High-performance ball valves available in WCB, CF8, and CF3M materials, offering exceptional durability and corrosion resistance. Designed for industries like oil and gas, chemical processing, and water treatment, these valves accommodate sizes ranging from 1/2″ to 8″. Options include pneumatic and electric ball valves for rapid or precise automated control, three way ball valves for flexible flow management, and flanged ball valves for secure, high-pressure applications. Featuring reliable ON-OFF control and 4-20mA signal compatibility

-

3 three way ball valve? with electric actuator

Read more -

3 way ball valve pvc? with electric actuator

Read more -

3 way ball valve t port? l port with electric actuator

Read more -

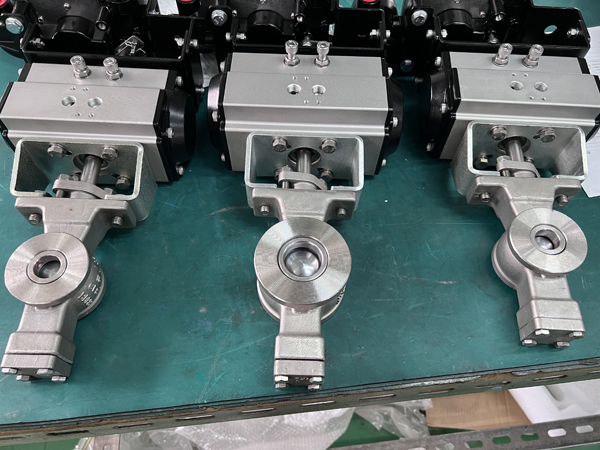

3 way ball valve?? with pneumatic actuator

Read more -

actuated ball valve? with pneumatic actuator 1/2″-4″

Read more -

electric actuated ball valve?

Read more -

Electric ball valve

Read more -

Pneumatic actuated thread ball valve 3 way?

Read more -

pneumatic ball valve?

Read more -

three way ball valve pvc? with pneumatic actuator

Read more -

Y pattern 3 way ball valve? 120 degree 135 degree

Read more

FAQs

What are the primary industry applications of ball valves?

Ball valves are widely used across industries for their efficiency and reliability. Common applications include:

– Oil and Gas: Used for controlling the flow of crude oil, natural gas, and processed fuels.

– Chemical Processing:** Ensures the safe transport of chemicals with precise flow control.

– Water Treatment:** Regulates water flow in filtration, distribution, and wastewater management systems.

– Manufacturing:** Provides precise control of fluids in automated production systems.

How does a ball valve operate?

A ball valve works using a spherical ball with a hole (or port) in the middle. When the hole aligns with the pipeline, fluid flows through freely. By rotating the ball 90 degrees using a handle or actuator, the hole is perpendicular to the flow, effectively stopping it. This ON-OFF mechanism ensures quick and reliable fluid control.

Why are ball valves preferred in high-pressure applications?

Ball valves are constructed with robust materials, such as stainless steel (CF8, CF3M) or carbon steel (WCB), that can withstand high pressures and extreme temperatures. Their tight sealing prevents leaks, making them ideal for critical operations in industries like oil and gas.

What types of ball valves are available for specific uses?

– Pneumatic Ball Valves: Best for frequent and rapid actuation in automated systems.

– Electric Ball Valves: Offers precise control with integration into advanced systems.

– Three-Way Ball Valves: Versatile for mixing, diverting, or regulating flows.

– Flanged Ball Valves: Ensure secure connections in high-pressure setups.

What sizes and materials are ball valves available in?

Ball valves are available in a range of sizes, typically from 1/2″ to 8″, to suit different pipeline diameters. Common materials include WCB, CF8, and CF3M, which offer durability and resistance to corrosion. These options ensure compatibility with diverse operational demands.