An altitude valve controls how much water is in tanks. It opens or closes by itself when water gets to a certain height. This valve can sense the water level and changes the flow on its own. People do not need to do anything for it to work. A pneumatic valve or a butterfly valve often needs someone to control it. The altitude valve uses hydraulic force to stop the tank from overflowing. Some systems use an electric valve instead. But many systems use this automatic control to keep things steady.

Altitude Valve Basics

Definition

An altitude valve is a special valve for water systems. It helps control how much water is in tanks. The valve opens or closes when water gets to a certain height. It works by itself and does not need electricity or someone to run it. The valve uses water pressure to know the tank’s level. This makes it good for places with no power.

Main Function

The main job of an altitude valve is to keep tanks full but not overflowing. It stops water from spilling out and wasting water. The valve senses water pressure changes. When the tank is full, the valve shuts to block more water. When water goes down, the valve opens to let water in. This keeps water steady in city and factory systems.

Altitude valves are important for water control because they do not need outside power. They are great for faraway places and for emergencies since they only use hydraulic pressure.

Here are the main jobs of altitude valves in water systems:

- Keep water tanks at the same level.

- Stop overflow and save water by closing at set levels.

- Work on their own with little help from people.

- Make water flow better between tanks and reservoirs.

- Do not need outside power, so they work in remote places.

- Have different types like single-level, two-way, or modulating for different uses.

- Used in city water, factories, farms, and fire safety systems.

Key Features

Altitude valves have many features that help control water:

- They use different controllers like displacer, caged ball float, internal ball float, or differential pressure.

- The valve is put in pipes that fill tanks, basins, or reservoirs.

- It keeps the reservoir at the same level and stops overflow.

- The valve does not need outside energy; it uses water pressure.

- It is simple and works well, so fixing it is easy.

- Good for places with no power.

- Most fixes can be done on site except for the main valve.

- It controls water level by itself without extra systems.

- It works with water pressure, not electricity.

- The valve shuts at a set high level to stop overflow.

- Pilot valves can help if power goes out.

- Often used in water systems to keep water service steady.

Tip: Altitude valves help water companies give steady water and keep tanks safe from overflow.

Operation

Hydraulic Control

Hydraulic control is how an altitude valve works. The valve uses water pressure to check the water level in a tank. Many new valves, like ones from BERMAD, use a 3-way altitude pilot. This pilot can tell if the water goes up or down. When water gets to a set high point, the valve closes all the way. If water drops by about one meter, the valve opens to let more water in.

- The double chamber design helps the valve move smoothly and stay steady.

- The valve body lets water move easily, even with high pressure.

- These valves do not get damaged by bubbles forming and popping inside.

- They close tightly to stop leaks and are simple to fix.

Some valves, like those from Cla-Val, do not use floats. They stay open until water gets to the shut-off point. People can set these valves for one-way or two-way flow. Extra hydraulic controls can add things like pressure reduction or solenoid override. Modulating float valves can change the flow to keep water steady, opening or closing as needed.

Note: Hydraulic control lets the valve work without power. This makes it good for faraway places or emergencies.

Pressure Differential

Pressure differential is important for how the valve opens and closes. The valve checks the pressure before and after itself. A sensing line often connects to the tank to help find changes in water level. When the pressure difference hits a set point, the valve opens to let water in. As the tank fills and pressure changes, the valve closes to stop water.

- The pressure difference across the valve controls how it moves.

- Adjustable closing speed helps stop water hammer by slowing the valve.

- Some valves have a pressure sustaining loop. This makes sure the valve only opens if there is enough pressure and need.

- Putting the valve close to the tank helps it sense pressure better.

The pressure difference changes all the time. How the valve works depends on how it is set and adjusted. Most altitude valves need the supply pressure to be much higher than the full tank pressure. Usually, a difference of at least 15 psi is best. This helps the valve open and close by itself to keep water steady.

Non-Throttling Action

Altitude valves often use non-throttling action. This means the valve is either fully open or fully closed, not partly open. The valve does not slowly cut flow as water rises. Instead, it lets water move freely until the tank is full. Then, it shuts off all the way.

- Non-throttling action stops wear on valve parts.

- The valve does not waste energy by blocking flow.

- This keeps the water system simple and easy to fix.

Some modulating float valves can change flow to keep water steady. But most altitude valves use non-throttling for better reliability and less fixing.

Adjustment Method

Altitude valves let workers pick the water level for opening or closing. This helps the tank fill to the right height and stops overflow. How you adjust the valve changes how well it keeps the right water level. Using different tools can make the settings more or less exact.

Adjusting Screw

Most altitude valves have an adjusting screw for the shut-off point. The worker turns the screw to change when the valve closes. This screw is linked to the pilot inside the valve. Turning the screw right makes the set point higher. Turning it left makes it lower. The screw lets you fine-tune the system easily and you do not need special tools.

Tip: Always read the manufacturer’s guide before making changes. Even small turns of the screw can change the water level a lot.

Set Level Changes

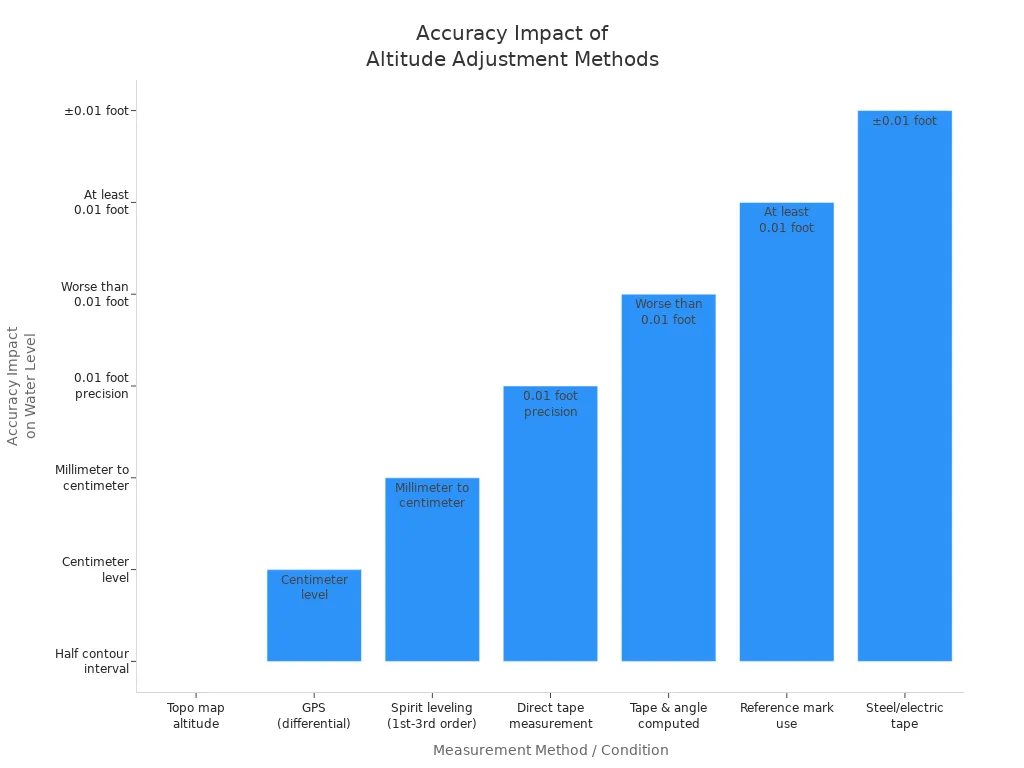

Changing the set level needs careful measuring. How well you measure affects how close you get to the right water level. For example, a spirit level is more exact than a topographic map. Using a tape to measure straight up and down is the most exact. If you use tape and angles, it is less exact.

| Aspect | Measurement Method / Condition | Accuracy Impact on Water Level Measurement |

|---|---|---|

| Measuring Point (MP) Altitude | Topographic maps | About half the contour interval; not very exact |

| GPS (differential) | Can be exact to centimeters | |

| Spirit leveling (1st to 3rd order) | From millimeters to centimeters; most exact | |

| MP Correction Length (Vertical Stickup) | Direct tape measurement | About 0.01 foot; most exact for vertical stickups |

| MP Correction Length (Non-Vertical Stickup) | Computed from tape length and angles | Not as exact as 0.01 foot; depends on tape and angle |

| Reference Marks (RM) | Used to check MP or LSD movement | Should be at least 0.01 foot for good comparison |

| Water Level Measurement Tools | Graduated steel or electric tape | Usually ±0.01 foot; check for errors from tools or weather |

| Comparison Context | Single well | Altitude is less important; measuring is more important |

| Multiple wells | Very exact altitude needed for comparing |

The way you measure changes how well the valve keeps the water where you want it. If you have more than one tank or well, being exact is even more important.

Workers should use the best tools they have when setting or changing the set level. This helps keep water steady and stops problems like overflow or low water.

Applications

Elevated Tanks

Altitude valves are very important in elevated tanks. These tanks hold water above ground to make pressure. The valves open by themselves to let water in. They close when the tank is full to stop overflow. Most elevated tanks use altitude valves because they do not need power. They work by sensing water height and reacting fast. For example, some valves use a sensing line to check water level. When water gets high enough, the valve shuts tight. If pressure goes down, the valve lets water back into the pipes. This helps cities keep water safe and ready in tall tanks.

Altitude valves in tall tanks stop waste and keep water ready for daily use and emergencies.

Reservoirs

Big reservoirs need good water control to stop overflow and keep water clean. Altitude valves help by using two positions: open or closed. The valve stays open while water fills the reservoir. It closes all the way when water reaches the set level. This stops overflow and keeps water at the right height. Some valves have extra controls for pressure and flow. These make the system work better. The valves react quickly to water changes and shut off tight. Many are made from materials that do not rust, so water stays safe to drink. Some altitude valves open slowly to help water move and stay fresh.

Tip: Using altitude valves in reservoirs helps workers keep water levels right and the system healthy.

Remote Installations

Remote places have special problems for altitude valves. These sites are often high up or far away from main buildings. Engineers must fix things like loud noise, damage from bubbles, and drops in pressure. For example, a mine in Peru used special pump packages and control panels to keep water steady at high elevation. In other places, anti-cavitation trims cut down noise and shaking. Control panels help run many valves at once for better tank control. SCADA systems let workers watch and control valves from far away. Surge relief and air valves help with pressure changes and protect pipes. These ideas have worked well in places like Butler County, Ohio, and Pepperdine University. There, altitude valves stopped noise and damage and kept water flowing smoothly.

- Common problems in remote places:

- Loud noise and shaking

- Damage from bubbles

- Pressure drops

- Running many valves together

- Keeping water levels right at different heights

- Ways to fix these problems:

- Anti-cavitation trims

- Special control panels

- SCADA systems

- Surge relief and air valves

Note: Good altitude valve systems help remote sites keep water safe and protect equipment, even in tough places.

Level Control Benefits

Overflow Prevention

Altitude valves help stop tanks from overflowing. They use level control to know when water is high. When the tank is full, the valve shuts tight. This keeps extra water from spilling out. Cities and towns use this to save water and protect gear. Overflow can hurt buildings and waste water. Level control helps keep tanks at the right level every day. This system works without power, so it helps in far places.

Tip: Stopping overflow keeps water safe and cuts repair costs.

Water Hammer Reduction

Water hammer happens when water stops or changes fast. This can make loud sounds and break pipes. Altitude valves help by opening and closing slowly. They use level control to check the tank’s water height and move right. Here are ways altitude valves lower water hammer risk:

- The valve checks the water level and opens or closes to keep it steady.

- The valve opens and closes at a set speed during filling.

- Modulating valves change flow slowly to stop sudden pressure jumps.

- The valve controls how fast it closes and how much water moves.

- By stopping quick changes, the valve keeps the system safe.

Many water systems use altitude valves for this reason. Careful control of flow and pressure keeps pipes safe and quiet.

Pressure Regulation

Good pressure keeps water systems working well. Altitude valves help by keeping tank levels steady. When the tank stays full enough, pipe pressure stays even. This protects pumps, pipes, and other parts. Some states, like West Virginia, require altitude valves for extra water storage. These rules show how important these valves are for safety. Workers trust altitude valves to stop pressure from getting too high or low. This helps stop leaks and keeps water moving where it is needed.

Note: Good pressure means fewer problems and better water service.

Limitations

Pressure Needs

Altitude valves need enough pressure to work right. If pressure is too low, the valve might not open or close when it should. Tanks could fill slowly or not fill at all. The table below shows the least pressure needed for different jobs:

| Condition / Requirement | Minimum Pressure Requirement (psi) | Equivalent Water Height (feet) | Notes |

|---|---|---|---|

| Pressure needed to fill tank | 0.433 psi per foot of tank height | N/A | Example: 10 psi can fill up to about 23 feet tank height |

| Minimum differential pressure for non-modulating valve operation | 5 psi | N/A | Needed for the valve to work right |

| Minimum total pressure to open valve | 3-4 psi | 7-9 feet | Valve might close too soon if pressure is lower |

| Minimum differential pressure with modulating controls or check feature | 10 psi | N/A | More pressure needed when extra valve features are used |

| Check valve cracking pressure (example Swingflex) | 0.25 psi | N/A | Less pressure needed to open check valve than diaphragm actuated control valve |

Operators should check system pressure before putting in an altitude valve. If pressure goes below the least amount, the valve may not work right. This could cause not enough water or too much water.

Cold Weather Issues

Cold weather can make problems for altitude valves. Freezing can turn water inside the valve into ice. Ice can break valve parts or block sensing lines. If the valve cannot sense water level, it will not work right. Big changes in temperature can also hurt pipes and cause leaks. Sometimes pipes burst because of the cold.

To stop these problems, workers use insulation or heat tape on pipes and valves. They might drain water from pipes not used in winter. Valves made from freeze-resistant materials help protect the system. Checking valves often in cold months helps find problems early.

Note: Cold weather can break altitude valves fast. Insulation and regular checks help keep everything safe.

Maintenance

Altitude valves need regular care to keep working well. Hard water can leave minerals that clog the valve. This happens a lot in high places or country areas. Changes in pressure from hills can wear out valve parts. Workers need to look at and clean valves to stop problems.

Common maintenance problems are:

- Mineral buildup can block fittings and strainers, so cleaning or new parts may be needed.

- The main valve diaphragm can wear out or leak from age or minerals.

- Pilot diaphragms can leak, shown by water dripping, and may need new diaphragms.

- Air stuck in pilot systems can make the valve work wrong.

- Ball valve handles can rust or get stuck, stopping the valve and needing replacement.

- Workers should check and test pilots often to find slow or bad operation.

Operators should watch water pressure and keep it between 45 and 60 psi. Using parts made for altitude and cleaning often helps stop trouble. Keeping a schedule for care makes valves last longer and work better.

Comparison

Electronic Controls

Electronic controls use sensors and controllers to watch water levels. These systems check water levels right in the tank. This makes them more exact than mechanical altitude valves. Electronic controls react fast when water changes. They can also do many jobs at once, like control flow, lower pressure, and watch levels. Many electronic controls let workers check them from far away. They send alarms if something is wrong. This makes them easier to use and more dependable, especially in big water systems. Some systems use both electronic and hydraulic controls together. This way, the system still works if the power goes out. Altitude valves use moving parts and water pressure. This can make them slower and less exact.

Electronic controls help water systems by reacting quickly and giving more information to workers.

Cost and Complexity

When looking at costs, electronic controls can save money over time. They often cost less to put in and take care of than altitude valves. Electronic systems need less fixing because they have fewer moving parts. They can also find problems early. These systems let workers check them from far away, send alarms, and work by themselves. This means workers do not have to visit as much. Altitude valves cost more to fix, especially where it is cold or there are lots of minerals. These valves may need more repairs and checks. Electronic sensors can also watch temperature and warn if it might freeze, which helps stop damage.

- Electronic controls:

- Cost less to put in and fix

- Break less and have less downtime

- Have alarms and can be checked from far away

- Altitude valves:

- Cost more to fix

- Break more in cold or rough places

- Do not have alarms or remote checking

Best Use Cases

The best choice depends on what the water system needs. The table below shows where each type works best:

| Feature/Aspect | Altitude Valves | Electronic Level Controls |

|---|---|---|

| Operation Type | Mechanical, uses water pressure and diaphragm | Electronic sensors with solid-state controllers |

| Power Requirement | No outside power needed | Needs power, but works with automatic systems |

| Typical Applications | Big water tanks, reservoirs, places with no electricity | Fire tanks, modern storage needing alarms and checking |

| Benefits | Stops overflow, simple, works without power | Very reliable, can be checked from far away, has alarms, less trouble with dirt or rust |

| Restrictions | Not for pressurized tanks, limited materials, needs more fixing | Needs power, more parts to set up |

| Best Use Cases | Simple, big storage where power is not wanted | Systems needing high reliability, alarms, and checking, like fire protection |

Altitude valves are good for simple, big water storage where there is no power. They stop overflow and keep water steady without needing electricity. Electronic controls are best for systems that need to work all the time, be watched, and have alarms. Fire safety systems use electronic controls because they must always work and follow safety rules. Electronic systems also connect to building systems, so they are great for new water storage needs.

Picking the right system depends on the place, if you need to watch it, and how important it is to have alarms and easy control.

Altitude valves are important in water systems. They control water levels by themselves. This stops tanks from overflowing and saves water in cities. These valves work well in many jobs and can handle changes. When picking between altitude valves and electronic controls, engineers should think about flow, pressure, water quality, and how complex the system is. Electronic controls have more features and let people check them from far away. Mechanical valves are better when there is not much power.

FAQ

What is the main job of an altitude valve?

An altitude valve stops tanks from overflowing. It opens when water gets low. It closes when water reaches a set height. This helps save water and keeps tanks full.

Can altitude valves work without electricity?

Yes, altitude valves use water pressure to sense levels. They do not need electricity to work. This makes them good for faraway places or when power is out.

How often should someone check or maintain an altitude valve?

Workers should check altitude valves every six months. Regular checks help find leaks or worn parts. Cleaning and fixing keeps the valve working well.

Where do people usually install altitude valves?

People put altitude valves in tall tanks, reservoirs, and remote sites. These valves help control water levels where there is no power.

What problems can happen if an altitude valve fails?

If an altitude valve fails, tanks can overflow or run dry. Overflow wastes water and can hurt buildings. Low water can make pressure drop in pipes.

How does an altitude valve prevent water hammer?

Altitude valves open and close slowly. This stops sudden changes in water flow. It helps keep pipes safe from loud sounds and damage.

Are altitude valves better than electronic controls?

Altitude valves are good for simple systems with no power. Electronic controls have more features like alarms and remote checks. The best choice depends on what the water system needs.

Can altitude valves handle freezing weather?

Altitude valves can freeze in cold weather. Workers use insulation or heat tape to protect them. Checking valves in winter helps stop freezing and damage.