Understanding the control valve Cv is a critical skill for engineers working with steam systems. It determines flow capacity and plays a key role in sizing and selecting components such as the Steam Control Valve and steam flow control valve. Accurate Cv calculations ensure optimal performance in applications like steam pressure reducing valves and steam pressure regulating valves, where maintaining precise flow is essential. This practical guide simplifies the process of determining Cv for steam systems, helping engineers optimize performance, reduce energy waste, and enhance system reliability. By mastering these calculations, you’ll be equipped to design and maintain steam systems that meet stringent performance and efficiency standards, ensuring success across diverse industrial applications.

Introduction to Control Valve Cv

The control valve Cv is a fundamental parameter in the design and optimization of steam systems, as it defines the flow capacity of the valve under specific conditions. This measurement is essential for pressure regulating valve manufacturers to ensure their products meet precise system requirements. Whether applied in a temperature regulating valve, a Pneumatic diaphragm control valve, or a Pneumatic globe valve, accurately determining Cv allows engineers to select components that align with the system’s operational demands. By understanding Cv, engineers can effectively optimize valve performance, ensuring reliable flow control, enhanced system efficiency, and compliance with industry standards. Mastering this concept is key to achieving precision in steam control applications across diverse industrial settings.

Define “control valve Cv” and explain its role in determining valve sizing and performance.

The control valve Cv is a key measure of a valve’s flow capacity, representing the volume of fluid (in gallons per minute) that can pass through the valve with a one-pound pressure drop. For steam systems, accurately determining Cv is essential for proper valve sizing and achieving optimal performance. It helps engineers select valves capable of meeting the system’s specific flow and pressure requirements, ensuring efficiency and reliability. Whether designing a new system or improving an existing one, understanding Cv allows for precise control of steam flow, contributing to energy savings, operational stability, and enhanced system functionality.

Overview of why Cv is critical for engineers working with steam systems.

For engineers working with steam systems, understanding Cv is paramount to maintaining efficiency, reliability, and energy optimization. Cv, or flow coefficient, defines how much steam a valve can regulate and directly impacts valve sizing and selection. A well-calculated Cv ensures precise steam flow control, minimizing pressure drops, and optimizing energy usage. Missteps in determining Cv can lead to underperforming systems, unexpected failures, or energy waste. Engineers rely on this critical parameter to design systems that meet operational demands while adhering to performance standards. Mastering Cv empowers engineers to ensure smooth operation, extend equipment lifespan, and achieve cost-effective solutions in steam applications.

Importance of Cv in Control Valves

The importance of Cv in control valves cannot be overstated when working with steam systems. Cv, or flow coefficient, determines a valve’s ability to control and regulate steam flow under specific conditions. This parameter is pivotal in ensuring the valve performs as intended, maintaining system pressure and flow rates. Properly calculated Cv allows engineers to achieve optimal system efficiency, minimize energy loss, and ensure consistent operational reliability. Without an accurate Cv, steam systems risk inefficiencies, operational instability, and increased maintenance costs. Engineers depend on Cv to design control valves that meet application-specific demands while contributing to overall system performance and longevity.

Understanding the Basics of Control Valve Cv

Control valve Cv represents the flow coefficient, a measure of the valve’s capacity to allow fluid to pass through under specific conditions. It is expressed as the volume of fluid, typically in gallons per minute, that flows with a one-pound pressure drop across the valve. For steam systems, understanding Cv is fundamental in designing and operating effective and reliable setups. It ensures proper valve selection and sizing, meeting precise flow and pressure requirements. By mastering the basics of Cv, engineers can optimize steam system performance, minimize energy losses, and maintain stable operations across a wide range of industrial applications.

Steps to Calculate Control Valve Cv for Steam Systems

Calculating control valve Cv for steam systems involves several essential steps. First, determine the steam flow rate and operating conditions, including inlet and outlet pressures and temperature. Next, calculate the pressure drop across the valve, as Cv is directly tied to flow and pressure differential. Use the steam flow formula to link flow rate, pressure drop, and Cv, factoring in key details like the valve’s intended operating range. It’s critical to consider the steam’s specific properties, such as density and enthalpy, which vary with temperature and pressure. Lastly, confirm the calculated Cv aligns with operational requirements for efficiency and reliability.

Common Challenges in Measuring Control Valve Cv

Accurately measuring control valve Cv for steam systems presents several challenges. One common issue is inaccuracies in flow measurement, which can arise due to improper instrumentation or fluctuating operating conditions. Estimating the pressure drop across the valve is another hurdle, often complicated by system variability and transient states. Additionally, steam properties like density and enthalpy significantly influence Cv calculations, as these factors shift with changes in temperature and pressure. Neglecting these variations can lead to incorrect Cv values, resulting in misaligned valve sizing and compromised performance. Engineers must address these complexities to ensure precise Cv determination and optimal system functionality.

Practical Applications of Control Valve Cv in Steam Systems

Control valve Cv is a critical parameter in numerous practical applications within steam systems. Engineers rely on Cv to accurately size and select valves that optimize steam flow under varying load conditions. This ensures systems meet operational demands without excessive pressure drops or energy losses. For example, in power generation, Cv plays a key role in maintaining precise steam distribution for turbines. Similarly, in industrial heating or production processes, Cv enables consistent temperature and pressure control, safeguarding both equipment and product quality. By integrating Cv into system design and operation, engineers enhance efficiency, reduce downtime, and achieve reliable, cost-effective performance.

Choosing the Right Control Valve Based on Cv

Selecting the right control valve based on Cv is essential for achieving optimal performance in steam systems. Cv directly influences valve sizing, ensuring it aligns with the required flow rate and pressure drop for a given application. Engineers must evaluate several factors, including operating conditions, steam properties, and system load fluctuations, to match the valve’s Cv with actual flow requirements. Choosing an incorrect Cv can lead to either underperforming systems or energy inefficiencies. Additionally, the valve’s material, design, and operational range should complement the Cv value to maintain system reliability, reduce wear, and maximize efficiency in demanding industrial environments.

How to interpret Cv results to select a compatible control valve.

Interpreting Cv results is critical for selecting a compatible control valve that meets specific system requirements. The Cv value represents the valve’s capacity to handle a given flow rate with a defined pressure drop, making it a key metric for performance optimization. Engineers must compare calculated Cv values to the valve’s operational range to ensure accurate flow control across varying conditions. It’s essential to align Cv with factors like system load, steam properties, and required precision to avoid oversizing or undersizing the valve. Proper interpretation of Cv results ensures efficient energy use, smooth operation, and long-term system reliability in industrial applications.

Discuss features to consider for steam-specific valves.

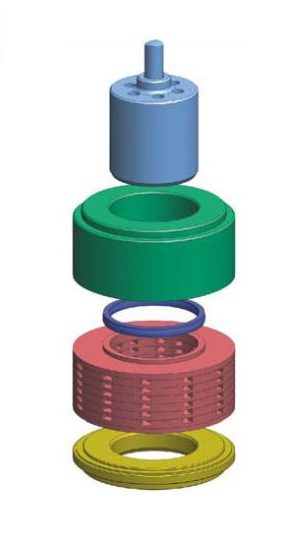

When selecting steam-specific valves, several critical features must be considered to ensure efficient and reliable operation. Material compatibility is paramount, as the valve must withstand high temperatures, pressure variations, and corrosive elements present in steam systems. Temperature and pressure ratings must align with the system’s operating conditions to maintain safety and performance. Additionally, valve design, including leak-tight seals, anti-cavitation features, and precise modulating control, is crucial to handle the unique challenges of steam flow. Engineers should also prioritize thermal expansion tolerance and minimize wear to enhance durability and system efficiency. Choosing the right features optimizes valve reliability in demanding steam applications.

Best Practices and Recommendations

Accurately calculating Cv for steam control valves requires adherence to best practices to ensure optimal performance. Engineers should begin by employing precise instrumentation for flow and pressure measurements, minimizing errors caused by fluctuating conditions. Thorough data analysis is crucial; consider variables such as steam temperature, pressure, and load changes to determine realistic Cv values. Selecting standard conditions for measurement ensures consistency and facilitates comparison. It’s also vital to account for system-specific characteristics, such as piping configuration and process dynamics, to align Cv calculations with operational needs. Implementing these practices ensures reliable valve sizing, energy efficiency, and long-term system effectiveness.

Provide tips for ensuring accurate Cv calculations.

Ensuring accurate Cv calculations for steam control valves demands meticulous attention to data collection and measurement techniques. Begin by using calibrated instruments to measure flow rate, pressure, and temperature under stable operating conditions, reducing errors caused by fluctuations. Verify that measurements are taken close to actual system operating points to improve relevance. Account for system variables such as pressure losses in piping, steam density changes, and load variations to refine calculations. Cross-check collected data against established standards to verify consistency and reliability. By adhering to these practices, engineers achieve precise Cv values, resulting in better valve selection and system performance.

Recommend tools and software for Cv calculations.

To streamline Cv calculations for steam control valves, engineers should leverage specialized software and tools designed for precision and efficiency. Software such as valve sizing programs provided by leading manufacturers or platforms like PIPE-FLO and ProSim offer advanced capabilities for analyzing flow characteristics and system dynamics. These tools enable quick input of system variables such as pressure, flow rate, and temperature for accurate Cv determination. Additionally, they provide simulation features to model changes in operating conditions, ensuring the selected valve performs reliably. Incorporating these resources not only saves time but also enhances the accuracy and reliability of system optimization efforts.

Highlight the importance of regular reviews and audits in steam control systems.

Regular reviews and audits are essential for maintaining the efficiency, safety, and reliability of steam control systems. By routinely assessing system performance, engineers can identify issues such as valve wear, improper sizing, or inadequate Cv values that may compromise operations. These evaluations ensure the system operates within its design parameters, minimizing energy losses and preventing costly downtime. Regular audits also enhance safety by uncovering potential risks from pressure imbalances or material fatigue. Additionally, they provide valuable data for optimizing performance, contributing to long-term sustainability. Incorporating systematic reviews into maintenance schedules significantly improves system reliability and reduces unexpected operational disruptions.

Frequently Asked Questions (FAQ) on Control Valve

Q1: What considerations should engineers keep in mind when calculating the control valve Cv for an electric globe valve in steam systems?

A: When calculating the control valve Cv for an electric globe valve, engineers must consider the valve’s flow coefficient under specific operating conditions, including pressure, flow rate, and temperature. Compatibility with the steam environment is crucial, as the electric globe valve must handle high temperatures and pressures. Additionally, performance factors like precise modulation and thermal expansion tolerance are critical to ensure reliable and efficient operation in steam control applications.

Q2: How does the control valve Cv differ for pneumatic control valves compared to electric control valves in steam applications?

A: The control valve Cv for pneumatic control valves and electric control valves in steam applications reflects their respective performance characteristics. Pneumatic control valves are known for their responsiveness and adaptability, particularly in systems requiring frequent adjustments. On the other hand, electric control valves offer precise control and are suited for automated and energy-conscious operations. Engineers must calculate the Cv accurately for both types, factoring in differences in actuation speed, system dynamics, and operating conditions to optimize performance.

Q3: What role does accurate control valve Cv calculation play in selecting an electric control valve for steam control systems?

A: Accurate control valve Cv calculation is essential when selecting an electric control valve for steam control systems. The calculated Cv ensures that the valve can handle the desired flow rate while maintaining efficiency under varying temperature and pressure. A well-matched Cv prevents operational issues like pressure drops or improper flow control, leading to improved system reliability and reduced energy costs. Electric control valves rely on precise Cv values to deliver optimal performance in complex and automated setups typically found in modern steam environments.

Conclusion control valve cv

Accurately calculating the control valve Cv is vital for optimizing steam system performance and ensuring long-term efficiency. Whether working with a self-operated pressure regulating valve, a self-operated regulating valve, or a self-operated control valve, precise Cv values are necessary to match the valve’s capabilities with the system’s operational needs. Proper calculations reduce energy losses, enhance reliability, and prevent costly downtime. This guide equips engineers with the tools and methodologies to achieve accurate Cv determinations, empowering them to make informed decisions during valve selection and system design. By prioritizing precision, engineers can improve system functionality and maintain consistent performance across varying conditions.