The post What is the difference between PFA valve and ptfe valve material? appeared first on Control Valve Manufacturers?.

]]>

pfa valve and ptfe valve Introduction

Material selection is a critical factor in the design and performance of industrial valves, influencing their durability, efficiency, and suitability for specific applications. Among the most widely used materials in this field are PTFE and PFA, both renowned for their superior chemical resistance and adaptability across diverse industries. PTFE, commonly referred to as Teflon, has become synonymous with reliability in harsh environments. Making it the material of choice for components like PTFE valves and PTFE lined valve systems.

On the other hand, PFA offers a unique blend of properties. Including improved flexibility and resilience against cracking. Which positions it as the ideal option for specialized uses, as seen in PFA lined valve designs. The distinction between a PFA valve and PTFE valve lies in their performance under varying conditions. Such as temperature extremes, chemical exposure, and physical stress. Understanding these differences is vital for engineers and decision-makers who aim to ensure system integrity, minimize maintenance, and reduce operational costs. This article unpacks the key attributes of PTFE and PFA, how they impact valve functionality. And provides guidance on choosing between a PFA valve and PTFE valve for optimal results in industrial fluid control.

Understanding PFA and PTFE Materials

Polytetrafluoroethylene (PTFE) and Perfluoroalkoxy (PFA) are two high-performance fluoropolymers that play critical roles in the design and functionality of industrial valves. PTFE, widely recognized by its trade name Teflon, celebrate for its exceptional chemical resistance, high thermal tolerance, and low friction coefficien. Making it an indispensable material in the production of PTFE valves and PTFE lined valve systems used in industries such as chemical processing and pharmaceuticals.

On the other hand, PFA shares many properties with PTFE but offers enhanced flexibility. Improved crack resistance, and transparency. Which makes it a preferred choice for specialized applications like semiconductor manufacturing and corrosive gas handling. These qualities are particularly evident in PFA lined valve designs. Which are engineered for demanding environments where mechanical stress and chemical exposure are prevalent. While both materials excel in areas such as resistance to extreme temperatures and aggressive chemicals. Their differences make them suitable for distinct industrial scenarios. The versatility and reliability of these materials ensure that selecting between a PFA valve and PTFE valve depends largely on the specific operational requirements. Such as system rigidity, environmental demands, and longevity expectations. By understanding the unique characteristics of PTFE and PFA. Engineers and manufacturers can make informed decisions, ensuring optimal performance, safety, and cost-effectiveness in their fluid control systems.

Key Differences Between PFA Valve and PTFE Valve Materials

While both PFA and PTFE high-performance fluoropolymers know for their exceptional chemical resistance and durability. There are distinct differences between the two that greatly impact their application in industrial valves. PTFE, also commonly referred to as Teflon, renown for its outstanding resistance to extreme temperatures, low friction coefficient. And unmatched stability in chemically aggressive environments. Making it a popular choice for PTFE valves and PTFE lined valve systems used in industries such as chemical processing, oil and gas, and pharmaceuticals.

On the other hand, PFA offers similar chemical resistance but provides added benefits. Such as improved flexibility, superior crack resistance, and the ability to maintain its integrity under mechanical stress. These features make PFA lined valve systems especially well-suited for demanding applications such as semiconductor manufacturing and handling corrosive gases. The key difference lies in the material properties under stress and thermal conditions. While PTFE excels in high thermal resistance and static applications. PFA’s flexibility and structural integrity under dynamic conditions give it an edge in environments requiring resilience against mechanical wear or thermal cycling. Selecting the right solution between a PFA valve and PTFE valve depends on the specific requirements of your operation. Including factors like operating temperature, chemical exposure. And mechanical loads. Understanding these differences allows engineers to optimize system longevity and performance while reducing maintenance costs in a wide range of industrial fluid control applications.

Applications of PFA and PTFE Valves

PFA and PTFE valves are integral components in a variety of industrial applications due to their exceptional chemical resistance and durability. PTFE, widely recognized as Teflon, commonly use in PTFE valves and PTFE lined valve systems for industries like chemical processing, pharmaceuticals, and oil and gas. Its ability to withstand extreme temperatures and resist harsh chemicals makes it indispensable for processes involving highly corrosive or reactive substances. On the other hand, PFA valves and PFA lined valve systems are specifically designed for even more demanding environments. With enhanced flexibility, superior crack resistance. And the ability to maintain structural integrity under dynamic conditions. PFA valves excel in applications such as semiconductor manufacturing, where purity and resilience are paramount.

Both PFA and PTFE are used in environments requiring minimal friction and no contamination. But their distinctions in mechanical strength and thermal performance often dictate their suitability for specific tasks. For example, while a PTFE valve might be ideal for static applications in high-temperature settings, a PFA valve offers advantages in dynamic systems where mechanical stress and thermal cycling occur. Whether discussing PFA valve and PTFE valve requirements for corrosive fluids, gas handling. Or precision-focused industries, the unique properties of these materials allow for safe, efficient, and long-lasting fluid control in critical applications.

Benefits of PFA and PTFE Valves

PFA and PTFE valves offer a wide range of benefits that make them indispensable in industrial fluid control systems. Both materials are renowned for their outstanding chemical resistance. Allowing them to perform reliably even when exposed to highly aggressive or corrosive substances. PTFE, commonly recognized as Teflon, showcases exceptional resistance to extreme temperatures and low friction. Making PTFE valves and PTFE lined valve systems ideal for processes requiring stability and safety in harsh chemical environments.

Similarly, PFA valves and PFA lined valve systems build on these properties while offering additional advantages such as enhanced flexibility, superior crack resistance. And the ability to handle mechanical stress and thermal cycling. These attributes ensure that PFA valve and PTFE valve solutions deliver long-lasting durability and reduced risk of failure under demanding conditions. Their versatility extends across industries including chemical processing, oil and gas, pharmaceuticals, and semiconductor manufacturing. By minimizing wear, reducing maintenance requirements, and sustaining operational reliability in critical systems, PFA and PTFE valves enhance overall efficiency. Additionally, the ability of these valves to prevent contamination makes them an excellent choice for applications where purity is paramount. Whether selecting a PTFE valve for a high-temperature application or a PFA valve for dynamic mechanical loads, the benefits provided by these materials contribute to cost-effectiveness, system longevity, and optimal performance in industrial operations.

Choosing Between a PFA Valve and PTFE Valve

Choosing between a PFA valve and PTFE valve requires a thorough evaluation of your specific operational needs. As both options excel in distinct industrial environments. PTFE, widely recognized as Teflon, is a material of choice for PTFE valves and PTFE lined valve systems due to its unrivaled chemical resistance and ability to withstand extreme temperatures. This makes PTFE an excellent option for static applications and industries that require resilience in chemically aggressive or high-temperature conditions, such as chemical processing, oil and gas, and pharmaceuticals.

On the other hand, a PFA valve or PFA lined valve offers similar chemical compatibility but engineer with enhanced flexibility. Superior crack resistance, and the ability to endure repeated thermal cycling and mechanical stress. These features make PFA valves particularly suitable for dynamic environments, such as those in semiconductor manufacturing and precision fluid systems, where material integrity under stress is critical. When making a decision, factors like chemical exposure, operating temperature, mechanical load, and cost must be carefully weighed. For instance, a PTFE valve might be ideal for processes requiring high thermal resistance without frequent mechanical impact, while a PFA valve stands out in situations where durability under cyclical conditions or purity standards are paramount. By aligning the choice of material with specific industrial requirements, operators can ensure optimal performance, longevity, and cost-efficiency in fluid control systems..

Summary and Recommendations

PFA and PTFE valves, widely recognized for their exceptional chemical resistance and durability. Are critical components in industrial fluid control systems across various sectors. PTFE, commonly referred to as Teflon, exhibits unparalleled resistance to aggressive chemicals and extreme temperatures.Making PTFE valves and PTFE lined valve solutions ideal for static applications in harsh environments such as chemical processing, oil and gas, and pharmaceuticals. PFA valves and PFA lined valve systems, while offering similar chemical resilience. Provide additional benefits like enhanced flexibility, superior crack resistance, and the ability to withstand mechanical stress and thermal cycling.

These qualities make PFA valves a preferred choice for dynamic applications, such as those found in semiconductor manufacturing or systems requiring high material purity. When selecting between a PFA valve and PTFE valve, factors like operating temperature, chemical compatibility, exposure to mechanical stresses, and long-term cost considerations should guide the decision. A PTFE valve may be the best option for high-temperature static systems. While a PFA valve highly recommend for environments involving repetitive mechanical loads or stringent purity standards. Understanding these properties and differences ensures that operators can achieve optimal performance, system longevity, and cost-effectiveness, while addressing the specific demands of their industrial processes.

FAQ

Q1. What is the warranty period for your pfa valve?

Pfa valve come with a standard warranty period of 12 months (1 years) from the date of delivery. This warranty covers manufacturing defects and materials under normal operating conditions as specified in the product manual.

Q2. How are? Pfa valve prices determined?

Prices for Pfa valve is influenced by several factors. Including the valve’s size, material composition (e.g., stainless steel, brass, or PVC), pressure ratings, end connection types. And any additional customisation or certifications required. Specialised features such as fire-safe designs or anti-static devices can also impact the cost.

Q3. What is the standard delivery time for a Pfa valve?

Our standard delivery time for Pfa valve is 4–6 weeks, depending on the order size and customisation requirements. For urgent requests, we offer expedited delivery options upon request.

Our logistics partners ensure fast and reliable delivery to meet engineering project timelines, regardless of location.

Q4. Common Applications of? Pfa?valve

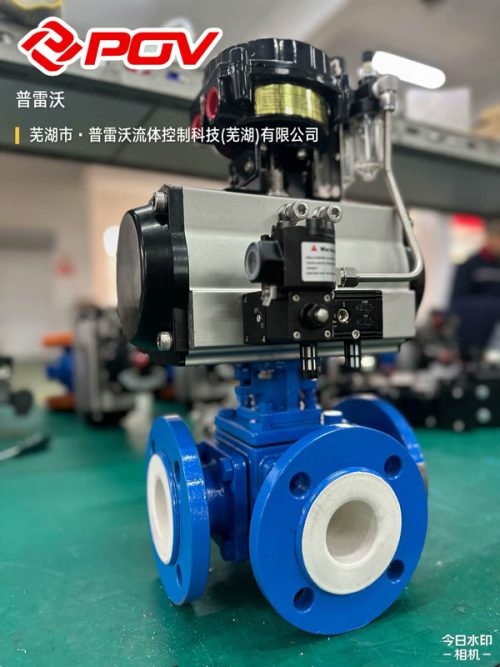

Pfa valve a versatile valve type design with three/two ports for fluid flow. These ports can be configured to allow various functions. Such as mixing, diverting, or completely shutting off flow.

pfa valve and ptfe valve Conclusion

PFA and PTFE materials each excel in distinct applications, making the choice between a PFA valve and PTFE valve highly dependent on operational requirements. PTFE, commonly recognized as Teflon, offers outstanding chemical resistance and remarkable thermal stability. Making PTFE valves and PTFE lined valve systems ideal for static environments exposed to extreme temperatures and aggressive chemicals. This makes them a reliable option for industries such as chemical processing, oil and gas, and pharmaceuticals.

On the other hand, PFA valves and PFA lined valve systems combine similar chemical resistance with superior mechanical flexibility, crack resistance, and the ability to endure thermal cycling. These features make PFA particularly well-suited for dynamic applications like semiconductor manufacturing or systems requiring high purity standards. Ultimately, while PTFE provides resilience in harsh, static conditions, PFA better handles dynamic stresses and repeated thermal variations. Carefully considering factors like chemical compatibility, temperature, mechanical load, and purity needs will help operators choose the most effective solution. Whether it’s a Teflon-based PTFE valve or a PFA valve for more demanding mechanical conditions, these materials ensure efficiency, durability, and cost-effectiveness in diverse industrial applications.

The post What is the difference between PFA valve and ptfe valve material? appeared first on Control Valve Manufacturers?.

]]>The post What is PTFE lined butterfly valve? appeared first on Control Valve Manufacturers?.

]]>The article explores the unique components and features of PTFE lined butterfly valves. Comparing them to alternatives like PFA and PTFE valves, as well as FEP lined ball valves. It also highlights the benefits of using PTFE lining. Including reduced maintenance needs, extended lifespan, and resistance to high temperatures and caustic materials.

Introduction

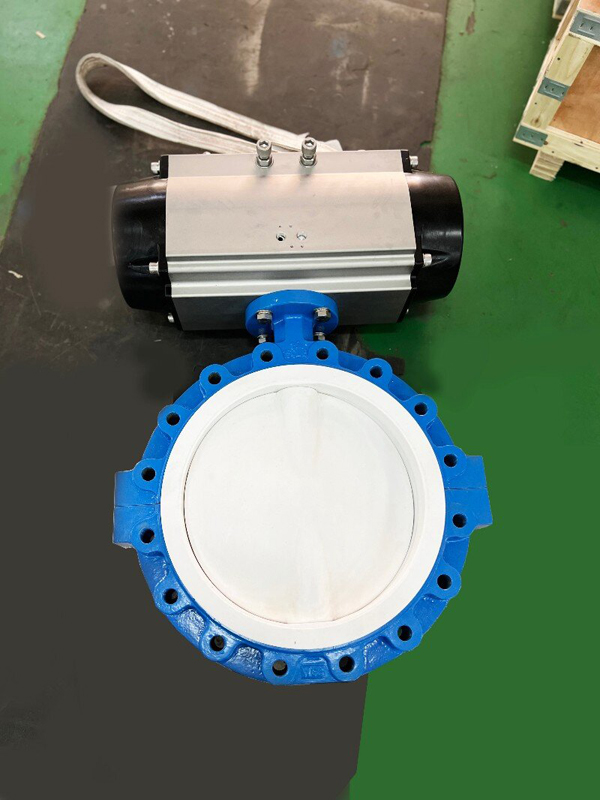

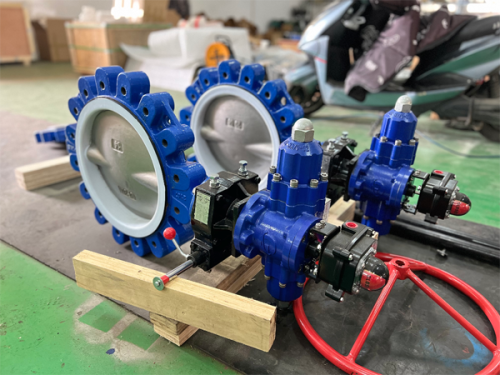

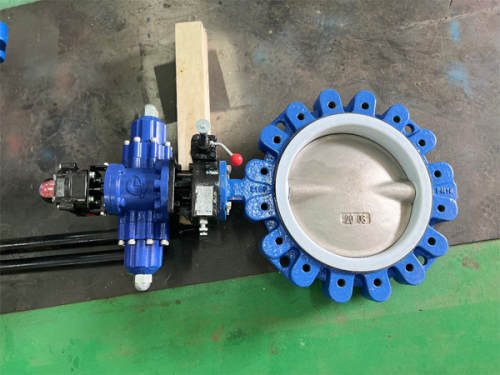

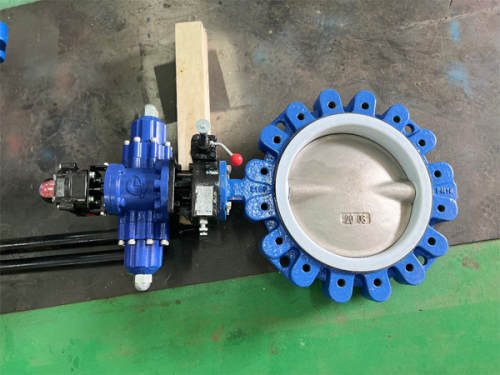

A PTFE lined butterfly valve is a high-performance valve engineered for demanding industrial tasks that require superior chemical resistance and durability. Designed to improve upon traditional butterfly valves. These valves are lined with PTFE, a material renowned for its ability to withstand corrosive chemicals and extreme conditions. Industries such as chemical processing, pharmaceuticals, and food production often rely on PTFE lined butterfly valves to ensure consistent and safe operation in aggressive environments. They stand out due to their efficiency and reliability, offering advantages like reduced maintenance costs and extended lifespan.

When compared to other options, such as PFA valve and PTFE valve configurations or even fep lined ball valve systems. PTFE butterfly valves excel in delivering robust and versatile solutions. With their advanced butterfly valve lining and high compatibility across various applications. These lined butterfly valve models remain a top choice for professionals seeking optimal performance and operational integrity.

What is a PTFE Lined Butterfly Valve?

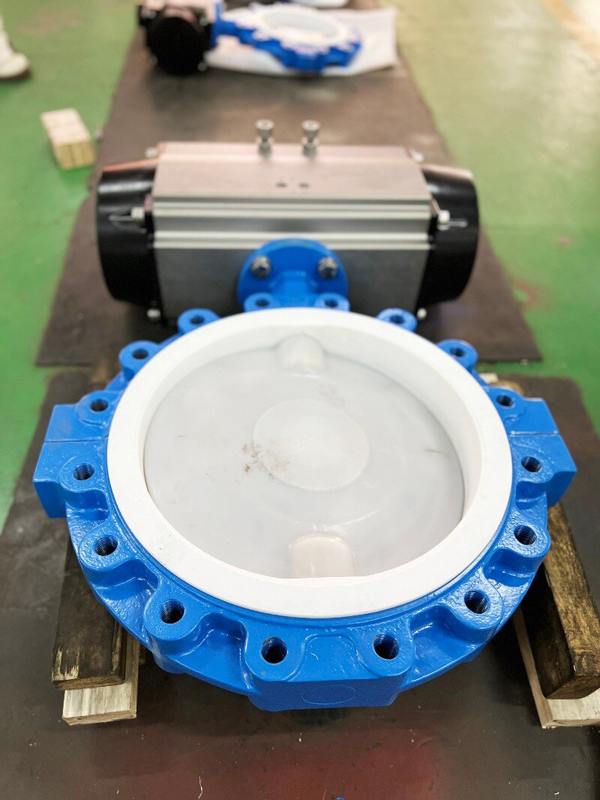

A PTFE lined butterfly valve is a specialized type of valve designed for precision control and reliability in complex industrial settings. Unlike standard valves, a PTFE lined butterfly valve incorporates a lining made from polytetrafluoroethylene (PTFE), a highly resilient material known for its outstanding chemical resistance and ability to endure abrasive and corrosive environments. This design ensures smooth operation and extended durability. Even under high temperatures or with corrosive media.

Commonly compared to other configurations like a PFA valve and PTFE valve or even the fep lined ball valve. PTFE lined butterfly valves are favored for their lightweight architecture, efficient flow regulation, and ease of maintenance. The butterfly valve lining provides an additional layer of protection. Making these valves particularly suitable for industries such as chemical processing, food and beverage production, and pharmaceutical manufacturing. These lined butterfly valves not only minimize the risk of contamination or system failure but also deliver cost-effective solutions with enhanced operational lifespan and energy efficiency. Cementing their role as an indispensable choice in demanding applications.

Components and Features of PTFE Lined Butterfly Valves

A PTFE lined butterfly valve incorporates advanced components and materials designed to deliver exceptional performance in harsh industrial environments. At its core, the valve consists of a disc that regulates flow, a valve body, and a resilient PTFE lining that provides superior chemical resistance and prevents wear caused by corrosive or abrasive media. The lining acts as a protective barrier, ensuring smooth operation even under extreme pressures and temperatures. The valve’s stem and seal engineer for reliability. Reducing the risk of leakage and enhancing operational efficiency.

When compared to alternatives like a PFA valve and PTFE valve or even an fep lined ball valve. The PTFE lined butterfly valve stands out for its compact design, lightweight construction, and ease of installation. The butterfly valve lining provides superior durability, making the valve suitable for industries such as chemical processing, pharmaceuticals, and water treatment. Additionally, these lined butterfly valves are known for their low maintenance requirements and long service life,. Ensuring cost savings for operators while delivering reliable and consistent performance across a wide range of applications.

Applications and Benefits of PTFE Lined Butterfly Valves

PTFE lined butterfly valves are indispensable across a wide range of industries that require reliable and efficient fluid control in challenging conditions. These valves are particularly vital in sectors like chemical processing, pharmaceuticals, food and beverage production, and water treatment. Where the ability to handle corrosive or abrasive media is essential. The PTFE lining acts as a shield, protecting the valve components from deterioration and ensuring long-term operational longevity. When compared to other options, such as PFA valve and PTFE valve designs or even the fep lined ball valve. PTFE lined butterfly valves excel due to their lightweight structure, compact design. And superior resistance to chemical attacks. The butterfly valve lining not only minimizes wear and tear but also contributes to leak-free performance. Making these valves highly dependable.

Additionally, their easy maintenance and extended life cycle reduce overall operating costs. Making them a cost-effective choice for facilities requiring high performance and durability. These lined butterfly valves are also known for their versatility, seamlessly integrating with various systems to maintain process efficiency and safety, even under the most demanding conditions.

Comparisons with Other Valve Types

When comparing the PTFE lined butterfly valve to other valve types. Such as the PFA valve and PTFE valve or the fep lined ball valve, distinct advantages in design, functionality, and application become evident. The PTFE lined butterfly valve characterize by its compact size and lightweight construction. Which makes it a versatile choice for installations where space is limited or weight constraints are critical. This sets it apart from the fep lined ball valve, which, while robust, is bulkier and often less efficient for quick shut-off applications. The butterfly valve lining in PTFE lined models offers unmatched resistance to corrosive chemicals and abrasive materials. Providing a longer operational life even in extreme environments. Unlike some PFA valve and PTFE valve options that may wear out faster under similar conditions.

Additionally, the simple yet effective design of the lined butterfly valve enables smooth flow control. Reducing pressure drops and improving overall efficiency compared to other valve types. This makes the PTFE lined butterfly valve particularly advantageous in industries like chemical processing and water treatment. Where consistent performance and low maintenance are crucial. By offering higher durability, ease of operation, and superior chemical resistance. The PTFE lined butterfly valve stands out as a cost-effective and reliable solution for demanding industrial applications.

How to Choose the Right PTFE Lined Butterfly Valve

Choosing the right PTFE lined butterfly valve requires a thorough understanding of your application’s specific needs and operating requirements. Start by evaluating the chemical compatibility of the valve with the media it will handle,. As this ensures the PTFE lining provides maximum protection against corrosion and wear. Consider the pressure and temperature ratings of the valve to ensure it can withstand the operating conditions without compromising performance or structural integrity.

Additionally, assess the differences between a PTFE lined butterfly valve, PFA valve and PTFE valve. And an fep lined ball valve, as each offers distinct advantages. For instance, PTFE lined butterfly valves are lightweight and compact, making them ideal for systems with space and weight constraints,. While fep lined ball valves may be better suited for applications requiring higher pressure tolerances. Pay close attention to the butterfly valve lining, as its durability directly impacts longevity and reliability in demanding environments.

Lastly, factor in maintenance needs and ease of installation to optimize long-term operational efficiency and cost-effectiveness. Selecting the correct lined butterfly valve not only enhances system performance but also ensures safety and reduced downtime in industrial processes.

Maintenance and Longevity of PTFE Lined Butterfly Valves

Proper maintenance is key to ensuring the longevity and optimal performance of PTFE lined butterfly valves across a variety of industrial applications. The PTFE lining, known for its exceptional resistance to chemicals and wear, significantly reduces the likelihood of corrosion. Extending the lifespan of the valve components even under harsh operating conditions. Regular inspections to detect wear on the butterfly valve lining. As well as prompt replacement of seals and gaskets, help maintain leak-free operation and prevent system failures. When compared to alternatives like PFA valve and PTFE valve designs or fep lined ball valves. PTFE lined butterfly valves often require less intensive maintenance due to their fewer moving parts and straightforward construction. This simplicity translates into fewer opportunities for mechanical failure.

Additionally, their lightweight and compact design streamline servicing, minimizing downtime during repairs. Using high-quality PTFE lined butterfly valves and adhering to proper maintenance practices. Such as routinely cleaning and lubricating moving components, ensures consistent performance, reduced operational costs, and extended service life. These factors make lined butterfly valves a reliable and efficient choice for industries demanding durable and low-maintenance fluid control solutions.

FAQ

What is a PTFE-lined butterfly valve?

A PTFE-lined butterfly valve is a type of butterfly valve where the internal surface, including the disc and the body, is coated with PTFE (Polytetrafluoroethylene). This lining provides exceptional chemical resistance and low friction, making the valve ideal for handling corrosive or abrasive media.

What are the main features of PTFE-lined butterfly valves?

PTFE-lined butterfly valves feature a robust design with a corrosion-resistant PTFE coating, ensuring reliable performance in challenging environments. They offer smooth operation due to PTFE’s low friction properties, excellent sealing capabilities, and compatibility with a wide range of chemicals.

What are the benefits of using PTFE-lined butterfly valves?

These valves provide superior resistance to harsh chemicals, high thermal stability, and a long service life. They minimize wear and tear, reduce the risk of leaks, and require low maintenance. PTFE’s non-stick property also helps prevent media buildup, ensuring smooth flow and reducing downtime.

What industries commonly use PTFE-lined butterfly valves?

PTFE-lined butterfly valves are a favored choice in industries such as chemical processing, wastewater treatment, food and beverage, pharmaceuticals, and power generation. They are particularly effective when dealing with corrosive fluids, slurries, or media with suspended particles.

Conclusion

A PTFE lined butterfly valve is a highly reliable and efficient solution for managing fluid flow in demanding industrial environments. Featuring a durable butterfly valve lining made from PTFE, these valves offer exceptional resistance to corrosive chemicals, high temperatures, and abrasive materials. Ensuring longevity even under extreme conditions. Unlike other options, such as PFA valve and PTFE valve designs or an fep lined ball valve, PTFE lined butterfly valves stand out for their lightweight, compact design, and simplified functionality. These characteristics make them ideal for installations where space, weight, and maintenance accessibility are critical factors. Lined butterfly valves? commonly use in industries like chemical processing, pharmaceuticals, water treatment, and food production.

Where maintaining system integrity and ensuring safety are paramount. Their easy operation, low maintenance needs, and compatibility with aggressive chemicals make them a cost-effective choice. By combining resilience, operational efficiency, and versatility, PTFE lined butterfly valves have become an essential component in modern industrial fluid control systems. Whether for precise flow regulation, reliable isolation. Or consistent performance under harsh conditions, these valves deliver the durability and quality necessary for optimal system performance.

The post What is PTFE lined butterfly valve? appeared first on Control Valve Manufacturers?.

]]>The post What is PFA lined valves? appeared first on Control Valve Manufacturers?.

]]>Industries such as chemical processing, pharmaceuticals, oil & gas, and water treatment heavily rely on pfa lined valve systems for their durability and ability to maintain operational integrity under extreme conditions. Whether used in a lined ball valve configuration or for specialized tasks involving reactive chemicals. PFA-lined solutions meet stringent safety and efficiency requirements, underscoring their critical role in modern industrial operations.

Introduction

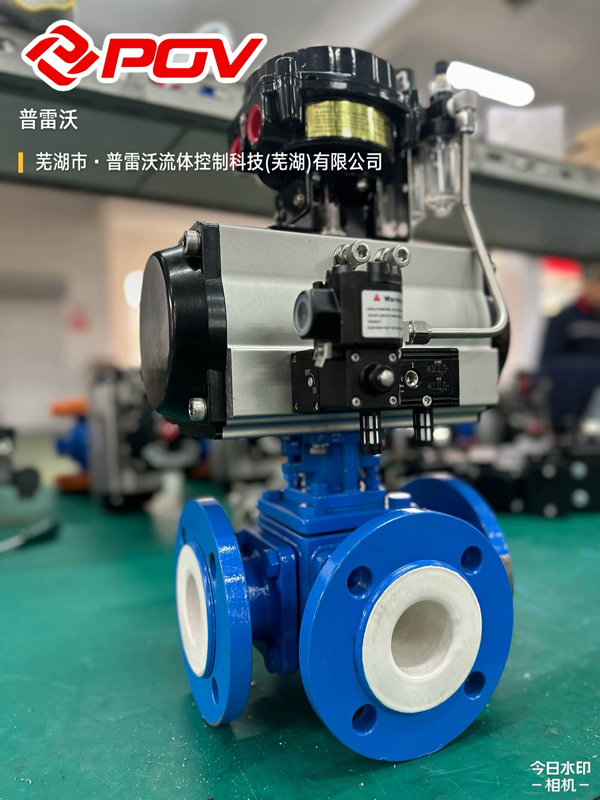

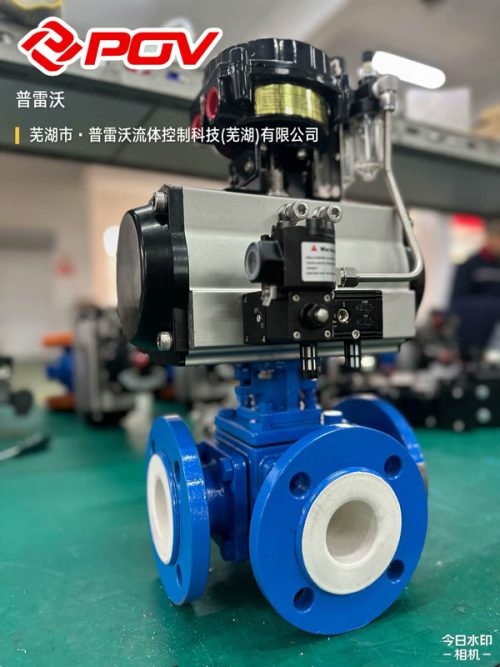

PFA lined valves are an advanced solution for industries requiring robust and reliable equipment to handle corrosive and high-purity substances. Featuring a Perfluoroalkoxy (PFA) polymer lining, these valves stand out for their exceptional chemical resistance, stress crack tolerance. And ability to perform under extreme temperatures and pressures. A pfa lined valve is frequently compared to other solutions such as ptfe lined valve, lined ball valve, fep lined ball valve, and teflon valve. But it offers unique advantages in terms of flexibility and durability. These attributes make PFA lined valves indispensable in industries like chemical processing, pharmaceuticals, water treatment, and oil & gas. Where operational integrity and safety are paramount. Whether utilized in a ball valve design to control fluid flow or incorporated into systems requiring high-purity standards. PFA lined valves deliver unmatched performance, meeting the critical demands of modern industrial applications efficiently and reliably.

What are PFA Lined Valves?

PFA lined valves, short for Perfluoroalkoxy polymer lined valves, are high-performance components crafted to handle corrosive liquids, gases. And high-purity mediums in demanding industrial environments. A pfa lined valve features a protective inner lining made of PFA, a fluoropolymer known for its exceptional chemical resistance, high-temperature tolerance, and flexibility. This makes it particularly effective for applications involving aggressive acids, alkalis, and solvents. When compared to a ptfe lined valve, PFA offers improved stress crack resistance and superior reliability in extreme conditions. Making it a preferred choice for long-term use.

Similarly, while other options like lined ball valve, fep lined ball valve, and teflon valve provide corrosion resistance. PFA stands out due to its enhanced durability and ability to maintain consistency in both high-pressure and high-temperature environments. Industries such as chemical processing, pharmaceuticals, oil & gas. And water treatment heavily rely on PFA lined valves for their ability to safeguard operations from contamination and material degradation. Whether in a ball valve configuration for precise flow regulation or as part of a larger system. PFA lined valves offer unmatched efficiency, ensuring both safety and operational excellence across various applications.

Benefits of PFA Lined Valves

PFA lined valves offer a range of advantages that make them indispensable in industries dealing with corrosive or high-purity substances. A pfa lined valve features a robust Perfluoroalkoxy polymer lining, which provides exceptional resistance to a wide variety of aggressive chemicals. Including strong acids, bases, and solvents. This superior chemical resistance ensures long-term durability and minimizes the risk of material degradation. Even in extreme operating conditions. Compared to alternatives like the ptfe lined valve, lined ball valve, fep lined ball valve, and teflon valve. PFA lined valves stand out for their enhanced flexibility, stress crack resistance, and consistent performance under high temperatures and pressures.

Their versatility also makes them ideal for various critical applications in industries such as chemical processing, pharmaceuticals, and water treatment. PFA lined valves are suitable for precise flow regulation in lined ball valve configurations while ensuring maximum operational safety and efficiency. Their ability to maintain structural integrity and resist contamination makes them a trusted solution for environments where reliable performance is paramount.

Applications of PFA Lined Valves

PFA lined valves are indispensable in a wide range of industries that require superior resistance to corrosive substances, high temperatures, and stringent purity standards. A pfa lined valve commonly use in chemical processing plants, where it safely handles aggressive acids, bases. And volatile organic compounds without degrading.

Similarly, these valves play a critical role in the pharmaceutical sector. Where maintaining contamination-free environments is essential. Their applications extend to water treatment systems. Ensuring the efficient regulation of fluid flow in processes that involve harsh chemicals. Compared to other solutions like the ptfe lined valve, lined ball valve, fep lined ball valve, and teflon valve. PFA lined valves deliver higher reliability and flexibility under extreme conditions.

For example, in lined ball valve configurations, these valves provide precise control in operations involving high pressures and reactive chemicals. Additionally, their durability and chemical resistance make them ideal for handling substances in industries such as oil & gas, food processing, and semiconductor manufacturing. Whether used in high-purity applications or in systems requiring robust corrosion resistance. PFA lined valves consistently meet the diverse demands of modern industrial environments.

Industries that Rely on Lined Valves

Industries across the globe depend on the superior performance of pfa lined valves to handle demanding operational requirements while ensuring safety and efficiency. The chemical processing industry heavily relies on these valves to manage corrosive acids, alkalis, and reactive chemicals. As their PFA lining provides exceptional resistance to chemical attack and degradation. Similarly, the pharmaceutical sector uses pfa lined valves to maintain sterile and contamination-free environments critical for producing high-purity medications. Water treatment facilities also benefit from these valves in applications where aggressive disinfectants and chemicals are involved. Guaranteeing long-term reliability and durability.

Additionally, industries like oil & gas and food processing turn to lined ball valve configurations with PFA lining for their ability to withstand harsh environments. Ensuring precise flow control and operational stability. While alternatives such as ptfe lined valves, fep lined ball valves, and teflon valves offer notable chemical resistance. PFA excels in providing superior flexibility, stress crack resistance, and consistent performance in extreme conditions. Whether managing volatile compounds or high-temperature processes. PFA lined valves are a trusted solution for industries where operational integrity and safety are non-negotiable.

Comparison of PFA Lined Valves with Other Lined Valves

When comparing a pfa lined valve to other lined valve options like ptfe lined valve, fep lined ball valve, and teflon valve, it becomes evident that each material offers unique benefits tailored to specific industrial needs. PFA (Perfluoroalkoxy polymer) lined valves excel in chemical resistance, stress crack resistance, and durability. Making them an ideal choice for managing highly corrosive and reactive substances under extreme temperatures and pressures. Unlike ptfe lined valves. Which are also chemically resistant but less flexible, PFA’s polymer structure provides enhanced mechanical strength and better performance in dynamic environments.

Similarly, while fep lined ball valves share some high-purity and chemical resistance properties with PFA, they tend to have lower thermal stability and flexibility, limiting their use in more extreme conditions. The term teflon valves often refers to those lined with PTFE or similar fluoropolymers. But they can lack the same robustness and stress crack resistance that PFA offers. Especially in high-temperature or high-pressure applications. Furthermore, lined ball valves with PFA linings ensure precise and safe fluid control in aggressive chemical processing, water treatment, or pharmaceutical pipelines. Although all these materials demonstrate outstanding chemical resistance. PFA stands out as a versatile and high-performance lining solution for industries demanding ultimate reliability without compromising on safety or efficiency.

Selection Criteria for PFA Lined Valves

Selecting the right valve for industrial processes often involves a detailed comparison of criteria. Particularly when evaluating a pfa lined valve against alternatives like ptfe lined valve, fep lined ball valve, and teflon valve variants. One critical factor is chemical compatibility; PFA lining delivers exceptional resistance to a wide range of aggressive chemicals. Surpassing PTFE and FEP linings in handling more reactive substances over extended periods. Temperature resistance is another key consideration. With PFA’s ability to maintain integrity at higher temperatures, it is a preferred choice for environments that demand thermal stability, whereas ptfe lined valves and fep lined ball valves may? more limit in extremely high-heat scenarios.

Mechanical strength also sets PFA apart, as its superior flexibility and stress crack resistance allow it to endure dynamic operating conditions and prolonged use without compromising valve functionality. Cost-effectiveness can vary depending on the application. But the durability and long service life of PFA lined valves often provide better value in industries requiring long-term, reliable solutions.

Additionally, when choosing a lined ball valve, PFA linings ensure precise flow control even in highly corrosive or high-purity systems. While coverings like FEP or generic teflon valves may not match PFA’s performance under extreme demands. Therefore, the selection process hinges on balancing these factors to align with the specific operational requirements of applications in industries such as chemical processing, water treatment, and pharmaceuticals.

Maintenance and Longevity of PFA Lined Valves

When choosing a pfa lined valve, several critical selection criteria set it apart from other options like ptfe lined valve, fep lined ball valve, and teflon valve configurations. Chemical compatibility is often a primary factor. With PFA linings excelling in resistance to highly aggressive chemicals. Including strong acids and alkalis, outperforming PTFE and FEP linings in many applications. Temperature resistance also plays a pivotal role. As PFA can withstand higher thermal ranges without losing structural integrity. Making it ideal for processes involving elevated operational temperatures.

Meanwhile, ptfe lined valves and fep lined ball valves may exhibit limitations under extreme heat. Mechanical strength is another area where PFA stands out, offering excellent flexibility and superior resistance to stress cracks. Even in dynamic and demanding systems. This durability ensures long-term reliability under harsh operating conditions. Which some generic teflon valve options cannot consistently provide. Cost-effectiveness is equally important; while PFA lined valves may involve a higher initial investment. Their extended service life and reduced maintenance requirements often translate to lower total lifecycle costs. For industries requiring precise flow control, such as chemical processing, pharmaceuticals, and water treatment, lined ball valves with PFA offer unparalleled performance, delivering both safety and efficiency. By weighing these factors, businesses can identify the most suitable valve option to meet their specific operational needs.

FAQ

What does PFA stand for in valves?

PFA stands for Perfluoroalkoxy Alkane. It is a fluoropolymer known for its chemical resistance, non-stick properties, and high thermal stability, making it an excellent lining material for industrial valves.

What are PFA-lined valves?

PFA valves are industrial valves with an internal coating or lining of PFA. This lining provides exceptional resistance to corrosive chemicals and extreme temperatures, protecting the valve body and ensuring reliable performance in harsh environments.

What are the benefits of PFA-lined valves?

PFA-lined valves offer superior corrosion resistance, making them suitable for aggressive chemicals like acids, alkalis, and solvents. They also withstand high temperatures and provide a smooth, non-stick surface that minimizes wear and buildup, extending the valve’s service life.

What industries use PFA-lined valves?

PFA-lined valves are widely used in industries such as chemical processing, petrochemicals, pharmaceuticals, food and beverage, and power generation. They are particularly effective in applications involving highly corrosive or hazardous substances.

How do PFA-lined valves compare to PTFE-lined valves?

While both PFA and PTFE offer exceptional chemical resistance and thermal stability, PFA is more flexible and has a smoother surface finish. This makes PFA-lined valves more resistant to cracking and easier to clean, making them the preferred choice in applications requiring higher durability and hygiene.

Conclusion

PFA lined valves are a critical solution for industries requiring superior chemical resistance, durability, and high-performance flow control. Engineered with Perfluoroalkoxy (PFA) lining, these valves excel in handling highly corrosive substances, extreme temperatures, and demanding operating conditions. When compared to options like the ptfe ball valve, ptfe lined valve, fep lined ball valve, and teflon valve, PFA lined valves often stand out due to their enhanced stress crack resistance, mechanical strength, and thermal stability. These qualities make them ideal for aggressive chemical processing, water treatment, and high-purity pharmaceutical applications.

A lined ball valve with PFA lining ensures precise, reliable fluid control even in the harshest environments, outperforming other lined materials in long-term durability and safety. While PTFE and FEP valves also offer excellent chemical resistance, they may fall short in handling higher thermal ranges or dynamic stress scenarios where PFA demonstrates superior flexibility and longevity. Similarly, while Teflon valves are highly effective in standard applications, they may not consistently deliver the same robustness as PFA under extreme conditions. Overall, PFA lined valves offer a versatile, high-performance solution, ensuring operational reliability and safety across a wide range of demanding industries.

The post What is PFA lined valves? appeared first on Control Valve Manufacturers?.

]]>The post What is the full form of PTFE in ball valve? appeared first on Control Valve Manufacturers?.

]]>PTFE plays a critical role in enhancing the performance of PTFE lined valves and lined ball valves. Offering exceptional durability and efficiency. The post also highlights the differences between FEP lined ball valves and PTFE-lined alternatives. Including specific industry applications like chemical processing, pharmaceuticals, and oil & gas.

Introduction

Polytetrafluoroethylene, better known as PTFE, has become a groundbreaking material in the valve manufacturing industry. Especially in the design of the highly efficient PTFE ball valve. Renowned for its exceptional chemical resistance, low friction properties, and adaptability to a wide range of temperatures. PTFE has set a high standard for durability and performance across various industries. When incorporated into the design of PTFE lined valves and lined ball valves. This unique polymer ensures reliable operation even under harsh conditions. Such as exposure to corrosive chemicals or high-pressure environments.

Additionally, advancements in technology have led to the development of FEP lined ball valves. Offering similar efficiency with slight variations in application suitability. Often referred to by its trademark name, Teflon valve. PTFE has earned its reputation as a benchmark material for improving the safety, longevity. And functionality of ball valves across sectors like chemical processing, pharmaceuticals, and oil & gas. This article unpacks the full form of PTFE and explores its pivotal role in revolutionizing valve manufacturing.

What is PTFE?

Polytetrafluoroethylene, commonly abbreviated as PTFE, is a high-performance polymer known for its exceptional chemical resistance, non-reactive nature, and low friction properties. Structurally, PTFE is composed of carbon and fluorine atoms, forming a material that can withstand extreme temperatures and corrosive substances. Making it indispensable in various industrial applications. A key innovation in the valve industry, PTFE is integral to the design of the PTFE ball valve. Where its properties enhance sealing performance and reduce wear and tear.

Similarly, PTFE lined valves and lined ball valves leverage this material for superior durability, reliability. And longevity in handling aggressive chemicals or high-pressure operations. Beyond PTFE-lined options, related systems like FEP lined ball valves. Which use Fluorinated Ethylene Propylene, provide alternatives for specific applications while maintaining similar chemical resistance. Often referred to as Teflon valves due to Teflon being the trademark name for PTFE. These valves underscore the material’s industry-wide importance in ensuring safety, efficiency. And performance in demanding environments like pharmaceuticals, oil & gas, and chemical processing. The versatility and reliability of PTFE make it a central component in modern valve technology.

PTFE in Ball Valves

Polytetrafluoroethylene (PTFE) has transformed the performance and functionality of ball valves. Establishing itself as a critical material in the valve manufacturing industry. Its integration into the design of the PTFE ball valve has paved the way for valves that deliver unmatched chemical resistance, low friction, and exceptional reliability. PTFE lined valves and lined ball valves, engineered with a PTFE lining, are ideal for handling aggressive chemicals, abrasive materials, and high-pressure systems. Ensuring durability even in the harshest environments.

Further innovations, such as FEP lined ball valves, offer alternatives tailored to specific industrial needs while maintaining the same exceptional standards for efficiency and safety. Often referred to as Teflon valves, due to the widespread recognition of Teflon as a trade name for PTFE. These valves have become indispensable across sectors like pharmaceuticals, oil & gas, and chemical processing. By minimizing wear and tear, enhancing sealing efficiency, and extending operational lifespans. PTFE has revolutionized ball valve technology, providing industries with solutions that prioritize performance and long-term reliability.

Applications and Industries

PTFE lined valves, including ptfe ball valve, ptfe lined valve, and lined ball valve, are integral to a wide range of industries due to their exceptional chemical resistance and durability. One of their primary applications is in chemical processing. Where they handle aggressive acids, caustics, and reactive chemicals without degrading. Pharmaceuticals also rely on these valves for sterile and contamination-free processes, as PTFE’s non-stick properties ensure clean handling of sensitive media.

In the oil & gas sector, teflon valve solutions are trusted for their ability to endure harsh environments involving high pressures, temperatures, and corrosive substances. Water treatment facilities use fep lined ball valves and PTFE variants to manage highly corrosive cleaning agents and maintain the integrity of potable water systems. Additionally, PTFE’s low friction coefficient and high temperature resistance make these valves suitable for applications in power generation and food processing. Where performance consistency is critical. By offering reliable sealing, longevity, and versatility. PTFE lined valves have become indispensable across these industries, meeting strict safety and efficiency requirements with unmatched precision.

Differences Between PTFE Lined Valves and Other Lined Valves

PTFE lined valves stand out in the industry due to their exceptional chemical resistance, low friction, and ability to withstand extreme temperatures. Making them a preferred choice for handling aggressive or corrosive media in critical operations. Compared to other lined valves, such as FEP lined ball valves. PTFE lined valves demonstrate higher thermal stability. Making them suitable for environments with fluctuating or higher operating temperatures. While both provide excellent chemical resistance, FEP, or Fluorinated Ethylene Propylene, offers better flexibility and clarity. Which may be advantageous in specific applications where mechanical stress or visibility is a concern.A PTFE ball valve or Teflon valve, thanks to its broad compatibility. Also exhibits a longer service life in demanding conditions like chemical processing or pharmaceuticals.

On the other hand, general lined ball valves, which may feature different polymeric linings. Often tailor for less extreme applications, offering cost-efficiency for certain industries without heavily compromising performance. The choice between a PTFE lined valve, FEP lined ball valve. Or other alternatives largely depends on the requirements for temperature tolerance, media compatibility, and mechanical performance. With PTFE remaining a benchmark for durability and reliability in industrial valve technology.

Why Choose PTFE for Valve Linings?

Polytetrafluoroethylene (PTFE) has earned its position as the go-to material for valve linings due to its unparalleled chemical resistance, durability. And versatility in handling extreme operating conditions. This high-performance polymer, famously used in the PTFE ball valve, excels in resisting corrosive chemicals. Ensuring reliability in even the most aggressive environments. Its inclusion in PTFE lined valves and lined ball valves allows for smooth operation with minimal friction. Reducing wear and extending the lifespan of the equipment.

Compared to other materials, such as those used in FEP lined ball valves. PTFE offers superior thermal stability and performance at higher operating temperatures. Making it an ideal choice for industries like chemical processing, pharmaceuticals, and oil & gas. Often referred to as a Teflon valve due to PTFE’s trademark name. Its non-reactive and non-stick properties further enhance its utility in preventing material buildup, ensuring consistent functionality over time. Whether for handling harsh acids, solvents, or high-pressure systems, PTFE remains the material of choice for applications that prioritize safety, efficiency, and long-term value. Making it an indispensable material in modern valve technology.

Common Misconceptions About Teflon Valves

One common misconception about Teflon valves, widely recognized as valves incorporating PTFE (Polytetrafluoroethylene). Is that they are fragile or unsuitable for rigorous industrial applications. This misunderstanding likely arises from the perception of Teflon being a softer polymer. But in reality, PTFE’s unique properties provide unmatched durability for challenging environments. Valves such as the PTFE ball valve, PTFE lined valve, and lined ball valve are engineered to handle extreme conditions. Including highly corrosive chemicals and elevated temperatures, without compromising performance.

Another myth is that Teflon-lined valves are limited to niche uses. But their versatility spans industries like chemical processing, oil & gas, and pharmaceuticals. Where reliability in harsh conditions is a must. Concerns about leakage or degraded performance are also unfounded. As manufacturers extensively test PTFE linings for exceptional sealing efficiency and long-term stability. For applications requiring even greater material flexibility or transparency. Innovations like FEP lined ball valves provide alternatives without diminishing key benefits. Clarifying these inaccuracies demonstrates that Teflon valves excel in both durability and versatility. Proving themselves as indispensable components in modern valve technolog

Considerations When Selecting a PTFE Lined Valve

When selecting a PTFE lined valve, careful consideration of application-specific requirements is crucial to ensure optimal performance and reliability. Key factors include chemical compatibility, as PTFE offers exceptional resistance to aggressive chemicals. Making it ideal for environments dealing with highly corrosive or reactive substances. Temperature range is another significant aspect; PTFE lining, used in products like the ptfe ball valve or teflon valve. Withstands a wide range of operating temperatures, surpassing many alternative materials like FEP. That said, for applications requiring greater mechanical flexibility or transparency. Options like FEP lined ball valves may be more suitable. Pressure requirements should also be evaluated, as the robust lining in PTFE valves enhances durability under high-pressure conditions. Particularly vital in industries like oil & gas or chemical processing.

Other considerations include abrasion resistance, sealing efficiency, and maintenance demands. All of which impact the valve’s long-term performance. Beyond the technical specifications, the versatility of a lined ball valve. Whether PTFE lined or otherwise, makes it a preferred choice across diverse sectors. Including pharmaceuticals and water treatment. Balancing these elements ensures the chosen PTFE lined valve delivers unmatched efficiency, safety, and value in its intended application.

FAQ

What does PTFE stand for in ball valves?

PTFE stands for Polytetrafluoroethylene, a high-performance polymer known for its exceptional non-stick properties, chemical resistance, and durability.

What role does PTFE play in ball valves?

PTFE is commonly used as the material for seats and seals in ball valves. Its low friction coefficient ensures smooth operation of the valve, while its excellent sealing capabilities prevent leaks even under high-pressure conditions.

Why is PTFE widely used in ball valve applications?

PTFE is highly resistant to chemicals, extreme temperatures, and corrosion, making it ideal for applications where the flow media might be aggressive or abrasive. Its durability reduces wear and ensures reliable, long-term performance in demanding environments.

What are the key benefits of PTFE in ball valves?

Key benefits of PTFE include low maintenance, extended service life, resistance to nearly all chemicals, and excellent thermal stability. These properties make it a preferred choice for industries such as chemical processing, pharmaceuticals, food and beverage, and petrochemicals.

Conclusion

Polytetrafluoroethylene (PTFE) is the full form of PTFE, a revolutionary material at the heart of many high-performance valves like the ptfe ball valve, ptfe lined valve, and lined ball valve. Known for its exceptional properties, PTFE offers unmatched chemical resistance, minimal friction, and the ability to endure extreme temperatures. Making it a preferred choice across industries such as chemical processing, oil & gas, and pharmaceuticals. Its integration into valves ensures reliable operation even in harsh environments dealing with corrosive or reactive substances. Variants like the fep lined ball valve provide added flexibility and transparency, catering to specialized needs without compromising on key advantages.

Commonly referred to as teflon valve due to its trademarked counterpart, PTFE continues to lead in durability and efficiency. Preventing leaks, reducing wear and tear, and enhancing overall system performance. The versatility and reliability of PTFE make it indispensable in modern valve technology. Solidifying its role as a benchmark material for industrial applications worldwide. The importance of PTFE lies not just in its technical excellence but also in its ability to address evolving industry demands with precision and consistency.

The post What is the full form of PTFE in ball valve? appeared first on Control Valve Manufacturers?.

]]>The post What is a lined ball valve? appeared first on Control Valve Manufacturers?.

]]>Introduction

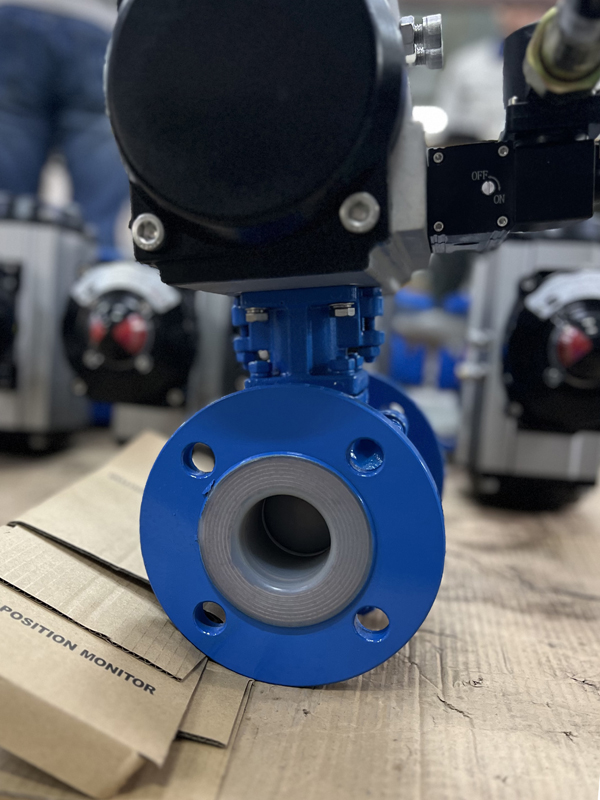

A lined ball valve is a vital component in industrial systems that deal with highly corrosive or abrasive substances. At its core, this specialized valve features a robust ball seated within a protective lining. Such as PTFE (Polytetrafluoroethylene), that shields the valve body and internal components from harsh media. Known for their unparalleled chemical resistance and durability, PTFE lined ball valves are widely employed in demanding sectors like chemical processing, pharmaceuticals, and water treatment.

The lining, whether in a PTFE lined valve or a PFA-lined alternative. Enhances operational reliability by preventing corrosion-related damage and minimizing maintenance needs. By incorporating advanced materials like PTFE, these valves, including the versatile PTFE ball valve. Play a critical role in ensuring process efficiency, reducing system failures. And sustaining long-term performance even in the most aggressive environments. Understanding the functionality and benefits of a lined ball valve is essential for industries seeking high-quality, reliable flow control solutions.

What is a Lined Ball Valve?

A lined ball valve is a highly specialized type of valve designed to handle abrasive and corrosive substances efficiently. Unlike standard valves, a lined ball valve features a lining material that covers the internal surfaces. Providing robust protection against chemical attack and wear. The lining, often made from materials like PTFE (Polytetrafluoroethylene), ensures exceptional durability and resistance to aggressive media. Making PTFE lined ball valves a preferred choice for industries like chemical processing, pharmaceuticals, and water treatment. The core components of a lined ball valve include the valve body, a ball with a smooth lining for precise sealing,. And a durable lining layer that minimizes damage from reactive or high-pressure environments.

Whether it is a PTFE lined valve or another variant such as the PTFE ball valve. The inclusion of PTFE allows these valves to perform reliably across a wide temperature range while minimizing the risk of leaks, failures, or costly downtime. Lined ball valves are crucial for maintaining operational safety and efficiency in demanding industrial applications. Making them an indispensable solution for handling challenging flow control scenarios.

Lining Materials Used in Ball Valves

Lining materials are a critical consideration in the design and functionality of a lined ball valve. As they directly impact the valve’s ability to withstand aggressive and corrosive substances. PTFE (Polytetrafluoroethylene) is one of the most widely used materials due to its remarkable chemical resistance, non-reactive properties. And ability to perform across extreme temperature ranges. PTFE lined ball valves? specifically prefer in highly demanding sectors like chemical processing. Where exposure to harsh acids, solvents, and other corrosive substances is common.

Another popular material is PFA (Perfluoroalkoxy), which shares PTFE’s chemical resistance but offers additional benefits such as improved mechanical strength and durability under high pressures. Whether choosing a PTFE lined valve or a PFA-lined alternative, these linings create a protective barrier within the valve, preventing corrosion, reducing wear, and enhancing the lifespan of the components. The inclusion of such advanced materials in PTFE ball valves not only ensures reliable sealing and low maintenance but also minimizes the risk of leaks, downtime. Or system failures. Selecting the right lining material is as essential as the valve itself. As it directly correlates with optimal performance and longevity in industrial applications.

a. PTFE Lined Ball Valve

A PTFE lined ball valve is a highly effective solution for controlling the flow of aggressive or corrosive fluids in industrial processes. This type of lined ball valve features a core ball and internal surfaces coated with PTFE (Polytetrafluoroethylene),. A material well-known for its exceptional chemical resistance and non-reactive properties. PTFE lined ball valves are designed to withstand exposure to harsh media such as strong acids, alkalis, and solvents. Making them indispensable in industries like chemical manufacturing, pharmaceuticals, and wastewater management.

The PTFE lining acts as a protective barrier, not only preventing corrosion of the valve’s internal components but also significantly reducing maintenance requirements and prolonging the valve’s lifespan. PTFE lined valves and PTFE ball valves are particularly valued for their smooth operation, reliable sealing. And remarkable durability under extreme temperature and pressure conditions. These attributes make PTFE lined ball valves a top choice for industries that demand precision, safety, and performance in managing corrosive or abrasive materials.

b. PFA Lined Valve

A PFA lined ball valve is a specialized type of lined ball valve designed to deliver superior performance in harsh industrial conditions. Featuring a lining made from PFA (Perfluoroalkoxy), this innovative valve builds upon the properties of PTFE lined ball valves by offering enhanced mechanical strength and durability. PFA combines exceptional chemical resistance with the ability to withstand high temperatures and stresses. Making it an ideal choice for industries handling highly corrosive or abrasive substances. Such as in chemical processing, petrochemical plants, and semiconductor manufacturing.

Compared to standard PTFE lined valves or PTFE ball valves, PFA lined ball valves provide additional resistance to cracking under pressure. Ensuring a longer lifespan and even greater reliability in demanding applications. The lining creates a robust barrier that safeguards the valve’s internal components against wear and corrosion. Minimizing maintenance requirements while ensuring leak-free operation. With their ability to maintain integrity under extreme operating conditions. PFA lined ball valves are a critical solution for industries that prioritize efficiency, durability, and safety in their flow control systems.

Applications of Lined Ball Valves

Lined ball valves essential in a wide range of industrial applications where the handling of corrosive, abrasive, or high-temperature substances is required. These valves, including PTFE lined ball valves and PTFE lined valves, widely use in chemical processing facilities to manage the flow of aggressive chemicals, acids, and solvents. Ensuring safe and efficient operations. They are also indispensable in the pharmaceutical industry, where stringent flow control is vital for producing high-quality medicines. As the non-reactive PTFE lining prevents any contamination during the process.

Additionally, lined ball valves extensively utilize in wastewater treatment plants to regulate the movement of harsh and abrasive sludge. Offering reliability and durability in such demanding environments. The robust construction and chemical resistance of PTFE ball valves make them suitable for petrochemicals, food and beverage production. And even semiconductor manufacturing, where precision and safety are critical. By effectively preventing corrosion, minimizing downtime, and ensuring leak-free performance. Lined ball valves have become the preferred choice for industries seeking to maintain operational integrity in highly challenging flow control scenarios.

How to Choose the Right Lined Ball Valve

Selecting the right lined ball valve is crucial for ensuring optimal performance, safety. And longevity in complex industrial applications. The first step is to evaluate the type of media being handled. Corrosive chemicals, abrasive substances, or high-purity fluids often require a PTFE lined ball valve due to its exceptional chemical resistance and non-reactive properties. For applications that demand enhanced mechanical durability under higher stress or temperature ranges. A PFA-lined option may be more appropriate. Understanding the operating temperature and pressure is also essential, as these factors directly influence the valve’s material compatibility and structural integrity.

Additionally, the specific lining material, whether PTFE lined valve or PFA lined. Must be compatible with the chemicals or compounds in use, ensuring the valve performs reliably without risk of corrosion or leakage. Selecting the right size and flow characteristics for the lined ball valve is equally important to maintain efficiency in flow control systems. Ensuring compliance with industry standards and certifications is critical. As this validates the valve’s ability to operate safely in demanding environments. By considering all these factors and collaborating with trusted manufacturers. Industries can select the perfect PTFE ball valve or lined ball valve, tailor-made to meet their unique operational needs.

Maintenance and Longevity of Lined Ball Valves

Proper maintenance is essential for ensuring the longevity and reliable performance of a lined ball valve. Including PTFE lined ball valves, PTFE lined valves, and PTFE ball valves. Routine inspection is the first line of defense against potential issues. Regularly check for signs of wear, corrosion, or deformation in the valve body, lining, and seals. Cleaning the internal surfaces of the valve is also crucial. Especially when handling chemicals or abrasive media, to prevent buildup that could compromise functionality. Always use cleaning agents that are compatible with the lining material. Such as PTFE, to avoid accidental damage.

To avoid valve failures, do not expose the valve to pressures beyond its rated capacity, as overpressure can cause cracking or deformation. Ensure that the media handled is fully compatible with the PTFE lining to prevent chemical degradation and leaks. When operating or installing a lined ball valve, handle it with care to avoid physical damage to the lining or internal components. Lubricate the moving parts as recommended by the manufacturer to preserve smooth operation and reduce wear. By adhering to these maintenance practices and collaborating with certified suppliers for replacement parts and servicing. Industries can maximize the lifespan and efficiency of their PTFE lined ball valves while ensuring safe and dependable flow control.

Advantages of Using Lined Ball Valves

Lined ball valves, including PTFE lined ball valves, PTFE lined valves, and PTFE ball valves. Offer a range of significant advantages that make them indispensable in various industries. One of their most notable benefits is their exceptional chemical resistance, making them ideal for handling corrosive and abrasive fluids in sectors like chemical processing and wastewater treatment. The PTFE lining acts as a protective barrier. Preventing the valve body from being degraded by aggressive chemicals, thus ensuring a longer operational life and reducing replacement costs.

Additionally, these valves deliver excellent leak-proof performance, thanks to their precision engineering and high-quality sealing mechanisms, which are critical for ensuring safety and environmental compliance in sensitive operations. Their durability in high-stress conditions, including exposure to extreme temperatures and pressures. Further enhances their reliability for demanding industrial applications. Beyond their robustness, lined ball valves are highly versatile, serving a wide range of purposes in pharmaceuticals, food processing, and petrochemical industries. Where precision and contamination prevention are paramount. By ensuring efficient flow control, minimizing downtime, and reducing maintenance needs. Lined ball valves not only enhance operational efficiency but also provide a cost-effective and dependable solution for managing challenging industrial processes.

FAQ

Q1. What is the warranty period for your ball valve?

Ball valve come with a standard warranty period of 12 months (1 years) from the date of delivery. This warranty covers manufacturing defects and materials under normal operating conditions as specified in the product manual.

Q2. How are? ball valve prices determined?

Prices for ball valve is influenced by several factors. Including the valve’s size, material composition (e.g., stainless steel, brass, or PVC), pressure ratings, end connection types. And any additional customisation or certifications required. Specialised features such as fire-safe designs or anti-static devices can also impact the cost.

Q3. What is the standard delivery time for a? ball valve?

Our standard delivery time for? ball valve is 4–6 weeks, depending on the order size and customisation requirements. For urgent requests, we offer expedited delivery options upon request.

Our logistics partners ensure fast and reliable delivery to meet engineering project timelines, regardless of location.

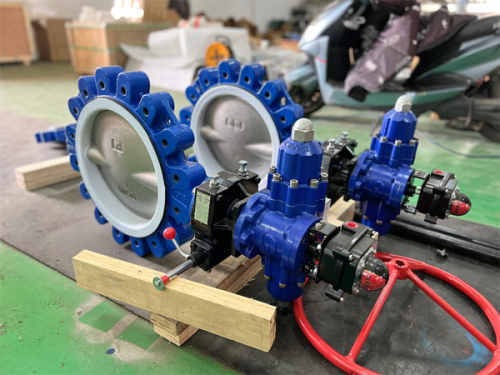

Q4. Common Applications of ball valve

Ball valve a versatile valve type design with three/two ports for fluid flow. These ports can be configured to allow various functions. Such as mixing, diverting, or completely shutting off flow.

Conclusion

A lined ball valve is an advanced flow control solution designed to handle challenging industrial conditions with precision and reliability. Featuring a resilient lining material like PTFE. Which offers exceptional chemical resistance, the lined ball valve serves as a protective barrier against corrosive and abrasive media. PTFE lined ball valves and PTFE lined valves specifically engineer to maintain durability and performance under extreme temperatures and pressures. Making them vital for industries such as chemical processing, pharmaceuticals, and wastewater treatment.

One of the key advantages of a PTFE ball valve is its leak-proof sealing capability. Which ensures safety and operational efficiency. These valves are also versatile, accommodating a wide range of fluids and gases while successfully preventing contamination. By combining strength, flexibility, and outstanding resistance to harsh substances. Lined ball valves reduce wear and tear, prolong operational life, and minimize downtime. Their design ensures cost-effectiveness and environmental compliance, helping industries achieve reliable and seamless flow control even in the most demanding applications. If durability, safety, and efficient performance are paramount, a lined ball valve stands out as an indispensable component in industrial systems, offering unmatched reliability and value.

The post What is a lined ball valve? appeared first on Control Valve Manufacturers?.

]]>The post What Quantifiable Advantages Do ptfe-Lined Diaphragm Valves Offer in Corrosive Environments? appeared first on Control Valve Manufacturers?.

]]>ptfe lined diaphragm valve Introduction

Industrial environments that handle corrosive substances demand robust, reliable equipment to maintain operational efficiency and safety. The PTFE-lined diaphragm valve stands out as a critical component in such settings, offering unmatched protection against chemical degradation. Designed with a specialized fluoropolymer lining, the PTFE-lined valve exhibits exceptional resistance to aggressive chemicals. Making it indispensable across industries such as chemical processing, wastewater treatment, and pharmaceuticals. The innovative design of these valves minimizes the risk of leaks, reduces maintenance needs. And extends the equipment’s operational life. This article examines the quantifiable advantages of PTFE-lined diaphragm valves. Exploring how they solve the challenges posed by harsh environments while ensuring seamless performance and cost savings. Whether you’re seeking to optimize your process or address current operational inefficiencies. Understanding the role of these highly engineered valves will give you a clear advantage in selecting the right solution for your needs.

The Science Behind PTFE-Lined Diaphragm Valves

PTFE-lined diaphragm valves are at the forefront of innovation when it comes to tackling corrosive environments. The science behind these valves lies in their unique lining made from polytetrafluoroethylene (PTFE). A high-performance fluoropolymer known for its outstanding chemical resistance and non-reactive nature. This lining creates a protective barrier between the valve’s internal components and the aggressive substances being transported. Ensuring long-term durability and corrosion resistance. PTFE’s low coefficient of friction also enhances the functionality of these valves. Allowing for smoother flow control and reduced wear over time.

Unlike standard valves, a PTFE-lined diaphragm valve can withstand exposure to highly reactive chemicals. Such as acids, alkalis, and solvents, without compromising performance. This makes it not only ideal but essential in industries like chemical processing, pharmaceuticals, and water treatment, where maintaining material integrity is critical. Beyond chemical resistance, the PTFE-lined valve contributes to operational efficiency by minimizing the likelihood of leaks and the need for frequent maintenance. Ultimately reducing downtime and operational costs. By combining robust material science with precision engineering. PTFE-lined diaphragm valves provide an unparalleled solution for applications requiring extreme reliability in hostile environments.

Key Advantages of PTFE-Lined Diaphragm Valves

PTFE-lined diaphragm valves offer a range of advantages that make them indispensable in industries handling aggressive and corrosive substances. Central to their effectiveness is the PTFE lining. Which provides an exceptional barrier against chemical attack, protecting the valve’s internal components from degradation. This chemical resistance enables the PTFE-lined diaphragm valve to operate reliably in environments that involve exposure to acids, alkalis, solvents. And other reactive agents without compromising performance or safety. The durability of the PTFE-lined valve extends its service life. Reducing the frequency of replacements and maintenance, which directly translates into lower operational costs.

Additionally, the smooth surface of the PTFE lining minimizes the potential for buildup or contamination. Making these valves highly effective in applications where cleanliness and precision are essential. Such as in chemical processing or pharmaceutical production. Beyond these practical benefits, the PTFE-lined diaphragm valve also supports efficient system performance. Offering tight sealing capabilities that prevent leaks and ensure consistent flow control. This combination of robust material properties, cost-efficiency. And practical versatility positions PTFE-lined valves as a critical solution for industries requiring reliability under harsh operating conditions.

Applications of PTFE-Lined Diaphragm Valves in Corrosive Environments

PTFE-lined diaphragm valves are an essential component in industries where corrosive environments pose significant operational challenges. Thanks to the exceptional chemical resistance of their PTFE lining, these valves are widely utilized in applications that involve handling aggressive substances such as acids, alkalis, and solvents. The chemical processing industry, for example, often relies on PTFE-lined diaphragm valves to ensure safe and efficient transportation of reactive chemicals, reducing the risk of leaks or equipment failure. Similarly, in the pharmaceutical sector, these valves are critical for maintaining the purity and integrity of sensitive formulations, as the PTFE lining prevents contamination while ensuring precise flow control.

The water and wastewater treatment industry also benefits from the use of PTFE-lined valves, where they are employed to manage highly acidic or abrasive mediums during purification and disposal processes. Additional applications can be found in mining, where corrosive slurries need to be safely handled, and in power generation plants, particularly in systems dealing with harsh chemical byproducts. The versatility and reliability of the PTFE-lined diaphragm valve make it a crucial solution for any process where long-term durability, operational efficiency, and resistance to corrosive materials are non-negotiable.

Industries Benefiting from PTFE-Lined Valve

PTFE-lined valves, including PTFE-lined diaphragm valves, play a vital role in various industries, offering exceptional performance in demanding applications. The chemical processing industry benefits significantly from these valves due to their unparalleled chemical resistance, making them ideal for handling aggressive substances like acids, alkalis, and solvents without risk of corrosion or degradation. Similarly, the pharmaceutical sector relies on PTFE-lined valves for maintaining sterility and contamination-free processes, as the non-reactive nature of PTFE ensures the safe handling of high-purity substances. The food and beverage industry also leverages these valves for managing fluids and products where hygiene and chemical resistance are critical, helping adhere to stringent safety regulations.

Water treatment facilities utilize PTFE-lined valves to manage corrosive chemicals like chlorine and other agents used in disinfection and purification processes, enhancing operational reliability. Additionally, in the oil and gas sector, PTFE-lined diaphragm valves are valued for their ability to withstand harsh environments, including exposure to corrosive hydrocarbons and extreme temperatures. Across all these industries, the durability, non-stick properties, and adaptability of PTFE-lined valves make them indispensable for ensuring both efficiency and safety in highly specialized operations. Their versatility cements their position as a practical solution for a wide range of industrial challenges.

Teflon Valves and Their Place in the Market

Teflon valves, particularly PTFE-lined diaphragm valves, have solidified their place in the industrial market as a superior solution for handling aggressive and corrosive substances. The defining feature of these valves is their PTFE lining, which leverages the exceptional chemical resistance and non-stick properties of polytetrafluoroethylene to ensure durability and reliability even in the harshest environments. This characteristic distinguishes Teflon valves from conventional options, as they can withstand prolonged exposure to acids, alkalis, solvents, and other reactive chemicals without degradation.

PTFE-lined diaphragm valves, in particular, are widely regarded for their precision flow control and tight sealing capabilities, making them indispensable in industries such as chemical processing, pharmaceuticals, and wastewater treatment. Additionally, their low maintenance requirements and extended lifespan enhance their cost-effectiveness, positioning them as a preferred choice for sectors aiming to minimize downtime and operational expenses. As industries continue to prioritize efficiency, safety, and environmental compliance, the demand for PTFE-lined valves continues to grow, ensuring their role as a vital component in modern industrial operations. Their ability to combine advanced material science with practical functionality solidifies their competitive advantage in a market that values both performance and reliability.

How to Choose the Right PTFE-Lined Valve for Your Application