A 3 way butterfly valve helps you control fluid flow in pipes. You use this valve to mix or divert water, air, or chemicals. The three ports, called A, B, and AB, let you send fluid in different directions. Many HVAC systems rely on this butterfly valve for smooth operation. You may see it used instead of a ball valve, electric valve, or pneumatic valve in buildings and factories.

3 Way Butterfly Valve Basics

What Is a 3 Way Butterfly Valve

A 3 way butterfly valve helps you control fluid direction. It has three ports, not just two. This design lets you mix two fluids or send flow to two places. You often find this valve in systems needing flexible flow, like HVAC or water treatment plants.

A regular butterfly valve has two ports. It is good for simple open and close jobs. If you need more control, the 3 way butterfly valve gives extra choices. You can send water, air, or chemicals different ways. You do not need extra valves or tricky piping.

Key Features

The 3 way butterfly valve has features that help you manage your system:

- Three-Port Design: The ports are called A, B, and AB. You can mix or send fluids where you want.

- Compact Size: This valve is small. It fits in tight spaces easily.

- Quick Operation: You can turn the handle or actuator fast to change flow.

- Versatile Materials: Makers use different materials for different needs. The table below shows common choices and how they work:

| Material Type | Properties and Impact on Performance |

|---|---|

| Cast Iron | Used in water systems, cheap but can rust, so it does not last long. |

| Cast Steel | Strong and resists rust, good for medium or high pressure. |

| Stainless Steel | Great at stopping rust, best for pipelines needing anti-corrosion. |

| Aluminum Alloy | Light, strong, and resists oxidation, used in special places with high or low temperature and pressure. |

| Plastic | Light and cheap, works for corrosive fluids but cannot handle much pressure. |

| Disc Materials | Can be nylon, cast steel, stainless steel, and more, important for touching the fluid. |

| Seat Materials | Different elastomers like EPDM, NBR, PTFE, and VITON, each changes sealing and how long it lasts. |

Tip: Pick the right material for your butterfly valve. The wrong one can cause leaks or break early.

Ports and Flow Paths

The three ports give you more ways to move fluids. Here is how you use the ports and flow paths:

- You can send fluid to two places. For example, send water to two tanks.

- You can mix fluids from two sources. Ports A and B let fluids in. They mix inside and leave through port AB.

- You can handle fluids with different properties. Mixing helps blend chemicals or change temperatures before sending the fluid out.

This makes the 3 way butterfly valve a smart pick for many uses. You get mixing and diverting in one small device.

How It Works

Butterfly Valve Mechanism

A butterfly valve helps control how fluids move. Inside, there is a round disc on a shaft. When you turn the handle, the disc spins. The disc’s position decides how much fluid can go through.

- If the disc is flat with the flow, fluid moves easily.

- If the disc stands up, it stops the flow.

- Changing the disc’s angle changes how fast fluid moves. This also changes how rough the flow is and how much pressure drops.

- How hard it is to turn the disc depends on fluid pressure and the disc’s shape.

This simple design makes the valve work quickly and well. You can open or close it fast. It is easy to control your system.

Pneumatic actuator

A pneumatic actuator lets you control a butterfly valve automatically. It uses air pressure to move the actuator. The actuator turns the disc inside the valve. You do not need to turn it by hand.

There are many good things about pneumatic actuators:

- You can control flow rates very well.

- They work fast, much quicker than doing it by hand.

- They do not need much care, so you save money.

- They are small and light, so they fit in tight spaces.

Pneumatic actuators are great when you have lots of valves. They are also good when you need to change flow quickly. You see them a lot in factories and big plants.

Electric actuator

An electric actuator is another way to control a butterfly valve. It uses electricity to move the actuator. The actuator turns the disc to open or close the valve. Electric actuators are very accurate and can be used for advanced controls.

Here is a table that compares pneumatic and electric actuators:

| Feature | Pneumatic Actuator | Electric Actuator |

|---|---|---|

| Power source | Compressed air | Electricity |

| Response time | Quicker | Slower |

| Medium of pipes | Liquid in small pipes & gas | Gas in large pipes & liquid |

| Accuracy | Lower | Higher |

| Sensitivity | Lower | Higher |

| Maintenance | Lower | Higher |

| Control system | More complex | Integral |

| Environmental factor | Sensitive to water in air source | Not suitable in damp environments |

| Safety & reliability | Higher, needs stable air supply | Less reliable, can jam |

You pick the type that fits your needs best. Pneumatic actuators cost less and last longer. They are good for small pipelines. Electric actuators cost more but are more accurate. They work well for big pipelines. Both types help you control your valve and make your system better.

Tip: Always choose the actuator that matches your system for the best results.

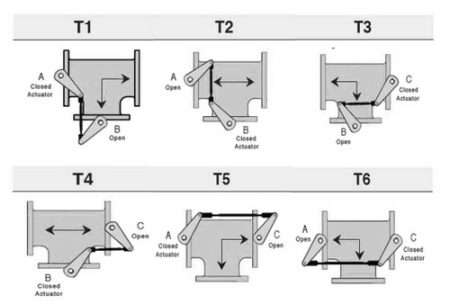

Flow Control (90° and 180° Turns)

You control the flow in a 3 way butterfly valve by turning the disc inside the valve. The angle of the disc changes how the fluid moves. Most butterfly valves use two main types of turns: 90° and 180°. Each type gives you different ways to manage your system.

90° Turn OperationWhen you turn the handle or actuator 90 degrees, you move the disc from fully open to fully closed. This simple operation lets you start or stop the flow quickly. You can also set the disc at any angle between 0° and 90° to adjust the flow rate. Many systems use this method because it is fast and easy.

- At 0°, the disc lines up with the flow. Fluid passes through the valve with little resistance.

- At 90°, the disc stands across the flow. The valve blocks the fluid almost completely.

- You can stop the disc at 45° or any other angle to let some fluid pass. This gives you good control over how much fluid moves.

180° Turn Operation

Some 3 way butterfly valves use a 180° turn for more complex flow paths. You can rotate the disc from one port to another. This type of operation helps you switch the direction of the fluid or mix two streams.

- A 180° turn lets you connect different ports. You can send fluid from port A to port B, or from port B to port AB.

- This operation is useful when you need to change the flow path without stopping the system.

- You can also use this method to mix fluids from two sources before sending them out through a single port.

Note: Always check the valve design before you use a 180° turn. Not all butterfly valves support this type of operation.

You get flexible control with both 90° and 180° turns. This makes the butterfly valve a smart choice for many systems. You can adjust the operation to fit your needs, whether you want to stop, start, or mix the flow.

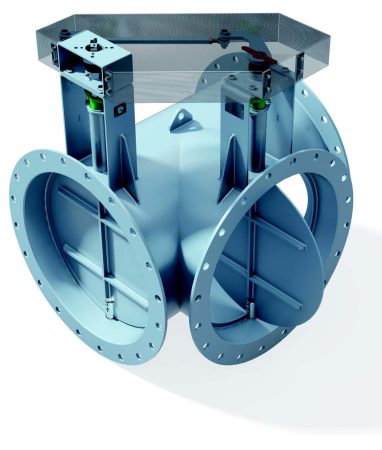

Components

Body

The body sits in the middle of every butterfly valve. It gives the valve its shape and keeps it strong. The body holds the stem and disc tightly. You often see bodies made from cast iron, stainless steel, or ductile iron. These materials help the valve last longer and fight damage from pressure or chemicals. The body connects to the pipes in your system. It keeps all the parts together and helps the valve work safely.

Here is a simple look at the main parts and what they do:

| Component | Role in Valve Operation |

|---|---|

| Body | Holds the stem and disc, gives the valve its shape. |

| Disc | Turns to control fluid flow, lets fluid move different ways. |

| Stem | Links the disc to the actuator, moves the disc. |

| Seat | Seals the valve to stop leaks when closed. |

The body is like the backbone of the butterfly valve. You need a strong body to handle high pressure and keep your system safe.

Disc or Plate

The disc, also called the plate, controls how fluid moves inside the butterfly valve. You turn the disc to open, close, or change the flow. The disc sits in the center and spins on the stem. When you turn the disc, you change the speed or direction of the fluid.

Manufacturers use different materials for the disc. Each material changes how long the valve lasts and how well it works. Here is a table showing common disc materials and what they do:

| Material | Properties | Durability Impact |

|---|---|---|

| Aluminum Bronze | Fights corrosion and erosion, very strong | Good for tough places, lasts a long time |

| Duplex Stainless Steel | Stops pitting and stress corrosion, very strong | Works in harsh and high-pressure places, lasts longer |

| Ductile Iron | Very strong, fights corrosion | Good for many uses, lasts a fair amount of time |

| Stainless Steel | Stops rust, very strong | Works in many factories, lasts a long time |

| Carbon Steel | Strong and tough | Needs coatings for rust, changes how long it lasts |

| Nickel Alloys | Great at stopping corrosion in tough places | Used in chemical plants, important for lasting |

| PTFE | Fights chemicals, does not stick | Good for tough fluids, helps the disc last longer |

Pick the disc material that fits your system best. If you use chemicals, choose a disc that fights rust. For water or air, ductile iron or stainless steel works well. The right disc helps your valve last longer and stops leaks or problems.

Stem and Shaft

The stem and shaft link the disc to the actuator. You use the stem to turn the disc and change the flow. The shaft goes through the body and keeps the disc steady. When you move the handle or actuator, the stem turns and the disc spins.

You need a strong stem and shaft for smooth movement. These parts must not bend or wear out easily. Makers often use stainless steel or carbon steel for the stem. This helps the valve last longer and work well under pressure.

Tip: Always check the stem and shaft for damage. If you see rust or wear, replace them fast to keep your butterfly valve safe.

Seals and Seats

Seals and seats play a big role in how well your butterfly valve works. You find these parts inside the valve, where they help stop leaks and keep fluids moving the right way. The seat sits around the edge of the disc. It forms a tight seal when you close the valve. The seal keeps water, air, or chemicals from escaping. You need a good seal to make sure your system stays safe and clean.

Manufacturers use different materials for seats and seals. Each material works best for certain fluids and pressures. You see seats made from rubber, PTFE (a type of plastic), or other elastomers. Rubber seats work well with water and low-pressure systems. PTFE seats resist chemicals and high temperatures. Some valves use VITON or EPDM for extra strength against harsh fluids.

Here is a simple table to help you choose the right seat material:

| Seat Material | Best Use | Strengths |

|---|---|---|

| EPDM | Water, steam | Handles heat, resists wear |

| PTFE | Chemicals | Fights corrosion, lasts long |

| NBR | Oil, gas | Good for oils, flexible |

| VITON | Chemicals, acids | Strong against harsh fluids |

Tip: Always check the fluid type and temperature before you pick a seat material. The wrong choice can cause leaks or damage.

Seals also come in many shapes. You see O-rings, gaskets, or molded seals. These parts press against the disc and seat when you close the butterfly valve. A strong seal means you get less leakage and better control. If you notice drips or drops near your valve, check the seals first. You may need to replace them to keep your system working well.

Seats and seals do not last forever. You should inspect them often. If you see cracks, swelling, or wear, change them right away. This simple step helps your butterfly valve last longer and keeps your system safe.

Actuator

The actuator gives you control over your butterfly valve. You use it to open, close, or adjust the valve without turning it by hand. Actuators come in different types. You see manual, electric, and pneumatic actuators in many systems.

Manual actuators use a handle or lever. You turn the handle to move the disc inside the valve. This type works well for small systems or places where you do not need fast changes.

Electric actuators use motors. You send a signal, and the motor turns the disc. You get precise control with electric actuators. These work best in systems where you need to change flow often or from a distance.

Pneumatic actuators use air pressure. You send air into the actuator, and it moves the disc. Pneumatic actuators work quickly and fit well in large factories or places with many valves.

Here is a quick list of actuator types and their main uses:

- Manual: Simple, low cost, good for small jobs

- Electric: Accurate, remote control, best for advanced systems

- Pneumatic: Fast, reliable, good for big plants

Note: Pick the actuator that matches your system size and needs. The right actuator helps your butterfly valve work better and last longer.

You should check actuators often. Look for signs of wear, rust, or slow movement. If you see problems, fix or replace the actuator. This keeps your valve working smoothly and helps you avoid costly repairs.

Functions and Uses

Mixing Fluids

You can use a 3 way butterfly valve to mix two different fluids in your system. This type of valve helps you blend liquids or gases from separate sources. For example, you might want to control the temperature or the makeup of a fluid by mixing hot and cold water. In factories, you often see T-port valves used for mixing. Here are some real-world examples:

- T-port valves combine fluid flows from different sources in industrial mixing services.

- In beverage production, you can use a T-port valve to mix pure water with juice concentrate from a storage tank.

- You can blend two fluid streams into one controlled output, adjusting the mix to get the right result for your process.

When you use a 3 way butterfly valve for mixing, you get flexibility. You can change the proportions of each fluid to match your needs. This makes it easy to keep your process steady and safe.

Tip: Mixing with a butterfly valve helps you save space and reduce the number of valves you need.

Diverting Flow

A 3 way butterfly valve also lets you divert flow from one line to another. You can send fluid to different tanks, machines, or process lines. This is helpful in systems where you need to switch between two destinations without stopping the flow. For example, in an HVAC system, you might want to send chilled water to one part of a building or direct it to another area during maintenance.

You can use this valve to:

- Switch between two process lines quickly.

- Direct flow to a backup tank if the main tank is full.

- Change the path of chemicals or water in a treatment plant.

This function gives you more control over your system. You can manage where fluids go with just one valve, making your setup simpler and more reliable.

Isolation

You can use a 3 way butterfly valve for isolation in fluid control systems. This means you can stop the flow to one part of your system while keeping other parts running. The multiport design of this valve gives you flexibility. You do not need to install extra valves to block off a section.

Here is how isolation works with this valve:

- You can shut off flow to a tank or process line for cleaning or repairs.

- You can keep the rest of your system working while you isolate one area.

- The design handles many flow applications, so you do not need several single-port valves.

Note: Using a butterfly valve for isolation saves space and reduces costs in your system.

You often see this function in HVAC systems, chilled water control, and industrial plants. The 3 way butterfly valve helps you keep your system safe and easy to manage.

Applications

HVAC Systems

Butterfly valves are common in HVAC systems. They help control hot or cold water flow. You can mix water from two places or send it to different rooms. When you need to switch between heating and cooling, just turn the valve. This changes where the water goes. It makes your system flexible and helps save energy.

Big buildings need fast water control. Butterfly valves work quickly and fit in small spaces. You can add an electric or pneumatic actuator for automatic control. This lets you change room temperatures without doing it by hand. You get more comfort and lower energy bills.

Tip: Butterfly valves make HVAC maintenance simple. You can shut off parts for repair without stopping the whole system.

Water Treatment

Water treatment plants use butterfly valves to move water through each step. These plants handle lots of water every day. The valve’s simple design helps move water fast with little effort. You can also automate the valve for better control.

Here is a table that shows why this valve is good for water treatment:

| Performance Indicator | Description | Impact on Water Flow Control |

|---|---|---|

| Increased Flow Capacity | Simple design lets more water move through | Makes water flow easier to manage |

| Low Pressure Drop | Keeps pressure low while working | Saves energy and money |

| Ease of Automation | Can be automated for better control | Makes work faster and easier |

| Precise Flow Control | Gives accurate control over water flow rates | Helps keep water safe and clean |

You can use the valve to mix, send, or stop water flow. This keeps water safe and clean. You also save money because the valve uses less energy and needs less fixing.

Chemical Processing

Butterfly valves are used a lot in chemical plants. They help control acids, bases, and other chemicals. You need a valve that works fast and does not take up much space. Butterfly valves are quick and small.

Think about these things when picking a valve for chemicals:

- Material: Make sure the valve matches the chemicals you use.

- Body Style: Pick a design that fits your process.

- Operation: Choose if you want to use your hand or an actuator.

Butterfly valves give many benefits in chemical plants:

- You can control flow rates very well.

- The valve is reliable and saves money.

- You can use it for flow control, isolation, mixing, and pressure control.

Note: Always check if the valve material works with your chemicals. This helps stop leaks and damage.

Industrial Uses

Butterfly valves are used in many industries. They help control fluids like water, oil, steam, and chemicals. You find them in factories, power plants, and food plants. Their simple design makes them easy to use and install.

Factories need valves that are strong and reliable. Butterfly valves can start or stop flow in big pipes. The disc inside turns fast, so you get quick control. These valves do not need much space. This saves time and money when installing.

Power plants use butterfly valves for steam and cooling water. You can open or close the valve with an actuator. This helps control temperature and pressure in the system. It keeps the plant safe and working well.

Food plants need clean and safe equipment. You can pick a butterfly valve made from stainless steel. Stainless steel does not rust and keeps food safe. You can clean these valves easily. The smooth surface does not hold dirt or germs.

Here is a table showing how butterfly valves are used in different industries:

| Industry | Fluid Controlled | Main Benefit |

|---|---|---|

| Chemical Plants | Acids, bases | Fast shut-off, corrosion resistance |

| Power Generation | Steam, cooling water | Quick operation, safety |

| Food Processing | Water, liquids | Easy cleaning, hygiene |

| Oil & Gas | Oil, gas | High pressure handling |

| Paper Mills | Pulp, water | Reliable flow control |

Tip: Always check what your valve is made of before using it. Picking the right material helps stop leaks and damage.

Butterfly valves can be used for isolation, mixing, and diverting flow. They work well in systems that use automation. You can connect them to electric or pneumatic actuators. This lets you control the valve from far away and makes your job easier.

Butterfly valves help keep industrial systems running smoothly. You get quick response, low maintenance, and long life. These valves are trusted to handle tough jobs every day.

Advantages

Versatility

You get more control over your system when you use a 3 way butterfly valve. This valve works well in many situations. You can mix two fluids or send flow in different directions. You do not need extra equipment to do these jobs. The design lets you handle complex systems with ease.

- You can manage both mixing and redirecting of fluids. This gives you better control in systems that need flexible flow.

- The lightweight design makes it easy for you to install and operate.

- You spend less time on maintenance. The valve works well for large-scale fluid handling and helps you save money.

You can use this valve in water treatment, HVAC, and chemical plants. The versatility helps you solve many problems with one device.

Space and Cost Savings

You save space and money when you choose a butterfly valve. The compact shape fits into tight spots. You do not need to change your piping layout much. This makes installation faster and cheaper.

- Wafer and lug types are lighter and more compact. You pay less for installation because you need fewer supports.

- Triple eccentric butterfly valves take up less room than other valves. Your system design becomes simpler and more efficient.

- The strong build means you do not have to fix or replace the valve often. Businesses like this because it keeps costs low and standards high.

- You get more savings from easy installation and low maintenance. These valves help you run your system without spending too much.

You can use the saved space for other equipment or make your system easier to reach. The cost savings help you stay within budget.

Easy Operation

Operating a butterfly valve is simple. You turn the handle or use an actuator to change the flow. You do not need special tools or training. The disc inside moves quickly, so you get fast results.

- The lightweight design makes it easy for you to move the valve.

- You can automate the valve with electric or pneumatic actuators. This lets you control the system from a distance.

- You spend less time on repairs. The valve needs little care and works well for a long time.

Tip: If you want a valve that is easy to use and maintain, a butterfly valve is a smart choice.

You get quick response and reliable performance. The easy operation helps you keep your system running smoothly every day.

Selection Tips

Material Choices

You need to pick the right material for your valve. The choice depends on what kind of fluid you control and the conditions in your system. Some materials work better with certain chemicals or temperatures. If you use the wrong material, your valve may leak or break early. Here is a table that shows common material options and where you should use them:

| Material | Application/Characteristics |

|---|---|

| NBR | Works well in hydraulic oil pipelines; resists oil; handles up to 120°C; does not resist ozone. |

| VITON | Stays stable with chemicals; handles high heat; does not bend well in cold. |

| PTFE | Fights corrosion; best for corrosive fluids below 200°C; can deform under pressure. |

| Ductile Iron + EPDM | Good for city water supply; low chance of leaks; saves money. |

| Stainless Steel 316L + PTFE | Best for hydrochloric acid; meets strict corrosion standards. |

| Super Duplex Steel + VITON | Great for sour oil and gas; resists cracking from sulfides. |

Tip: Always match the material to your fluid and temperature needs. This helps your valve last longer and work safely.

Sizing

You must choose the right size for your valve. The size affects how much fluid can move through your system. If you pick a valve that is too small, you may not get enough flow. If you pick one that is too big, you waste money and space. Use the table below to help you decide:

| Factor | Description |

|---|---|

| Flow Rate Requirements | Check how much fluid you need to move. Pick a size that matches your system’s flow rate. |

| Pressure Drop | Figure out how much pressure will drop when fluid passes through. This helps you manage flow. |

| Temperature Compatibility | Make sure the valve material can handle your system’s temperature. |

| Valve Type | Different butterfly valves fit different jobs. Pick the type that matches your application. |

| Compliance with Standards | Make sure your valve size meets safety and performance rules. |

| Manufacturer Specifications | Look at the manufacturer’s catalog for sizes and ratings. |

Note: Always check your system’s needs before you buy. The right size helps your system run smoothly.

Installation

You want your valve to work well after you install it. Good installation keeps your system safe and helps your valve last longer. Follow these best practices:

- Tighten bolts in a star or cross pattern. This spreads pressure evenly and stops leaks.

- Flush your system after you install the valve. This removes dirt and debris.

- Test for leaks before you start using the valve. Make sure everything is sealed.

- Move the valve through its full range. Check that it opens and closes smoothly.

- Adjust actuators if needed so the valve works right.

- Set up a maintenance plan. Inspect for damage and keep records of repairs.

Tip: Careful installation and regular checks help your butterfly valve perform at its best.

A 3 way butterfly valve lets you control fluid flow in many ways. You can mix fluids, send them to different places, or block them. These valves work in HVAC, water treatment, and chemical plants. When picking a valve, look at some key things:

- Make sure it works with your fluid and system.

- Check the pressure and temperature it can handle.

- See if the size and flow fit your needs.

- Look at what people say about the maker.

- Think about your budget and what features you want.

To get the best valve, ask an expert for advice before you buy. This helps you choose the right valve and keeps your system working well.

FAQ

What is the main job of a 3 way butterfly valve?

You use a 3 way butterfly valve to mix or divert fluids. This valve lets you control where water, air, or chemicals go in your system.

Can you use a 3 way butterfly valve for both hot and cold fluids?

Yes, you can. You need to pick the right materials for your valve. Stainless steel and EPDM seats work well for hot and cold fluids.

How do you know which actuator to choose?

You look at your system size and how fast you want to control flow. Pneumatic actuators work fast. Electric actuators give you more accuracy.

Tip: Always match the actuator to your system needs for best results.

Is it hard to install a 3 way butterfly valve?

You can install this valve easily. You tighten bolts in a cross pattern and check for leaks. You do not need special tools.

What is the difference between a 2 way and a 3 way butterfly valve?

| Valve Type | Number of Ports | Main Use |

|---|---|---|

| 2 Way | 2 | Open/close flow |

| 3 Way | 3 | Mix/divert flow |

You get more control with a 3 way valve.

How often should you check seals and seats?

You should inspect seals and seats every few months. Look for cracks or leaks. Replace them if you see damage.

Can you automate a 3 way butterfly valve?

Yes, you can. You add an electric or pneumatic actuator. Automation helps you control flow from a distance and saves time.