A bulk material valve allows you to control the flow of dry bulk materials such as powders, pellets, and granules in industrial settings. Unlike valves designed for liquids or gases, bulk material valves feature large openings and specialized shapes to prevent material from getting stuck or jammed. These valves can be used to stop, measure, move, feed, or discharge bulk materials efficiently. For instance, a bulk bag valve in a packaging line enables the safe and rapid release of dry bulk material.

Bulk material valves come in various types, including electric ball valves and pneumatic ball valves, which provide reliable actuation options. Pneumatic control valves are also commonly used to manage the flow of bulk solids with precision and responsiveness.

| Aspect | Bulk Material Valves | Liquid/Gas Valves |

|---|---|---|

| Flow Characteristics | Handles solids, prevents jamming and packing | Controls steady liquid or gas flow |

| Design Features | Large openings, round or dome shapes, no pinch points | Regular closures for sealing fluids |

| Actuation | Larger sizes, options include pneumatic ball valve and electric ball valve | Standard actuator sizes |

Key Takeaways

- Bulk material valves help control how powders, pellets, and granules move. They do this safely and efficiently in factories.

- There are different valve types like rotary, slide gate, bulk bag, and ball segment valves. Each type does a special job like controlling flow, measuring, stopping, or changing direction.

- You must pick the right valve for your material’s size, roughness, and wetness. You also need to think about your system’s pressure and temperature.

- Strong seals and tough parts stop leaks and lower dust. This helps the valve last longer and keeps your workplace safe and clean.

- Automated valves give better control and less waste. They make things safer by letting you change settings quickly and exactly.

- You should check, clean, and take care of valves often. This stops expensive problems and keeps your system working well.

- Do not make mistakes like picking the wrong size, ignoring flow direction, or using bad seals. These things help your valve work right.

- Valves for food, chemical, or medicine use must follow strict rules. This keeps products safe and meets important laws.

Bulk Material Valve Functions

Flow Control

Bulk material valves help move dry bulk material in a system. They let you start, stop, or change the flow of powders, pellets, or granules. Flow control is important for safety and efficiency. When you need to move bulk materials, a valve gives you control. You can open or close the valve to let material go through or stop it. Some valves, like butterfly or rotary valves, let you adjust how fast the material moves. Using the right valve helps prevent spills and saves time. For example, in a food plant, a rotary valve can control how much flour goes from storage to a mixer. This keeps things steady and stops waste.

- Open or close a valve to control material flow.

- Butterfly and rotary valves help you set the flow rate.

- The right valve stops overflows and cuts down on delays.

Metering and Feeding

Bulk material valves are important for metering and feeding dry bulk material. You need to control how much material goes into or out of a process. Metering means you set the amount of material over time. Feeding means you send material at a steady speed. Volumetric feeders, like rotary airlock valves, are usually accurate within 1% to 5%. This is good when you do not need super tight control. Gravimetric feeders, like loss-in-weight systems, can be accurate from 0.25% to 1%. These systems weigh the material as it moves, so you get better results. Sensors and quick response help keep your process correct, even with slow flows. These valves are used in chemical and drug factories, where you must add exact amounts. The right bulk valve helps you avoid mistakes and keeps your product good.

Tip: Pick a bulk material valve with the right accuracy. This saves material and makes your process better.

Shut-Off and Isolation

Bulk material valves are used to shut off and isolate parts of your system. This is important for safety, repairs, and control. If you need to stop the flow fast, a shut-off valve helps you do that. You can close off equipment for cleaning or fixing without stopping everything. Shut-off valves help stop spills, keep things clean, and prevent accidents. In emergencies, these valves protect people and machines.

| Safety Standard / Certification | Relevance to Shut-off and Isolation Valves in Bulk Material Handling |

|---|---|

| IEC 61508 / IEC 61511 | These are important rules for safety systems. They make sure emergency shutdown valves work right for shut-off and isolation. |

| SIL 3 Certification | Valves with this rating are very reliable for emergency shutoff. |

| Fire Safety Certification | This shows valves work even during fires, which is important for emergency isolation. |

| Fugitive Emission Compliance | This means valves leak less dangerous stuff, which is safer for people and the environment. |

| Pneumatic Actuators and Intelligent Safety Solenoids | These parts are made to meet safety rules and help emergency shutdown valves work well. |

| Intelligent Valve Controllers (e.g., Neles? ValvGuard?) | These give tests and checks to keep valves working and safe. |

Always make sure your bulk valves meet the right safety rules for your job. This keeps your system safe and working well.

Diverting and Routing

Sometimes you need to send dry materials to different spots. Bulk valves work like traffic lights for your bulk materials. Diverter valves let you send powders, pellets, or granules to more than one place. You do not have to stop your process. This keeps things moving and saves time.

Diverter valves help you control where your materials go. You can change routes fast. This helps stop mixing and leaking. In a pneumatic conveying system, an inflatable seal diverter makes a tight path. This stops material from leaking out and keeps things clean. Clean flow diverters have smooth shapes. This stops material from getting stuck. It is easier to clean and you have less downtime. This is very important in food and drug factories.

A swing ball diverter valve uses a moving ball to send bulk solids to different places. A pneumatic cylinder moves the ball. This gives you quick and smooth changes. Proximity switches let you watch the valve as it works. This makes things safer and easier to control. These bulk valves are strong. They can handle rough or sharp materials. You do not need to fix them often and they work well.

Tip: Use diverter bulk valves to keep your process flexible. You can send materials to different places without stopping the system.

Preventing Leakage

It is very important to keep bulk materials inside the system. Bulk valves use special designs to stop leaks and keep your workplace safe. If you work with powders or fine granules, even a small leak can cause dust, waste, or safety problems.

Many bulk valves use wear-compensating bonnet seals. These seals use hard polymer and rubber to press tightly against moving parts. This keeps material from escaping and holds dust inside. Some valves have liners you can replace. These are made from tough steel or special polymers. Liners protect the inside of the valve from wearing out. This helps the valve last longer.

Some bulk valves have recessed blade edges. This design keeps seals safe from the flow of material. It helps stop leaks, mixing, and dust. Removable panels let you check and fix seals without taking the valve out. This saves time and cuts down on downtime.

Some bulk valves, like roller gates and slide gates, clean themselves and have dust-tight seals. Stainless steel parts help stop rust and keep your product clean. Diverter valves, like Wye Line Diverters, can clean out lines between batches. This stops leaks and mixing, which is very important in food and chemical plants.

- Wear-compensating seals keep dust and material inside.

- Replaceable liners protect against wear from rough bulk materials.

- Recessed blades and self-cleaning features improve sealing and reduce leaks.

- Removable panels make maintenance easy and fast.

Note: Pick bulk valves with strong seals and liners. This helps you avoid leaks, keep your product safe, and spend less time cleaning.

Types of Bulk Material Valves

Rotary Valves

Rotary valves are important in moving bulk materials. You use them to move powders, pellets, or granules from one place to another. The rotary valve has a spinning rotor with pockets. These pockets hold the material and move it from the inlet to the outlet. This design lets you control how much material moves. It also keeps different parts of the system apart. The rotor fits tightly in the housing. This helps stop leaks and keeps air or material inside. Rotary valves can also work as airlocks. This is helpful if you need to keep pressure different in two areas.

Applications

You see rotary valves used for these jobs:

- Metering dry bulk material into pneumatic lines.

- Feeding powders into mixers or reactors.

- Acting as airlocks in dust collection systems.

- Handling rough or sticky materials with special rotors.

Advantages

Rotary valves have many good points:

- Give steady and accurate flow control.

- Work as feeders and airlocks at the same time.

- Handle many types of materials, even rough or sticky ones.

- Can be made with special rotors or pockets to help flow and stop jams.

- Can be used by hand or with machines, but pneumatic ones are best for lots of use.

Tip: Pick a rotary valve if you need exact flow and pressure control in your system.

Slide Gate Valves

Slide gate valves make it easy to start or stop bulk material flow. You move a flat blade over an opening to control the flow. This valve works well in gravity-fed systems. It can handle many kinds of dry materials. There are many designs for different jobs and industries.

Applications

Here is a table that shows where slide gate valves are used:

| Application Type | Size Range | Conveyance Type | Typical Use Case Description |

|---|---|---|---|

| Handslide Gate | 2-14″ (50-355mm) | Gravity Flow | Controls flow at hoppers, bins, or totes. |

| Rounded Blade Gate | 6-24″ (150-610mm) | Gravity Flow | Used above storage bins to meter flow and hold back large material heads. |

| Titan Maintenance Gate | 6-20″ (150-510mm) | Gravity Flow | Shuts off abrasive material during maintenance. |

| Quick Clean Gate | 2-10″ (50-255mm) | Gravity Flow | Used for sanitary handling with frequent cleaning. |

| Clear Action Gate | 6-16″ (150-400mm) | Gravity/Pneumatic | Isolates rotary airlocks from feeders. |

| Titan Pressure Valve | 2-12″ (50-305mm) | Gravity/Pneumatic | Handles high temperature/pressure abrasive solids. |

| Aggregate Gate | 6-24″ (150-610mm) | Gravity Flow | Handles large, abrasive solids. |

| Roller Gate | 6-30″ (150-760mm) | Gravity Flow | Used above/below hoppers, silos, mixers, and conveyors. |

| Orifice Gate | 2-16″ (50-400mm) | Gravity/Pneumatic | Handles dry solids in gravity or low-pressure pneumatic systems. |

Slide gate valves are used in food, cement, mining, chemical, and plastic plants.

Advantages

Slide gate valves have these benefits:

- Shut off flow fast for safety or repairs.

- Are easy to use by hand, air, or electricity.

- Are simple to clean, especially quick-clean types.

- Can work with many materials and system shapes.

Note: Slide gate valves are great when you need fast shut-off and easy cleaning.

Bulk Bag Valves

Bulk bag valves help you empty material from big bags safely. You use them to control the flow of powders or granules from a bag into your system. The right valve keeps dust and spills low. This makes your workplace safer and cleaner.

Applications

Bulk bag valves are used for:

- Emptying powders, pellets, or granules from big bags into hoppers or conveyors.

- Handling materials that clump, like flour or plastic pellets.

- Cutting down dust and spills when emptying bags in food, chemical, or drug plants.

Advantages

Bulk bag valves give you these good things:

- Let you control flow slowly and carefully, so there is less dust.

- Use tight seals and special closures, like iris or petal valves, to stop leaks and jams.

- Make work safer with easy-to-use and changeable designs.

- Fit many plant layouts and material types, so they are useful in many places.

Tip: Use a bulk bag valve with tight seals to keep your area clean and your workers safe.

Ball Segment Valves

Ball segment valves help control tough materials. They work well with hot or rough powders, slurries, and granules. These valves are used when regular valves wear out too fast. Their special shape stops clogging and keeps things moving.

Applications

Ball segment valves are used for hard jobs. You see them in these places:

- Moving rough powders in cement or mining plants.

- Controlling slurries in chemical or water systems.

- Handling hot flows in steel or glass factories.

- Working with harsh chemicals in processing plants.

These valves handle pressure changes and even full vacuum. You can use them for both dry solids and liquids.

Advantages

Ball segment valves have many good points:

- They work in heat from 200°C to 600°C.

- Strong metals stop damage from rough or harsh stuff.

- Their small shape means less material gets stuck.

- Big openings help stop wear and breaking.

- No extra space inside, so you get good control.

- One seat keeps leaks and old fluid away.

- The open design stops jams, even with sticky stuff.

Tip: Pick ball segment valves for hot or rough materials. You will have less trouble and better control.

Locking Valves

Locking valves keep your system safe and locked. You use them when you need to stop flow for repairs or safety. The lock stops anyone from opening the valve by mistake.

Applications

Locking valves are used where safety is very important:

- Closing off machines for cleaning or fixing.

- Stopping flow in chemical plants to avoid spills.

- Locking lines in food plants to stop mixing.

- Keeping workers safe in mining or bulk systems.

These valves are good when only certain people should open or close them.

Advantages

Locking valves give you safety and control:

- Stop mistakes during repairs.

- Help you follow safety rules.

- Easy to use with locks or lockout tools.

- Lower the chance of spills or mixing.

- Make the workplace safer for everyone.

Note: Use locking valves to control who can open the valve and keep things safe.

Butterfly Valves

Butterfly valves are liked because they are small and cheap. You use them when you do not have much space or money. The disc turns in the flow to open or close the valve.

Applications

Butterfly valves work best with liquids, gases, or slurries. You find them in:

- Water plants.

- Chemical systems.

- Air and heating units.

- Some bulk systems with gentle flow.

Do not use butterfly valves for dry solids. The disc can block flow and get worn by rough stuff.

Advantages

Butterfly valves have some good sides:

- They are light and fit in small spots.

- They cost less for big jobs.

- They open and close fast and are easy to use.

- They are good for low pressure and soft flows.

But butterfly valves do not work well with dry solids. Soft seals can wear out and leak. Rough materials can break the seals and disc.

Tip: Use butterfly valves for liquids or gases, not for rough dry solids. This way, your valves last longer and work better.

How Bulk Valves Work

Operating Mechanisms

Bulk valves use different ways to control dry bulk material. Each valve type moves in its own way. This helps handle powders, pellets, or granules. The table below shows how each mechanism works and what it does:

| Valve Type | Operating Mechanism | Impact on Performance and Application |

|---|---|---|

| Ball Valves | Quarter-turn with a hollow sphere | Good for stopping or adjusting flow; works well in high-pressure jobs. |

| Butterfly Valves | Rotating flat disk or flap | Fast flow control; small and affordable; not for high pressure. |

| Check Valves | Uses pressure difference to allow one-way flow | Stops reverse flow and keeps your system safe from damage. |

| Plug Valves | Rotating plug with a hole | Common in air and heating systems; controls flow by turning. |

| Gate Valves | Moves a gate up or down | Best for fully open or closed; not for adjusting flow. |

| Globe Valves | Raises or lowers a disc | Can adjust flow; more flexible than gate valves. |

Pick the right mechanism for your dry bulk material. Think about how you want to control the flow. Rotary valves are good for steady feeding. Slide gate valves are best for quick shut-off.

Manual vs. Automated Control

You can use your hand or machines to run bulk valves. Manual control means you turn or move the valve yourself. This is fine for simple jobs or when you do not need fast changes. But using your hands can cause mistakes or slow things down.

Automated control uses motors, air, or electric parts. You can press buttons or use computers to control the flow. This makes things faster and more exact. You waste less material and keep people safer. Automated bulk valves also help stop injuries and save on work costs. You can link these valves to plant computers. This lets you watch and track your system as it works. It helps keep your process safe and smooth.

Note: Automated bulk valves cost more at first, but you save money and make things safer later.

Design Features

Open-Body Configurations

Open-body designs help bulk valves move dry material without clogging. These valves have big, smooth openings. This lets material pass through easily. You will see fewer jams and less buildup. Open-body bulk valves are also easier to clean. You can reach inside to clear stuck material or check for damage.

- Big openings stop blockages.

- Smooth surfaces help material move.

- Easy to clean and check inside.

Sealing and Wear Resistance

Bulk valves need strong seals and tough parts to last. Tight seals, like gates and gaskets, stop leaks and keep dust in. Many bulk valves use hard metals or special plastics. These stand up to rough or heavy dry bulk material. Some valves have self-cleaning parts that wipe away buildup as they move. This means less fixing and keeps your system working well.

- Tight seals stop leaks and protect your product.

- Tough materials handle rough or heavy bulk material.

- Self-cleaning parts mean less downtime and fixing.

Tip: Choose bulk valves with strong seals and tough parts. This helps them last longer and work better.

Bulk Material Handling Applications

Storage and Discharge

Bulk material handling often begins with storage and discharge. You need to control how dry bulk material leaves silos, hoppers, or bins. Bulk material valves help you do this safely and quickly. These valves let you release powders, pellets, or granules from the bottom of a silo. This helps you manage flow and stop blockages. Valves also help discharge dust from cyclones or baghouse dust collectors. This keeps your system clean and cuts down on downtime.

Here are some common ways bulk material valves are used for storage and discharge:

- Control flow at the cone bottom to discharge dry bulk solids from silos.

- Separate dust particles from air streams to release them from cyclones.

- Discharge dust from baghouse collectors, which means less manual work.

- Feed and discharge bulk solids into mills, hoppers, and conveyors with steady flow.

- Feed pneumatic conveying systems and keep air from leaking out.

- Handle large bulk solids like chickpeas or hazelnuts in a safe way.

You can see how different valves work for these jobs in the table below:

| Valve Type | Main Use in Storage and Discharge Systems | Industries Served | Key Benefits |

|---|---|---|---|

| Iris Valves | Precise flow control, dosing, handling powders and fibrous substances | Pharmaceuticals, chemicals, construction | Adjustable, tight seal, fits many bag sizes |

| Butterfly Valves | Metering, batching, transferring bulk materials | Agriculture, mining, food processing | Quick, compact, needs little maintenance |

| Cone Valve Systems | Controlled discharge of tough materials, breaking bridges, handling dense materials | Chemicals, minerals, food, pharma | Self-cleaning, durable, tight pressurized seal |

These valves help keep material inside, cut down on waste, and make things safer.

Transfer and Conveying

You need to move dry bulk material from one part of your system to another. Bulk material handling uses valves to control this transfer. Rotary valves can feed powders into a pneumatic conveying line. These valves keep flow steady and stop air leaks. Slide gate valves can start or stop flow when you need. This helps you avoid spills and keeps your process smooth.

Valves also help direct bulk materials to different conveyors or equipment. Diverter valves send material to the right place without stopping your system. This saves time and makes things more efficient. If you handle rough or sticky materials, you can use special valves that resist wear and clogging.

Tip: Pick the right valve for your transfer system. This helps you avoid jams and keeps your dry bulk material moving.

Packaging and Filling

Many bulk material handling processes end with packaging and filling. Bulk material valves are important here. You use them in automated filling machines to load dry bulk material into bags, boxes, or containers. These valves help fill containers fast and accurately. They also keep dust inside, which makes your workplace safer and cleaner.

Valve bags and filling machines use special designs to seal bags while filling. This stops dust from escaping and keeps your product clean. You can use auger, impeller, air, gravity, or vacuum systems to fill bags based on your product type. Advanced sealing methods, like ultrasonic sealing, protect your product from air and moisture. This makes packages stronger and easier to stack or move.

Bulk material valves in packaging systems help you:

- Fill containers faster and more accurately.

- Cut down on dust and contamination.

- Keep your product safe during storage and transport.

- Lower manual work and make things safer.

You get more value when you use the right valves in your packaging and filling operations.

Industry Examples

Bulk material handling is important in many industries. Each industry uses different valves and systems. These valves help move, control, and protect dry bulk materials. Let’s see how bulk material valves work in four big industries.

Food Processing

Food must stay safe and clean. In food processing, you handle flour, sugar, salt, and other powders. You use butterfly valves, cone valve systems, and spout top and bottom valves. These valves guide bulk flows in pipes or air lines. You can control how much goes into mixers or packaging machines. Stainless steel and food-grade seals keep food from getting dirty. Some valves empty bags all the way, so you do not waste ingredients.

Tip: Pick valves that are easy to clean. This helps you follow hygiene rules and avoid recalls.

Chemical and Pharmaceutical

You handle powders that can be sticky, rough, or dangerous. Chemical and pharmaceutical plants use iris valves, cone valve systems, and spout valves. These valves help you measure and mix materials exactly. You can control how fast material leaves and make sure bags are emptied well. Some valves have inflatable seals or ceramic linings. These features help with tough powders and stop leaks. Some valves work with purge gas units to keep powders from settling.

Here is a table that shows common valve types and uses:

| Industry | Common Valve Types | Typical Uses |

|---|---|---|

| Pharmaceutical | Iris, cone, spout valves | Exact dosing, clean discharge, little waste |

| Chemical | Iris, cone, spout valves | Handling rough powders, safe mixing |

Mining and Minerals

You work with heavy materials like ores, sand, and gravel. Mining uses butterfly valves for flow control and metering. These valves move lots of bulk solids through chutes and conveyors. You need strong valves that last and handle high pressure. Some valves have special linings to stop wear. Diverter valves send materials to crushers or storage bins.

- Use butterfly valves for quick flow control.

- Choose valves with tough linings for longer use.

Plastics and Resins

You move plastic powders and granules in bulk systems. Diverter valves help you send these materials without damage. Gentle handling stops wear and keeps quality high. Some valves have smooth insides and stainless steel inserts. These features help stop jams and keep things running well. Weatherproof covers protect valves in cold weather.

Note: Use diverter valves with smooth surfaces. This keeps plastic powders moving and stops jams.

Bulk material handling helps many industries work safer, cleaner, and faster. You can pick the best valve by looking at your material and what your process needs.

Selecting Bulk Material Valves

Material Characteristics

When you pick a bulk material valve, you must think about your material. The size of the particles, how rough they are, and how wet they are all matter. Fine powders need smooth valves with tight seals so nothing leaks out. Big pellets or granules need wide openings so they do not get stuck. If your material is rough, it can wear out the valve fast. You should use valves with hard coatings or liners to help them last longer. Sticky or wet material can block the valve. Special coatings can help keep things moving and stop jams.

Here is a simple list to help you:

- Find out your material’s size, wetness, and roughness.

- Pick a way to move heavy or rough material, like dense phase.

- Figure out how much air you need for your material.

- Use valves that resist wear for rough material.

- Make feeding and discharge systems for different sizes.

- Add wear protection to stop damage.

- Use control systems to watch your process.

- Have experts put in and test your system.

- Plan to check and fix parts that wear out quickly.

Tip: Always choose a valve that matches your material. This helps your system work well and last longer.

System Requirements

You have to think about what your system needs before you choose a valve. The kind of material you use changes what the valve is made of. If your material is corrosive, you may need PTFE or stainless steel valves. If you have high pressure or heat, you need strong metal valves. Think about what the valve will do. Some valves are for letting material in, some for letting it out, and some for control. The size of the valve depends on how much material you move. You might need to test your material to find the right size.

The table below shows important system needs:

| System Requirement Category | Key Considerations & Details |

|---|---|

| Industry | Agriculture, Energy, Food, Chemical, Manufacturing, Pharmaceutical, Plastics |

| Material Characteristics | Abrasive, corrosive, light, heavy; sanitary needs |

| Valve Function | Inlet, outlet, inline control |

| Operating Conditions | Pressure, temperature, flow rate |

| Valve Size | Based on flow rate and material type |

| Valve Construction Material | Cast iron, carbon steel, stainless steel, titanium |

| Surface Finish | Buffed, satin, mirror finish for sanitary needs |

| Mounting Options | ANSI, DIN, quick clamps, socket weld, tri-clamps |

| Seat Types | Metal seats for abrasive material, reinforced Teflon for sealing |

| Service Conditions | Dust tight, liquid tight, vacuum, low/high pressure |

| O-Ring Materials | Silicone, Viton, Teflon encapsulated silicone |

| Actuator Types | Manual, pneumatic, electric, hydraulic |

| Maintenance Considerations | Easy cleaning, resistance to clogging, clean-in-place options |

Note: Make sure your valve fits your system’s pressure, heat, and flow. This keeps your process safe and working well.

Application Fit

You must match your valve to the job you need it to do. Think about where you will use the valve and what it must handle. If you work with food, you need valves that are easy to clean and have smooth finishes. Chemical plants need valves that do not rust and can handle rough stuff. Mining needs strong valves for heavy and rough material. You should also check if the valve fits your space and how it mounts. Some jobs need quick clamps or special seats. Always ask your supplier if the valve is right for your system.

- Food and drink: Use clean valves with smooth finishes.

- Chemical and drug plants: Pick valves that do not rust and seal tight.

- Mining: Use strong valves for rough material.

- Plastics: Choose valves that are gentle to protect granules.

Tip: Picking the right valve for your job helps you avoid trouble and keeps your system working well.

Common Mistakes

When you pick a bulk material valve, you want your system to last. Many people make easy mistakes that cause big problems. If you know what to look for, you can stop costly repairs and downtime.

Here are some common mistakes you might see:

| Common Mistake | Consequences | How to Avoid It |

|---|---|---|

| Improper sizing | Lower flow, higher pressure, system works badly | Pick the right size using flow rate, pressure, and job type; check charts and standards |

| Ignoring flow direction markings | Leaks, system breaks, uneven pressure | Follow arrows or marks on the valve; install it the right way |

| Incorrect sealing methods | Leaks, seals break early | Use the right gaskets or PTFE tape for your job; put seals on evenly; check them often |

| Misalignment during installation | Lower flow, more wear, rough flow | Use tools to line up the valve; make sure it matches the pipes |

| Incorrect torque application | Leaks, valve breaks, fails early | Use a torque wrench; follow the maker’s rules; tighten bolts in a cross pattern |

| Neglecting maintenance | Valve sticks, wears out, works worse | Check valves often; oil them as needed; change seals when worn |

Let’s look at these mistakes more closely:

- Improper sizing: If the valve is too small or big, your system will not work well. You might get slow flow or too much pressure. Always check what your system needs. Use charts from the maker to pick the right size.

- Ignoring flow direction markings: Every valve has a right way for material to move. If you put it in backward, it can leak or break. Always look for arrows or marks before you put it in.

- Incorrect sealing methods: Using the wrong gasket or not sealing well can cause leaks. Make sure you use the right material for heat and pressure. Put seals on evenly and check them often.

- Misalignment during installation: If the valve does not line up with the pipes, you get more wear and bad flow. Use tools to make sure everything is straight before you tighten bolts.

- Incorrect torque application: If you tighten bolts too much or too little, the valve can break or leak. Use a torque wrench and follow the maker’s rules. Tighten bolts in a cross shape for even pressure.

- Neglecting maintenance: If you do not check your valves, they can stick or wear out. Make a plan to check, clean, and oil your valves. Change seals when they look worn.

Tip: Always read the instructions that come with your valve. Take your time when you put it in and check it. Careful work now saves you trouble later.

If you avoid these mistakes, your bulk material system will run better and safer. You also save money and time by stopping leaks and breakdowns.

Maintenance and Reliability

Wear Parts

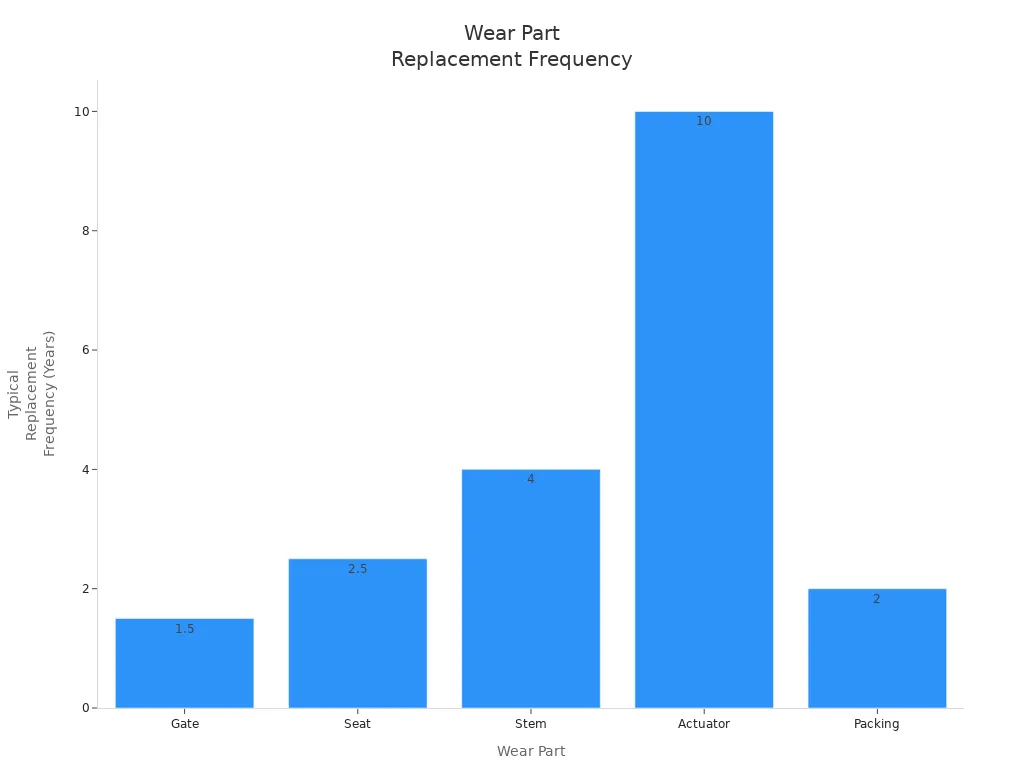

You should know which parts wear out the fastest. These parts work hard every day in your bulk material valve. If you check them often, you can stop problems early. The table below lists the main wear parts, what they do, and when to replace them if you use your valve a lot or handle rough materials.

| Wear Part | Role/Description | Maintenance Tips | Typical Replacement Frequency in High-Use/Abrasive Environments |

|---|---|---|---|

| Gate | Cutting part of the valve | Check for wear, keep sharp and rust-free, clean debris and scale | Every 1-2 years, more frequent if highly abrasive environment |

| Seat | Provides sealing to prevent leaks | Inspect for wear, deformation, keep surface smooth and lubricated | Every 2-3 years depending on product handled |

| Stem | Connects actuator to gate, enables movement | Test for straightness, lubricate, check for bends or damage | Every 3-5 years, shorter intervals under heavy use |

| Actuator | Controls gate movement (manual, pneumatic, electric) | Ensure smooth operation, check for leaks or electrical issues | Up to 10 years with routine checks |

| Packing | Prevents leaks around stem | Inspect regularly for leakage, tighten gland if needed | Replace within 2 years if leakage occurs |

You should also look at the chart below. It shows how often to replace each part. This helps you plan ahead and avoid sudden breakdowns.

Tip: Clean all valve parts often and use the right oil or grease. Check your valves every month to catch wear early and keep things working well.

Preventive Maintenance

You can make your bulk material valves last longer with good care. Simple steps help you avoid big problems. Follow these tips to keep your valves working:

- Look at your valves and parts often. Find wear, leaks, or blockages early.

- Change seals and gaskets when needed. This stops leaks and keeps your system strong.

- Clean rotary airlock valves and check blades and seals. Replace worn parts right away.

- Check pipes for damage or rust. Fix problems quickly to avoid leaks.

- Oil moving parts like bearings and actuators. Use the right oil or grease.

- Test safety valves and pressure relief devices. Make sure they work to stop overpressure.

- Fix leaks fast. This stops product loss and keeps your workplace safe.

- Check and set sensors and control systems. Good readings help your process run right.

Note: Cleaning and checking your valves often keeps them in good shape. You save money and avoid downtime when you follow these steps.

Troubleshooting

You might have problems with your bulk material valves. Knowing what to look for helps you fix things fast. Here are some easy troubleshooting tips:

- Never use hammers or screwdrivers to clear blockages. These tools can break valve parts.

- Make sure you install valves the right way. Wrong direction causes leaks and bad flow.

- Store valves inside in a clean, dry place. This stops rust and damage.

- Do not overfill the valve. Keep pocket fill at about 70% for best results.

- Always follow lockout/tagout safety steps before you work on valves.

The table below lists common problems and how to fix them:

| Common Issue Indicator | Underlying Problem | Recommended Solution |

|---|---|---|

| High pressure or no product transfer | Product build-up in convey lines | Inspect and clean lines and rotary valve parts |

| Material escaping from lines | Leaks in couplings or elbows | Repair or replace damaged line parts |

| Fluctuating filter pressure | Dirty or plugged filter bags | Clean or change filter bags |

| Inconsistent filter pulses | Bad solenoid or diaphragm valves | Replace damaged solenoids and diaphragms |

| Drop in conveying rate or plugging | Worn rotary valve or build-up in rotor pockets | Check valve for wear; replace if needed; clean pockets |

| Airlock noises | Build-up on airlock bore or housing | Clean inside surfaces of rotary valve |

| Incorrect valve operation | Wrong installation direction | Check and fix valve orientation |

| Valve damage or corrosion | Outdoor storage or bad conditions | Store valves indoors in dry, controlled spaces |

| Material blockage or slow flow | Overstuffed valve | Adjust feed rate and valve speed; avoid overfilling |

| Safety hazards during maintenance | Not following lockout/tagout | Always use lockout/tagout before maintenance |

Tip: If you check your valves often and fix small problems, you can avoid bigger repairs and keep your system safe.

Quality and Compliance

You need to care about quality and compliance when picking bulk material valves. If you work in food or medicine, you must follow strict rules. These rules keep products safe and protect your business from problems.

Valves for food and drugs use special materials. Seals and parts should not react with your product. They must resist rust and high heat. Some seals need to handle cleaning with steam or chemicals. The materials must be safe and not toxic for food or medicine.

Here is a table that lists important standards and needs for bulk material valves in regulated industries:

| Aspect | Details |

|---|---|

| Key Compliance Standards | FDA 21 CFR 177.2600 (rubber seals), EC 1935/2004 (food contact materials), 3-A Sanitary Standards (dairy), WRAS & NSF (potable water) |

| Material Requirements | Non-toxic, chemically inert, corrosion & temperature resistant, compatible with CIP/SIP cleaning |

| Preferred Elastomers | Silicone (thermal stability, biocompatibility), NBR (oil/fat resistance), EPDM (water/steam resistance) |

| Pharmaceutical Seal Standard | USP Class VI certification required for pharma-grade seals |

| Documentation & Traceability | Material certifications, batch traceability, performance data essential for compliance |

| Business Risks of Non-Compliance | Regulatory fines, product recalls, production shutdowns, brand reputation damage |

| Engineering & Quality Assurance | Custom engineering and quality assurance critical to meet stringent industry requirements |

Look for valves with FDA-approved silicone or USP Class VI EPDM seals. These keep your product clean and stop contamination. Some industries use colored seals for different jobs. Orange silicone seals mean strength and food safety. You may need organic nitrile seals for oil or fat resistance.

Tip: Always ask your supplier for material certifications and batch records. This helps you show your system follows the rules.

Quality checks are very important. Valves must pass tough tests for seal inflation and performance. Oil-free seals are best for medicine use. Custom engineering helps you get the right valve for your job. Make sure your valves use strong rubber and silicone. Good materials help stop leaks and keep your product safe.

If you do not follow these rules, you can get fines, recalls, or shutdowns. Your brand can get a bad name. Work with suppliers who know the rules and offer custom solutions. Good engineering and careful material choices help you meet all compliance needs.

- Pick valves with certified seals and materials.

- Ask for paperwork and batch records.

- Test your valves for safety and performance.

- Work with experts who know your industry’s rules.

You protect your business and customers when you focus on quality and compliance. This keeps your system working well and your products safe.

Dry Bulk Material Flow Challenges

Material Buildup

When you work with dry bulk materials, buildup can happen. Powders, pellets, and granules may stick inside valves and pipes. This can block the way and slow down your system. You might see clumps where the material does not move much. Sticky or wet materials make this worse. If you do not clean these spots, the buildup can stop flow.

To help with buildup, pick valves with smooth and open designs. Some valves have blades that clean themselves as they move. You can use panels you can remove to clear out clogs. Cleaning and checking your system often keeps it working well.

Tip: Look at your valves often for buildup. Clean them before it gets bad.

Flow Consistency

It is hard to keep material flow steady in bulk systems. Sometimes, the flow rate changes while you work. This is because bulk density is not always the same. The size and shape of particles also change how things move. Humidity and heat can make powders clump or move too fast. Dangerous materials need extra care to stop leaks and keep people safe.

Here are some reasons why flow is not always steady:

- Bulk density changes during the process.

- Particle size and shape are not always the same.

- Humidity and heat affect how material moves.

- Flow can go up and down, changing production speed.

- Equipment may not work as well because of these things.

You can make flow better by testing your material first. Work with companies that know about bulk materials. They can help you choose the best valves and setup. Good planning and the right tools help you keep things steady.

Cleaning and Access

Cleaning and getting inside your system is important for safety and good work. You need to reach inside valves and pipes to get rid of stuck material and dust. Some valves have panels you can take off or quick-clean parts. These make cleaning easier without taking apart everything. If you work with food or chemicals, cleaning often stops contamination and keeps products safe.

Set up a cleaning plan and use tools that fit your valves. Make sure you can reach all parts of your system. Easy access helps you fix problems fast and keeps things running.

| Cleaning Feature | Benefit |

|---|---|

| Removable panels | Easy to reach for cleaning |

| Self-cleaning blades | Less work to clean by hand |

| Smooth surfaces | Material does not stick easily |

Note: Pick valves that are easy to clean. This saves time and helps you avoid stopping your system.

Bulk material valves help you control, measure, and direct dry materials in your system. You get better safety and less waste when you pick the right valve for your job. Regular checks and good-quality parts keep your system running smoothly.

- Choose valves that match your material and process.

- Clean and inspect valves often for best results.

Need help? Talk to a bulk material valve expert or read more guides before you decide.

FAQ

What is the main purpose of a bulk material valve?

A bulk material valve helps you control dry material flow. You can start, stop, or send powders, pellets, or granules where you want. This keeps your system safe and working well.

Can you use liquid or gas valves for dry bulk materials?

No, do not use liquid or gas valves for dry bulk materials. Bulk material valves have special shapes and seals for solids. These stop clogs and jams.

How do you choose the right bulk material valve?

Check your material’s size, shape, and how rough it is. Think about your system’s pressure and heat. Pick a valve that fits your job and keeps material moving.

How often should you check or maintain bulk material valves?

Look at your valves every month for leaks or wear. Clean and oil moving parts when needed. Change seals or broken parts fast to keep things safe.

What happens if a bulk material valve leaks?

If a valve leaks, you can lose product or make a mess. Dust and waste can cause safety problems. Fix leaks fast and use strong seals to stop this.

Are bulk material valves safe for food or medicine?

Yes, you can use these valves for food or medicine if they have the right seals. Look for FDA-approved or sanitary valves. These keep your product clean and safe.

Can you automate bulk material valves?

Yes, you can use electric or pneumatic actuators to automate these valves. Automation gives better control and keeps workers safer. You can also connect them to your plant’s control system.