When you compare a 2 way vs 3 way solenoid valve, you notice they control fluid differently. A 2 way solenoid valve turns flow on or off, functioning similarly to a butterfly valve or a ball valve. These valves are designed to stop or allow fluid movement. In factories, people commonly use 2 way valves for straightforward on/off tasks or to regulate temperature. On the other hand, 3 way valves can mix fluids or redirect the flow, making them essential for heating and cooling systems. Choosing the right valve, whether it’s a 2 way solenoid valve, a butterfly valve, or a ball valve, is crucial for maintaining the safety and efficiency of your system.

Key Takeaways

- 2-way solenoid valves turn fluid flow on or off. They are good for simple jobs.

- 3-way solenoid valves can mix or move fluids in different ways. This helps in more complicated systems.

- Pick a 2-way valve for easy uses like watering plants or heating and cooling. These only need basic on and off control.

- Use a 3-way valve if you need to control more than one flow path. They are also good for mixing fluids in things like medical tools or food machines.

- Both types of valves need regular care to stop leaks and work well.

- 2-way valves usually cost less and are easier to put in and take care of. 3-way valves need more attention and space.

- Always pick the right valve for your system to make it work better.

- Think about the kind of fluid, how much pressure there is, and the place where you will use the valve. This helps the valve last longer and work right.

Solenoid Valves Overview

What Are Solenoid Valves

Solenoid valves help control how liquids or gases move. They use electricity to open or close a path. This makes them important for automatic fluid control. If you need to start or stop fluid fast, solenoid valves work well. They let you manage water, air, oil, or other fluids with just a signal. Their design lets you find them in both simple and complex machines.

How Solenoid Valves Work

Solenoid valves use a simple idea to work. Here is what happens:

- When the valve is off, a spring keeps the plunger in place. This can block or let fluid move through the valve.

- When you turn on electricity, a magnetic field appears. This field moves the plunger and changes the valve’s position.

- When you turn off the power, the spring pushes the plunger back.

This fast movement lets you control fluid flow very well. Solenoid valves react almost right away. This makes them great for systems that need quick and accurate control.

?? Tip: New solenoid valves can save up to 80% more energy than old ones. Some use only 0.55 watts. This makes them a smart pick for saving energy.

Common Uses

You can find solenoid valves in many places and products. They give you exact control, remote use, and quick action. This makes them useful for many jobs. Here is a table that shows where solenoid valves are used and what they do:

| Industry | Applications |

|---|---|

| Automotive | Fuel injectors, transmission shifters, turbochargers |

| HVAC | Zone control, pneumatic thermostats, air conditioning, humidifiers |

| Medical | Oxygen concentrators, patient monitors, dialysis machines |

| Refrigeration | Ice machines, water coolers, beverage dispensers |

| Plumbing | Commercial dishwashers, water faucets, gas valves |

| Industrial Automation | Automated processes for efficiency and quality control |

| Smart Homes | Water purifiers and other fluid flow controls |

| Energy Management | Temperature management to reduce energy use |

When you use solenoid valves, you get many good things:

- You can control fluid movement very well.

- You can use them from far away and connect to smart devices.

- The valves move fast, which helps keep things safe and efficient.

- You can use them with many kinds of liquids and gases.

- They help you save energy and lower maintenance costs.

Solenoid valves make your systems safer, work better, and easier to use.

2 Way Valve Basics

2 Way Valve Operation

A 2 way valve has two ports. One port lets fluid in. The other port lets fluid out. This design helps control fluid flow well. When you send power to the solenoid, the plunger lifts up. This opens the path for fluid to move. Fluid goes from the cavity port to the body orifice port. If you turn off the power, the plunger drops down. This closes the orifice and stops the flow right away.

Here is how it works step by step:

- The valve connects to two pipes. One pipe brings fluid in. The other pipe lets fluid out.

- When you turn on the solenoid, the plunger opens. Fluid flows through the valve.

- When you turn off the power, the plunger closes. The flow stops.

This fast action makes 2 way valves great for jobs that need quick timing. You can use them in air systems, water lines, and gas controls. The two-port design gives you good control and helps manage flow easily.

?? Tip: If you want fast and steady on/off control, a 2 way valve is usually the best pick.

2 Way Valve Applications

You see 2 way valves in lots of industries. Their simple on/off job makes them helpful when you need to start or stop fluid quickly. Here are some common uses:

| Industry | Example Uses |

|---|---|

| HVAC | Turning water or air flow on/off |

| Industrial | Managing pneumatic tools |

| Automotive | Fuel line control |

| Medical | Oxygen delivery systems |

| Plumbing | Water supply shut-off |

You can use 2 way valves for water, air, oil, and gas. Their design works for both small and big systems. You find them in machines, factories, and even home appliances.

2 Way Valve Pros

There are many good things about 2 way solenoid valves. The simple design makes them easy to put in. You can take care of them without much trouble. Checking them often helps you find leaks or strange sounds early. Cleaning inside keeps dust and dirt from causing problems. Testing the electrical parts makes sure the valve works right.

Here are the main pros:

- Good flow control for many fluids and gases

- Fast response for exact operation

- Simple to install and take care of

- Works well in tough places

You will see fewer problems with 2 way valves than with more complex ones. Their simple design means fewer parts can break. With basic care, your system will run smoothly.

2 Way Valve Cons

While 2 way valves offer many benefits, you should also know about their drawbacks. Understanding these cons helps you make better choices when picking solenoid valves for your system.

Here are some common disadvantages of 2 way valves:

- Limited Flow Control

You can only turn the flow on or off with a 2 way valve. You cannot adjust or direct the flow to different paths. If your system needs to mix or divert fluids, you will need a different type of valve. - Not Suitable for Complex Systems

Many industrial systems need more than just simple on/off control. If you want to switch between two outputs or mix two fluids, 2 way valves will not work. In these cases, 3-way solenoid valves offer more flexibility. - Possible Water Hammer

When you close a 2 way valve quickly, it can cause a sudden stop in the fluid. This may create a loud banging noise called water hammer. Water hammer can damage pipes and other parts of your system. - No Flow Direction Change

You cannot change the direction of the fluid with a 2-way valve. The fluid always moves from the inlet to the outlet. If you need to reverse the flow, you must use extra valves or a different setup. - May Need Extra Components

Sometimes, you need more than one 2 way valve to control a complex process. This can increase the cost and make the system harder to maintain.

?? Note: If your application needs more than just starting or stopping the flow, you should look at other solenoid valves. For example, 3-way solenoid valves can mix, divert, or switch flow paths.

Summary Table: 2 Way Valve Cons

| Drawback | Impact on System |

|---|---|

| Limited flow control | Only on/off, no mixing or diverting |

| Not for complex systems | Cannot handle multiple flow paths |

| Water hammer risk | Can damage pipes and equipment |

| No flow direction change | Always flows one way |

| Extra components needed | Increases cost and complexity |

When you choose solenoid valves, always think about what your system needs. If you only need simple on/off control, a 2 way valve works well. If you need more options, look at other types of valves. Knowing the cons of 2 way valves helps you avoid problems and keeps your system running smoothly.

3 Way Valve Basics

3 Way Valve Operation

A 3 way valve gives you more control over fluid flow than a simple on/off valve. This type of valve has three ports. You can use it to mix two fluids together or to send one fluid to two different places. When you use solenoid valves with three ports, you can switch the flow path quickly by sending an electric signal.

Here is how a 3-way valve works:

- You can connect two sources to one outlet. The valve lets you mix the fluids before they leave.

- You can also connect one source to two outlets. The valve lets you choose which way the fluid goes.

- The valve changes position when you turn the solenoid on or off. This moves the plunger inside and opens or closes different paths.

This design helps you handle more complex jobs. You can use a 3 way valve to mix, divert, or switch flow paths without needing extra valves.

?? Tip: If you need to control where the fluid goes or mix two fluids, a 3 way valve is a smart choice.

3 Way Valve Applications

You will find 3 way valves in many systems that need flexible flow control. These valves work well in places where you need to mix, divert, or switch fluids. Here are some common uses:

| Industry | Example Applications |

|---|---|

| HVAC | Switching between heating and cooling lines |

| Medical | Mixing gases for patient care |

| Industrial | Diverting air or liquid in machines |

| Food & Beverage | Mixing ingredients or cleaning fluids |

| Automotive | Switching fuel or coolant flow |

In HVAC systems, you can use a 3 way valve to switch between hot and cold water. In medical devices, you can mix oxygen and air for patients. In factories, you can direct fluids to different machines. These solenoid valves help you save space and reduce the number of parts in your system.

3 Way Valve Pros

You get many benefits when you use 3 way valves in your setup. Here are some of the main advantages:

- You can mix fluids from two sources or send one fluid to two places.

- You can change flow paths without adding more valves.

- You get fast and reliable switching with solenoid valves.

- You can use these valves in many industries and for many fluids.

- You can make your system simpler and easier to control.

A 3 way valve gives you more options than a basic on/off valve. You can handle complex routing jobs with just one valve. This makes your system more flexible and efficient.

?? Note: When you compare a 2 way vs 3 way solenoid valve, you see that 3 way valves offer more ways to control flow. You can mix, divert, or switch fluids with just one valve.

3 Way Valve Cons

When you choose solenoid valves for your system, you need to know the drawbacks of a 3 way valve. These valves offer many benefits, but you may face some challenges. Understanding these cons helps you make better decisions and avoid problems in your setup.

Here are the main disadvantages of 3-way valve designs:

- Complex Installation

You will notice that installing a 3 way valve takes more time than a simple two-port valve. You must connect three ports correctly. If you make a mistake, the fluid may not flow as you expect. You may need extra instructions or help from a professional. - Higher Cost

You pay more for 3 way valves than for basic solenoid valves. The extra parts and features increase the price. You also spend more on installation and maintenance. If your system does not need mixing or diverting, you may waste money by choosing this type. - More Maintenance

You must check 3 way valves often. The moving parts inside can wear out faster because they switch between different flow paths. If you do not clean or inspect the valve, you may see leaks or slow response times. You may need to replace seals or other parts more often. - Larger Size

You need more space for a 3 way valve. The extra port and internal parts make the valve bigger. If you have a small area or tight piping, you may struggle to fit the valve. You may need to change your system layout. - Possible Flow Restrictions

You may see lower flow rates with 3 way valves. The design can create more resistance inside the valve. If you need high flow, you should check the valve’s specs before you buy.

?? Note: If you compare a 2 way vs 3 way solenoid valve, you see that 3 way valves offer more control but also bring more complexity. You should only choose a 3 way valve if your system needs to mix, divert, or switch flow paths.

Summary Table: 3 Way Valve Cons

| Drawback | What You May Notice |

|---|---|

| Complex installation | More time and care needed |

| Higher cost | More expensive to buy and maintain |

| More maintenance | Frequent checks and part replacements |

| Larger size | Needs more space in your system |

| Flow restrictions | May reduce fluid speed or volume |

You should always match the valve type to your system’s needs. Solenoid valves give you many options, but you must balance control with cost and maintenance. If you want simple on/off control, you may prefer a basic valve. If you need to mix or switch fluids, a 3 way valve works well, but you must plan for the extra work and expense.

2 Way vs 3 Way Solenoid Valve Comparison

Ports and Flow Control

When you look at a 2 way vs 3 way solenoid valve, the first thing you notice is the number of ports. A 2 way valve has two ports, while a 3 way valve has three. This difference changes how you control the flow of fluids.

Here is a table that shows the port configuration and main function for each type:

| Valve Type | Number of Ports | Port Labels | Primary Function |

|---|---|---|---|

| 2-Way Valve | 2 | Inlet “A”, Outlet “AB” | On/Off Control |

| 3-Way Valve | 3 | “A”, “B”, “AB” | Diverting or Mixing Fluids |

A 2 way valve lets you start or stop the flow. You use it when you want simple on/off control. For example, you might use it in an irrigation system to turn water on or off.

A 3 way valve gives you more options. You can mix two fluids together or send one fluid to two different places. This makes it useful in systems where you need to change the flow path or combine fluids, like in crop spraying or heating systems.

?? Tip: If you need to mix or divert fluids, choose a 3 way valve. If you only need to open or close the flow, a 2 way valve works best.

Operation Differences

Both 2 way valves and 3 way valves use solenoid valves for fast and reliable control. When you send an electric signal, the valve moves quickly. This quick response helps you control fluids with precision.

- 2 way valves open or close the flow path. You get a simple on/off action.

- 3 way valves switch the flow between two paths or mix two flows into one. You can direct the fluid where you need it.

Both types offer high reliability. You can trust them to work in many different systems. The main difference comes from how each valve moves the fluid. A 2 way valve gives you a single flow path, while a 3 way valve lets you choose between paths or mix fluids.

?? Note: Both types respond quickly, but the 3 way valve gives you more control over where the fluid goes.

Application Differences

You need to pick the right valve for your system. The choice depends on what you want to do with the fluid.

- 2 way valves work best for simple on/off jobs. You see them in heating and cooling systems, water supply lines, and irrigation. They help you save energy and reduce costs because they only open or close the flow.

- 3 way valves fit systems that need constant flow or more complex control. You use them to mix hot and cold water, switch between two outputs, or send fluid to different machines. In some cases, you need to combine fluids of different temperatures or pressures. The 3 way valve handles these tasks well.

Here are some examples:

- In a heating system, you use a 2 way valve to turn the water flow on or off.

- In a mixing system, you use a 3 way valve to blend two fluids before sending them to the next step.

- In crop spraying, a 3 way valve lets you switch between different chemicals or mix them as needed.

??? Tip: Always match the valve to your system’s needs. If you need to change flow paths or mix fluids, a 3 way valve is the better choice.

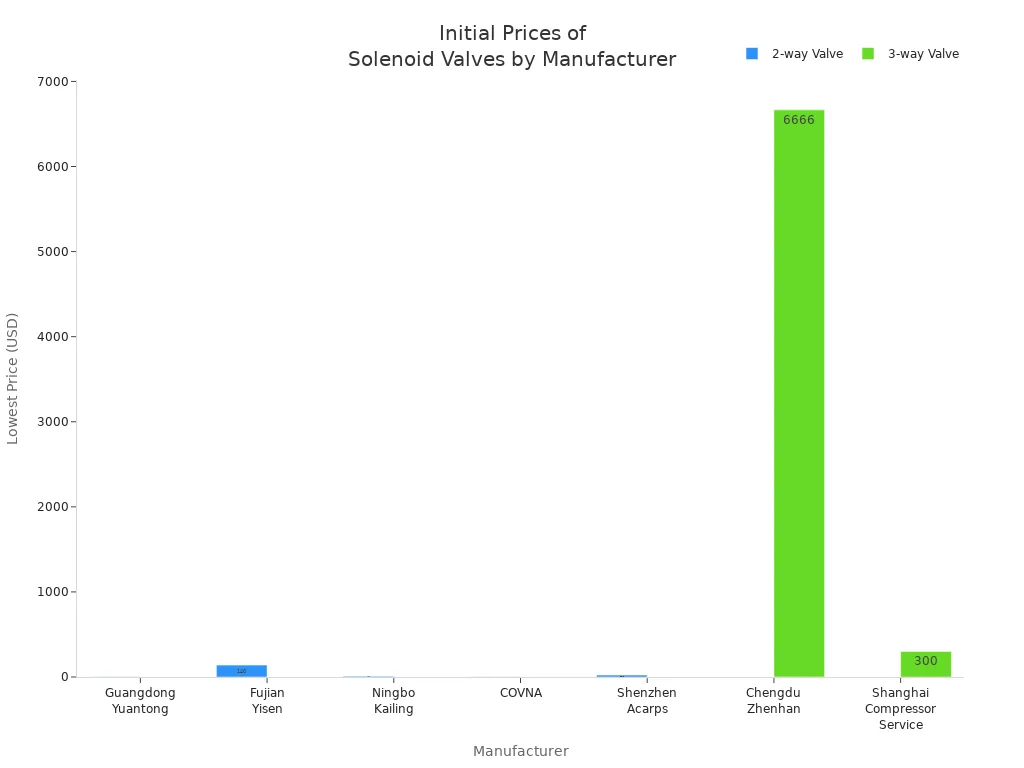

You can see from the chart that 3 way valves often cost more than 2 way valves. The extra port and added features increase the price. Make sure you choose the right type for your job to get the best value.

Installation and Maintenance

When you install solenoid valves, you need to think about the number of ports and the space in your system. A 2 way valve has a simple design. You connect one inlet and one outlet. This makes installation quick and easy. You can often fit these valves into tight spaces. You do not need special tools or extra steps.

A 3 way valve has three ports. You must connect each port to the right pipe or hose. This takes more time and care. You need to check the flow direction before you finish the job. Sometimes, you need more space for a 3 way valve because it is larger. If you make a mistake during installation, the fluid may not flow as you want.

Maintenance for solenoid valves is important. You should check for leaks, dirt, or worn parts. A 2 way valve is easy to clean. You can remove the valve, clean the inside, and put it back. You do not have to take apart many parts. This saves you time.

A 3 way valve needs more attention. You must check all three ports and the moving parts inside. If you see a leak or slow response, you may need to replace seals or clean the valve. The extra port means more places for dirt to build up. You should follow the manufacturer’s guide for cleaning and repairs.

| Feature | 2 Way Valve | 3 Way Valve |

|---|---|---|

| Number of Ports | 2 | 3 |

| Installation Time | Short | Longer |

| Space Needed | Small | Larger |

| Maintenance Steps | Simple | More Detailed |

| Cleaning Frequency | Less Often | More Often |

Cost Factors

When you choose between solenoid valves, you need to think about cost. The price depends on the type of valve, the number of ports, and the features you need.

A 2 way valve usually costs less. The simple design means fewer parts and lower prices. You also spend less on installation and maintenance. If you need to buy many valves for a big project, the savings add up.

A 3 way valve costs more. The extra port and complex design increase the price. You may also pay more for installation because it takes longer. Maintenance can cost more because you need to check and clean more parts. If you need special features, like high-pressure ratings or special materials, the price goes up.

Here are some cost factors to consider:

- Initial Purchase Price: 2 way valves are cheaper than 3 way valves.

- Installation Costs: You spend less time and money installing 2 way valves.

- Maintenance Costs: 3 way valves may need more repairs and cleaning.

- System Complexity: More complex systems with 3 way valves may need extra parts or controls.

- Replacement Parts: 3 way valves may need more seals or moving parts replaced over time.

?? Note: If your system only needs simple on/off control, a 2 way valve saves you money. If you need to mix or divert fluids, a 3 way valve gives you more options but costs more.

You should always match the valve to your needs and budget. Solenoid valves give you many choices, so you can find the right balance between price and performance.

Similarities of 2 Way and 3 Way Valves

Shared Features

When you compare 2-way and 3-way solenoid valves, you see they have a lot in common. Both types use an electric coil to move a plunger inside the valve. This lets you control liquids or gases with a simple signal. The valves react fast, so your system can change quickly. You do not need to turn them by hand. Both work well in automatic systems that need to start or stop fluid flow.

These valves are small, so they fit in tight spaces. They seal well, which helps stop leaks and keeps things safe. You can use them in many places, like HVAC, medical tools, and factories. Both types can handle many kinds of fluids, so they are very useful.

?? Tip: Both solenoid valves save energy because they only use power when switching.

Electrical Control

You control both 2-way and 3-way solenoid valves with the same simple method. When you turn on the coil, the plunger lifts and opens the path. When you turn off the power, the plunger drops and closes the valve. This on/off action gives you good control over fluids.

Here are some main points about how they work:

- You turn the coil on or off to change the flow.

- The plunger stays closed if the coil is off.

- Both valves use this way to open or close the path.

This shared control makes it easy to automate your system. You can connect the valves to timers, sensors, or remote switches. This lets you run your system from far away and react fast to changes.

Materials and Build

Both 2-way and 3-way solenoid valves use similar materials. Makers often pick metals like brass, stainless steel, or aluminum for the body. These metals are strong and do not rust easily. For seals, you might see Buna-N (NBR), EPDM, PTFE, or FKM. These help stop leaks and work with many fluids.

Here are some common materials used in solenoid valves:

- Brass

- Stainless steel (302, 303, 316, 430)

- Aluminum

- Copper

- Delrin

- Nylon

- Polyurethane

- PTFE

- Buna-N (NBR)

- EPDM

- FKM

You can pick the best material for your fluid and where you put the valve. Both types give you choices for strong and long-lasting use.

??? Note: Always check if the material works with your fluid to keep things safe.

Maintenance Needs

You need to keep solenoid valves working well to avoid problems in your system. Both 2-way and 3-way solenoid valves share similar maintenance needs. You should check them often to make sure they open and close as they should. Regular checks help you spot leaks, dirt, or worn parts before they cause bigger issues.

Start by looking at the outside of the valve. You may see signs of leaks or corrosion. If you notice any damage, you should fix it right away. Clean the valve body with a soft cloth. Remove dust and dirt that can block the moving parts. You can use a mild cleaner if needed, but make sure it does not harm the materials.

Next, listen for strange sounds when the solenoid valves operate. A clicking or buzzing noise may mean the coil or plunger needs attention. You can test the coil with a multimeter to check if it works. If the coil does not get power, the valve will not open or close. Replace faulty coils to keep your system safe.

You should also check the seals inside the valves. Seals stop fluid from leaking out. Over time, seals can wear out or crack. If you see drops of fluid near the valve, you may need to change the seals. Most solenoid valves let you replace seals without taking apart the whole unit.

Here is a simple checklist for solenoid valve maintenance:

- Inspect for leaks or corrosion

- Clean the valve body and ports

- Listen for unusual sounds

- Test the coil for power

- Replace worn seals

??? Tip: Always turn off the power and release pressure before you work on solenoid valves. This keeps you safe and protects your equipment.

pe. Both 2-way and 3-way solenoid valves use the same steps for maintenance. You can follow these tips for any type in your system.

Choosing the Right Solenoid Valve

Assessing Needs

You must start by understanding what your system requires. Look at the job you want the solenoid valves to do. Ask yourself if you need simple on/off control or if you need to mix or divert fluids. Think about the type of fluid, how fast it moves, and where the valve will work. Write down your goals before you choose a valve.

?? Tip: Make a list of your system’s needs. This helps you match the right solenoid valves to your application.

Key Factors

Fluid Type

The fluid you control affects your choice. Some fluids need special materials. Water, oil, air, and chemicals all have different needs. You must pick a valve made from materials that work with your fluid. Bronze, aluminum, steel, and plastic are common choices. If you use a gas, you may need a different design than for a liquid. Always check if the seal material matches your fluid. Buna-N, EPDM, PTFE, and FKM are popular seal options.

- Choose materials that resist corrosion if your fluid is harsh.

- Make sure the valve can handle the fluid’s temperature.

- Pick a seal that does not break down in your fluid.

Pressure/Flow Rate

Pressure and flow rate decide how well solenoid valves work. If your system has high pressure, you need a valve that can handle it. Low pressure may need a different type. You must know the inlet and outlet pressure. This helps you find the pressure drop across the valve. If the flow rate is high, pick a valve that does not restrict the fluid. For mixing or diverting, a 3-way valve gives you more control. For simple on/off jobs, a 2-way valve works best.

- Check the valve’s pressure rating.

- Make sure the flow rate matches your system.

- Avoid using a valve outside its limits.

Control Requirements

Think about how you want to control the fluid. If you only need to start or stop flow, a 2-way valve is enough. If you need to mix two fluids or send fluid to different places, use a 3-way valve. The extra port in a 3-way valve lets you do more with one device. This saves space and money. You do not need two separate valves for mixing or diverting.

- Decide if you need on/off or mixing/diverting control.

- Understand the port configuration for each valve.

- Use a 3-way valve for complex jobs.

Environment

Where you install the valve matters. High temperatures can damage some solenoid valves. Humidity may cause electrical problems. Dust, water, and chemicals can wear out seals and bodies. If you work outdoors, pick a valve that resists UV rays and weather. In explosive areas, use explosion-proof valves. For places with vibration, choose vibration-resistant valves.

| Environmental Factor | Considerations |

|---|---|

| Maximum Temperature | Make sure the valve’s rating matches your system’s heat. |

| Relative Humidity | High humidity can lower insulation and cause failures. |

| Corrosive Atmosphere | Use valves with strong seals and bodies for dusty or chemical-rich places. |

| Explosion Risk | Pick explosion-proof valves for hazardous areas. |

| Vibration | Select valves that resist shock and movement. |

?? Note: Always check the valve’s IP rating for dust and water protection.

Selection Tips

You can use these tips to help you pick the right solenoid valves for your job:

- Sizing: Make sure the valve fits your system’s flow needs. A valve that is too small or too big will not work well.

- Operating Conditions: Look at real conditions, not just ideal ones. Pressure changes, dirty fluids, and temperature swings affect performance.

- Cycle Rates: Think about how often the valve will open and close. High cycle rates need tough valves.

- Media Compatibility: Check if the valve works with your fluid. Some fluids can damage seals or bodies.

- Electrical Operation: Match the valve’s voltage to your system. Wrong voltage can cause problems.

- Maintenance: Plan for regular checks and cleaning. This keeps solenoid valves working longer.

- Valve Type: Pick a 2-way valve for simple control. Use a 3-way valve for mixing or diverting.

- Pressure Ratings: Do not choose a valve with much higher pressure than needed. Match ratings closely.

- Contamination Prevention: If your fluid is dirty, use filters or strainers before the valve.

?? Checklist:

- What fluid do you control?

- What is the pressure and flow rate?

- Do you need on/off or mixing/diverting?

- Where will you install the valve?

- What size and voltage do you need?

- How often will the valve cycle?

- Is maintenance easy?

You can use this decision guide to choose between 2-way and 3-way solenoid valves:

| Question | Best Choice |

|---|---|

| Need simple on/off control? | 2-way valve |

| Need to mix or divert fluids? | 3-way valve |

| High pressure or flow rate? | Check valve specs |

| Harsh environment? | Use strong materials |

| Frequent cycling? | Durable valve |

Solenoid valves give you many options. When you match your needs to the right valve, your system works better and lasts longer.

Troubleshooting Solenoid Valves

Common Issues

Solenoid valves can have problems that stop your system or cause leaks. If you know the usual issues, you can fix them faster. Here is a table that shows what you might see:

| Issue | Description |

|---|---|

| Not opening/closing | Solenoid valves may not open or close right because of dirt, broken parts, or electrical trouble. |

| Leaking | Leaks happen if seals are damaged or if the valve is put in wrong. |

| Overheating | Electrical trouble or too much pressure can make valves get hot. |

| Low differential pressure | Indirect operated solenoid valves need enough pressure to work. If pressure is too low, they may not operate. |

You might also see these problems: power loss, uneven pressure, wrong voltage, dirt under the diaphragm, rust, missing pieces, or coil burn out. Sometimes, manual override does not work, pressure is different, or the armature tube is broken. Valve seats can be upside down or damaged, and missing parts can cause trouble. If your solenoid valves do not work, check for these signs first.

Maintenance Tips

Taking care of solenoid valves helps them last longer. Keep them clean and remove dirt often. Clean inlet filters and flush pipes to stop dirt from blocking the valve. Always look at coils and wires. Loose wires or bad connections can make the valve fail.

Make a schedule for checking valves based on how much you use them and where they are. If you use the system a lot, check more often. Make sure the fluid does not hurt the valve. Some chemicals can cause rust. Test the coil to see if it works. If the coil is weak or broken, change it right away.

Here are some quick tips: clean filters and pipes, check wires, watch for leaks or rust, test the coil, and use the right materials for your fluid.

??? Tip: A good plan for care stops most problems before they start.

Error Prevention

You can stop many problems before they happen by using smart steps. Predictive maintenance uses system data to find trouble early. This helps you fix things before the system stops. Fail-safe systems make sure the valve goes to a safe spot if power goes out. This keeps your system safe.

Advanced control systems help too. These systems look for faults and warn you if something is wrong. You can use these tools to keep solenoid valves working well.

| Strategy | Description |

|---|---|

| Predictive Maintenance | Uses system data to guess when valves might fail, so you can fix them early and make them last longer. |

| Fail-Safe Mechanisms | Makes sure valves go to a safe spot if power fails or the system breaks, so nothing happens by accident. |

| Advanced Control Algorithms | Uses special controls to find problems and keep solenoid valves working safely and reliably. |

?? Note: If you follow these steps, you can stop errors and keep your system safe.

You can find the main differences and similarities between 2-way and 3-way solenoid valves in this table:

| Feature | 2-Way Valves | 3-Way Valves |

|---|---|---|

| Functionality | Simple on-off control | Divert, mix, or separate flow |

| Number of Ports | Two | Three |

| Cost | Cheaper | More expensive because of design |

| Installation & Maintenance | Quick and easy | Needs more skill and extra care |

- If you know these differences, you can choose the best valve for your system.

- Three-way valves let you control flow in more ways, so your setup can work better.

- Picking the right valve helps your fluid system run smoother, especially for harder jobs.

??? Tip: Always pick the valve type that fits your system’s needs to get the best results.

FAQ

What is the main difference between a 2-way and a 3-way solenoid valve?

You control flow with a 2-way valve by turning it on or off. A 3-way valve lets you mix, divert, or switch fluid paths. You get more options with a 3-way valve.

Can you use a 2-way solenoid valve for mixing fluids?

You cannot mix fluids with a 2-way valve. You only start or stop flow. If you want to mix fluids, you need a 3-way valve.

Which industries use 3-way solenoid valves most often?

You see 3-way valves in HVAC, medical devices, food processing, and industrial automation. These industries need to mix or switch fluids quickly.

How do you choose the right solenoid valve for your system?

You should check your fluid type, pressure, flow rate, and control needs. Use a checklist to match your system with the best valve.

?? Tip: Always read the valve’s specifications before you buy.

Do solenoid valves need regular maintenance?

You need to inspect, clean, and test solenoid valves often. Regular care helps you prevent leaks and keeps your system safe.

Can you install a solenoid valve yourself?

You can install a 2-way valve easily. A 3-way valve may need more skill. Always follow the manufacturer’s instructions for safety.

What materials work best for solenoid valves?

You find brass, stainless steel, and plastic in solenoid valves. Pick a material that matches your fluid and environment.

| Material | Best For |

|---|---|

| Brass | Water, air |

| Stainless Steel | Chemicals, high pressure |

| Plastic | Light-duty, low cost |

Why does my solenoid valve make a clicking noise?

You hear clicking when the coil moves the plunger. If the noise gets loud or strange, you should check for dirt or worn parts.