oil, gas, power, and chemical plants. Severn’s engineers design valves for high pressure, very hot or cold, and harsh fluids.

Severn’s products include:

- Control valves for important process jobs

- Isolation valves for safety and repairs

- Severe service valves with special trims to lower noise, shaking, and damage

Severn spends money on research to make their valves better and last longer. They work closely with customers to make custom solutions that meet strict rules. Their focus on new ideas and quality puts them among the best for custom and tough valve needs.

Leading Chinese Manufacturers

China is now very important in the global valve industry. Many Chinese companies compete with Western brands. They use advanced technology and strict quality checks. They also offer many custom solutions. These companies help oil and gas, power, water treatment, chemical, and HVAC industries.

Some well-known Chinese manufacturers are:

- Plumberstar: Started in 2006, Plumberstar makes industrial valves for export. The company follows ANSI, API, DIN, BS, and JIS standards. It uses ISO 9001 processes. Plumberstar is flexible with order size and custom valve making.

- Neway Valve (Suzhou) Co., Ltd.: Neway Valve has many products. These include gate, ball, globe, check, butterfly, control, safety, and nuclear valves. The company serves oil and gas, chemical, power, shipbuilding, mining, and water treatment.

- Xhval Co., Ltd.: Xhval began in 1986. It makes custom valves like gate, ball, check, butterfly, cast iron, globe, plug valves, and strainers. The company meets international standards. It supplies oil, marine, gas, and energy industries.

- Sanhua Valve-Zhejiang Sanhua Co. Ltd.: Sanhua is a world leader in refrigeration and air conditioning valve parts. It makes solenoid and electronic expansion valves.

- SUFA Technology Industry Co. Ltd.: SUFA makes industrial valves and controllers for engineering jobs. The company has many international certifications, like API and CE.

- Wenzhou Valve Co., Ltd.: Wenzhou Valve makes many industrial valves. These are for oil, chemical, shipbuilding, power, and steel industries.

- Ameco Valve Co. Ltd.: Ameco is in Ningbo. It makes copper valves, water meters, and taps. The company has ISO9001 and API 6D certifications. It serves water, gas, power, chemical, food, and beverage sectors.

- Harbin Power Station Valve Company: Harbin started in 1954. It makes power station valves and has a long history.

The table below shows top Chinese manufacturers, what they do best, their certifications, and main markets:

| Manufacturer | Founded | Certifications | Specialties | Key Markets / Projects |

|---|---|---|---|---|

| KARON VALVE | 1991 | CE, ISO 9001, ISO 14001, ISO 45001 | Gate, globe, ball, butterfly, check valves; high-pressure hydrogenation valves | Oriental Pearl Tower, Three Gorges Project |

| Jiangnan Valve Group | 1995 | API 6D, ISO 9001, CE, TS | High-pressure ball valves, cryogenic valves (-196°C LNG) | West-East Gas Pipeline, Saudi Aramco |

| Zhejiang Petrochemical Valve | 1985 | API 6D, SIL 3, GOST-R | Sour gas-resistant valves, smart electric actuators | Kazakhstan’s Tengiz Oilfield |

| SANHUA | 1994 | CQC, CE, TüV, UL, VDE, ISO9001 | Refrigeration control components, automotive valves | Panasonic, Daikin, Tesla, BYD |

| Tianjin Worlds Valve | 2007 | ISO 9001, CE, API 609 | Butterfly valves for various pressure systems | Fire protection, high-pressure pipelines |

Chinese companies use modern production lines and automated testing. They spend money on research and development. Many now make forged steel valves, anti-coking ball valves, and smart valve solutions for tough jobs. They meet international standards and make custom products. This makes them trusted partners for big projects around the world.

Buyers should look at Chinese manufacturers for projects that need affordable, reliable, and custom valve solutions. Many of these companies ship quickly, give good after-sales help, and have strong results in big engineering jobs.

Comparison Matrix: Custom Valve Manufacturer Strengths

Comparison Table

The table below helps buyers compare top suppliers. It shows important things like certifications, products, and support. Buyers can use this chart to see which custom valve manufacturer fits their project.

| Manufacturer | Certifications | Product Range | Customization | Lead Times | After-Sales Support | Industries Served |

|---|---|---|---|---|---|---|

| Flowserve | ISO 9001, API, ASME | Ball, gate, globe, butterfly, control | High | Moderate to Fast | Global service, training | Oil & Gas, Power, Water, Chem |

| Emerson (Fisher) | ISO 9001, API, PED | Control, isolation, safety, nuclear | High | Fast (QuickShip) | Technical, digital tools | Oil & Gas, Chemical, Power |

| Velan Inc | ISO 9001, API, ASME | Gate, globe, check, ball, severe svc | High | Moderate | Field support, training | Nuclear, Mining, Oil & Gas |

| Bray International | ISO 9001, API, SIL | Butterfly, ball, rotary, actuators | Medium-High | Fast | Local support, training | Water, HVAC, Chem, Power |

| Samson Control | ISO 9001, PED | Control, ball, accessories | High | Moderate | Technical, on-site | Power, Chem, Food, Water |

| Severn | ISO 9001, API | Severe service, control, isolation | High | Moderate | Engineering, field | Oil & Gas, Power, Chem |

| Leading Chinese | ISO 9001, API, CE, TS | Gate, ball, butterfly, custom valves | High | Fast to Moderate | Local, global support | Oil & Gas, Water, Power, Chem |

Buyers should look at certifications and product range first. These things show if a supplier can meet project needs.

Manufacturer Highlights

- Flowserve: This company has many products and strong engineering help. Their worldwide team gives fast service for big projects.

- Emerson (Fisher): Emerson is known for smart automation and digital valve solutions. Their QuickShip program ships fast, so they are good for urgent jobs.

- Velan Inc: Velan makes high-performance valves for important uses. Their valves last long and meet strict rules.

- Bray International: Bray makes affordable and accurate valves. Their valves are easy to install and take care of. Their rotary valves control flow very well.

- Samson Control: Samson is great at control valves with smart automation. Their valves work in high pressure and heat.

- Severn: Severn designs custom valves for tough jobs. They help fix hard flow problems in big industries.

- Leading Chinese Manufacturers: These companies use new technology and have global certifications. They offer flexible custom options and good prices for worldwide projects.

- When comparing, buyers should check:

- Product details and technical facts

- Where the valves can be used and which industries

- Good things like quality, custom options, and delivery speed

- Bad things like not enough model info or higher prices

A custom valve manufacturer with strong certifications, many products, and good after-sales help will help buyers succeed. Good suppliers give advice, quick shipping, and help with repairs. This chart helps buyers pick the best partner for their project.

Industry-Specific Recommendations

Oil & Gas

The oil & gas industry needs valves that work well in tough places. Buyers should pick companies that know the rules and needs of this field. Valves here must handle high pressure, strong chemicals, and very hot or cold temperatures. Custom valves help control flow, stop emergencies, and work on offshore rigs.

- Write down all technical and rule needs before talking to suppliers.

- Pick companies with clear certifications like ISO 9001, API, and ATEX.

- Work with suppliers who have strong skills and can make custom valves.

- Check if the supplier can deliver on time and has a good supply chain.

- Think about both price and long-term value, like warranty and support.

- Look for extra help like on-site setup, remote help, and smart maintenance.

- Make sure they offer spare parts and good maintenance plans.

- Check if the supplier is known for being reliable and helpful.

Tip: Oil & gas valves must meet API rules and use materials that fight rust and high pressure. Makers should give papers and help to prove they follow the rules.

Chemical Processing

Chemical plants need valves that can handle many chemicals and different working conditions. The best valve makers know about many types of stainless steel and use safe, traceable materials. Certifications like ISO and ANSI are needed for safety and trust.

- Certification: Companies must have ISO and ANSI certificates.

- Material traceability: Suppliers should track all materials used.

- Stainless steel expertise: The supplier must know which steel works for each chemical.

- Engineering support: Find experts who help with repairs and care.

- Timely delivery: Fast shipping helps keep plants running.

- Cost vs. quality: Good valves stop leaks and accidents, saving money later.

Custom valve design lets plants use automation and smart systems. Sensors and smart tools help watch valves and fix problems early. Working with engineers from the start makes sure the valve fits the plant’s needs.

Note: It is very important to use the right material. The wrong one can cause rust, leaks, or even system failure. Always check if the supplier knows your chemicals.

Power Generation

Power plants work in hard and changing conditions. Valves must handle heat, pressure, and quick changes. Old plants and new rules make picking the right valve even more important. Makers must think about size, material, heat and pressure ratings, and seat type to make sure valves last.

Valves in power plants often face rust and wear. Strong materials and good seals are needed. Bad quality checks can cause big problems, so strict testing is a must. Good sizing and picking tools help avoid waste.

- Corrosion resistance: Pick valves that fight rust and harsh places.

- High-pressure and temperature: Use valves made for high pressure and special seals.

- Quality control: Make sure the maker follows strict rules and tests.

- Automation: Smart valves with sensors help watch and fix problems fast.

Power plants do better with digital valve tools and automation. These tools cut downtime, lower costs, and make things more reliable.

Water & Wastewater

Picking the right custom valve manufacturer for water and wastewater jobs is important. You need to make sure the valves follow rules and use safe materials. Cities, treatment plants, and factories use valves to control water flow and keep people safe. These places must follow strict rules to keep water clean and systems working.

When buying valves, you must follow local and global standards. WRAS in the UK, NSF/ANSI 61 in the US, ACS in France, and WaterMark in Australia show valves are safe. These rules make sure valves do not add bad stuff to water or change its taste or smell. EN 1074, AWWA C509/C515, API 600/602, and ISO 5208 also set rules for safety and pressure. One city had problems when they used the wrong valves. The water tasted and smelled bad because the seals were not right. They fixed it by using WRAS-certified valves and better coatings. This shows why picking the right certified valves and materials is very important for safe drinking water.

Valve bodies and seals must not rust or change how water tastes or smells. Ductile iron with safe epoxy, stainless steel 304 or 316, and WRAS EPDM are good choices. These materials stop bad stuff from getting into the water and last a long time. Manufacturers should give all papers, like Material Test Certificates, Inspection and Test Plans, and Factory Acceptance Test reports. Buyers should ask for these to make sure the valves are safe.

Some best ways to buy valves are:

- List all needed rules and certificates in your order.

- Write down the pressure and temperature needed for each job.

- Ask the manufacturer for all safety papers.

- Work with suppliers who can track quality.

- Think about things like rust, easy repairs, actuator fit (ISO 5211), and spare parts.

You should also think about special problems for each job. Wastewater can have rough or harsh liquids. Valves must handle these without breaking often. The valves should work with actuators for easy control. Easy repairs and spare parts help save time and money.

Tip: Always check if the manufacturer knows about water and wastewater jobs. Their experience helps you avoid mistakes and follow local rules.

The table below shows important rules and good materials for water and wastewater valves:

| Standard / Certification | Region / Country | Recommended Materials | Application Focus |

|---|---|---|---|

| WRAS | UK | Ductile iron, WRAS EPDM | Potable water |

| NSF/ANSI 61 | US | Stainless steel, potable elastomers | Drinking water |

| ACS | France | Epoxy-coated iron, ACS elastomers | Municipal water |

| WaterMark | Australia | Stainless steel, WaterMark EPDM | Water supply |

| EN 1074 | EU | Ductile iron, stainless steel | Water distribution |

| AWWA C509/C515 | US | Epoxy-coated iron, resilient seals | Waterworks valves |

Picking a custom valve manufacturer with the right certificates, good material knowledge, and strong support keeps water and wastewater systems safe and working well.

Technology and Market Trends

Smart Valve Technologies

Smart valve technologies have changed how companies control flow. Top manufacturers now use systems that watch valves in real time. These systems check things like valve position, flow, pressure, and temperature. Operators get quick updates, so they can fix problems early. For example, smart valves move sometimes to show they still work. Data tools watch power use and motor heat. Special programs spot changes and plan repairs only when needed.

Companies like Emerson Electric Co. and Flowserve Corporation lead in valve automation. Their products react fast and give feedback to users. These features help valves last longer and work better. Pentair makes electric control valves for water. Their designs save energy and respond quickly. IMI plc, Emerson, and Flowserve add tools for smart repairs and energy savings. These new ideas help cut costs and support green goals.

A recent project with SAMSUN Makine Sanayi used butterfly valves with special actuators. These valves connect to cloud servers using Modbus. People can check and control them from far away, even with solar power. Diagnostic systems find worn parts and tell workers about valve health. This makes repairs easier and helps things run smoothly.

Smart valve technologies help companies stop downtime, save energy, and stay safe. These trends show the market is moving to smarter, more connected systems.

Digitalization and IoT

Digitalization and IoT are now very important in the valve world. Makers use sensors and cloud tools to collect data from valves all the time. Operators can check valve health and energy use from anywhere. This helps companies make good choices and fix problems fast.

IoT valves send alerts if they find leaks or pressure drops. Maintenance teams can fix things before they get worse. Digital tools also let people control valves from far away. This is helpful for big plants and remote places. Flowserve and Emerson use IoT to link valves to main systems. These tools help track how valves work and plan repairs when needed.

A table below shows some benefits of digitalization and IoT in valve management:

| Benefit | Description |

|---|---|

| Real-time monitoring | Operators see valve status instantly |

| Predictive maintenance | Repairs happen before failure |

| Remote control | Valves managed from any location |

| Data analytics | Trends and patterns identified |

Digitalization and IoT help companies trust their valves, spend less, and use smart tools. These trends are shaping the future of custom valve solutions.

Sustainability Initiatives

Sustainability is now a big goal for custom valve makers in 2025. Companies upgrade their buildings with LED lights, smart thermostats, and new machines. These changes use less energy and lower pollution. Some companies put solar panels on roofs to make clean power. One factory used 46% less energy after adding LED lights.

Waste control is also important. Makers recycle plastics, metals, and oils to help the planet. They use green materials, like recycled valve parts and energy-saving coils. Biodegradable packaging helps cut waste. These steps make factories work better and help products last longer.

- Use of recycled parts and energy-saving designs

- Biodegradable packaging for shipping

- Building upgrades to save energy

Sustainability helps companies follow rules and show they care about the planet. These trends change how products are made and designed. Ceramic-lined valve makers help too by making valves that last longer and fight rust, which cuts waste and saves energy.

Companies that care about sustainability earn trust from buyers and rule-makers. Their actions help the earth and support business for the future.

Ceramic-Lined Valve Manufacturers

Ceramic-lined valves are very important for industries with rough or dangerous fluids. These valves have ceramic parts inside. The ceramic helps stop damage from wear, rust, and heat. Mining, chemical plants, and power stations use ceramic-lined valves to make machines last longer and need fewer repairs.

Ceramic-lined valve manufacturers make valves for hard jobs. They use special ceramics like alumina, zirconia, and silicon carbide. These materials keep the valve safe from sand, slurry, acids, and other tough stuff. This makes the valve last longer than ones made only of metal.

Key Benefits of Ceramic-Lined Valves:

- Very strong against wear and rust

- Last longer in tough places

- Need less fixing and fewer new parts

- Work well even when it is very hot

Note: Ceramic-lined valves fix problems where metal valves break fast. They help companies stop surprise shutdowns and costly fixes.

Many industries trust ceramic-lined valve manufacturers for special solutions. These companies make many valve types, like ball, butterfly, gate, and check valves. Some also help pick the best ceramic for each job.

The table below shows some top ceramic lined valve manufacturers and what they do best:

| Manufacturer | Main Products | Industries Served | Key Features |

|---|---|---|---|

| Foyo Valve | Ball, butterfly, gate valves | Mining, chemical, power | Custom ceramic linings |

| Cera System | Ball, check, control valves | Chemical, food, pharma | High-purity ceramics |

| Nil-Cor | Ball, butterfly valves | Water, wastewater, mining | Lightweight composite bodies |

| Huamei Machinery | Ball, plug, check valves | Oil & gas, mining | Wear-resistant designs |

| Fujikin | Ball, globe, check valves | Semiconductor, chemical | Precision ceramic components |

Procurement Tips for Industrial Buyers

Defining Requirements

Industrial buyers do better when they start with clear needs. They should write down what kind of valve they want. They need to list the size, pressure, and material. It is important to say where the valve will be used. This helps stop mistakes. For example, chemical plants need valves that do not rust. Buyers should also add rules and certifications to their list. This helps suppliers know what is needed and stops confusion.

A simple checklist helps buyers keep track:

- Valve type and what it does

- Size and pressure level

- Material and coating

- Industry rules (API, ISO, etc.)

- Job details (temperature, media, flow rate)

- Needed certifications

- When it should arrive

Tip: Buyers who plan early save time and avoid changes later.

Engaging Manufacturers

After making a list, buyers should talk to many suppliers. They can send a request for price or proposal with all details. Good talking helps suppliers give the right price and advice. Buyers should ask if the supplier has done similar jobs. They should check if the supplier can make custom valves for special needs.

When looking at suppliers, buyers should check:

- How fast they reply and how clear they are

- If they answer questions

- If they give technical help

- If they can change designs and how they make things

- If they have good reviews from other clients

A table helps compare supplier answers:

| Supplier Name | Response Time | Custom Options | Technical Support | References Provided |

|---|---|---|---|---|

| Supplier A | 2 days | Yes | Strong | Yes |

| Supplier B | 5 days | No | Moderate | No |

Note: Buyers should keep notes of all talks. This helps them see progress and make better choices.

Quality Assurance

Quality assurance keeps projects safe from problems. Buyers should ask each supplier about how they check quality. They should ask for test papers, inspection plans, and certificates for every valve. Visiting the factory can show how they check quality. Some buyers use outside inspectors to look at products before shipping.

Important quality checks are:

- Material test papers

- Pressure and leak tests

- Following industry rules

- Factory acceptance tests (FAT)

- Tracking parts

Buyers who care about quality get safer valves that last longer. They also lower the chance of delays.

Post-Purchase Support

After buying valves, buyers need good help to keep things working. A reliable supplier does more than just send valves. They help with putting in, fixing, and finding problems. Good support after buying can stop long breaks and make equipment last longer.

Buyers should look for these important services from their supplier:

- Technical Assistance: The supplier should help by phone, email, or visits. Fast answers to questions help fix problems quickly.

- Spare Parts Availability: A good supplier keeps spare parts ready. Quick delivery of parts means less waiting during repairs.

- Warranty and Claims Handling: The supplier must explain the warranty rules clearly. They should handle claims fast and fairly.

- Maintenance Programs: Some suppliers offer regular check-ups. These programs help stop breakdowns and keep valves working well.

- Training and Documentation: The supplier should train workers. Easy-to-read manuals help staff use and care for the valves.

Tip: Buyers should ask about support before signing a contract. Good help after buying shows the supplier cares about long-term customers.

The table below shows what buyers get from top suppliers:

| Service | Description | Benefit to Buyer |

|---|---|---|

| Technical Support | Phone, email, or on-site help | Fast problem solving |

| Spare Parts | Stocked and shipped quickly | Less downtime |

| Warranty | Clear terms and fast claims | Lower repair costs |

| Maintenance | Scheduled service visits | Longer valve life |

| Training | Staff instruction and manuals | Safer, more efficient use |

FAQ

What certifications should a custom valve manufacturer have?

Buyers should look for API, ISO 9001, and ASME certificates. These show the company follows world safety and quality rules. Some jobs need PED, CE, or ATEX marks for extra safety.

How long does it take to receive a custom valve order?

Standard valves can ship in just a few days. Custom valves take longer, from 4 to 18 months. The time depends on design, materials, and tests. Planning early helps stop project delays.

Why is after-sales support important for industrial valves?

After-sales support gives fast help with setup and repairs. Good support means less downtime and safer systems. Top suppliers also give training and spare parts.

Can manufacturers provide valves for harsh chemicals or high temperatures?

Yes. Top companies use special materials like stainless steel, alloys, or ceramics. These materials fight rust and heat. Buyers should share all job details to get the best valve.

What information should buyers give when requesting a quote?

Buyers should list valve type, size, pressure, temperature, material, certifications, and when they need it. Clear info helps suppliers give the right price and delivery time.

How do smart valves help industrial operations?

Smart valves have sensors and digital tools to watch how they work. They send live data to workers. This helps find problems early, plan repairs, and keep things safe.

Are Chinese valve manufacturers reliable for global projects?

Many Chinese companies follow world rules like API and ISO. They have good prices, ship fast, and make custom valves. Buyers should check their certificates and past jobs.

What is the difference between standard and custom valves?

Standard valves are for common jobs and ship fast. Custom valves are made for special needs, like different sizes or materials. Custom valves take longer but fix hard problems.