When you look at check valve vs gate valve, you see they work differently. Check valves let fluid go one way and stop it from going back. This makes them save energy and react fast. Gate valves turn flow on or off and seal tightly, but they are slower to work. More people want industrial valves now. The global market was USD 82.82 billion in 2024. Energy and utilities use the most at 28%. You can also find butterfly valve, ball valve, and pneumatic valve in these systems.

Key Takeaways

- Check valves let fluid move in only one way. They stop fluid from going backward by themselves. This helps protect pumps and other parts of the system.

- Gate valves are made to start or stop fluid flow all the way. They give a strong seal but need someone or a machine to work them.

- Pick a check valve if you must stop fluid from going backward. This is important in water supply and wastewater systems.

- Use a gate valve for high-pressure systems that need a strong shutoff. These are used in oil and gas pipelines.

- It is very important to take care of both valve types. Look for leaks, clean out dirt, and oil the moving parts. This helps them last longer.

- Check valves usually cost less because they are simpler. Gate valves can cost more at first but last a long time.

- Always pick the right valve for your system. Think about pressure, which way the fluid goes, and what kind of fluid it is. This helps the system work best.

- Look at industry rules and certifications when picking valves. This keeps your system safe and working well.

Key Differences

Check Valve vs Gate Valve

When you look at check valve vs gate valve, you notice they are not the same. Check valves let fluid move in just one way. They stop the fluid from going back. You do not need to use your hands to work them. They open and close by themselves. Gate valves work differently. They use a gate inside to start or stop the flow. You need a handle or machine to move the gate. Gate valves can block flow from both sides.

Here is a table that shows the main differences:

| Feature | Check Valve | Gate Valve |

|---|---|---|

| Flow Direction | One-way (unidirectional) | Two-way (bidirectional) |

| Function | Prevents backflow | Opens/closes flow |

| Operation | Automatic | Manual or automated |

| Valve Type | Non-return | Shut-off |

| Typical Use | Pump discharge lines | Isolation in pipelines |

| Suitable for Automation | Yes | Yes, with actuator |

| Pressure Drop | Low | Moderate to high |

| Cost | Generally lower | Generally higher |

This table helps you pick the right valve for your job. If you want to stop fluid from going backward, use a check valve. If you need to turn flow on or off, use a gate valve.

Pressure Suitability

You should think about pressure before you choose a valve. Check valves are good when flow might change direction. They also protect pumps and other equipment from backflow. They work well with changing pressure. You see them in water pipes, wastewater plants, and fuel lines.

Gate valves are better for places with high pressure. You find them in pipes that need a tight seal. They can handle hot or cold liquids and gases. They work from -200°C to 700°C and up to 16 bar pressure. Gate valves give strong shutoff. But do not use them to slow down flow. That can break the valve.

Tip: Always pick a valve that matches your system’s pressure. This keeps things safe and helps your valve last longer.

A look at pressure shows check valves are best for changing flow. Gate valves are best for high-pressure shutoff.

Flow Direction

Flow direction is another big difference between check valve and gate valve. Check valves only let fluid go one way. You must put them in the right way, following the arrow. This stops backflow and keeps pumps and pipes safe. You often see check valves at pump exits and in fire systems.

Gate valves let fluid move both ways. You can put them in any direction. This makes them good for stopping flow and for fixing pipes. You can block flow from either side.

- Check valves: One-way flow, follow the arrow.

- Gate valves: Two-way flow, install any way you want.

Knowing these facts helps you pick the best valve for your needs.

Main Functions

When you choose a valve, you need to know what job it does best. Check valves and gate valves have different main functions in a fluid system.

- Check valves act like a one-way door. You use them to let fluid move in only one direction. When fluid tries to go backward, the check valve closes by itself. This stops backflow and keeps your pumps, pipes, and equipment safe. You often see check valves at the outlet of pumps or compressors. They work without you needing to control them. This makes them important for safety and system protection.

- Gate valves work like a switch for your pipeline. You use them to start or stop the flow of fluid. When you open a gate valve, fluid moves freely. When you close it, the flow stops completely. Gate valves do not control how much fluid passes through. They only let you turn flow on or off. You should not use them to slow down or adjust flow. This can damage the valve and the system.

Here is a quick summary of what each valve does:

| Valve Type | Main Function | How It Works |

|---|---|---|

| Check Valve | Prevents backflow (one-way flow) | Closes automatically if flow reverses |

| Gate Valve | Starts or stops flow (on/off control) | Opens or closes a gate inside |

Note: Always match the valve to your system’s needs. Use check valves for backflow prevention. Use gate valves when you need to fully open or fully close a pipeline.

You can see that each valve has a special job. Check valves protect your system from reverse flow. Gate valves give you control to stop or allow flow. Picking the right valve helps your system run safely and smoothly.

Check Valve Overview

What Is a Check Valve

A check valve is a device you use to control the direction of fluid in a pipe. You find it in many systems where you want to stop water, gas, or other fluids from flowing backward. When you install a check valve, you make sure that fluid can only move forward. This simple device does not need you to turn it on or off. It works by itself, using the pressure of the fluid.

You see a check valve in pump lines, water supply systems, and even in some home appliances. Its main job is to protect pumps and equipment from damage caused by reverse flow. If you want to keep your system safe and running well, you often need a check valve.

How Check Valves Work

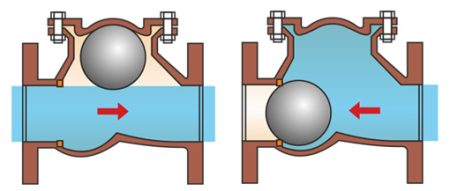

A check valve works by letting fluid pass in one direction and blocking it in the other. The basic operating principle is simple. The valve opens when the pressure on the inlet side is higher than the pressure on the outlet side. This difference in pressure is what moves the valve and allows flow.

- The check valve opens when the upstream pressure is greater than the downstream pressure.

- It closes when the upstream pressure drops below a set point, stopping backflow.

- The lowest pressure needed to open the valve is called the “cracking pressure.”

You do not need to use electricity or manual controls. The check valve responds to the flow and pressure in the pipe. If the flow tries to reverse, the valve shuts right away. This quick action keeps your system safe from backflow.

Tip: Always check the cracking pressure of a check valve before you install it. This helps you match the valve to your system’s needs.

Features

Unidirectional Flow

One of the most important features of a check valve is unidirectional flow. This means fluid can only move in one direction through the valve. You must install the check valve in the correct orientation. Most check valves have an arrow on the body to show you the right way to install them.

- A check valve acts like a one-way door for fluid.

- It opens when fluid flows in the correct direction.

- It closes if fluid tries to move backward.

This feature makes the check valve different from other valves that allow flow in both directions.

Backflow Prevention

Backflow prevention is the main reason you use a check valve. When the flow in your system tries to reverse, the check valve closes automatically. You do not need to do anything. The valve uses a spring or a hinged clapper to shut quickly.

- The check valve prevents damage to pumps and equipment.

- It keeps your water supply clean by stopping dirty water from flowing back.

- It works without electricity or manual help.

You should always consider the flow rate, pressure, and the type of fluid when you choose a check valve. The material of the valve must match the fluid to avoid corrosion. Size and weight also matter for easy installation. Some check valves need more maintenance than others, so think about long-term care.

Note: A check valve is a simple, automatic way to protect your piping system from backflow and keep everything running smoothly.

Advantages

When you use a check valve in your system, you get many important benefits. This simple device helps you keep your pipes and equipment safe. You can see how a check valve makes your job easier and your system more reliable.

Here is a table that shows the main advantages of using a check valve, especially in water and wastewater treatment plants:

| Advantage | Description |

|---|---|

| Preventing backflow | A check valve lets fluid flow in one direction, stopping backflow when pressure drops. |

| Protecting pumps | It protects pumps from damage by blocking backflow when pumps turn off. |

| Reducing water hammer | A check valve helps reduce water hammer by stopping water from reversing direction. |

| Improving energy efficiency | It boosts energy efficiency by preventing backflow, which lowers the workload on pumps. |

| Reducing maintenance costs | Simple rubber check valves can lower maintenance needs for water and wastewater systems. |

You can use a check valve to prevent dirty water from flowing backward into clean water lines. This keeps your water safe and clean. When you install a check valve, you also protect your pumps. If the pump stops, the check valve closes and stops water from rushing back. This action saves your equipment from damage.

A check valve also helps you avoid water hammer. Water hammer is a loud banging noise that happens when water suddenly stops or changes direction. This can break pipes and valves. By using a check valve, you reduce this risk.

You will notice that a check valve can make your system more energy efficient. It stops water from moving backward, so your pump does not have to work as hard. This saves you money on energy bills. Many check valves are simple and do not need much care. This means you spend less time and money on repairs.

Tip: Always choose the right size and type of check valve for your system. This helps you get the most benefits and keeps your system running smoothly.

Disadvantages

While a check valve gives you many benefits, you should also know about its limitations. Some problems can happen if you do not pick the right check valve or if you do not take care of it.

Here is a table that lists the most common disadvantages:

| Disadvantage | Description |

|---|---|

| Pressure Drop | A check valve creates resistance, which lowers pressure downstream. |

| Water Hammer | If a check valve closes suddenly, it can cause shock waves that damage pipes and parts. |

| Maintenance Needs | You need to inspect and replace parts often to keep the check valve working well. |

| Noise and Vibration | Sometimes, a check valve makes noise or shakes, which can harm your system. |

| Compatibility Issues | The check valve must match the fluid type, or it may fail or get damaged. |

| Cost | High-quality check valves can cost a lot, and maintenance costs can add up over time. |

You may also face cavitation. This happens when the pressure drops too low inside the check valve. Vapor bubbles form and can damage the valve and pipes. You need to check your system often to make sure the check valve works right. Over time, the inside parts can wear out or break. This can cause leaks or poor performance.

Some other problems include:

- Water hammer can happen if the flow stops or reverses too quickly.

- This can break pipes, cause valve failures, or even shut down your system.

You may also find that check valves need regular care. If you put them in hard-to-reach places, maintenance can be tough. The first cost of a check valve can be high, especially for special types. Over time, the cost of repairs and replacements can grow, especially in big systems.

Note: Always check your check valve often and pick the right one for your fluid and system. This helps you avoid problems and keeps your system safe.

Gate Valve Overview

What Is a Gate Valve

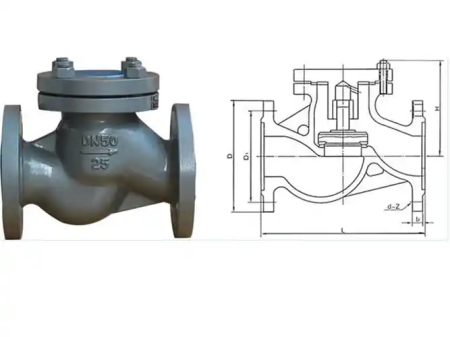

You use a gate valve to control the flow of liquids or gases in a pipeline. This valve works by moving a gate up or down inside the valve body. When you lift the gate, fluid flows freely. When you lower the gate, the flow stops completely. You find gate valves in water supply systems, oil and gas pipelines, and many industrial plants. The main job of a gate valve is to provide a tight shutoff. You do not use it to adjust or throttle flow. The design makes it easy for you to open or close the valve fully.

Gate valves stand out because they use a flat gate or disc that moves straight up and down. The valve body, seat, stem, gate, cover, and sealing ring all work together to make sure the valve seals well. Most gate valves use high-grade ductile iron, which makes them lighter than older models. The flat-bottomed seat keeps debris from building up, so fluid moves without blockage. You get a strong seal and reliable performance with this type of valve.

How Gate Valves Work

A gate valve operates by converting rotary motion into linear motion. When you turn the handle or actuator, the stem moves the gate vertically along the center line of the passage. The trapezoidal thread on the lifting rod helps change the turning motion into straight movement. The gate rises out of the fluid path when you open the valve. This lets fluid pass with very little resistance. When you close the valve, the gate presses against the seat and blocks the flow.

Here is a table that explains the basic operating principle of a gate valve:

| Feature | Description |

|---|---|

| Movement | The gate moves vertically along the center line of the passage. |

| Components | Valve body, seat, stem, gate, cover, and sealing ring. |

| Functionality | Used for full-open and full-close cut-off; not suitable for adjustment or throttling. |

| Motion Conversion | Rotary motion changes to linear motion via a trapezoidal thread. |

| Sealing Mechanism | Medium pressure presses the gate against the seat for self-sealing. |

| Forced Sealing | External force may be needed for tight sealing when closed. |

When you raise the gate, you allow fluid to flow with minimal resistance. When you lower the gate, you block the passage and stop the flow. You should not use a gate valve to control the amount of fluid passing through. This can damage the valve and reduce its lifespan.

Features

Multi-Directional Flow

You can install a gate valve in either direction in a pipeline. This makes it very flexible for many systems. Most gate valves work well with high pressure and temperature. You get bi-directional use, which means the valve can handle flow from both sides. The design ensures minimal pressure loss, so your system stays efficient. The flat-bottomed seat prevents debris from collecting, keeping the flow smooth. You do not need to worry about silt or dirt blocking the valve.

- You can use a gate valve for both directions of flow.

- The valve works well in high-pressure and high-temperature systems.

- The flat-bottomed seat keeps the passage clear.

Start/Stop Control

A gate valve gives you strong control over starting and stopping fluid flow. You get full flow when the gate is raised. You get complete shutoff when the gate is lowered. This makes the gate valve perfect for on/off control in large pipelines. You should not use it for throttling or regulating flow. The valve provides good shutoff and keeps pressure stable during operation.

Here is a simple list of how gate valves control flow:

- Gate valves provide full flow or complete isolation.

- They excel in on/off control for large pipelines.

- They are not suitable for throttling or regulating flow.

Tip: Always use a gate valve when you need to open or close a pipeline completely. Avoid using it to adjust flow, as this can harm the valve.

Advantages

When you pick a gate valve, you get many good things. This valve works well in hard places. You can use it in oil and gas pipes, water lines, and chemical plants. The gate valve lets you start and stop flow with strong control.

Here is a table that shows the main advantages of using a gate valve in oil and gas pipelines:

| Advantage | Description |

|---|---|

| Temperature Resistance | Gate valves can operate in temperatures exceeding 300°C, suitable for industrial applications. |

| Corrosion Resistance | Made from special alloys like Inconel and Hastelloy, they resist rust and extend lifespan. |

| Sealing Performance | They provide tight seals to prevent leaks, crucial for safety in high-pressure systems. |

| Durability | Constructed from strong materials like carbon steel and cast iron, they withstand frequent use. |

| Automation Benefits | Integration with smart technology allows for real-time monitoring of flow, pressure, and temperature. |

A gate valve can handle very hot or cold fluids. It does not rust easily, so it lasts longer. The tight seal keeps your system safe from leaks. Strong materials help the valve last through lots of use. You can connect a gate valve to smart systems for better control.

Tip: If you need a valve for high pressure and heat, a gate valve is a smart pick.

A gate valve helps you save money over time. You do not have to replace it often because it is tough. You can use it in many kinds of pipes. The valve works with both hand and automatic controls. You get a system that is flexible and reliable.

Disadvantages

You should know about some problems with gate valves. Even though they have many good points, there are some things to think about before you use one.

Here is a table that lists the most common disadvantages of using a gate valve in industrial systems:

| Disadvantage | Description |

|---|---|

| Slow Operation | Gate valves require multiple turns to open or close, making them slow compared to other valve types. |

| Limited Throttling Capability | They are not designed for precise flow control, leading to potential erosion and leaks. |

| Susceptibility to Wear and Tear | The mechanical interaction within the valve leads to wear over time, compromising functionality. |

| Vulnerability to Corrosion | Gate valves can corrode in harsh environments, affecting their integrity and performance. |

| Difficulty in Maintenance | Regular maintenance is complex and requires precision, making it challenging in large systems. |

A gate valve opens and closes slowly. You must turn the handle many times to move the gate. This is not good if you need to act fast. Gate valves do not work well for adjusting flow. If you try to use them this way, you might break the valve or cause leaks.

Gate valves can wear out as parts rub together. You might see rust if you use them in rough places. This can make the valve leak or stop working. Taking care of a gate valve can be hard. You need skill and time, especially in big systems.

Note: Always check your gate valve often and use it only for full open or close positions. This helps you avoid problems and keeps your system safe.

Check Valve Standards

International Standards

ISO 5752: Metal Valves for Use in Flanged Pipe Systems—Face-to-Face and Center-to-Face Dimensions

It is important to know how valves fit in your pipes. ISO 5752 gives rules for valve sizes and how they line up. This helps you make sure your check valve matches other parts. If you follow ISO 5752, you can stop leaks and make putting in the valve easier. The valve fits well and works safely when you use this standard.

API 594: Check Valves—Flanged, Lug, Wafer, and Butt-welding

API 594 tells you what check valves need for types like flanged, lug, wafer, and butt-welding. It covers how the valve is made and tested. If you pick a check valve that meets API 594, it will not rust easily and can handle changes in pressure. You know the valve will stop backflow and keep your system safe.

Here is a table with some main international standards for check valves and other valves:

| Standard | Description | Applicable Valve Types |

|---|---|---|

| API6D Annexure F/QSL | Validations for various valve types | Axial, Ball, Check, Gate, Plug |

| EN 14141 | Type test on general design and production | Plug, Ball, Gate, Check |

| ISO 5208 Rate C | Leakage test procedure for check valves | Check Valves, Plug Valves |

Tip: Always make sure your check valve follows these standards before you buy. This helps you avoid leaks and makes sure your valve works well.

American Standards

ASME B16.34: Valves—Flanged, Threaded, and Welding End

ASME B16.34 gives rules for building and testing valves. It covers flanged, threaded, and welding end valves. If your check valve meets ASME B16.34, it will be strong and work well. You also follow safety rules for pressure and temperature.

MSS SP-61: Pressure Testing of Steel Valves

MSS SP-61 sets rules for testing steel valves under pressure. You need this standard to make sure your check valve can handle the pressure in your pipes. It helps you find leaks before you use the valve.

API 6D: Pipeline Valves

API 6D is important for pipeline valves, including check valves. It covers how the valve is made and tested. If your check valve has API 6D approval, it will work in oil, gas, and water pipes.

European Standards

EN 12334: Industrial Valves—Cast Iron Check Valves

EN 12334 gives rules for cast iron check valves. It covers how the valve is made and tested. You use this standard to make sure your check valve works well in water and wastewater systems.

DIN 3202: Face-to-Face and Center-to-Face Dimensions of Valves

DIN 3202 helps you match your check valve size with other pipe parts. This makes putting in the valve easier and helps stop leaks.

Here is a table with key European standards for check valves used in water and wastewater systems:

| Specification Aspect | Details |

|---|---|

| Standard Name | BS EN ISO 16137:2006+A1:2019 |

| Material Type | Thermoplastics materials |

| Application | Water supply and wastewater management |

| Key Requirements | Design, manufacturing, and testing protocols |

| Backflow Prevention | Ensures flow in one direction only |

| Temperature Range | ?40 °C to +120 °C |

| Lifetime | 25 years |

| Applicable DN Sizes | DN 8 to DN 600 |

| Applicable PN Classes | PN 6, PN 10, PN 16, PN 25, Class 150, Class 300 |

Note: Always check the markings and papers for your check valve. Standards help you get safe, reliable, and approved valves.

Common Certifications and Markings

CE Marking (European Conformity)

You might notice the CE marking on check valves sold in Europe. This marking means the check valve follows strict safety and quality rules from European law. If you want to use a check valve in Europe, you must look for the CE marking. The CE marking shows the valve passed tests for safety, health, and the environment. You can trust a check valve with this marking to work safely in your system.

Manufacturers have to follow special steps to get the CE marking. They test the check valve for leaks, pressure, and strength. You should always check the label and papers for the CE marking before you buy. This helps you avoid problems with inspections or legal rules. If you see the CE marking, you know the check valve is ready for use in Europe.

Tip: Always ask for the CE marking if you need a check valve for a European project. This keeps your system safe and helps you follow the law.

UL/FM Approval (Fire Protection Applications)

You may need UL or FM approval for check valves in fire protection systems. UL stands for Underwriters Laboratories, and FM means Factory Mutual. Both groups test check valves to make sure they work well in fire safety systems. If you see UL/FM approval, you know the check valve passed tough tests for fire, pressure, and reliability.

Fire protection systems must work every time. You cannot risk using a check valve that fails during an emergency. UL/FM approval means the valve will open and close as needed, even under high pressure or heat. You should always check for these markings when you buy a check valve for fire safety. This helps you protect people and property.

Note: UL/FM approval is not just for fire systems. Many water and industrial systems also use these markings to show the check valve meets high standards.

Here is a table that shows common certifications and markings for check valves in regulated industries:

| Certification/Marking | Description |

|---|---|

| CE marking | Needed for selling valves in Europe; shows compliance with safety and quality rules. |

| UL/FM approval | Required for fire protection; proves the valve passed strict safety tests. |

| ATEX certification | Ensures safety in explosive atmospheres in the EU. |

| API 607 | Tests fire safety for valves with soft seats. |

| ISO certifications | Global standards for quality and safety. |

| ASME certification | Ensures safety in high-pressure systems. |

You should always check the markings and paperwork before you install a check valve. Certifications help you know the valve will work safely and meet legal rules. If you see these markings, you can trust the check valve in your system.

Tip: Always check certifications and markings before you buy or install a check valve. This helps you avoid mistakes and keeps your system safe.

Gate Valve Standards

International Standards

ISO 10434: Bolted Bonnet Steel Gate Valves

ISO 10434 is a big rule for gate valves. It covers bolted bonnet steel gate valves used in oil and gas. This standard tells how the valve should be made and how it should work. If you pick a gate valve that follows ISO 10434, it will work well in tough places. The standard helps you get a safe and strong valve.

API 600: Steel Gate Valves—Flanged and Butt-welding Ends

API 600 is another important rule for gate valves. It is for steel gate valves with flanged and butt-welding ends. You see these valves in oil and gas pipes. API 600 tells what materials to use, how to test the valve, and how to mark it. If your gate valve has API 600 certification, it can handle high pressure and heat.

Here is a table that lists some main international standards for gate valves:

| Standard | Description | Key Focus Areas |

|---|---|---|

| API 600 | Steel gate valves for natural gas and petroleum sectors | Materials, design, marking, testing |

| ISO 10434 | Bolted bonnet steel gate valves for petroleum and natural gas | Design and performance specifications |

| ASME B16.34 | Valves in piping systems, including gate valves | Dimensions, tolerances, pressure ratings |

Tip: Always check if your gate valve follows these international standards. This helps you get a safe and long-lasting product.

American Standards

ASME B16.34: Valves—Flanged, Threaded, and Welding End

ASME B16.34 is a rule you should know. It covers many kinds of valves, including gate valves. This standard tells you how big the valve should be, what materials to use, and how much pressure it can take. If your gate valve follows ASME B16.34, it will fit well and work safely.

MSS SP-70: Cast Iron Gate Valves, Flanged and Threaded

MSS SP-70 is a rule for cast iron gate valves. It tells how to make and test these valves. You use cast iron gate valves in water and wastewater pipes. This standard helps you pick a valve that lasts long and does not leak.

AWWA C509: Resilient-Seated Gate Valves for Water Supply Service

AWWA C509 is important for water supply systems. This rule covers resilient-seated gate valves. These valves have a soft seat for tight sealing. AWWA C509 makes sure your gate valve will not leak and works well in water pipes.

European Standards

EN 1171: Industrial Valves—Cast Iron Gate Valves

EN 1171 is a European rule for cast iron gate valves. It sets rules for materials, pressure ratings, and how to test the valve. If your gate valve meets EN 1171, it will work well in water and wastewater pipes.

DIN 3352: Gate Valves for Industrial Use

DIN 3352 is another big European rule. It covers gate valves used in many places. This standard helps you pick a valve that fits your pipes and works safely under pressure.

Here is a table with some key European standards for gate valves:

| Standard | Description |

|---|---|

| EN 1074-1 | General requirements for gate valves in water supply systems |

| EN 1074-2 | Special requirements for isolating valves, including leak-tightness tests |

| EN 1171 | Specifications for ductile iron gate valves, including material and pressure ratings |

Note: Always check the markings and papers for your gate valve. Standards help you get a safe, reliable, and approved valve for your system.

Common Certifications and Markings

CE Marking (European Conformity)

When you choose a gate valve for your system in Europe, you need to look for the CE marking. This mark shows that the gate valve meets strict safety and quality rules set by European law. You can trust a gate valve with the CE marking because it has passed tests for pressure, leaks, and durability. The CE marking also means the manufacturer followed steps to make sure the gate valve is safe for people and the environment.

You will see the CE marking on the body or packaging of the gate valve. Always check for this mark before you buy or install a gate valve in a European project. If you do not see the CE marking, the gate valve may not meet legal requirements. This can cause problems during inspections or when you need to prove your system is safe.

Tip: Ask for the CE marking and check the paperwork. This helps you avoid mistakes and keeps your system safe.

Here is a quick table to help you understand what the CE marking means for gate valves:

| Marking | What It Proves | Why It Matters |

|---|---|---|

| CE Marking | Meets EU safety and quality standards | Legal use in Europe |

| Passed pressure and leak tests | Reliable performance | |

| Safe for people and environment | Fewer risks and problems |

UL/FM Approval (Fire Protection Applications)

If you need a gate valve for fire protection, you should look for UL or FM approval. UL stands for Underwriters Laboratories. FM means Factory Mutual. Both groups test gate valves to make sure they work well in fire safety systems. A gate valve with UL/FM approval will open and close as needed, even during emergencies.

You will find UL/FM markings on gate valves used in fire sprinkler systems, hydrants, and other safety equipment. These approvals show that the gate valve passed tough tests for heat, pressure, and reliability. You can trust a gate valve with these markings to protect people and property.

Note: Fire protection systems must work every time. UL/FM approval helps you feel confident that your gate valve will not fail when you need it most.

Here are some reasons why UL/FM approval is important for gate valves:

- Proves the gate valve can handle high pressure and heat.

- Shows the gate valve will work in emergencies.

- Helps you meet insurance and legal rules for fire safety.

Always check for UL/FM markings and ask for test reports. This helps you pick a gate valve that meets safety standards and works well in your system.

Remember: Certifications and markings are not just labels. They prove your gate valve is safe, reliable, and ready for use. Always verify markings and documentation before you buy or install a gate valve.

Fluid Flow Control

Flow Regulation

It is important to know how each valve controls flow. A check valve works by itself. It lets fluid move one way and stops it from going back. You do not need to use your hands to open or close it. The valve moves because of fluid pressure. This makes it quick and easy to use. But you cannot change how much fluid goes through with a check valve.

A gate valve gives you more control over flow. You turn a handle or use a machine to open or close it. When you open the gate valve, fluid moves freely. When you close it, the flow stops. You cannot use a gate valve to make small changes to flow. It is best for turning flow all the way on or off. If you try to adjust flow with a gate valve, you might break it.

Here is a table that shows how each valve controls fluid flow:

| Feature | Gate Valves | Check Valves |

|---|---|---|

| Core Function | Shut off or open fluid flow | Allow one-way flow and stop backflow |

| Operation | Manual or machine control | Automatic, works with fluid pressure |

| Flow Regulation | Cannot change flow rates | Stops backflow automatically |

| Installation Position | Can go in any direction | Must follow the flow arrow |

| Advantages | Low pressure loss, seals both ways | Stops backflow, simple design |

| Disadvantages | Slow to work, can wear out | Can cause water hammer if flow reverses |

Tip: Pick the right valve for your system. Use a check valve to stop backflow. Use a gate valve to turn flow on or off.

Efficiency

You want your system to work well and save energy. A gate valve is good for high pressure and heat. When it is open, it does not slow down fluid much. This helps your system run better. But a gate valve opens and closes slowly. It can wear out if you use it a lot.

A check valve also helps your system work well. It stops backflow without you doing anything. The simple design means fewer parts can break. The valve reacts fast to changes in flow. This keeps your system safe. Both valves can cause water hammer if flow stops or reverses quickly. You should watch for this problem.

- Gate valves work well in high-pressure systems and seal tightly.

- They open and close slowly and can wear out with lots of use.

- Check valves stop backflow by themselves and react fast.

- Their simple design makes them good for changing flow.

Note: For best results, match the valve to your system’s pressure and flow.

System Response

You want your system to react fast and stay safe. A check valve closes right away if fluid tries to go backward. It protects pumps and pipes from damage. This quick action helps keep your system safe.

A gate valve takes longer to open or close. You need to turn the handle or use a machine. This slow action can be a problem if you need quick changes. Gate valves are best when you do not need to change flow often.

- Check valves react fast to changes in flow.

- Gate valves react slowly and need manual or machine help.

- Both valves help control fluid, but they work at different speeds.

Tip: Use a check valve for quick, automatic protection. Use a gate valve for strong shutoff in high-pressure systems.

Structure and Materials

Internal Mechanisms

When you look inside a valve, you see how its parts work together. The way the inside works decides how the valve does its job. Gate valves and check valves have different designs to control fluid.

Here is a table that shows the main internal mechanisms for each valve type:

| Valve Type | Internal Mechanism | Functionality |

|---|---|---|

| Gate Valve | Movable gate or wedge that slides vertically | Starts or stops fluid flow, providing an unobstructed path when open. |

| Check Valve | Ball, swing, or lift design to allow one-way flow | Prevents backflow automatically based on flow pressure, no manual operation. |

A gate valve has a flat or wedge-shaped gate inside. You move the gate up or down to let fluid pass or stop it. When the gate is all the way up, fluid moves through easily. This design gives a clear path for liquids or gases.

A check valve works in another way. It uses a ball, a swinging disc, or a lifting part inside. When fluid goes the right way, the part moves and lets it pass. If fluid tries to go backward, the part closes and blocks the flow. You do not need to do anything. The valve works by itself.

Note: The inside design changes how fast the valve reacts and how well it seals. Always pick the right design for your system.

Materials Used

The material you choose for your valve is very important. It decides how long the valve lasts and if it can handle tough fluids. Some fluids can cause rust or damage if you use the wrong material.

For places with lots of corrosion, stainless steel is a great choice. Stainless steel 316 protects well against rust. You see it in marine, chemical, and drug factories. Stainless steel 304 is also good for food and water systems. Red brass is safe for drinking water because it does not rust and keeps water clean. Polypropylene is used in labs and chemical plants. It does not react with acids, bases, or solvents.

Here is a table to help you compare materials for corrosive settings:

| Application need | Recommended material | Key features |

|---|---|---|

| Corrosive environments | Stainless steel (316) | Enhanced corrosion resistance, ideal for marine, chemical, and pharmaceutical industries. |

| Stainless steel (304) | Good corrosion resistance for general-purpose applications like food processing and water treatment. | |

| Red brass | Higher corrosion resistance for potable water systems. | |

| Polypropylene | Resistant to acids, bases, and solvents, suitable for chemical processing and labs. |

Gate valves can also be made from bronze and copper-nickel. These metals work well with harsh fluids. You should not use carbon steel or cast iron with strong chemicals. These can rust or break down fast.

Tip: Always match the valve material to your fluid. This helps you stop leaks, rust, and early failure.

When you pick the right inside design and material, your system is safer and lasts longer. You also save money on repairs and new parts. Choosing the right valve means thinking about what flows in your pipes and how tough the place is.

Applications

Check Valve Applications

Check valves are used in many places. They help control which way fluid moves. These valves are important in pipeline systems. You use them to keep water, chemicals, and other fluids moving forward. Here are some ways check valves are used:

- Municipal water plants use check valves to keep water clean.

- Wastewater systems use check valves to stop pollution.

- Water utility networks use check valves to help treat waste.

- Fire protection systems use check valves to keep water safe.

- Swing check valves are good for water supply and pumping stations.

- Foot valves help pumps in wells and ponds work better.

- Dual disc check valves are used in chemical pipes and fire systems.

- Homes use check valves to protect pipes from backflow and pressure spikes.

Pick a check valve if you want automatic backflow protection. These valves work by themselves. They are great for places that need fast and reliable action.

Tip: Always choose the right check valve for your system. This helps stop leaks and keeps your equipment safe.

Gate Valve Applications

Gate valves help you start or stop flow in big pipes. You see them in many industries and city systems. Gate valves are used for many jobs. Here is a table that shows where gate valves are used:

| Application Type | Description |

|---|---|

| Industrial Applications | Used to isolate processes in water systems |

| Municipal Applications | Used in sewage and wastewater treatment |

| Other Applications | Used in slurry, pulp, and paper industries |

You also find gate valves in these places:

- Salt plants

- Biogas plants

- Raw water inlets

- Vacuum trucks

- Fly ash handling

- City waste plants

- Clean water and steam services

Gate valves are best for tight shutoff in pipelines. Use them when you need to fully open or close a pipe. They do not work well for changing flow rates. If you need to block off a pipe for repairs, use a gate valve.

Note: Use gate valves for high-pressure systems and strong isolation. Do not use them to adjust flow.

When you look at check valves and gate valves, you see they have different jobs. Use check valves for automatic backflow protection. Use gate valves for strong shutoff and isolation in big pipes.

Installation and Maintenance

Installation

You need to install valves the right way to keep your system safe and working well. Start by checking the valve type and size. Make sure the valve matches your pipe and fluid. Look for arrows on check valves. These arrows show you the correct flow direction. Gate valves do not have arrows, so you can install them in either direction.

Follow these steps for a smooth installation:

- Clean the pipe ends before you start.

- Place the valve between the flanges or connect it to the threaded ends.

- Tighten the bolts or threads evenly. Do not overtighten.

- Check for leaks after you finish.

Tip: Always use the right tools. A torque wrench helps you avoid damaging the valve.

You should read the manufacturer’s instructions. Some valves need special gaskets or supports. If you install a valve upside down, it may not work. Double-check the markings before you finish.

Maintenance

Regular maintenance keeps your valves working longer. You should inspect valves every few months. Look for signs of rust, leaks, or wear. Clean the valve body and moving parts. Lubricate the stem on gate valves. This helps the gate move smoothly.

Here is a simple checklist for valve maintenance:

- Check for leaks around the valve.

- Clean dirt and debris from the valve body.

- Lubricate moving parts if needed.

- Test the valve by opening and closing it.

- Replace worn seals or gaskets.

You can prevent big problems by fixing small issues early. If you see rust or damage, replace the valve right away. Always keep spare parts on hand.

Note: Maintenance saves you money. A well-kept valve lasts longer and works better.

Common Issues

Valves can have problems if you do not install or maintain them well. You may see leaks, stuck gates, or noisy operation. Check valves sometimes cause water hammer. This happens when the valve closes too fast. Gate valves may get stuck if you do not lubricate the stem.

Here is a table of common issues and how you can fix them:

| Problem | Cause | Solution |

|---|---|---|

| Leak | Loose bolts or worn gasket | Tighten bolts, replace gasket |

| Stuck gate | Rust or dirt on stem | Clean and lubricate stem |

| Water hammer | Fast closing check valve | Use slow-closing check valve |

| Noise | Debris inside valve | Clean valve body |

| Backflow | Wrong check valve direction | Reinstall valve correctly |

If you fix problems early, you keep your system safe and avoid costly repairs.

You should always follow a regular inspection plan. This helps you spot trouble before it gets worse. If you need help, ask a valve expert or read the manufacturer’s guide.

Cost and Reliability

Initial Cost

When you choose a valve, you often look at the price first. Check valves usually cost less than gate valves. The design of a check valve is simple. You do not need many moving parts. This makes the price lower. Gate valves have more parts and a bigger body. You pay more for these features.

Here is a table to help you compare the typical costs:

| Valve Type | Average Initial Cost | Why the Cost Differs |

|---|---|---|

| Check Valve | Lower | Fewer parts, simple design |

| Gate Valve | Higher | More parts, larger size, heavy-duty |

You might find that small check valves are very affordable. Large gate valves for big pipes can cost much more. If you need many valves for a project, the price difference adds up fast.

Tip: Always check the total cost, including installation and any special features you need.

Lifespan

You want your valves to last a long time. Both check valves and gate valves can last for years if you pick the right material and take care of them. The lifespan depends on how often you use the valve, what flows through it, and how well you maintain it.

- Check valves often last 5 to 10 years in normal water systems. If you use them with clean fluids and check them often, they can last even longer.

- Gate valves can last 10 to 20 years or more. They are strong and handle tough jobs. If you use them in dirty or rough systems, they may wear out faster.

You should always follow a maintenance plan. Clean the valves and check for leaks. Replace worn parts before they fail.

Note: The right material makes a big difference. Stainless steel and brass last longer than iron or plastic.

Reliability

Reliability means you can trust the valve to work when you need it. Check valves work by themselves. They react fast to changes in flow. You do not need to control them. This makes them very reliable for stopping backflow.

Gate valves give you strong shutoff. You control when they open or close. They work well in high-pressure systems. If you use them the right way, they rarely fail.

Here are some points to help you judge reliability:

- Check valves: Great for automatic backflow protection. Simple design means fewer things can break.

- Gate valves: Best for full shutoff. Strong and safe in big pipelines.

If you want less maintenance and fast action, choose a check valve. If you need tight shutoff and control, pick a gate valve.

You should always match the valve to your system. The right choice gives you safe, reliable service for years.

Choosing the Right Valve

Decision Factors

When you choose a valve, you need to look at your system and what it needs. Start by thinking about the main job you want the valve to do. Do you need to stop backflow, or do you want to turn flow on and off? You should also check the pressure in your pipes. Some valves work better with high pressure, while others fit low or changing pressure.

Here are some important things to consider:

- Purpose: Decide if you need to prevent backflow or control flow.

- Pressure: Check the pressure range in your system.

- Flow Direction: Know if your system needs one-way or two-way flow.

- Fluid Type: Think about what kind of liquid or gas will move through the valve.

- Maintenance: Ask yourself how often you can check or fix the valve.

- Space: Make sure you have enough room to install and operate the valve.

Tip: Always read the manufacturer’s guide. It helps you match the valve to your system.

You now understand the key differences in the check valve vs gate valve debate. Check valves stop backflow and work automatically. Gate valves let you start or stop flow with strong shutoff. If you need quick protection from reverse flow, choose a check valve. For full control in high-pressure pipes, pick a gate valve. Always match your valve to your system’s needs and check standards before you buy.

FAQ

What is the main difference between a check valve and a gate valve?

You use a check valve to stop fluid from flowing backward. You use a gate valve to turn flow on or off. Check valves work automatically. Gate valves need you to open or close them.

Can you use a gate valve for backflow prevention?

You should not use a gate valve for backflow prevention. Gate valves do not close by themselves if flow reverses. You need a check valve to stop backflow.

Where do you install a check valve in a water system?

You install a check valve after a pump or at the outlet of a tank. This keeps water moving in one direction and protects your equipment.

How do you know which valve to choose for high-pressure systems?

You pick a gate valve for high-pressure systems. Gate valves handle strong pressure and give you tight shutoff. Check valves work best for changing flow and backflow protection.

Do check valves need regular maintenance?

You need to check your check valves often. Look for leaks, noise, or stuck parts. Clean and replace worn pieces to keep your system safe.

Can you install a gate valve in any direction?

You can install a gate valve in either direction. The valve works the same way no matter which way fluid flows.

What materials work best for corrosive fluids?

You should use stainless steel or polypropylene for corrosive fluids. These materials resist rust and damage, keeping your valve working longer.

How do you prevent water hammer with check valves?

You use a slow-closing check valve to prevent water hammer. This type closes gently and stops shock waves in your pipes.