An actuating valve uses force and movement to control flow. It helps move liquids or gases in a system. This device is important for both automatic and manual jobs. It lets workers make quick changes when needed. Many industries use actuating valves for safety. Chemical, oil and gas, and water treatment companies need them. These valves help handle delicate materials. They also keep the process safe. Some common types are pneumatic valve, electric valve, and pneumatic control valve. These valves work in many places. You can find them in food factories and power plants.

Actuating Valve Overview

What Is an Actuating Valve

An actuating valve is a device that controls flow. It uses mechanical force to move liquids or gases. The valve body connects with a valve actuator. The actuator moves parts inside the valve. These parts open, close, or change the flow. Main parts are the valve stem, disc, seat, trim, and actuator. The actuator can be manual, electric, pneumatic, hydraulic, or spring-powered. Each actuator moves the valve stem and disc in its own way. Manual actuators use levers or wheels. Pneumatic actuators use air pressure. Hydraulic actuators use fluid pressure. Electric actuators use motors. Spring actuators store energy for emergencies.

Note: The actuator type matches the valve. Rotary actuators work with ball or butterfly valves. Linear actuators work with gate or globe valves.

How Actuating Valves Work

An actuating valve changes energy into movement. This movement shifts the valve stem and disc. It changes how much flows inside the pipe. The process starts when a control system sends a signal. The actuator uses its power source to move the valve. Power can be manual force, air, electricity, or hydraulic fluid. In pneumatic systems, air pressure pushes a diaphragm or piston. This moves the stem and opens or closes the valve. In electric systems, a motor turns gears to move the valve. Some actuators have sensors and controls. These help control the valve position exactly.

Typical steps in actuating valve operation:

- The control system sends a signal to the actuator.

- The actuator gets energy from its power source.

- The actuator turns energy into movement.

- The movement shifts the valve stem and disc.

- The valve opens, closes, or changes flow.

Key Functions

Actuating valves do many important jobs in fluid systems. These valves protect systems from pressure spikes. They stop uncontrolled fluid release. Control valve actuators give the force needed for these jobs. They help the valve work fast and correctly.

Primary functions of actuating valves:

- Start or stop flow (on/off control)

- Regulate flow (throttling or modulating)

- Direct flow (change flow path)

- Relieve excess pressure (over-pressure protection)

- Prevent uncontrolled release (excess flow protection)

Control valves with the right valve actuator keep systems safe and reliable. They are used in water treatment, oil and gas, and manufacturing. The actuator and valve type depend on the job and how much control is needed.

Types of Valve Actuators

Valve actuators help control how fluids move. They use different kinds of power and motion. This lets them work in many jobs. The main types are manual, electric, and pneumatic actuators. Each type works best for certain needs and places.

Manual Actuators

Manual actuator valves need people to work them. Someone turns a lever, knob, or wheel to open or close the valve. These actuators are simple and cost less. They do not need outside power. This makes them good for faraway places or when power is out.

Manual actuator valves are best for small valves or backup use. They are often used in low-pressure jobs and for emergency shut-off.

| Aspect | Manual Actuators Advantages | Manual Actuators Disadvantages |

|---|---|---|

| Cost | Cheapest type of valve actuation | N/A |

| Power Dependency | Does not depend on external power source | N/A |

| Design Complexity | Simpler design, easy to maintain | N/A |

| Operation Speed | N/A | Slow to open and close, especially large valves |

| Labor Requirement | N/A | Labor-intensive operation |

| Automation Suitability | N/A | Not suitable for remote or automatic control |

| Application Context | Used in low pressure and as backup valves | Difficult for large valves |

Manual actuator valves have some downsides. They need people to use them and can be slow. Big valves might need extra tools or gearboxes. These actuators cannot be controlled from far away or by machines.

Electric Actuators

Electric actuators use motors to move the valve stem. They give exact control and quick action. Electric actuator valves are great for systems that run by themselves or from far away. These actuators are good for jobs that need to be very accurate and dependable.

Electric valve actuators can move in two ways: rotary or linear. The kind of electric actuator matches the valve shape. Rotary electric actuators spin the valve stem. Linear electric actuators push or pull the stem.

Rotary Electric Actuators

Rotary electric actuators spin the valve stem around. They work with ball, butterfly, and plug valves. These actuators give strong turning force and can stop at the right spot. They are easy to use with control systems.

Rotary electric actuators are found in water plants, HVAC, and chemical factories. They help turn flow on or off and adjust it. These actuators can be run by machines and checked from far away.

Linear Electric Actuators

Linear electric actuators move the valve stem straight up or down. They fit gate, globe, and diaphragm valves. These actuators move smoothly and steadily. Electric valve actuators with linear motion give exact flow control and fast action.

Factories use linear electric actuators for moving materials, robots, and process jobs. Electric actuator valves help control flow in making things and in oil and gas plants. They also help with safety and emergency shut-off.

Control Modes

Electric actuators can work in different ways. Some just turn on or off. Others can make small changes for better control. Some advanced electric valve actuators have sensors to check their position. These features make them more accurate and reliable.

Electric actuators are used in many fields, like cars, food, and electronics. They help with automation, safety, and saving energy.

| Industry Sector | Typical Applications of Electric Actuators |

|---|---|

| Automotive | Driverless transport vehicles, welding, gluing, riveting |

| Food and Beverage | Bottle manufacturing, filling, labeling, robotic milking |

| Materials Handling | Servo presses, clamping, packaging |

| Electronics & Assembly | Robotics, machine tools |

| Oil and Gas | Plant operations |

| Pulp and Paper | Various plant operations |

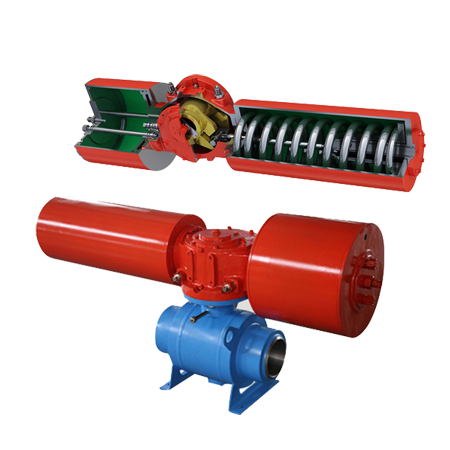

Pneumatic Actuators

Pneumatic actuators use air pressure to move the valve stem. These actuators give steady force and quick action. Pneumatic valve actuators work well in tough places and hard jobs. They are good for jobs that need to be fast and reliable.

Pneumatic actuators come in rotary and linear types. The kinds of pneumatic valve actuators are piston, diaphragm, and rotary vane. Pneumatic valve actuators can be double-acting or spring-return. Spring-return types use air to move one way and a spring to go back for safety.

Rotary Pneumatic Actuators

Rotary pneumatic actuators turn the valve stem around. They fit ball and butterfly valves. These actuators last a long time, switch fast, and are strong. There are rack-and-pinion, scotch yoke, and vane types.

Rotary pneumatic actuators are used in car factories, packaging, and water plants. They help with quick shut-off and adjusting flow.

Linear Pneumatic Actuators

Linear pneumatic actuators move the valve stem up and down. They fit gate, globe, and diaphragm valves. Pneumatic actuators with linear motion give smooth and exact flow control.

Factories use linear pneumatic actuators in electronics, food making, and chemical plants. Pneumatic valve actuators help keep things moving and safe in automatic systems.

Pneumatic actuators work in many places. They last long, need little care, and work with modern control systems.

Hydraulic Actuators

Hydraulic actuators use fluid under pressure to move valves. These actuator valve types give strong force and work very well. Hydraulic actuators are used for big jobs that need lots of power. Many industries use hydraulic actuator valves to lift, press, or move heavy things.

Hydraulic actuators use oil or other fluids that do not squeeze. This helps them make more force than pneumatic actuators. Hydraulic actuator valves can handle very high pressure. This makes them great for building, flying, and making things.

Rotary Hydraulic Actuators

Rotary hydraulic actuators spin the valve stem in a circle. These actuators fit ball, butterfly, and plug valves. Rotary hydraulic actuator valves use fluid to turn gears or vanes. This movement opens or closes the valve fast and with strong force.

Rotary hydraulic actuators are good for systems that need strong turning power. Big machines, cranes, and large valves use these actuator valve types. Rotary hydraulic actuators work well in tough places and keep working when things get hard.

Linear Hydraulic Actuators

Linear hydraulic actuators move the valve stem up and down. These actuators fit gate, globe, and diaphragm valves. Linear hydraulic actuator valves use a piston inside a tube. When fluid goes in, it pushes the piston and moves the valve.

Linear hydraulic actuators give smooth and steady movement. They can lift or push very heavy things. Many factories use linear hydraulic actuator valves for pressing, stamping, or moving lots of fluid. These actuators are strong and work well where safety matters.

Hydraulic actuators are special because they give lots of force. They use fluids that do not squeeze and can reach higher pressure than pneumatic actuators. This makes them great for lifting heavy things and hard jobs.

| Actuator Type | Force Output | Reliability | Maintenance | Notes |

|---|---|---|---|---|

| Hydraulic | Highest force output, good for heavy loads | Works well in tough places | Harder to fix because of leaks and complex parts | Bigger, needs extra systems |

| Pneumatic | Less force than hydraulic and electric | Simple design, quick action | Easier to care for, but less exact | Needs air all the time |

| Electric | Strong force, but less than hydraulic | Very exact and easy to control | Clean, needs less fixing | Costs more at first but saves energy |

Hydraulic actuators are strong for their size. They work well in moving machines and have safety parts like rod locks. But hydraulic actuator valves need checks for leaks and fluid. Their systems are harder and need more care than other actuator valve types.

Self-Actuated Valves

Self-actuated valves use the pressure of the fluid to work. These valves do not need outside power or people to help. The fluid itself moves the valve to the right spot. Self-actuated valves are simple and work well.

Many industries use self-actuated valves for automatic control. These valves help keep pressure or temperature steady. They are used in oil and gas, chemical plants, and water cleaning. Self-actuated valves also work in watering and waste systems.

- Self-actuated valves control gas pressure for burners.

- They manage liquid flow in waste and watering systems.

- Pressure relief valves open to let out extra pressure and protect equipment.

- These valves help keep systems safe by working on their own.

- They are used when steady pressure or temperature is needed.

Self-actuated valves are good when power is not there or when safety is needed. They help keep systems working without extra controls.

Spring Force Actuators

Spring force actuators use a spring to move the valve to a safe spot. When power or pressure is lost, the spring pushes the valve back. This gives a true fail-safe feature. Spring force actuators do not need outside energy to return the valve.

Spring force actuators are important in safety systems. They are used in chemical plants, water cleaning, oil and gas, and firefighting. These actuators make sure valves close or open fast if something goes wrong.

- Spring force actuators return valves to a safe spot when power is lost.

- They are used in tunnels and subways to control smoke.

- Chemical plants use them for emergency shut-off.

- Oil and gas storage uses them for quick shut-off in emergencies.

- Firefighting systems use them for fast action.

Spring force actuators use air, electric, or hydraulic power to move the valve one way. The spring moves it back. This saves energy and adds safety. Spring force actuators can have shields to resist fire and work in dangerous places.

Spring force actuators have some limits. The spring can wear out, so checks are needed. Double-acting actuators, which use power both ways, are better when the valve must stay in place.

Spring force actuators are found on ball valves, butterfly valves, and damper valves. They are picked for their quick and automatic fail-safe action.

Valve Actuator Types: Rotary and Linear

Valve actuator types are split into two groups. These are rotary and linear. Each type moves in a special way. Each fits certain valve shapes. Knowing these types helps people pick the right actuator.

Rotary Actuators

Rotary actuators make things spin in a circle. They turn objects around a center point. This can be by a set amount or all the way around. This spinning matches valves that need to twist to open or close. Rotary actuators are small and fit in tight spots.

Rotary actuators work best with ball valves, butterfly valves, and plug valves. These valves need a quarter-turn or more to change flow. The actuator’s spin matches the valve’s movement. This makes the valve work smoothly and well.

Rotary actuators are great for jobs that need turning. They help move conveyor gates or change valve spots in systems.

Scotch Yoke Mechanism

The scotch yoke mechanism changes straight force into spinning motion. It uses a sliding yoke with a pin on a turning shaft. When the actuator pushes the yoke, the shaft spins. This design gives strong force at the start and end. It helps with hard valve jobs.

- Scotch yoke actuators are good for tough valves.

- They give strong force for fast opening and closing.

- Many oil and gas plants use scotch yoke actuators for safety shut-off.

Rack-and-Pinion Mechanism

Rack-and-pinion actuators use gears to change straight movement into spinning. A straight rack moves back and forth. This turns a round pinion gear. This setup gives steady force and smooth movement.

- Rack-and-pinion actuators work with ball and butterfly valves.

- They give steady work for jobs done often.

- Water treatment and chemical plants use rack-and-pinion actuators a lot.

| Mechanism | Motion Conversion | Torque Profile | Common Applications |

|---|---|---|---|

| Scotch Yoke | Linear to rotary | High at ends | Heavy-duty, safety shut-off |

| Rack-and-Pinion | Linear to rotary | Even throughout | Frequent, smooth operation |

Linear Actuators

Linear actuators move things in a straight line. They push or pull objects over a set space. This fits valves that slide or lift to open or close. Linear actuators are best when exact movement is needed.

Linear actuators work with gate valves, globe valves, diaphragm valves, and pinch valves. These valves need the stem to go up and down or back and forth. Linear actuators give the right control for careful flow changes.

Linear actuators are best for jobs like moving control surfaces or setting cutting heads in machines.

Key differences between rotary and linear actuator motion:

- Rotary actuators spin objects around a center.

- Linear actuators move objects in a straight line.

- Rotary actuators fit ball, butterfly, and plug valves.

- Linear actuators work with gate, globe, diaphragm, and pinch valves.

Valve actuator types must match the valve’s job for safe and good work. Picking the right actuator helps keep flow control working well.

Pneumatic Actuators in Industry

Pneumatic actuators are important in many factories. They use compressed air to move valves and parts. Many companies pick pneumatic actuators for their speed and safety. These devices help control flow quickly and keep things clean.

Advantages

Pneumatic actuators have many good points for factories:

- They give strong force and move fast with compressed air.

- These actuators last long and work under pressure without getting too hot.

- Pneumatic actuators work well and control movement exactly.

- They use clean air, so no oil or fluid leaks. This makes them safe for food and medicine factories.

- Factories like them because they are simple to set up and fix.

Tip: Pneumatic actuators are great for places that need to be clean and safe.

Disadvantages

Pneumatic actuators also have some problems:

- They are not as exact as electric actuators because air can change shape.

- These actuators need a steady air supply. If air stops, they may not work.

- Pneumatic actuators do not work well in very hot or cold places.

- It is hard to control their speed because air flow is tricky.

- Leaks from seals or valves can lower how well they work and cause safety problems.

- They can be noisy and shake, so extra steps may be needed.

- Pneumatic actuators use more energy than electric ones because air compressors run all the time.

| Feature | Pneumatic Actuators | Electric Actuators |

|---|---|---|

| Precision | Lower | Higher |

| Energy Efficiency | Lower | Higher |

| Maintenance | Needs regular checks | Needs less maintenance |

| Cleanliness | Very high | High |

| Noise | Can be noisy | Quiet |

Common Uses

Factories use pneumatic actuators in many ways:

- Manufacturing plants use them for picking, clamping, and stamping.

- Packaging lines use pneumatic actuators for moving and sorting things.

- Food and drink factories use pneumatic actuator valves to keep things clean and safe.

- Chemical plants use pneumatic actuators for valve control in dangerous places because they do not spark or leak oil.

- Automation systems use pneumatic actuators for moving robot arms, conveyor belts, and gates.

- Material handling uses them for lifting and moving things.

- Robotics teams use pneumatic actuators for grippers, wheels, and other moving parts.

Pneumatic actuators are still popular in factories. They are fast, safe, and easy to care for. Many companies choose them when they want quick and clean work.

Types of Valves Used with Actuators

Ball Valves

Ball valves have a round ball with a hole in it. When the actuator turns the ball, the hole lines up with the pipe. This lets fluid move through. If you turn the ball back, it blocks the flow. Ball valves only need a quarter turn to open or close. This makes them great for quick shut-off jobs. Actuators like electric, pneumatic, or hydraulic types work well with ball valves. They match the force and speed needed for turning the ball. The stem of the ball valve connects easily to actuators. This makes the movement smooth and dependable.

- Ball valves come in different sizes and materials like stainless steel, bronze, and polymers.

- Their seals are strong and can handle chemicals and high pressure.

- Many ball valves have manual override, so workers can use them by hand if needed.

Ball valves are a good match for actuators because their design fits the way actuators move. This helps control flow quickly and accurately.

Ball valves are used in water systems, gas pipes, and chemical plants. Their strong seals and fast action make them safe for emergencies. They can handle many pressures and temperatures. This makes them useful for lots of jobs. Ball valves also work well in systems that need fast flow control.

Butterfly Valves

Butterfly valves have a flat disc inside the pipe. The actuator turns the disc to open or close the flow. These valves are light and do not take up much space. Actuators can turn the disc easily. This makes butterfly valves good for moving large amounts of fluid. Their simple design means they need less fixing and cost less.

- Butterfly valves are simple to put in and take out.

- They work well with electric and pneumatic actuators.

- Their small size is good for tight places.

Butterfly valves are used in heating and cooling systems. Water treatment plants use them to control lots of water. Food factories pick butterfly valves because they are easy to clean. They can handle big flows and work fast, so many industries use them.

Gate Valves

Gate valves use a flat or wedge-shaped gate that moves up and down. This opens or closes the flow. Actuators with straight motion, like electric or hydraulic types, fit gate valves well. When the actuator lifts the gate, fluid moves with little resistance. Lowering the gate stops the flow. Gate valves are best for on/off control when you need a clear open or closed state.

- Gate valves let fluid move straight through, so there is less pressure loss.

- They are not good for controlling flow partway.

Gate valves are found in oil and gas pipes, water supply systems, and power plants. They can handle high pressure and shut off tightly, so they are trusted for important jobs. Actuators help gate valves work automatically in big systems. This makes things safer and more efficient.

Picking the right actuator and valve helps make sure things move well, control is accurate, and everything stays safe. Each valve type works best with certain actuators, depending on how much force, speed, and control is needed.

Globe Valves

Precise flow regulation, suitable for throttling

Globe valves can control flow very accurately. They have a disk that moves up and down. The disk sits on a ring called a seat. The actuator lifts or lowers the disk. This changes how much fluid can pass through. People use globe valves when they need to change flow rates often. These valves are good for throttling because they allow small changes.

Globe valves work best with linear actuators. Electric, pneumatic, or hydraulic actuators push the stem straight up or down. This gives workers fine control over the valve’s position. Globe valves react fast to actuator signals. They help keep systems safe and steady.

Tip: Globe valves give better control than ball or gate valves. They are best for jobs where flow changes a lot.

Used in process control, steam, and high-pressure systems

Many industries use globe valves for process control. Chemical plants use them to mix and control reactions. Steam systems use globe valves to handle pressure and heat. Power plants put globe valves in high-pressure pipes. These valves help keep equipment safe and working well.

Globe valves are also found in water treatment and oil refining. People pick them for jobs that need steady and exact flow. Their strong build lets globe valves handle tough jobs.

Common actuator types for globe valves:

| Actuator Type | Control Precision | Typical Use Case |

|---|---|---|

| Electric | High | Automated process lines |

| Pneumatic | Medium | Steam and air systems |

| Hydraulic | High | High-pressure pipelines |

Plug Valves

Simple design, quick operation, good for slurry or viscous fluids

Plug valves have a plug inside the valve body. The plug is shaped like a cylinder or cone. The actuator turns the plug to open or close the valve. Plug valves are simple and easy to use. They work well with rotary actuators. People choose plug valves for quick shut-off and fast changes.

Plug valves are good for thick or sticky fluids. Slurry, oil, and thick chemicals move through these valves easily. The plug shape helps stop clogs. Plug valves need less fixing than some other valves.

Note: Plug valves are great for fluids with solids or that are hard to pump.

Applied in chemical, petrochemical, and wastewater industries

Chemical plants use plug valves for acids, bases, and solvents. Petrochemical plants use them for oil and gas pipes. Wastewater plants use plug valves for sludge and dirty water. These valves do not rust or wear out fast.

Plug valves work with electric, pneumatic, or manual actuators. Rotary actuators match the turning of the plug. People pick plug valves for speed and dependability.

Plug valve advantages:

- Fast to use

- Good for thick fluids

- Easy to fix

Diaphragm Valves

Excellent for corrosive or sanitary applications

Diaphragm valves use a soft diaphragm to control flow. The actuator pushes the diaphragm down to close the valve. This keeps the fluid away from moving parts. Diaphragm valves do not rust and keep fluids clean. People use them for clean or dangerous fluids.

Diaphragm valves work best with linear actuators. Pneumatic and electric actuators move the diaphragm up and down. The valve seals tight to stop leaks.

Alert: Diaphragm valves stop contamination. They are best for sensitive or risky fluids.

Common in pharmaceutical, food, and water treatment

Medicine factories use diaphragm valves for clean processes. Food plants use them for clean water and ingredients. Water plants use diaphragm valves for chemicals and clean water. These valves meet strict safety and health rules.

People pick diaphragm valves because they are easy to clean and safe to use. The simple design makes them work well in tough places.

Diaphragm valve highlights:

- Safe for clean and harsh fluids

- Easy to care for

- Works with many actuator types

Pinch Valves

Ideal for abrasive or particulate-laden fluids

Pinch valves use a soft tube to control flow. The actuator squeezes the tube to stop or start flow. Moving parts stay outside the fluid path. The fluid only touches the inside of the tube. Pinch valves work well with fluids that have sand or grit. The soft tube can handle rough stuff and does not wear out fast.

Pinch valves do not have metal inside the flow path. This helps stop clogging and lowers damage from sharp bits. The valve can close tight, even if there are rocks or debris. Many industries pick pinch valves for their simple build and strong work with tough fluids.

Tip: Pinch valves last longer than other valves with slurries or fluids with solid bits.

Pinch valves work with different actuator types. Pneumatic actuators use air to squeeze the tube. Electric actuators can control pinch valves for more exact moves. Manual actuators, like handwheels, fit small systems or backup jobs. The actuator choice depends on how fast and how often the valve opens or closes.

Key benefits of pinch valves for abrasive or particulate-laden fluids:

- No metal touches the fluid

- Tube resists wear from sand or sludge

- Easy to swap the tube when needed

- Valve closes tight, even with solids in flow

Used in mining, wastewater, and bulk material handling

Mining uses pinch valves for slurries, tailings, and ore mixes. These fluids have rocks, sand, and chemicals. Pinch valves handle these hard jobs better than most valves. Workers can change the tube fast, which saves time.

Wastewater plants use pinch valves for sludge, grit, and chemical dosing. The valves keep working even with fibers, dirt, or stones. The soft tube stops blockages and makes care easy.

Bulk material systems use pinch valves for powders, pellets, and grains. The valve can start or stop dry stuff without jamming. Food plants sometimes use pinch valves for flour or sugar because the tube is easy to clean and swap.

| Industry | Common Pinch Valve Applications |

|---|---|

| Mining | Slurry transport, tailings control |

| Wastewater Treatment | Sludge handling, grit removal |

| Bulk Material Handling | Powder, pellet, and granule flow |

| Food Processing | Dry ingredient dosing, clean flow paths |

Note: Pinch valves give a strong choice for industries with tough or chunky fluids. The right actuator makes them work better and easier.

Pinch valves help keep systems working in hard places. Their simple build, strong tubes, and easy care make them a top pick for many tough jobs.

Choosing Types of Actuator Valves

Selection Criteria

Picking the right valve actuator needs careful thought. Engineers check what the actuator must do. They look at where it will work. The actuator must fit with the system. Every job needs a good match between actuator and control valves.

Key selection criteria include:

- Operating Conditions: Temperature and pressure are important. The actuator must be safe in these places.

- Connection Type: The actuator must fit the valve and system.

- Consistency with Existing Actuators: Using the same actuator types helps with fixing and learning.

- Control Functions: Some jobs need exact moves or feedback. Control valve actuators must do these things.

- Sizing and Torque Requirements: The actuator must give enough force for the valve.

- Failure Mode: Safety is important. Some actuators must go to a safe spot, like fail-open or fail-closed.

- Available Space: The actuator must fit in the space you have.

- Actuator Cost: Money matters. Think about both buying and using costs.

- Frequency of Use: Valves used a lot need strong actuators.

- Operating Speed: Some jobs need fast moves. Speed changes which actuator you pick.

- Ease of Operation and Maintainability: Good actuators save time and money.

- Available Power Source: You need electric, pneumatic, or hydraulic power.

Tip: Always check how much force, speed, and control you need before picking a valve actuator.

Selection Table:

| Selection Criteria / Considerations | Description / Importance |

|---|---|

| Operating Conditions | Temperature, pressure, hazardous environment compatibility |

| Connection Type | Must fit valve and system connections |

| Consistency with Existing Actuators | Uniformity and ease of maintenance |

| Control Functions | Precise positioning, speed control, feedback |

| Sizing and Torque Requirements | Sufficient torque for all conditions |

| Failure Mode | Fail-safe positions for safety |

| Available Space | Physical space constraints |

| Actuator Cost | Upfront and operating costs |

| Frequency of Use | Durability for high-frequency use |

| Operating Speed | Speed requirements |

| Ease of Operation and Maintainability | Long-term reliability and cost |

| Available Power Source | Electric, pneumatic, or hydraulic availability |

Application Scenarios

Different actuator valves work best in certain jobs. The process, place, and control needs help you choose.

Common application scenarios:

- Heavy Machinery: Hydraulic actuators give the most force. They are good for lifting and pressing. These actuators work well outside and in tough places.

- Packaging and Assembly Lines: Pneumatic actuators are fast and cheap. They are good for quick, repeated jobs but have less force and lower accuracy.

- Automation and Robotics: Electric actuators give great control and accuracy. They fit robots and control valves that need exact moves.

- Advanced Robotics and CNC Machines: Servo actuators mix strong force with smart control. They are fast and very accurate.

- Medical and Scientific Instruments: Piezoelectric actuators are best for tiny, careful jobs. They help in labs and with optics.

Note: Hydraulic and pneumatic actuators work well outside or in rough places. Electric and piezoelectric actuators are best for clean, controlled rooms.

Things to think about when picking actuator type:

- Does it work with control signals like voltage or pressure?

- How fast does it respond and settle?

- Does it give enough force or movement?

- Is it energy efficient?

- Does it fit in the space and handle the heat?

- Is it easy to fix and does it last long?

- How much does it cost to buy and use?

Steps for choosing actuator type:

- Decide if you need straight or spinning motion.

- For straight moves, pick linear actuators and check needed force.

- For spinning moves, pick rotary actuators and check needed torque.

- Add extra force or torque for safety.

- Make sure the actuator can handle the job.

Comparison Table

The table below shows how actuator valves compare by force, speed, control, and best uses.

| Actuator Type | Force Capacity | Speed Characteristics | Control Precision and Suitability | Typical Applications |

|---|---|---|---|---|

| Hydraulic | Highest force, good for big lifting and parts | Slower moves, steady pressure | Good control, best for tough jobs and outdoor places | Heavy machines, outdoor systems |

| Pneumatic | Less force, good for light jobs | Very fast moves, saves time | Lower control, best for quick, repeated actions | Packaging, assembly lines |

| Electric | Medium force, steady and saves energy | Medium speed, good accuracy | Great control, best for robots and automation | Automated jobs, control valves |

| Servo | Strong force with smart control | Fast moves, great for exact jobs | Top control, programmable, used in CNC and robots | CNC machines, advanced robots |

| Piezoelectric | Very little force, made for tiny loads | Slow moves, special for small jobs | Super exact control, used in labs and medical tools | Medical, science instruments |

Callout: Picking the right valve actuator keeps things safe, reliable, and working well. Always think about what the control valves and the place need.

Practical Uses of Actuating Valves

Water Treatment

Actuating valves are very important in water treatment plants. They help move water, chemicals, and waste where needed. Workers use actuators to open and close valves by machine. This makes it simple to control water coming in, getting cleaned, and going out. Electric and pneumatic actuators are used a lot because they are fast and accurate. These actuators can handle high pressure and heat, which is common in water plants.

Water treatment plants use actuating valves to add chemicals carefully. Ball valves and butterfly valves are used the most. Ball valves are good for adding chemicals and stopping flow in small pipes. Butterfly valves are better for moving lots of water in big pipes. Both types work well with actuators for remote or automatic use.

Workers trust actuating valves to do less work by hand and make things safer. Fail-safe features help valves go to a safe spot if something goes wrong.

Some actuators connect to control systems like PLCs or DCS. This lets workers watch and change valves from a control room. Checking actuators often keeps them working and stops problems.

Common uses in water treatment:

- Controlling water flow during cleaning and chemical steps

- Running pumps and pipes for fast changes

- Handling sludge and dirty water with strong shut-off

| Valve Type | Typical Use Cases | Actuator Types Used |

|---|---|---|

| Ball Valves | Chemical dosing, small pipes, high-pressure shut-off | Pneumatic, hydraulic, electric actuators |

| Butterfly Valves | Large pipelines, bulk flow control, aeration, sludge handling | Pneumatic, electric actuators |

Oil and Gas

The oil and gas industry needs actuating valves to work safely and well. These valves control how oil and gas move, their pressure, and their heat in pipes and plants. Actuators get signals from controllers and move valves by themselves. This means workers do not have to turn valves by hand.

Hydraulic, pneumatic, and electric actuators are used a lot in oil and gas. They work in tough places, even under the sea or on oil rigs. Some actuators have springs that close valves fast if there is trouble. In underwater wells, actuators shut valves to stop spills and protect nature.

Workers use actuating valves for many jobs:

- Changing flow in pipes

- Controlling pressure in machines

- Closing valves quickly in emergencies

- Adding chemicals very carefully

| Application | Role of Actuating Valves |

|---|---|

| Flow Control | Accurate, precise modulating control in harsh environments. |

| Choke Valves | Fast response and high stiffness for pressure control on well sites. |

| Pressure Control | Repeatable pressure control in pipelines, suitable for extreme climates. |

| Dump Valves | Simple on/off or precise modulation on separator dump valves. |

| Chemical Injection | Extreme precision for chemical injection pumps, minimizing waste. |

HVAC

Heating, ventilation, and air conditioning (HVAC) systems use actuating valves to keep buildings comfy and save energy. These valves control air, water, or steam in pipes and vents. Actuators move dampers and valves to change air flow and room temperature.

Electric and pneumatic actuators are the most used in HVAC. They listen to signals from thermostats or building systems. When a room needs more heat or cool air, the actuator opens or closes the valve to let more or less fluid through. This keeps rooms at the right temperature and saves power.

Actuating valves in HVAC also help clean the air by letting in fresh air and taking out old air.

Some actuators have fail-safe parts. If power or air stops, spring-return actuators move valves to a safe spot. This keeps machines safe and protects people.

Key functions in HVAC:

- Changing air flow by moving dampers

- Adjusting temperature by controlling hot or cold water

- Keeping system pressure steady

- Helping with automation and smart building controls

| Function of Actuating Valves in HVAC Systems | Explanation |

|---|---|

| Regulate flow of air, water, or other fluids | Actuators control valves to open, close, or modulate flow, influencing temperature, humidity, and climate control. |

| Types of actuation | Electric, pneumatic, hydraulic, thermal, manual actuators convert energy into mechanical motion to operate valves. |

| Modes of operation | Binary (fully open/closed), proportional (partial opening), and fail-safe (spring return) operations. |

| Energy efficiency | Precise valve control optimizes heating/cooling media flow, reducing energy consumption. |

| Automation and integration | Actuators enable remote and automated control, integrating with building management systems for optimal performance. |

Manufacturing

Factories need actuating valves to keep things running well. These valves help control liquids, gases, and powders in machines. Workers use them to start, stop, or change how materials move. This keeps machines working at the right speed. It also helps make products that meet quality rules.

Actuating valves are important for automation. They connect to plant control systems with special digital signals like Profibus DP, Modbus, and HART. These signals let the valves get commands and send updates to workers. Some systems even give data about problems or repairs. This helps workers find issues before machines stop working.

Automated valves mean less manual work for people. Operators can control valves from far away. This is safer in hot or dangerous places.

Factories use actuating valves for many reasons:

- They give exact and steady control of fluids. This makes fewer mistakes and keeps things the same.

- Automated valves make things safer by needing less hands-on work. They react fast to problems and work in tough places.

- Plants work better and faster with actuating valves. These valves help machines run all the time and stop less often.

- Valves that only work when needed save energy and money. This cuts waste and lowers costs.

- Actuating valves make it easy to add or change lines. Plants can grow or change faster.

- Remote control lets workers watch and change things from one room. They can fix problems right away and see the whole process.

- Strong designs and self-lubrication mean less fixing and lower costs.

- Connecting to smart control systems like PLCs and DCS helps with better control and planning repairs.

- Using resources well and saving energy helps companies be more green.

- Good, steady control helps factories follow industry rules.

| Benefit | How Actuating Valves Help Manufacturing |

|---|---|

| Process Control | Adjust flow for steady products |

| Safety | Less hands-on work in risky places |

| Efficiency | Faster, automatic production |

| Cost Savings | Use less energy and need less fixing |

| Flexibility | Change or add lines quickly |

| Compliance | Follow rules with steady control |

Actuating valves are now a must in modern factories. They help plants be safer, quicker, and work better. By linking to automation, these valves help manage equipment and keep companies ahead in the market.

FAQ

What is the main purpose of an actuating valve?

An actuating valve controls how liquids or gases move. It can start, stop, or change the flow. Many companies use these valves to keep things safe and working well.

Which industries use actuating valves most often?

Water treatment, oil and gas, chemical plants, factories, and HVAC systems use actuating valves. These valves help control flow, pressure, and safety in many jobs.

How does a pneumatic actuator work?

A pneumatic actuator uses air that is squeezed to move a valve. The air pushes a piston or diaphragm. This makes the valve open or close quickly and safely.

What is the difference between rotary and linear actuators?

Rotary actuators spin valves around, like ball or butterfly valves. Linear actuators move valves straight, like gate or globe valves. The right type depends on the valve and the job.

Can actuating valves be automated?

Yes, many actuating valves can connect to control systems. Automation lets people run and watch valves from far away. This makes things safer and means less work by hand.

Why do some actuators have a spring return feature?

A spring return actuator moves the valve to a safe spot if power or air stops. This keeps equipment and people safe during emergencies.

How should someone choose the right actuator for a valve?

Engineers think about force, speed, control, and where it will be used. They pick the actuator that fits the valve and the job. Using a table or checklist helps compare choices.

Tip: Always look at what your system needs before picking an actuator.