Choosing the right ball valve for your system needs careful thought. You should pick a ball valve manufacturer who knows how fluid type, pressure, temperature, and environment can change safety and reliability. Good ball valves with the right size and strong seal designs stop leaks. They also make maintenance easier and help save money. When you look at choices, think about how butterfly valve, control valve, and diaphragm valve options are different. Picking the best ball valve keeps your process safe and gives you value for a long time.

Choosing the Right Ball Valve Manufacturer

Picking a ball valve manufacturer that fits your system is important. This helps your fluid control work well and last a long time. You need to think about what your system needs and what the manufacturer can do. Doing this helps you avoid mistakes that cost money. It also makes sure your valves work in all situations.

Application Needs

You need to know your system before picking a ball valve. Every system is different and needs special valves.

Fluid Type

The kind of fluid in your valves, like water, oil, or gas, matters a lot. It changes what materials and designs you need. Some fluids need materials that do not rust or leak. If you use chemicals or rough particles, you need a ball valve with special coatings or linings. Always make sure the valve matches the fluid’s thickness, what it is made of, and if it has particles.

Tip: Ask your ball valve manufacturer if they have worked with your fluid type. This helps you get a valve that works well and lasts long.

Pressure & Temperature

You need to check the pressure and temperature limits for each ball valve. High pressure or heat needs strong valves with good seals. If your system changes pressure or gets very hot or cold, pick a manufacturer who tests for these things. The right size and pressure rating keep your system safe and stop problems.

Environmental Factors

Where you put your valve matters too. Outside valves may face hot and cold weather, shaking, or even fire. Some places need valves with special safety labels or fire-safe designs. Think about where you will put the valve and what could hurt it. This helps you stop surprise breakdowns and saves money on repairs.

- Key things to think about:

- What the fluid is like (thick, chemical makeup)

- Pressure and temperature range

- How the ends connect (threaded, flanged, welded)

- How you open the valve (manual, pneumatic, electric)

- How easy it is to fix and how long it lasts

- If it meets industry rules

Manufacturer Capabilities

Once you know what your system needs, look at what each manufacturer can do. Not every company has the same products or skills.

Product Range

A company with many products gives you more choices. Top manufacturers have ball valves for many flow rates and pressures. They offer different body materials, seat types, and ways to open the valve. This helps you find the best valve for your system.

| Manufacturer | Key Features Demonstrating Ability to Meet Diverse Application Requirements |

|---|---|

| Bonney Forge | Advanced sealing, forged steel, customizable designs, international standards, high pressure and temperature. |

| SAMSON | High rangeability, robust construction, versatile applications, energy efficiency. |

| NTGD Valve | Advanced materials, enhanced sealing, smart valve systems, energy-efficient, custom designs. |

| B?hmer | Advanced sealing, corrosion resistance, customizable, international standards. |

| Flowserve | Comprehensive product range, robust design, specialized lines for corrosive fluids. |

| KSB | Premium valves for energy and gas, durable, global support, tailored for harsh conditions. |

When you pick a manufacturer with lots of products, it is easier to buy what you need. All your parts will work together. This also helps if you want to add more to your system later.

Specialization

Some companies focus on certain industries or valve types. If your system has special needs, like high-pressure gas or strong chemicals, pick a manufacturer who knows about that. Companies that specialize know your industry’s rules and can help you choose the best valve.

Note: Always tell the manufacturer what your system needs and what it must work with. This helps them give you valves that fit your equipment.

Factors to Consider When Choosing

When you pick a ball valve, use a step-by-step plan. Here are the main things to think about when picking a manufacturer:

- Reliability and Maintenance: Pick a company known for good quality. Easy-to-fix valves, spare parts, and help from the company mean less downtime.

- Regulatory Compliance: Make sure the company meets industry rules and has certifications like API, ASME, or ISO.

- Cost Considerations: Do not just look at the first price. Think about how much it costs to use, fix, and run the valve over time.

- Future Expansion and Flexibility: Choose companies with designs you can change and many products.

- Application-Specific Factors: Make sure the company can meet your needs for fluid control, flow rate, pressure, and how you open the valve.

If you focus on these things, you will make a smart choice. You will get safe, reliable, and long-lasting ball valves for your project.

Ball Valve Quality

When you pick valves, you want them to work well and last. The quality of a ball valve depends on what it is made of and how it is built.

Materials

Corrosion Resistance

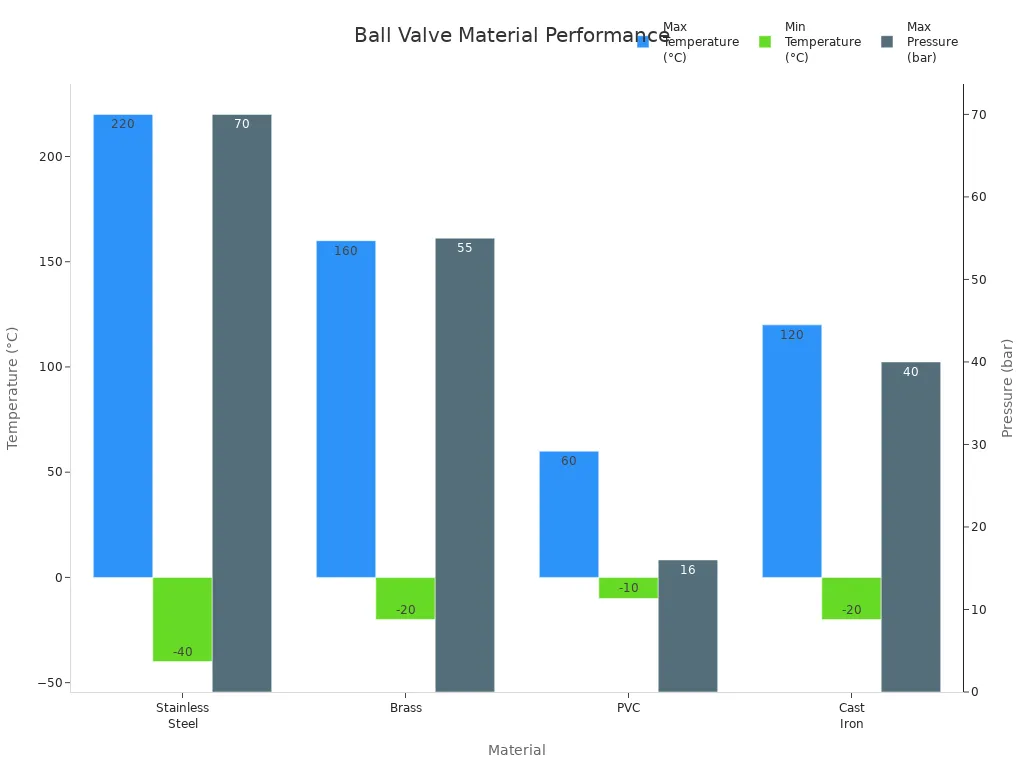

You need to pick materials that can handle your fluid and where you use the valve. Stainless steel, brass, PVC, and cast iron are used a lot for ball valves. Each one is good for different temperatures, pressures, and how well it fights rust.

| Material | Temperature Range (°C) | Max Pressure (bar) | Key Performance Effects and Applications |

|---|---|---|---|

| Stainless Steel | -40 to 220 | 70 | Handles high heat and pressure; does not rust easily; safe for food, marine, and chemical use. |

| Brass | -20 to 160 | 55 | Strong and tough; works for high pressure and heat; used in home plumbing and drinking water. |

| PVC | -10 to 60 | 16 | Light and does not rust; cannot take much heat or pressure; good for pools, water, and farms. |

| Cast Iron | -20 to 120 | 40 | Tough and heavy; can break if hit hard; used in water and air systems. |

If your system has harsh chemicals, pick valves made from stainless steel or special metals. These stop rust and damage, so you fix them less and they last longer. Strong materials also help the valve seal tight, even when it gets hot or has high pressure.

- Good, rust-proof materials help valves last longer.

- Strong materials mean you do not fix or change valves often.

- Picking the right material keeps your system safe and working.

Seat Materials

The seat inside the ball valve is very important too. PTFE (Teflon), FKM (Viton), and EPDM are common seat types. These seats can handle chemicals and heat, so the valve seals well. If you pick the right seat, your valve works better with different flows and pressures.

Design

Leak-Tight Performance

A well-made ball valve stops leaks in your system. The seal and seat must match your fluid and how hot it gets. Floating and trunnion ball types seal in different ways. The ball and seat are made to fit tightly, so leaks do not happen and flow stays steady. Some valves have special coatings to stop wear and keep the seal strong for a long time.

Tip: Ask your supplier about how the valve seals and if it stops leaks at your system’s pressure.

Testing Procedures

You want to know your valves are safe and work right. Makers test valves to check for leaks, strength, and safety. They do things like:

- Look for cracks or rust

- Test if the valve opens and closes well

- Check for leaks under pressure

- Write down all test results and repairs

Rules like API 598, API 607, and ISO 5208 tell how to test valves. For example, the seat leak test uses more pressure than normal to make sure there are no leaks. These tests help you trust your ball valve will work safely in your system.

Certifications

Certifications are very important when you pick a ball valve manufacturer. You should check if the company follows the right rules and standards. These certifications show the company makes good valves. They also prove the valves are safe and work well everywhere.

Industry Standards

Industry standards help you see how different companies compare. These rules say how valves should be made and tested. They also tell what materials to use. If you follow these standards, your valves will be safe and strong.

API 608

API 608 is a rule from the American Petroleum Institute. It is for metal ball valves used in factories. If you work with oil, gas, or chemicals, look for API 608. This rule checks how the valve is made and tested. It also checks if the valve can handle high pressure. API 608 helps you trust your valve will work in hard jobs.

Tip: Ask your supplier if their ball valves meet API 608. This helps your system stay safe and follow the law.

ISO

ISO rules are used in many countries. ISO 17292 tells how to make and test ball valves. ISO 9001 is about making sure the company has good quality checks. If a company has ISO certificates, they follow strict rules. This means their valves will work well in many places.

Here is a table with the most important standards for ball valve makers:

| Industry Standard / Certification | Description | Importance for Ball Valve Manufacturers |

|---|---|---|

| ANSI (American National Standards Institute) | Has rules like ANSI B16.34 for valve size, materials, and pressure. | Makes sure valves are safe and work well in the U.S. |

| ISO (International Organization for Standardization) | ISO 17292 is for design and testing. ISO 9001 is for quality checks. | Gives the same rules for many countries and shows good quality. |

| API (American Petroleum Institute) | API 6D is for pipeline valves in oil and gas. | Makes sure valves are safe and work well in tough jobs. |

| CE Marking | Shows the valve meets European safety and environment rules. | Needed for valves in Europe and proves they follow the law. |

| FDA Approval | Shows the valve is safe for food and medicine use. | Needed to stop germs and keep things clean in special jobs. |

Regulatory Compliance

Regulatory compliance means following the rules in each place. Every area has its own safety and environment laws. You must check if your valves follow these rules. This keeps you safe and out of trouble.

Companies that follow local and world rules can sell more valves. In North America, you need to follow OSHA and water safety laws. In Europe, you need CE marking and low lead in valves. In Asia-Pacific, there are new rules for water and energy. For oil and gas, you must follow API rules for safety.

| Region | Regulatory/Legal Factors | Marketability Impact |

|---|---|---|

| North America | OSHA rules, Safe Drinking Water Act, focus on saving energy | People want safe and green valves; you must follow the law to sell them. |

| Europe | Strong environment rules, PED, limits on lead in valves | Following rules helps you sell more valves and keeps people safe. |

| Asia-Pacific | Fast growth, new rules, more water and energy projects | People want cheap and safe valves; you must follow rules to sell them. |

| LAMEA | Oil and gas rules, valves that do not rust, smart valves | You must follow special rules to sell valves here; new technology is important. |

Regulatory compliance changes how you buy and sell ball valves. Pick companies that know these rules and give you proof. This helps you stay legal and keeps your valves safe everywhere.

Customization & Support

When you pick a ball valve manufacturer, do not just look at regular products. Custom options and good support can help your system work better and last longer.

Custom Solutions

Design Flexibility

Sometimes, you need a ball valve for special jobs. Top manufacturers can make custom valves for these needs. You can ask for:

- Special ball valves with unique materials like special alloys or PTFE linings. These help with fluids that are very hot, rough, or can cause rust.

- Different port shapes, more than one port, or top-entry designs. These can make your system work better or make fixing easier.

- Better sealing, like double or triple seals, special rubbers, or metal-to-metal seals. These stop leaks in hard places.

- Automation features, like pneumatic, hydraulic, or electric actuators. These help you control flow exactly.

- Valves that work in very hot, cold, or high-pressure places, or even in a vacuum.

- Valves that follow strict rules for industries like food, medicine, or oil and gas.

You can also get custom 3-way full port flanged diverting ball valves. There are sanitary clamp end stainless steel valves for clean jobs. Some valves save space for small places. Some makers mix connection types, like flanged on one side and TriClamp on the other, to fit your system.

Special Requirements

Custom valves start with knowing what you need. Manufacturers will:

- Look at your needs, like fluid type, temperature, pressure, flow, actuation, and rules.

- Make a plan and first design, picking the right valve and materials.

- Use special computer tools to make the design better.

- Build test valves and check how they work.

- Make the final valve and give you all the papers and certificates.

You get a valve that fits your needs. This helps your system work safely and smoothly.

After-Sales Service

Warranty

A good warranty makes you feel safe about your buy. The best companies have clear warranties. They fix or replace valves for free and make returns easy. This shows they trust their own products.

Technical Support

Good technical support is important for you. You get help with fixing, repairs, and keeping things working. This means less time when your system is down. Fast and smart help makes sure your valves work right. Many companies give repair kits for leaks, blockages, or worn parts. This helps you save money and not buy new valves.

Getting good after-sales help shows the company cares about you. You feel better knowing you have help when you need it. Regular checks and quick repairs by trained workers make your valves last longer and keep your system running well.

Always pick a manufacturer with great after-sales help. This keeps your valves working and protects your money.

Reputation of Ball Valve Manufacturer

When you pick a ball valve manufacturer, do not just look at the technical stuff. The company’s reputation shows if you can trust their valves. A good reputation means they make quality products and help customers. You want a partner who stands by their products and cares about your business.

Customer Feedback

Customer feedback helps you see how the company treats people. You should read reviews and stories from other buyers. These tell you if the company gives good service and helps after you buy. Many customers talk about how well the valves work and how fast the company fixes problems.

- Look for reviews that talk about:

- Quick and helpful answers to questions

- Easy returns or warranty help

- Help with setting up or fixing valves

- Happy customers who like how the valves work

If a company has good feedback, their team cares about you. You can trust them to help if you have problems. Good service makes buying easy and less stressful.

Industry Presence

You should check if the company is well-known in the industry. Companies with a strong presence often make custom valves and check quality closely. They use new technology and spend money to make better valves. These companies usually sell in many countries and follow big rules like ISO 9001 or API 6D.

A strong presence means the company can handle new needs. They keep up with new rules and trends. You get their experience and good name because they know what works. These companies often lead with new ideas and work more efficiently. They also give good support and help for all kinds of valves.

References

References help you check if the company tells the truth. You should ask for stories or contacts from old customers. Talking to other buyers gives you real facts about the company’s work and reputation. You learn how the valves work in real life and if the company keeps its promises.

- Ask these questions when you check references:

- Did the valves do what you wanted?

- Did you get your order on time?

- How did the company fix any issues?

- Would you buy from them again?

References help you trust the company more. They make you feel sure you are picking a company with a good history and strong reputation.

Industry Application Cases of Ball Valves

Oil & Gas Industry

Upstream Extraction and Wellhead Control

Ball valves are used a lot in oil and gas work. They help control how fluids move at wellheads. Floating ball valves are good for small jobs and low pressure. Trunnion-mounted ball valves work better for big wells and high pressure. These valves close tightly and work in hard places. Oil and gas can damage equipment, so you need valves that do not rust or wear out. Full port ball valves let lots of fluid move with little drop in pressure. This helps the system work well.

Pipeline Transmission Systems

Ball valves keep pipeline flow safe and steady. They must handle high pressure and heat. The valves need strong seals and tough materials. Trunnion-mounted ball valves are used a lot because they seal well and do not stick. You want valves that follow safety rules. Smart valve systems and new materials help you watch and control pipelines better.

Refinery Process Isolation

Refineries use ball valves to separate different steps. The valves must handle hot temperatures and strong chemicals. Metal-seated ball valves are best for these jobs. You also need valves that follow strict safety rules. Picking a good manufacturer helps your valves work well and keeps your refinery safe.

Chemical & Petrochemical

Corrosive Fluid Handling

Chemical plants use fluids that can break regular valves. You need ball valves made from stainless steel or special metals. These valves do not rust and last longer. Metal-seated valves help with rough and hot fluids. Always check if the valve matches what you need for your process.

Process Safety Applications

Safety is very important in chemical plants. Ball valves with electric or pneumatic controls help stop leaks. Explosion-proof valves and tight seals help prevent accidents. You need valves that follow safety rules and can shut off quickly in emergencies.

High-Temperature Operations

Some chemical jobs use very high heat. Metal-seated ball valves can take heat over 400°C. These valves stay strong and sealed even when it is very hot. Picking the right valve helps you avoid problems and saves money on repairs.

Water & Wastewater Treatment

Municipal Water Distribution

Ball valves are used in city water systems because they last long. Soft-seated valves made from polymers or stainless steel seal well at low heat. These valves help give clean water easily.

Effluent and Sludge Management

For wastewater and sludge, you need valves that do not clog and are easy to fix. Simple ball valves with manual controls work well. These valves handle solids and keep working without lots of repairs.

Desalination Plants

Desalination plants use ball valves for salty water. You need valves made from materials that do not rust. These valves help the plant run well and lower repair costs.

Tip: Pick a manufacturer who knows your industry. This makes sure your valves work safely and do what you need.

| Aspect | Chemical & Petrochemical Industry | Water & Wastewater Treatment Sector |

|---|---|---|

| Materials | Stainless steel, special metals, metal-seated valves | Polymers, stainless steel for less harsh fluids |

| Temperature Handling | Over 400°C | Low to medium temperatures |

| Pressure Ratings | High pressure (like class 300, 600) | Lower pressure (class 150 is common) |

| Sealing Mechanism | Metal seats for tough fluids | Soft seats (PTFE) for good seals at low heat |

| Actuation | Electric and pneumatic for safety | Manual or simple controls; more digital use |

| Operational Priorities | Handle rough, hot fluids; stop leaks | Save money, easy to fix, last long |

Ball valves give you strong shutoff, easy use, and long life. These reasons make ball valves a great choice for controlling fluids in many jobs.

HVAC & Building Services

Chilled and Hot Water Systems

Ball valves help control water in chilled and hot water systems. They let you stop or start water fast. This keeps your system working well. You can pick different sizes and materials for your building. Ball valves work in both small and big systems. They give you strong shutoff and are easy to use.

But there are some problems to know about:

- Ball valves are not good for slowing water down. If you only open them partway, the seat can wear out fast and leak.

- Dirty water or thick liquid can make the ball and seat wear out quicker. This can cause leaks.

- Ball valves cannot be used in very big or high-pressure systems. You might need another valve type for those jobs.

- Closing a ball valve too fast can make a loud bang called water hammer. This can hurt your pipes.

- Over time, the valve can wear out or rust, especially if you use it a lot or in hard places.

You should always pick the right valve for your system. Plan to check your valves often to keep them working well.

Steam Distribution

Steam systems need valves that can take high heat and pressure. Ball valves close tightly, so steam does not leak. This keeps your system safe. You can use them to shut off parts of the system for repairs. Ball valves are simple, so they are easy to use and fix.

Pick valves made from strong materials that do not rust or melt. This helps them last longer and not break. For steam, you often need metal seats and special seals for the tough job.

Fire Protection Systems

Fire safety systems need valves that always work. Ball valves are good because they open and close fast. This lets water move quickly in an emergency. You can use them in sprinklers, hydrants, and other safety systems. It is easy to see if the valve is open or closed.

Look for valves that are safe to use in fires and have the right certificates. This makes sure they work even in very hot fires. Test and check your valves often to keep your fire system ready.

Power Generation

Boiler Feedwater Control

Power plants use ball valves to control water going into boilers. These valves must handle high heat and pressure. Full port ball valves keep pressure steady. This helps your system stay safe and stops damage. The tight shutoff stops pressure jumps that could hurt pipes.

Cooling Water Circuits

Cooling water systems need valves that open and close fast. Ball valves let water flow easily, which saves energy. This helps pumps work better. You can use electric ball valves for better control and quick changes. This keeps the system cool and stops overheating.

Turbine Bypass Systems

Turbine bypass systems need valves that work fast and seal tight. Ball valves with electric controls let you change flow quickly. This helps during load changes or emergencies. Their design lets water move easily, which saves energy and makes the plant work better. In nuclear plants, you can use special electric ball valves that resist radiation to keep things safe.

Here are some good things about using ball valves in power plants:

- They keep pressure steady and shut off well for safety.

- They use less energy to open and close, so parts last longer.

- Automatic controls help you fix problems before they get big.

- Less resistance means you save money and release less CO2.

Tip: Always pick a manufacturer who knows your industry. This helps make sure your valves are safe and work well.

Key Certifications for Ball Valve Manufacturers

ISO Certifications

ISO 9001: Quality Management Systems

When you pick a ball valve manufacturer, look for ISO 9001 certification first. This means the company follows strict rules to make sure quality stays high. They check for mistakes and try to fix problems before they happen. The latest ISO 9001 version asks companies to find risks and solve them early. This helps you get ball valves that work well and last longer. Many top manufacturers use ISO 9001 to show they meet world standards. You do not need to check the company yourself because this certification proves the product is safe and good.

- ISO 9001 helps make products reliable.

- It keeps production quality the same every time.

- It is the base for other technical rules.

ISO 14001: Environmental Management

ISO 14001 certification means the manufacturer cares about the environment. This rule makes sure the company saves energy, cuts waste, and follows green laws. Picking a manufacturer with ISO 14001 helps protect nature and shows you care about the planet.

ISO 45001: Occupational Health and Safety

ISO 45001 is about keeping workers safe. This certification means the company works hard to stop accidents and health problems. You can trust that the company follows strong safety rules and cares about its team.

CE Marking

Compliance with European Directives

If you want to use ball valves in Europe, you need CE marking. This mark shows the valve meets European safety and health rules. Companies must test their products and get approval from special groups. CE marking lets you sell in Europe and proves the product is safe.

Pressure Equipment Directive (PED)

The Pressure Equipment Directive (PED 2014/68/EU) is a big rule for valves in Europe. It checks if ball valves can handle pressure safely. If a valve passes PED, it has gone through tough tests for strength and safety. Without PED, you cannot sell or use ball valves in the EU.

| Aspect | Description | Impact on Acceptance in European Markets |

|---|---|---|

| Material Safety | Limits dangerous stuff and controls heavy metals in valve materials. | Follows EU health and environment rules, so people trust it and you can sell it. |

| Mechanical Safety Design | Makes sure the valve is strong and safe to use. | Stops accidents and keeps people safe, which is needed to sell in Europe. |

| Electromagnetic Compatibility | For valves with electronics, makes sure they do not mess up other equipment. | Follows EU rules for electronics, so you can sell electronic valves easily. |

| Regulatory Compliance | Needed by PED for pressure equipment like valves. | You must have this to sell ball valves in the EU, so it helps you enter the market. |

| Testing and Certification | Tough tests to match CE rules and prove the valve is safe. | Shows you follow EU safety and environment rules, so people trust your product. |

SIL Certification

Safety Integrity Level Overview

SIL, or Safety Integrity Level, checks how safe a valve is in important systems. SIL levels go from 1 to 4, with SIL 3 meaning very high safety. To get SIL, the company must show the valve will not break often and works in hard places. An outside group checks the valve and system to make sure they follow the rules.

Importance for Critical Applications

You need SIL-certified ball valves in places where safety is very important, like oil and gas, chemical plants, or power stations. SIL 3 valves go through hard tests and risk checks. They help stop accidents and keep people and machines safe. When you see SIL certification, you know the valve follows strong safety rules and will work when you need it.

Always make sure the certifications are up to date and match the type of valve you need. This step keeps your project safe and helps you follow all the rules.

Other Relevant Certifications

ATEX Certification

If you work where there are explosive gases or dust, you need ATEX certification. ATEX means “Atmosphères Explosibles.” This shows a ball valve is safe in dangerous places. You see ATEX rules in oil and gas, chemical plants, and mining. When you pick a manufacturer with ATEX-certified valves, you lower explosion risks and keep workers safe. Always look for the ATEX mark on the valve. This mark proves the valve passed tough tests for explosive areas.

Tip: Ask your supplier for the ATEX certificate. Make sure it matches your site’s zone and gas group.

API Certifications

API certifications come from the American Petroleum Institute. These set safety and quality rules for oil and gas jobs. Look for API 6D for pipeline valves, API 598 for valve tests, and API 607 for fire safety. API Spec Q1 is for quality checks. If a manufacturer has these, their valves meet strict industry rules. API-certified valves work well in high-pressure, high-heat, and important jobs.

Here is a table that shows common certifications for ball valve makers in special industries:

| Certification Type | Specific Certifications / Standards | Industry Focus / Purpose |

|---|---|---|

| API (American Petroleum Institute) | API Spec Q1, API 6D, API 598, API 607 | Safety, quality management, fire safety, pipeline valve needs in oil & gas and related industries |

| ASME (American Society of Mechanical Engineers) | ASME B16.34, ASME Section VIII | Valve strength, safety under high pressure and heat, pressure vessel safety in power, petrochemical, and oil & gas industries |

| Other Certifications | CE Marking, ATEX, SIL, NSF | European safety, hazardous environment standards, safety integrity levels, and clean water safety requirements |

Note: API certifications are not just for oil and gas. Many industries use these rules to make sure valves are safe and reliable.

Local and Industry-Specific Approvals

You also need to check for local and special approvals. These include NSF for drinking water, WRAS for UK water systems, or FM and UL for fire safety. Some places need special marks to show the valve meets health, safety, or environment laws. Always ask your manufacturer for proof of these approvals. This helps you avoid legal trouble and makes sure your valves fit your project.

- Always check that certifications are up to date and cover your job.

- See if the manufacturer can give papers for each approval.

- Remember, the right certifications help you follow rules and sell in more places.

By picking a manufacturer with the right certifications, you protect your system, your team, and your money.

Choosing the Right Valves Manufacturers: Evaluation Steps

Picking the best valve supplier takes careful planning. You should not just look at catalogs or prices. By following these steps, you make sure your choice is safe and lasts a long time.

Documentation

Begin by checking all the papers the company gives you. This helps you see if the manufacturer is good and cares about quality. You should ask for and look at these things:

- The company’s reputation and awards, plus experience and certifications like API, ISO, and ASME.

- How they check quality and test their products to make sure they work well.

- Product details, like how much pressure and heat they can take, what materials they use, and what actuators fit.

- Help before you buy, like advice on what valve fits your job and how big it should be.

- Support after you buy, like help with repairs, spare parts, and regular check-ups.

- If they can make special valves for your unique needs.

- How they ship and deliver valves on time, even to other countries.

You should also use a checklist to make sure you do not miss anything:

- Make sure the valve matches your needs, like the right material and pressure or temperature ratings.

- Check how long the valve should last and what the warranty covers.

- Find out if the company makes the valves or just sells them.

- See if the actuator works with the valve and if it has enough power.

- Check if the company knows your industry and can give you good advice.

Tip: Always ask for papers that show the valves meet important rules. This helps you avoid mistakes and makes sure your valves work right.

Site Visits

Visiting the factory lets you see how things are made. You can watch how they build valves and check for good quality. When you visit, look at these things:

- Look at the valve bodies for cracks or rust using special tests like ultrasound or X-rays.

- Check flanges, gaskets, and bolts to make sure they are tight and not worn out.

- Look inside at discs, seats, and seals for damage or rust.

- Check the valve stems and how they open and close for rust or damage.

- Watch them test the valves for leaks and strength.

- Make sure they have the right certificates and test papers.

- Look at how well the valves are made, packed, and if the papers are correct.

- See if they use new tools like sound tests or special scans to check for problems.

- Make sure they follow rules like API 598, API 6D, and ISO 5208 when testing.

- Ask if they plan regular checks to find problems early.

A good visit helps you see if the company can give you the valves you need. You will feel better knowing they can help your project from start to finish.

Technical Guidance

Getting advice from the company is very important. Experts help you pick the right size, material, and type of valve. They can make special valves for hard jobs. They help you solve problems and make sure the valves work well.

You get help with sizing, sometimes with special tools like Cv calculators. The company tells you what materials work best and what the valve should do, like control flow or protect your system. They make sure the valves are tested in tough conditions and help you pick the right ends for easy setup and fewer leaks.

Working with experts helps you save money and keep your system running well. Good support means you get your valves on time and can fix them when needed.

Note: Always talk to the technical team early in your project. Their help keeps you from making mistakes and makes sure your valves are safe and work right.

Common Mistakes

Overlooking Certifications

Some people think certifications are just extra papers. But certifications show a manufacturer follows strict rules. If you do not check for certifications, you might buy valves that are not safe or good quality. Certified valves mean the manufacturer follows important rules like API, ISO, or CE. These certifications prove the valves passed tests for strength and safety.

Tip: Always ask for current certificates before you buy. Make sure the certifications fit your project’s needs.

Here is a simple table to help you remember which certifications are important:

| Certification | What It Proves | Why You Need It |

|---|---|---|

| API | Industry safety and quality | Needed for oil, gas, pipelines |

| ISO | Quality management | Trusted worldwide |

| CE | European safety compliance | Required in Europe |

| ATEX | Explosion safety | Needed for hazardous locations |

If you forget about certifications, you could have legal problems or system failures. You might also spend more money fixing things later.

Ignoring Support

You need more than just a good valve. Good support helps you fix problems fast. If you do not care about after-sales service, repairs and spare parts can be hard to get. Good manufacturers give clear warranties and quick help. They also make it easy to get new parts.

- Support helps you:

- Fix leaks or breakdowns fast

- Get help with setup or upgrades

- Keep your system working with less downtime

Note: Pick a manufacturer with strong technical support and a clear warranty. This saves you time and money.

If you skip support, you might wait longer and pay more. You could also have safety problems if you cannot fix things quickly.

Focusing Only on Price

Low prices can look good, but they can hide problems. If you pick the cheapest valve, it might break or leak. Cheap valves may not follow industry rules or last long.

Think about the total cost, not just the price. Remember you will spend money on repairs and downtime too. Good valves may cost more at first, but they save you money later.

Alert: Always balance price with quality, certifications, and support. The lowest price almost never gives you the best value.

You protect your system and your money when you look past price. Good valves keep your work safe and running well.

Skipping References

Some buyers forget to check references when picking a ball valve manufacturer. This can cause big problems and cost a lot of money. You need to know if the manufacturer does a good job in real life. References show if a company keeps its promises.

If you skip checking references, you miss important information. You will not know how the manufacturer deals with delays or broken products. You also will not learn about their customer service or technical help. Without references, you are taking a chance with your project.

Tip: Always ask for two or three references from recent customers. Make sure these are from projects like yours.

Why References Matter

References help you answer key questions:

- Does the manufacturer send valves on time?

- Do the valves work well in real jobs?

- How does the company fix problems or complaints?

- Is technical support quick and helpful?

- Would the customer buy from them again?

You can use a simple checklist when talking to references:

| Question to Ask | Why It Matters |

|---|---|

| Did the valves meet your specs? | Makes sure the product fits and works |

| Was delivery on schedule? | Shows if the company plans well |

| How was after-sales support? | Tells you about their service |

| Any issues with performance? | Points out possible problems |

| Would you recommend them? | Shows if customers trust the company |

Listen for honest answers. Customers will share both good and bad stories. This helps you make a smart choice.

How to Check References

- Ask the manufacturer for a list of recent projects.

- Contact the references by phone or email.

- Ask simple questions about their experience.

- Write down any problems or good things you hear.

- Compare what different people say.

Alert: If a manufacturer will not give references or only gives old ones, this is a warning sign. Good companies are happy to share their past work.

Checking references takes some time, but it keeps your money safe. You will not get surprises and you will pick a manufacturer who has done a good job before. Always check references before you decide. This helps you trust your final choice.

You can find the best ball valve manufacturer by using simple steps. First, think about what your system needs. Next, check if the manufacturer has the right certifications. Then, look at how they help customers after you buy. Use this checklist to help you choose:

- Make sure the ball valve fits your job.

- Check for certifications and ask for references.

- See what kind of help you get after buying.

Doing good research helps you pick a manufacturer who keeps your system safe and working well.

FAQ

What certifications should you check when choosing a ball valve manufacturer?

You should look for API, ISO, CE, and ATEX certificates. These certificates show the company makes safe and good quality valves. Always ask to see the latest certificates before you buy.

How do you know if a ball valve fits your system?

Check what the valve is made of, its pressure rating, and its size. Ask the company for help if you are not sure. Use a checklist to match the valve with your fluid, temperature, and how it connects.

Why does after-sales support matter?

After-sales support helps you fix problems fast. You get help with repairs, spare parts, and advice. Good support keeps your system working and saves you money.

Can you request custom ball valves for special applications?

Yes, you can ask for custom ball valves. Tell the company what your system needs. They can make valves with special materials, sizes, or controls for your project.

How do you verify a manufacturer’s reputation?

Read reviews from other customers and ask for references. Talk to people who bought from them before. Good companies share references and have happy customers.

What mistakes should you avoid when selecting a ball valve manufacturer?

Do not forget to check for certificates, support, or references. Do not pick just by price. Make sure the company knows your industry and can meet your needs.

How often should you inspect and maintain ball valves?

Check your ball valves often, at least once a year. Look for leaks, rust, or damage. Follow the company’s guide to keep your valves safe and working.