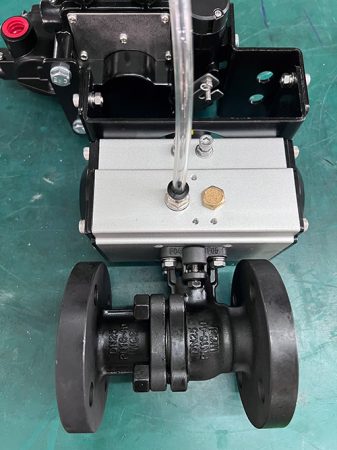

Actuated ball valves are important in automation. They let lots of liquid or gas flow and do not slow it down much. These valves are used in oil and gas, chemical plants, water cleaning, HVAC, power plants, food and drink, medicine, and clean energy. People pick electric ball valves, pneumatic valve, hydraulic actuator, or manual actuator for what their system needs. Electric ball valves and pneumatic actuated ball valve types help control things quickly or very carefully. Each actuator works well in tough systems. They can be used with butterfly valve and ball valve setups. The right electric valve or actuator makes systems safer and work better.

Key Takeaways

- Actuated ball valves help control liquids and gases fast. They make things safer and work better in many industries.

- Electric actuators give very exact control. Pneumatic actuators work quickly in hard places.

- Picking strong valve materials like stainless steel and PTFE is important. These materials last long and stand up to tough chemicals and conditions.

- Using actuated ball valves means less manual work. It saves energy and helps stop leaks and accidents.

- Safety parts like fail-safe actuators and tight seals keep workers safe. They also protect the environment during emergencies.

- Doing regular maintenance and picking the right valves keeps systems working well. This helps lower downtime.

- Many industries use actuated ball valves for better control. Oil, gas, food, medicine, and marine companies need them to follow safety rules.

- Being able to run and watch valves from far away makes things safer. It lets people act fast when systems change or emergencies happen.

Oil & Gas

The oil and gas industry needs good flow control. This keeps work safe and helps things run well. Actuated ball valves are used in many systems here. These valves handle strong pressure, tough chemicals, and very hot or cold places. They also help with automation. This makes work safer and stops mistakes.

Pipelines

Pipelines move lots of fluids far away. Workers need to control them carefully to keep things safe.

Flow Control

Actuated ball valves let lots of fluid pass through. Their full-bore design helps fluids move easily. There is little pressure lost. An actuator can open or close the valve fast. It only needs a 90-degree turn. This quick movement helps control oil or gas flow. It works for normal times or emergencies. The valves can be used with remote controls. This lets workers manage pipelines from far away.

Pressure Management

Pressure changes can hurt pipelines or make leaks. Actuated ball valves help control pressure. They open or close at the right time. The actuator listens to signals from control systems. This keeps pressure safe. The valves shut tightly to stop leaks. This protects nature and keeps people safe.

Note: Workers pick actuated ball valves for pipelines. They work fast, shut tight, and need little care. These things help stop problems and keep people safe.

Compressor Skids

Compressor skids make gas pressure higher before it goes in pipelines. These systems need quick and strong valve control. Actuated ball valves use automation instead of hand control. The actuator can act right away when it gets a signal. This is important in emergencies. Fail-safe and emergency shutdown features help the valve close off parts of the skid fast. This stops gas from flowing out of control and lowers accident risk. Strong actuator designs work in very hot or cold places. Some actuators have battery backup. The valve still works if power goes out. Workers connect actuated ball valves to monitors. This helps find problems early.

- Key benefits for compressor skids:

- Automated control for quick action

- Fail-safe and emergency shutdown help

- Works well in tough places

- Can connect to safety and monitor systems

Safety Systems

Safety matters most in oil and gas work. Actuated ball valves are important for safety systems. These valves must follow strict rules and get special certificates. This makes sure they work in dangerous places.

| Standard | Focus Area | Region | Key Requirements |

|---|---|---|---|

| ISO 5211 | Actuator mounting | Global | Interchangeable actuator-to-valve connections |

| API 6D | Pipeline valves | Worldwide | Fire safety, pressure, and leak tests |

| EN 12516 | Valve design | Europe | Strength, fire resistance, pressure |

| ASME B16.34 | Valve construction | USA | Fire safety, pressure, and overall safety |

Tests like API 607 and ISO 10497 check how valves work in fires. These tests make sure the actuator and valve can stop flow in hard times. Workers look for valves with explosion-proof actuators. They want valves made from materials that do not rust. High IP ratings mean the valve seals well.

Oil and gas places use actuated ball valves in turbine skids, generator skids, separator skids, and LNG plants. These systems need to be strong, automatic, and safe. The right actuator and valve help workers do their jobs, even in tough places.

Water Treatment

Water treatment is important for safe water. People, farms, and factories need clean water. Actuated ball valves help these systems work better. They make it easier to control flow and pressure. These valves are used in city, farm, and factory water systems.

Actuated Ball Valve Applications

Distribution Systems

Distribution systems send clean water to many places. They move water to homes, schools, and businesses. Valves must open and close fast to keep water moving. Actuated ball valves let workers control water quickly and easily. Their full-port design lets water move with little resistance. This helps pumps use less energy. Electric actuators can connect to control panels or remote systems. Workers can control valves from far away. This saves time and makes things safer.

Wastewater Plants

Wastewater plants clean dirty water before it goes back to nature. These plants need strong valves for dirty water and chemicals. Actuated ball valves work well in these hard places. Their tight seals stop leaks and protect the environment. Some valves have special coatings to stop rust and damage. This helps them last longer and need less care. Workers use automation to control valves during each cleaning step. This keeps things running smoothly and stops mistakes.

Pressure Regulation

Pressure control keeps pipes safe and stops bursts. Valves with actuators open or close when sensors send signals. This keeps pressure steady everywhere in the system. Steady flow helps pumps work less and saves energy. At the Findlay Water Treatment Plant, new ball valves stopped leaks and lowered repair costs. The plant saved money because the valves used less energy and needed fewer repairs.

- Key benefits of pressure regulation with actuated ball valves:

- Steady water flow

- Lower risk of pipe damage

- Less energy use

- Fewer leaks

Automation

Automation helps water treatment plants work better. Workers use control systems like SCADA or PLCs to manage valves. These systems can open or close valves at the right time. They do not need people to do it by hand. Electric actuated ball valves answer commands quickly. They also help with predictive maintenance. Sensors watch for problems and send alerts before a valve breaks. This means less downtime and lower repair costs. New designs, like modular parts and strong seals, help valves last longer and work better.

Tip: Automation in water treatment plants saves energy, cuts repairs, and makes the system work better.

Chemical Processing

Chemical processing equipment works in hard places. Many plants use electric ball valves for better safety and automation. These valves help control dangerous chemicals and protect workers.

Electric Ball Valves

Electric ball valves are important in chemical plants. They use electricity to open and close. This makes them easy to use from far away. Operators use them to turn flow on or off. They can also control how much flows through. These valves work well with machines. Their design lets them move the same way every time. This helps keep chemical work safe and correct.

Corrosive Media

Chemical plants use acids, bases, and solvents a lot. These chemicals can hurt valves if the materials are wrong. Electric ball valves use PTFE, PVDF, or stainless steel. These materials do not rust and last longer. If the wrong material is used, the valve can leak or break. Operators must pick the right valve for each chemical.

- Main problems for actuated ball valves in chemical plants:

- Chemicals that do not match can cause leaks.

- Thick or dirty chemicals can block the valve.

- Hot or cold changes can make parts move and leak.

High-Temperature Use

Some chemical jobs need high heat. Electric ball valves can work in these places if made right. They keep a tight seal even when it gets hot or cold fast. This stops leaks and keeps things safe. Operators must check how hot the valve can get before using it.

Batch Control

Batch control is very important in chemical plants. Electric ball valves help by giving exact flow control. They open and close fast for good mixing. These valves connect to machines. This lets operators control things from a control room. Electric ball valves do not need air or oil systems. This means less fixing and saves energy. They are strong and have digital parts for hard places. They also let workers shut off dangerous fluids and use them from far away. This makes things safer and faster.

Tip: Electric ball valves make batch control better and more exact. They help plants save time and stop mistakes.

Safety Isolation

Safety is very important in chemical plants. Plants use shut-off valves to stop dangerous chemicals in emergencies. Electric ball valves with fail-safe parts can close if power goes out. Some valves use springs to close fast. Plants use explosion-proof and fire-safe valves in risky places. Workers test and fix these valves often. Operators connect them to alarms for quick action. Locks stop people from using them by mistake. Plants follow rules like OSHA, NFPA, and ATEX to keep everyone safe. Using PTFE and stainless steel makes valves last longer and safer.

- Safety steps for actuated ball valves in chemical plants:

- Emergency valves stop dangerous chemicals fast.

- Fail-safe parts close valves if power is lost.

- Explosion-proof and fire-safe valves protect in risky places.

- Locks and lockout steps keep workers safe during repairs.

Electric ball valves help chemical plants control work, handle tough chemicals, and keep people safe. Picking the right valve and following safety rules keeps everything running safely.

Power Plants & Stations (Pneumatic Ball Valves)

Power plants need fast and reliable control. Pneumatically actuated ball valve technology is very important here. These valves help control steam, water, fuel, and waste. Operators use them in thermal, hydro, and nuclear stations. The actuator moves quickly and gives exact control. This helps keep the plant safe and working well.

Boiler Systems

Boiler systems make steam for power. They need strong valves and actuators for high pressure and heat.

Steam Flow Isolation

Steam flow isolation keeps equipment and workers safe. A pneumatically actuated ball valve opens or closes fast. The actuator listens to control signals and acts in seconds. This quick action stops steam flow for repairs or emergencies. The valve shuts tightly to stop leaks. Operators trust these valves for safe steam control.

Blowdown Automation

Boiler blowdown takes out dirty stuff from water. This keeps the boiler clean and working well. A pneumatically actuated ball valve makes blowdown automatic. The actuator gets signals from the control system. It opens the valve at set times to let out dirty water. This automation means less manual work and fewer mistakes. The valve and actuator help the process stay on schedule.

Cooling Water Circuits

Cooling water circuits stop equipment from getting too hot. These systems use many valves and actuators to control flow.

Intake & Discharge Control

Intake and discharge control manages water going in and out. A pneumatically actuated ball valve moves fast and accurately. The actuator lets operators change flow rates quickly. This keeps cooling systems steady. The valve design lasts longer and needs less fixing. Operators connect these valves to control systems for real-time checks. This helps catch problems early.

- Actuated ball valves in cooling water circuits give:

- Exact flow control with high accuracy

- Strong build for fewer breakdowns

- Special seals for almost no leaks

- Real-time checks and reports

- Remote control for better safety

Studies show these actuators work well under high pressure and heat. Good materials and seals stop leaks and keep things safe. These features mean less downtime and better reliability.

Emergency Shutoff

Emergency shutoff keeps the plant safe during trouble. A pneumatically actuated ball valve can close in seconds. The actuator gets emergency signals and acts right away. This quick move stops water flow and prevents damage. The valve’s strong build handles high pressure without leaking. Operators count on these valves for safety when it matters most.

Fuel Handling & Delivery

Fuel handling systems move gas and oil to boilers. These systems need strong valves and actuators.

Gas and Oil Feed Lines

Gas and oil feed lines send fuel to the plant. A pneumatically actuated ball valve controls flow in these lines. The actuator opens and closes the valve quickly. This helps operators change fuel supply as needed. The valve’s tight seal stops leaks and keeps things safe. These valves work well with control systems for automatic use.

Safety Interlocks

Safety interlocks stop accidents in fuel systems. The actuator connects to sensors and alarms. If something goes wrong, the actuator closes the valve right away. This stops fuel flow and lowers risk. The valve and actuator work together to protect people and equipment. Operators test these safety parts often to make sure they work.

Emission & Waste Management

Power plants need to control emissions and waste. This helps protect nature and follow rules. Actuated ball valves are very important in these systems. They help workers handle gases and ash safely.

Flue Gas Treatment

Flue gas treatment takes out bad gases before they leave. Workers use actuated ball valves in scrubbers and filters. These valves open and close fast. This lets workers change the system quickly. A pneumatically actuated ball valve reacts fast to signals. This is helpful when gas levels change quickly.

Workers can watch and control these valves from far away. Remote control keeps workers safe and lets them act fast in emergencies. The valves help stop leaks and keep dangerous gases inside. Plants with these valves have fewer emissions and work better. Some studies show 30% less emissions and 20% better operation.

- Main benefits of actuated ball valves in flue gas treatment:

- Exact control of gas and chemical flow

- Less chance of leaks and emissions

- Help with remote checks and quick changes

- Better at following environmental laws

Good valve design and testing, like ISO 15848-1, help control emissions for a long time. This keeps the plant safe and avoids big fines.

Ash Handling

Ash handling systems move and store leftover ash. These systems need strong valves because ash is rough. A pneumatically actuated ball valve works well in hard places. It opens and closes fast to control ash and water.

Workers use these valves to automate ash removal. Automation means less hand work and fewer mistakes. The valves also help with predictive maintenance using IoT. Sensors warn workers before a valve breaks. This saves money and stops downtime. Some plants save 20% on maintenance with automated valves.

Note: Using actuated ball valves in ash handling makes things safer. It also helps power plants save materials and energy. By stopping leaks and loss, these valves make the system work better.

Low fugitive emission valves protect workers by stopping leaks. This means workers can stay safe for longer. Plants with these valves follow strict rules and keep running smoothly.

Food & Beverage

Sanitary Applications

Bottling Lines

Bottling lines must be very clean. Actuated ball valves help move drinks like water, juice, or soda. These valves are made from stainless steel. The metal is polished until it shines. This smooth surface stops bacteria from growing. It keeps drinks safe for people. Every part that touches the drink is polished and cleaned. The seals use food-safe materials like PTFE or silicone. These do not change the taste or smell. The valves cannot have cracks or holes. This stops germs from hiding inside. The FDA says these valves are safe for food. Workers can clean and fix these valves easily. This helps the bottling line work well.

Dairy Processing

Dairy plants use actuated ball valves for milk, cream, and yogurt. These foods spoil fast if not handled right. The valves must be very clean and safe. They are made from stainless steel, like 304 or 316. The inside is polished to a mirror shine. This keeps bacteria from sticking. Food-grade seals stop leaks and keep milk safe. The valves are easy to take apart for cleaning. If not cleaned, milk can get stuck and grow germs. The design has no dead spots. This lets workers clean and sterilize everything. It keeps dairy foods safe and fresh.

Note: Ball valves in food and drink plants must follow rule 68-01. This rule says workers must take valves apart to clean them. If not, food can get trapped and cause safety problems.

Automation

Automation helps food and drink plants work better. Electric ball valves are important for this. They open and close when the control system sends a signal. Workers can control the flow from far away. The valves move fast and keep things steady. Automation lowers mistakes. Electric ball valves do not need much fixing. They save energy and help plants run longer.

| Benefit of Automation | Description |

|---|---|

| Remote Operation | Workers control valves from afar |

| Precise Flow | Valves open and close at the right time |

| Less Maintenance | Electric ball valves last longer |

| Product Safety | Fewer mistakes and less contamination |

CIP Systems

Clean-in-place (CIP) systems wash pipes and machines without taking them apart. Electric actuators help control the valves in these systems. This lets workers control cleaning from a control room. The valves stay in place, which saves time. Sometimes, ball valves in CIP can cause problems. They might make water hammer or pressure spikes. These problems can hurt the product. For steam, rotary globe valves work better. They shut tight and let steam flow smoothly. Still, electric ball valves are used for other cleaning jobs. They help keep the plant safe and clean.

Tip: Always check if the valve is right for cleaning. Some valves must be taken apart to clean them well. This is important for food safety.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems keep buildings comfy. Actuated ball valves are very important in these systems. They help control temperature, air quality, and how much energy is used. These valves work with building automation. This makes HVAC systems smarter and more efficient.

Flow Control

Flow control matters a lot in HVAC systems. Actuated ball valves move hot or cold water and air. They open or close fast to change the flow. This helps rooms stay at the right temperature. The control system sends signals to the valves. The valves help balance the system and stop pressure spikes. If the system needs more heat or cooling, the valves open more. If less is needed, they close. This quick action keeps things steady and saves energy.

Tip: Actuated ball valves for flow control help stop leaks. They also lower wear on pumps and pipes.

Zone Automation

Modern buildings have many zones. Each zone might need a different temperature. Actuated ball valves help automate each zone. They let workers control fluid flow to every area from far away. The control system tells the valves what to do. The valves change the flow to fit each zone’s needs. This lets people enjoy the right comfort in every room. The valves work with building management systems. They can also connect with lights and security for full building automation. Features like position feedback and modulating control help with advanced zone automation. The valves react fast to changes, so each zone stays comfy.

Energy Efficiency

Energy efficiency is important in HVAC systems. Actuated ball valves help save energy in many ways:

- Electric actuators give exact control of pressure and temperature.

- These valves use less energy than manual ones, so bills go down.

- Tight-closing valves stop leaks, so no energy is wasted.

- Fast actuators help heating and cooling work their best.

- Digital controls let workers watch and fix problems from far away.

- Brushless DC motors are quiet and accurate, saving energy and keeping comfort high.

- Characterized control valve technology stops clogs and keeps flow steady.

Building owners can meet energy rules like LEED by using these valves. The system works better, costs less to fix, and lasts longer. Automated control and quick response keep energy use low and comfort high.

Pharmaceuticals

Process Control

Pharmaceutical plants must control their process very carefully. This keeps products safe and the same every time. Workers use actuated ball valves to move liquids and gases. These valves help with mixing, dosing, and moving things. The valves react fast to signals from machines. Electric ball valves are important in these jobs. They open and close with great accuracy. This helps workers change flow and pressure as needed. Fast valve action keeps each batch the same. It also lowers mistakes made by people.

Workers often connect electric ball valves to PLCs. The system sends a command, and the valve moves in seconds. This lets workers watch and change things from far away. The valves help keep temperature and pressure just right. Good control keeps the process steady and stops contamination. Many drug plants use these valves to follow FDA and GMP rules.

Tip: Automated valves help workers keep control tight. This protects product quality and safety.

Clean-In-Place

Clean-in-place systems are very important in drug plants. These systems clean pipes, tanks, and valves without taking them apart. Actuated ball valves help by making cleaning cycles automatic. Workers set the system to wash equipment at certain times. The valves open and close as needed so all parts get cleaned.

Sanitary ball valves in these systems have smooth, shiny surfaces. They do not have many places for dirt or germs to hide. Many valves use FDA-approved elastomers for seals and seats. These materials do not break down and keep cleaning solutions pure. Tri-clamp fittings make it easy to take out valves for checks. Some systems use pigging. Pigging pushes a cleaning tool through pipes to clear out dirt.

A table below shows features of sanitary ball valves in CIP systems:

| Feature | Benefit |

|---|---|

| Polished surfaces | Stops bacteria from building up |

| Minimal dead spaces | Lowers risk of contamination |

| FDA-approved elastomers | Keeps cleaning pure |

| Tri-clamp fittings | Makes removal easy |

| Pigging compatibility | Cleans pipes better |

Sterile Fluid Handling

Sterile fluid handling is very important in drug making. Actuated ball valves help keep fluids clean and germ-free. Makers use strong stainless steel for these valves. This metal does not rust and can handle tough chemicals. Smooth inside parts and special valve trims stop germs and dirt from sticking. This design lowers the chance of contamination.

Workers pick valves with few dead spaces. This stops fluid from getting trapped and growing germs. Fast and sure valve action lets workers stop flow quickly. This helps stop cross-contamination. The valves seal tightly even when heat or pressure changes. Many sanitary ball valves work with clean-in-place systems. This means workers can clean equipment without taking out valves.

Other important features include:

- Full-bore design gives germs fewer places to hide.

- Tri-clamp fittings keep outside germs away.

- Seats and fillers use safe materials like Teflon.

- Shiny, clean surfaces keep fluids sterile.

- Making the valves removes iron and other bad stuff from the surface.

Workers trust these valves to meet strict FDA rules. The valves let fluids move smoothly, which is very important for clean drug making. Electric ball valves give exact control and help keep things very clean.

Note: Picking the right actuated ball valve helps drug plants keep products pure and follow the rules.

Marine & Shipbuilding

Onboard Piping Systems

Seawater Intake & Discharge

Ships use seawater for cooling and cleaning. Actuated ball valves help control this water. The actuator opens and closes the valve fast. This lets crew manage seawater flow exactly. Stainless steel, brass, and bronze do not rust in saltwater. These materials keep the system safe and working well. Shipbuilders pick these valves to stop leaks and avoid problems. The actuator can get commands from far away. Crew can control intake and discharge from the control room. This makes things safer and easier, even in rough seas.

| Requirement Category | Description |

|---|---|

| Corrosion Resistance | Valves need to be made from materials that do not rust. Ships face lots of seawater and tough weather. |

| Materials | Stainless steel, brass, and bronze are used. These materials last long and work well. |

| Compliance and Certification | Valves must follow rules from groups like ABS and Lloyd’s Register. This proves they resist rust and work right. |

| Safety and Reliability | Valves must work well in moving ships. They help keep the system safe and stop leaks. |

| Maintenance and Inspection | Valves should be easy to check and fix. This is important because space is tight on ships. |

Ballast Water Management

Ballast water helps ships stay steady. Actuated ball valves control ballast water flow. The actuator moves fast and gives exact control. This keeps the ship safe. These valves help ships follow world rules like the IMO Ballast Water Management Convention. Crew can use remote controls to move the valves. They do not need to go to hard places. The valves use materials that do not rust. Tight seals stop leaks and protect nature from bad water.

Fuel & Lubrication Systems

Automated Fuel Transfer

Ships need safe fuel transfer. Actuated ball valves move fuel between tanks and engines. The actuator reacts quickly to control signals. This lowers the chance of spills. Automation lets crew watch and change fuel flow from one place. This keeps the ship safe and working well. The actuator fits in small spaces, which is good for crowded ships.

Leak Prevention

Leaks can cause fires or pollution. Actuated ball valves help stop leaks by closing tight. The actuator acts fast when alarms or sensors go off. This stops fuel flow and keeps things safe. The valves are made from materials that do not rust. Crew can check and fix them easily. These steps protect the ship and the ocean.

Cargo Handling

Liquid Cargo Loading/Unloading

Ships carry liquids like oil and chemicals. Actuated ball valves control flow when loading and unloading. The actuator lets crew make small changes to flow. This helps stop spills. Automated systems let crew work from a safe spot. This lowers the risk of accidents. The actuator works fast and seals well. These valves meet safety rules like SOLAS and DNV.

Tank Isolation

Tank isolation keeps fluid handling safe. Actuated ball valves separate tanks during cleaning or emergencies. The actuator lets crew control valves from far away. This helps them stay safe. The valves use materials that do not rust and have tight seals. They help ships follow safety and nature rules.

Tip: Pick actuated ball valves that do not rust and have strong actuators. This helps ships stay safe and last longer at sea.

Automation & Safety

Remote Valve Operation

Modern ships use automation to make jobs easier and safer. Pneumatic actuated ball valves let crews control systems from one place. These valves connect to control panels on the bridge or in the engine room. Crew members can press a button or flip a switch. The actuator moves the valve right away. This saves time and keeps crew out of tight or dangerous spots. They do not have to go into risky areas to open or close valves.

Remote valve operation works in engine cooling, ballast water, and fuel transfer. The system uses sensors to check if valves are open or closed. Crew see updates on screens as things happen. If a valve does not move, the system sends an alert. This helps the crew fix problems before they get worse.

Tip: Remote valve operation helps ships follow safety rules from IMO and SOLAS. It also makes daily work faster and safer.

A table below shows the main benefits of remote valve operation:

| Benefit | Description |

|---|---|

| Safety | Crew stay out of dangerous places |

| Speed | Valves move fast with one command |

| Monitoring | Sensors show valve status right away |

| Efficiency | Crew control many valves from one spot |

| Compliance | Helps meet marine safety rules |

Emergency Shutoff

Safety is most important at sea. Ships face dangers like leaks, fires, or broken systems. Pneumatic actuated ball valves are key for emergency shutoff. These valves close quickly when the crew sends a signal. Some systems use sensors to find leaks or high pressure. The actuator gets the signal and shuts the valve in seconds. This fast action stops fuel, water, or chemicals from spreading.

Emergency shutoff valves use strong metals like stainless steel or bronze. These metals do not rust and can handle saltwater. The valves have tight seals to stop leaks. Small designs fit in tight ship spaces. Crew test emergency shutoff systems often to make sure they work.

Ships must follow strict rules for emergency shutoff. IMO and class societies require regular checks and records. Crew keep notes about tests and repairs. Good emergency shutoff systems protect the ship, crew, and nature.

- Main features of emergency shutoff valves:

- Close very fast

- Made from metals that do not rust

- Tight seals stop leaks

- Easy to test and fix

- Meet marine safety rules

Note: Emergency shutoff valves help ships avoid big problems. They keep people safe and protect the ocean from harm.

Paint & Coatings Industry

Factories that make paint and coatings use actuated ball valves. These valves help keep work safe and fast. Pneumatic actuated ball valves move quickly and handle strong chemicals. Workers use them to control paint, solvents, and other liquids. The right valve keeps people and nature safe.

Production Lines

Corrosive Media Handling

Paint making uses chemicals that can hurt equipment. Pneumatic actuated ball valves with stainless steel bodies do not rust. RPTFE silicone-free seals help stop damage from chemicals. These valves last longer and keep things safe. Operators pick valves that can handle acids and solvents. This stops leaks and keeps the plant working well. Electric ball valves also help control flow when chemicals are strong.

Automated Flow Control

Modern paint factories use machines to move liquids. Pneumatic actuators turn valves fast and accurately. This lets workers change flow rates quickly. Multi-port ball valves switch fluids between tanks without stopping work. Operators connect valves to control systems like PLC or SCADA. Real-time checks keep flow steady and stop mistakes. Good fluid control makes sure each batch is high quality.

Automated Filling Systems

VOC Emission Control

Paints and coatings can release VOCs into the air. Factories must follow rules to lower these emissions. Actuated ball valves seal tightly and stop leaks. This keeps VOCs inside and protects workers. The valves help save paint and energy. Plants use these valves to meet safety and environmental rules.

Precision Dosing

Automated filling needs exact control of liquid amounts. Pneumatic actuated ball valves move fast and very precisely. They can control dosing within ±1%. Operators use these valves to fill containers with the right amount. Electric ball valves also help with careful fluid control. Smart checks and feedback let workers find problems early. This helps fix things before the line stops.

Tip: Good fluid control in filling systems makes better products and less waste.

Solvent Transfer

Leak Prevention

Solvents in paint plants can catch fire and are dangerous. Actuated ball valves with tight shutoff stop leaks and keep workers safe. They close quickly, in 1-3 seconds, during emergencies. Stainless steel keeps valves working with strong solvents. Operators trust these valves to keep the plant safe.

Maintenance Efficiency

Factories need valves that last and are easy to fix. Pneumatic actuated ball valves work for many cycles and are easy to maintain. Smart feedback and checks help workers plan repairs early. This means less downtime and keeps work going. Good fluid control in solvent lines keeps things safe and efficient.

| Feature | Benefit |

|---|---|

| Corrosion Resistance | Handles harsh chemicals |

| Tight Shutoff | Prevents leaks and spills |

| Automation | Improves process efficiency |

| Smart Diagnostics | Reduces downtime |

Paint and coatings factories use actuated ball valves to reach safety and environmental goals. These valves help control strong chemicals, stop leaks, and keep production running well.

Powder Handling & Processing

Powder handling and processing use pneumatic actuated ball valves. These valves help keep the system working well. Factories move powders like cement, coal, and minerals. The valves must work in dusty and rough places. They also help keep workers and equipment safe.

Pneumatic Conveying

Pneumatic conveying uses air to push powders through pipes. The actuator opens and closes the ball valve very fast. This lets workers control how much powder moves. The valves must be strong because powders move fast and can scratch things.

Flow Isolation

Flow isolation is needed in powder systems. The actuator can close the valve quickly to stop powder flow. This helps workers fix problems or change batches. Ball valves use tough materials like stainless steel or ceramic linings. These materials help stop damage from rough powders. The table below lists some common materials and what they are good for:

| Material | Characteristics and Suitability |

|---|---|

| Cast Stainless Steel | Good for some corrosion resistance |

| Stainless Steel 316L | Better for welded valves and more corrosion resistance |

| Carbon Steel | Used a lot but does not resist corrosion well |

| Hastelloy | Best for strong chemicals and long life |

| Cast Iron | Not good for very rough or corrosive powders |

System Automation

System automation uses actuators so workers do not have to open valves by hand. Workers use control panels to send signals to the actuator. The actuator moves in just a few seconds. This makes the system safer and faster. Automation also helps stop powder leaks. This keeps workers and machines safe.

Tip: Check and clean actuators often to help them last longer in dusty places.

Silo Discharge

Silos hold lots of powder. The actuator controls the ball valve at the bottom. It lets powder out when needed.

Dust Control

Dust control keeps the work area safe and clean. The actuator closes the valve tightly to stop dust from getting out. Some valves use ceramic linings or special seals. These help with rough powders like quartz sand or cement. These features help keep the system clean and lower health risks.

Batch Release

Batch release means letting out a set amount of powder. The actuator opens the valve for a short time, then closes it. This gives workers exact control over how much powder leaves the silo. Tight seals and quick moves stop spills and waste.

Dust Collection Systems

Dust collection systems take dust out of the air in factories. The actuator is important in these systems. It opens and closes valves during cleaning times.

Valve Reliability

Valve reliability is important in dusty places. Actuators must work many times without breaking. Good actuators use hard parts and special seals to keep powder out. Scraper seats clean powder away before the valve closes. This stops jams.

Maintenance Reduction

Maintenance reduction saves time and money. Actuators with shock absorption and strong bearings last longer. Backup seals and X-shaped seals keep powder out of the actuator. Workers spend less time fixing valves. The system works better and lasts longer.

- Key features for powder handling valves:

- Materials like ceramics or stainless steel that resist damage

- Tight seals to stop leaks and dust

- Actuators made for fast and frequent use

- Easy to fix and last a long time

Note: Picking the right actuator and valve materials helps powder handling systems stay safe, clean, and work well.

Actuated ball valves help many industries stay safe and work well. They let workers control liquids and gases quickly and exactly. This makes machines run better and helps stop mistakes. People pick electric or pneumatic actuators based on what they need. Some things to think about are power, speed, and where the valve will be used. The table below shows how they are different:

| Factor | Pneumatic Actuators | Electric Actuators |

|---|---|---|

| Cost | Lower, needs air supply | Higher, needs electricity |

| Speed | Fast | Slower, more precise |

| Maintenance | Easier, fewer parts | Needs regular checks |

| Safety | Good for tough places | Needs protection in hazards |

Every system should use the right valve for its job. Experts can help choose the best one for safe and steady work.

FAQ

What is an actuated ball valve?

An actuated ball valve opens and closes with a motor or air. This lets the valve control liquid or gas by itself. The system does not need someone to turn it by hand.

Where are actuated ball valves most commonly used?

Engineers put actuated ball valves in many places. They use them in oil and gas, water plants, chemical factories, power plants, food factories, and ships. These valves help control flow, make things safer, and let machines work on their own.

How do electric and pneumatic actuators differ?

Electric actuators use power to move the valve. Pneumatic actuators use air that is squeezed tight. Electric ones give careful control. Pneumatic ones move faster and work well in hard places.

What materials work best for harsh chemicals?

Manufacturers pick stainless steel, PTFE, or PVDF for strong chemicals. These materials do not rust and last longer in chemical plants.

Can actuated ball valves help save energy?

Yes. Automated valves stop leaks and control flow better. This helps pumps use less energy and saves money.

How do actuated ball valves improve safety?

Actuated ball valves shut fast in emergencies. They stop leaks and spills. Many systems use alarms and sensors to close the valves for more safety.

What should engineers consider when selecting an actuated ball valve?

Engineers must look at the fluid type, pressure, heat, and where it will be used. They also need to pick the right actuator and valve material for the job.

Are actuated ball valves easy to maintain?

Most actuated ball valves do not need much care. Many are made for quick checks and easy repairs. Checking them often keeps the system working well.

Tip: Always use the manufacturer’s guide to keep valves working their best.