A plug valve lets you control flow fast and safely in pipes. You use plug valves when you want to turn flow on or off. They also help you change the direction of flow or slow it down a bit. The table below explains why many industries choose this valve instead of a diaphragm valve, ball valve, or butterfly valve. You can see what it mainly does and where it works best. This helps you pick the right valve for your work.

| Function/Application | Description |

|---|---|

| Flow Regulation | It closes tightly, opens fast, and does not lower pressure much. |

| Fire Safety and Durability | The plug and body are not exposed, so they do not rust or wear out easily. |

| Versatility | It works well with big flows and in many different jobs. |

| Applications in Industries | It is used in gas, petrochemical, paper, and harsh liquid systems. |

| Preferred Use | It is best when you need to shut off flow quickly or when small bits in the flow can cause damage. |

Key Takeaways

- Plug valves help control how fluids move fast and safely. They work well for turning flow on or off. They last a long time and do not rust easily. This makes them good for tough places. Plug valves can be used with many types of fluids. They even work with thick or dirty fluids. Their simple quarter-turn design makes them easy to use. You can change settings quickly. Plug valves are often found in oil and gas work. They are also used in chemical plants and water cleaning. Cleaning and adding oil to them helps them last longer. Picking the right plug valve depends on what you need it for. Plug valves seal tightly, so leaks are less likely. This helps keep the system safe.

Plug Valve Operation

Quarter-Turn Mechanism

Plug valves work with a simple quarter-turn. You only turn the handle 90 degrees to open or close it. The plug inside spins fast, so you can control flow easily. Many people like this because it saves time and effort. Plug valves need more force than ball valves, especially if you use them a lot. Look at the table below to see how plug valves and ball valves are different:

| Feature | Plug Valves | Ball Valves |

|---|---|---|

| Operational Speed | Needs more force, may be slower if used often | Works fast with less friction |

| Reliability | Very good at stopping leaks, even with harsh fluids | Good, but not as great with slurries |

| Maintenance | Simple to care for in tough places | Usually easy, but depends on design |

Plug valves are known for being reliable. They stop leaks, even with strong or dirty fluids. Maintenance is easy, so your system keeps working well.

Flow Control

Plug valves let you control fluid flow very well. You can move the plug to change how much fluid goes through. This makes them good for many jobs in factories. Plug type control valves are used where you need to manage flow, pressure, or temperature. The plug moves inside, so you can adjust flow exactly. Here are some reasons why plug valves are great for flow control:

- Plug type control valves help you control flow, pressure, or temperature.

- The plug shape lets you change flow very accurately.

- Full bore plug valves let you turn the plug to different spots for better control.

- You get a clear path for flow, so there is less resistance and lower pressure drop.

- Plug valves are important for jobs that need safe and exact flow control.

You can count on plug valves for quick changes or steady flow. Their design helps stop clogs and keeps things running smoothly.

Key Components

Plug valves have a few main parts that help them work well and last long. Most plug valves have these parts:

| Component | Description |

|---|---|

| Body | Holds the inside parts and connects to pipes. |

| Stem | Connects the disc to the actuator, so you can move the plug. |

| Disc | The plug part, shaped to seal tightly. |

Each part helps the valve control fluid flow. The body protects the inside and connects to pipes. The stem lets you turn the plug. The disc seals tight to stop leaks and control flow.

Plug valves use materials that fight rust and handle heat. Ductile iron is best for water jobs because it is cheap and strong. Bronze is good for marine work since it does not rust and is easy to shape. These things help plug valves last longer, even in hard jobs.

Plug Valves in Industry

Oil and Gas

Plug valves are used a lot in oil and gas. They help control flow in pipes, refineries, and storage tanks. Gas plug valves are good for high pressure and tough jobs. You can trust them to shut off flow fast and keep things safe. This is important when working with dangerous or flammable stuff.

Gas plug valves move crude oil, natural gas, and finished products. They work in both early and late steps of oil and gas work. You see them at drilling sites, plants, and places that send out oil and gas. Their strong build lets you use them for gas or liquid fuels without leaks.

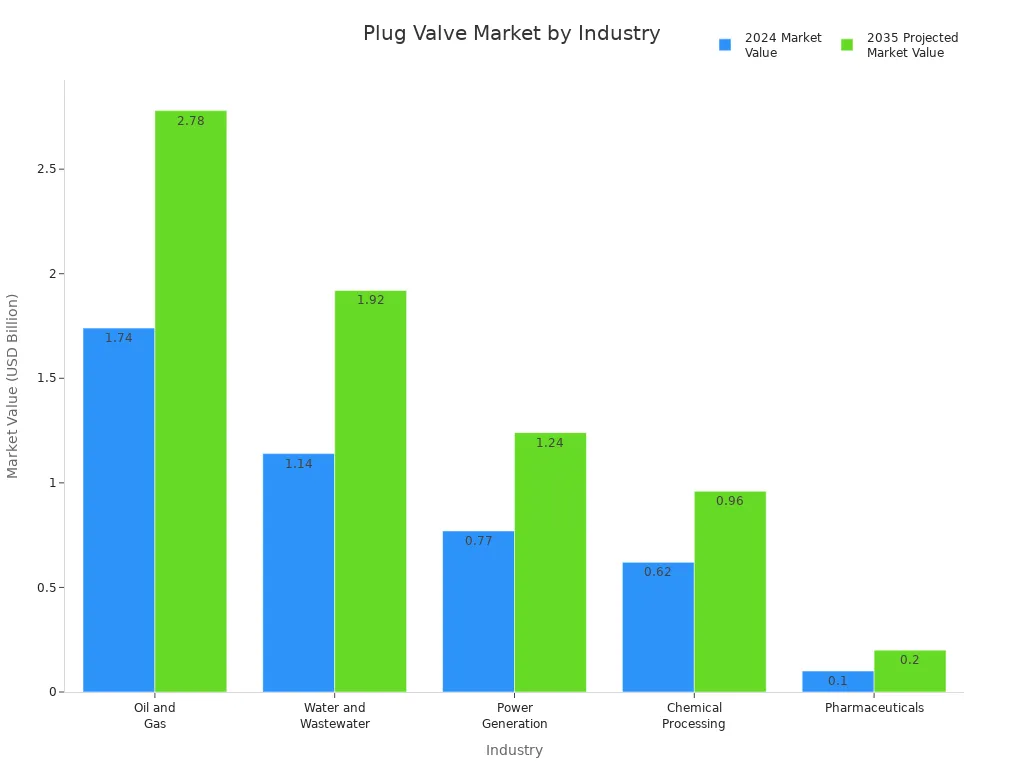

Here is a table that shows why plug valves are picked in many industries and how the market is growing:

| Industry | 2024 Market Value (USD Billion) | 2035 Projected Market Value (USD Billion) | Main Reasons for Selection |

|---|---|---|---|

| Oil and Gas | 1.74 | 2.78 | Good for flow control in getting, cleaning, and moving oil and gas. |

| Water and Wastewater | 1.14 | 1.92 | Helps save water and protect the environment. |

| Power Generation | 0.77 | 1.24 | Needed for steady energy and keeping power plants running. |

| Chemical Processing | 0.62 | 0.96 | Keeps people safe by handling strong or harmful chemicals. |

| Pharmaceuticals | 0.1 | 0.2 | Needed for careful fluid control in clean places. |

Oil and gas use plug valves the most. The world market for plug valves was about USD 3.5 billion in 2023. It might reach USD 5.2 billion by 2032. This is because people need strong gas plug valves for high pressure and safe flow control.

Chemical Processing

Plug valves are very important in chemical plants. You need valves that can handle strong acids and other harsh chemicals. Gas plug valves and other types help keep things safe and under control. Their design lets you stop flow quickly if there is a problem.

You use plug valves for mixing, moving, or stopping chemicals. These valves do not rust because they use stainless steel or special metals. They last longer and do not need much fixing.

Here is a table that shows the main good things about plug valves in chemical plants:

| Benefit | Description |

|---|---|

| Handling Viscous Fluids | Plug valves work well with thick stuff like oil and slurries. |

| Corrosion Resistance | Made from stainless steel or strong metals, they do not rust. |

| Emergency Shut-off Capability | You can stop flow fast, which keeps things safe. |

| Maintenance Simplicity | Their simple design makes fixing them easy. |

| Versatility in Applications | Good for many jobs, like handling harsh chemicals or rough slurries. |

Plug valves are used for high pressure and for moving dangerous or rough fluids. They are a top pick for many jobs in chemical plants.

Water and Wastewater

Plug valves are found in water plants and sewage systems. They help control clean water and dirty or gritty liquids. Gas plug valves are also used in some water jobs, especially when you need a tight seal.

Plug valves give you many good things in water and wastewater work:

- They are easy to open and close, so you use less energy.

- They seal well, so leaks do not happen and the environment stays safe.

- Strong materials and grease help them last longer, so you fix them less.

- You can use them for many kinds of fluids in the plant.

- It is easy to add grease without taking the valve apart.

Tip: If you pick plug valves for water or sewage, you get steady flow and less time fixing things. This helps you follow safety and environmental rules.

Plug valves work well in hard jobs, like sewage, mud, or sandy water. Their tough build and easy care make them a smart pick for water and wastewater systems.

Power Generation

You see plug valves used in many power plants. These valves help you control steam, water, and gases. You need strong valves for high-pressure jobs in turbines, heat exchangers, and cooling systems. Plug valves work well because they seal tightly and handle tough fluids.

You use plug valves in thermal power plants to manage steam flow. This helps you keep the plant safe and efficient. In hydropower stations, plug valves control water flow. This keeps the system stable and prevents damage. Nuclear power plants also rely on plug valves. These valves make sure cooling water flows safely and meet strict safety rules.

Here are some reasons why plug valves work well in power generation:

- You can use plug valves in steam and hydraulic systems.

- These valves control flow in high-pressure places.

- Plug valves handle aggressive fluids without leaking.

- You find plug valves in turbines, heat exchangers, and cooling systems.

- These valves help you follow safety standards in nuclear plants.

Tip: If you want a valve that lasts and keeps your power plant safe, choose a plug valve for high-pressure and tough jobs.

Slurries and Dirty Applications

Plug valves are a top choice when you deal with slurries, mud, or dirty fluids. You need valves that can handle grit, sand, and thick liquids. Plug valves give you a tight seal, so leaks do not happen even when pressure is high.

Mining and sewage systems use plug valves because these valves stand up to abrasive media. You do not have to worry about quick wear or breakdowns. Eccentric plug valve designs help reduce wear. This means your valves last longer and need less fixing.

You get these benefits when you use plug valves in dirty jobs:

- Plug valves seal tightly, even with high pressure.

- These valves work with abrasive and thick fluids.

- Plug valves shut off flow with little leakage.

- Eccentric designs help your valves last longer.

- You can trust plug valves in mining, sewage, and slurry systems.

| Application Area | Why Plug Valves Work Best |

|---|---|

| Mining | Handles sand, rocks, and thick slurries |

| Sewage Treatment | Seals tight against dirty, gritty water |

| Coal Slurry Systems | Reduces wear and lasts longer |

| Mud Handling | Stops leaks and stands up to tough jobs |

Note: If you work with dirty or abrasive fluids, plug valves help you keep your system running and reduce downtime.

Plug Valve Standards

When you pick plug valves, you should know the standards. These rules help make sure your valves are safe and work well. Standards come from groups around the world and in America. Each standard looks at things like pressure, materials, and testing.

International Standards

International standards let you use plug valves in many places. These rules make sure valves are safe and high quality.

ISO 5208: Industrial valves – Pressure testing of metallic valves

ISO 5208 tells you how to test metal valves for leaks. It sets limits for leaks and explains how to test for pressure. If a valve passes ISO 5208, it will keep your system safe.

ISO 14313: Petroleum and natural gas industries – Pipeline transportation systems – Pipeline valves

ISO 14313 gives rules for valves in oil and gas pipes. It covers pressure, materials, and how valves fit with pipes. Valves that meet ISO 14313 work well in tough jobs.

Here is a table that shows what these standards focus on:

| Standard | Focus Area | Key Requirements |

|---|---|---|

| ISO 5208 | Pressure Testing of Metallic Valves | Sets leak limits and pressure tests to keep valves strong. |

| ISO 14313 | Pipeline Valves | Lists rules for pressure, materials, and fitting in pipelines. |

American Standards

American standards matter if you work in the United States. These rules help you pick valves that fit your project and local laws.

API 6D: Specification for Pipeline and Piping Valves

API 6D covers valves for pipelines, including plug valves. It tells you what materials to use and how to test valves. API 6D works with ASME B16.34 to make sure valves are strong and safe.

API 599: Metal Plug Valves – Flanged, Threaded, and Welding Ends

API 599 gives rules for metal plug valves with flanged, threaded, or welded ends. It covers sizes from NPS 1 to NPS 24. This standard includes both lubricated and non-lubricated valves. API 599 also says the valve body must meet thickness rules in ASME B16.34.

ASME B16.34: Valves – Flanged, Threaded, and Welding End

ASME B16.34 sets basic rules for valve design and build. It covers body thickness, pressure ratings, and marking. Valves that meet ASME B16.34 can handle pressure and last long.

You can see the main uses and rules for these standards in this table:

| Standard | Primary Use | Pressure Rating | Temperature Range | Material Standards | Testing Requirements |

|---|---|---|---|---|---|

| API 599 | General industrial applications | Low to medium | Moderate | Corrosion-resistant alloys | Hydrostatic and operational testing |

| API 6D | Pipeline transportation systems | Medium to high | Wide | Strong pipeline materials | Pipeline-specific testing |

Note: API 599 and API 6D both say plug valves must meet thickness and design rules in ASME B16.34. The face-to-face sizes are also alike in both standards.

Other Common Standards

Some other standards are used in special jobs or places. These rules help you pick the right valve for your work.

MSS SP-78: Cast Iron Plug Valves, Flanged and Threaded Ends

MSS SP-78 covers gray iron plug valves. It tells you what materials to use and how big the valves should be. This rule helps your valves work well and last longer.

BS 5353: Steel Plug Valves for the Petroleum, Petrochemical, and Allied Industries

BS 5353 gives rules for steel plug valves. It covers design, testing, and marking. This rule helps you use valves safely in oil, gas, and chemical plants.

Here is a table that shows what these standards focus on:

| Standard | Focus Area | Key Requirements |

|---|---|---|

| MSS SP-78 | Gray Iron Plug Valves | Covers material and size rules for gray iron plug valves, making sure they work well. |

| BS 5353 | Steel Plug Valves | Lists design, testing, and marking for steel plug valves, making sure they are safe. |

Why Standards Matter

If you pick plug valves that meet these rules, your system is safer and works better. You also make sure your valves pass checks and follow industry rules. Standards help you compare products and choose the best one. Always check the rules before you buy or put in a valve.

Types of Plug Valves

Lubricated

Lubricated plug valves use grease to help the plug move. There is a small spot on top where you add grease. The grease makes a seal around the plug. This stops leaks and makes turning the valve easier. Lubricated plug valves work well with high pressure and heat. You often see them in oil, gas, and chemical plants. They are good when you need a tight seal and strong performance.

You must check and add grease often. If you forget, the valve can get stuck or leak. Lubricated plug valves cost more at first, but they last longer in hard jobs. Pick this type if you want a strong seal and do not mind extra care.

Non-Lubricated

Non-lubricated plug valves use special materials like Teflon. These materials help the plug move without grease. You do not need to add grease to these valves. This makes them easier to care for and lowers leak risks from dirty grease.

You find non-lubricated plug valves in water, food, and clean chemical jobs. They are best when you want less care and do not need high pressure or heat. These valves cost less and are easy to use. They may not seal as tight as lubricated ones in tough jobs.

Here is a table that shows the main differences between lubricated and non-lubricated plug valves:

| Feature | Lubricated Plug Valves | Non-Lubricated Plug Valves |

|---|---|---|

| Lubrication System | Yes, includes a lubrication system | No, uses self-lubricating materials |

| Friction | Reduced friction due to lubrication | Minimizes friction with coatings |

| Sealing Capabilities | Enhanced sealing, suitable for high-pressure | Adequate sealing, but may have limitations |

| Maintenance Requirements | Requires regular maintenance | Lower maintenance needs |

| Contamination Risk | Higher risk if lubricant is contaminated | Lower risk due to self-lubricating materials |

| Cost | Higher initial costs due to lubrication system | Generally lower initial and maintenance costs |

| Temperature/Pressure Limits | Suitable for demanding conditions | May have restrictions on temperature and pressure |

Tip: If you want a valve that is simple to care for and works in clean places, pick a non-lubricated plug valve.

Eccentric

Eccentric plug valves have a plug that sits off to the side. When you turn the handle, the plug moves away before it turns. This design lowers rubbing and helps the valve last longer. It works well with thick or dirty fluids.

You see eccentric plug valves where you handle slurries, sludge, or gritty fluids. These valves are used in water plants, power plants, and chemical factories. The off-center plug helps stop wear and keeps the valve from sticking.

Here is a table that shows where you might use eccentric plug valves:

| Industry | Applications |

|---|---|

| Petroleum and Natural Gas | Regulating flow of crude oil, natural gas, refined products, and slurries. |

| Chemical | Controlling corrosive and hazardous chemicals, acids, and alkalis. |

| Water Treatment | Managing flow of raw water, treated water, sludge, and chemicals in purification processes. |

| Power Industry | Applications in cooling water systems, ash handling, and flue gas desulfurization. |

Note: Eccentric plug valves help you control tough fluids and need fewer repairs.

Expanding

Expanding plug valves give you a tight seal without rubbing the plug against the seat. When you turn the handle, the plug moves sideways first. Then, it expands to press against the seat. This action creates a strong seal. You do not get much wear because the plug does not scrape the seat when you open or close the valve.

You often use expanding plug valves in pipelines that carry oil, gas, or other dangerous fluids. These valves work well when you need zero leakage. You can trust them in high-pressure jobs. Expanding plug valves also help when you need double block and bleed service. This means you can block flow from both sides and bleed off pressure in the middle. You get extra safety and can do repairs without shutting down the whole system.

Key benefits of expanding plug valves:

- You get a bubble-tight seal.

- You avoid seat wear, so the valve lasts longer.

- You can use them for double block and bleed.

- You can trust them in high-pressure and hazardous jobs.

Tip: If you need a valve that seals tight and lasts long, pick an expanding plug valve for your pipeline.

Multi-Port

Multi-port plug valves let you control flow in more than two directions. You can use one valve to send fluid to different places or mix flows from several sources. This design saves space and makes your piping system simpler.

You find multi-port plug valves in chemical plants, water treatment, and food processing. These valves help you change flow paths without using many valves. You can switch flow between tanks, blend fluids, or send fluid to different machines.

Here is a table that shows how different multi-port plug valves work:

| Valve Type | Functionality | Application |

|---|---|---|

| L-port | Diverts fluid to one direction at a time | Fluid diversion between two storage tanks |

| T-port | Can divert fluids to two destinations at once and allow straight-through flow | Mixing different fluid compositions and diverting flow from a single source to two destinations |

You can use multi-port plug valves for:

- Merging fluid flow from two different sources, such as in beverage production.

- Diverting flow from a single source to two different destinations.

- Changing flow between two storage tanks.

Note: Multi-port plug valves help you save space and reduce the number of valves in your system.

Three-Way Plug Valve

Three-way plug valves are a special type of multi-port valve. You use them to direct flow between three different ports. The plug inside has a hole or path that lines up with two or three ports at once. You can use these valves to mix fluids or send flow to different places.

You often see three-way plug valves in mixing, blending, or switching jobs. For example, you can mix two chemicals before sending them to a reactor. You can also switch flow from one tank to another without stopping the process.

Three-way plug valves come in L-port and T-port designs. L-port valves let you send flow to one place at a time. T-port valves let you send flow to two places at once or mix flows together. This makes them very flexible for complex piping systems.

Tip: If you need to mix fluids or change flow direction often, a three-way plug valve gives you the control you need.

Jacketed Plug Valve

Sometimes, you need to keep fluids warm or cool in pipes. A jacketed plug valve helps with this job. It looks like a regular plug valve but has a jacket around it. You can send steam, hot water, or cold fluid through the jacket. This keeps the main fluid inside at the right temperature.

Jacketed plug valves are best for fluids that get thick or hard when cold. You see these valves in chemical plants, oil refineries, and food factories. For example, chocolate or syrup can get hard if it cools down. The jacket keeps them warm and moving.

Here is a table that shows what makes jacketed plug valves special:

| Feature | Description |

|---|---|

| Core Design | Works like a standard plug valve with a plug for flow control. |

| Jacket System | Has an outer jacket for heating or cooling fluids. |

| Temperature Management | Keeps fluids from solidifying and controls viscosity. |

| Applications | Used in chemical, oil and gas, pharmaceutical, and food industries. |

| Advantages | Prevents clogs, lasts longer, and works for both heating and cooling. |

Tip: If you want your fluid to stay at the right temperature, use a jacketed plug valve. It helps stop clogs and keeps your system running well.

Connection Types: Compression, Threaded, and Flanged Plug Valves

You can pick from different connection types for your plug valve. Each type has its own good points for putting in and fixing the valve. Picking the right one saves time and helps you avoid problems.

- Flanged plug valves are easy to put in. You bolt them between two pipe flanges. This makes it simple to take out the valve for cleaning or repairs. Flanged connections also give a strong, leak-proof seal.

- Threaded plug valves screw onto the ends of pipes. You use these in small systems or when you need a quick setup. Taking them apart can be tough if the threads get stuck or rusty.

- Compression plug valves use special fittings that grip the pipe when you tighten a nut. You do not need to thread or weld the pipes. This makes putting them in fast, but you need the right tools for a tight fit.

Here is a table that compares these connection types:

| Connection Type | Installation Ease | Maintenance Considerations |

|---|---|---|

| Flanged | Easy | Simple maintenance |

| Threaded | Moderate | Challenges in disassembly |

| Compression | Easy | Requires specific tools |

Note: If you want the easiest time fixing your valve, pick a flanged plug valve. For quick jobs or small spaces, compression or threaded types might be better.

Choosing the right connection type helps your valve work well in your system. You get better results and fewer problems later.

Why Plug Valves

Advantages

When you choose a plug valve, you get several important benefits. This type of valve stands out because it gives you a strong seal and simple maintenance. You can use it in places where other valves might struggle, especially with dirty or thick fluids. The table below shows how plug valves compare to ball valves in key areas:

| Feature | Plug Valve | Ball Valve |

|---|---|---|

| Sealing properties | Larger sealing area, better sealing | Smaller sealing area, potentially less effective |

| Maintenance | Easy to clean | Difficult to clean due to deep-seated parts |

| Cost | Less costly | More costly |

| Application | Suitable for abrasive materials like sewage, mud, and slurries | Ideal for automation in industries like natural gas, oil, LNG, and plumbing |

You can see that plug valves give you a bigger sealing area. This means you get fewer leaks, even with tough materials like mud or slurries. Cleaning is easier because you can reach the inside parts without much trouble. You also save money since plug valves usually cost less than ball valves. If you work with fluids that have grit or debris, plug valves handle these conditions better than many other valves.

Tip: Plug valves work best when you need a tight seal and easy cleaning, especially in dirty or abrasive systems.

Limitations

You should also know the limits of plug valves before you pick them for your system. Here are some things to watch out for:

- Plug valves do not work well in high flow rate systems. Their design can cause resistance and pressure drop.

- You may find that throttling performance is not very accurate. Other valves give you better control for fine adjustments.

- Over time, frequent use can wear down the sealing surfaces. This can lead to leaks if you do not check and maintain the valve.

- Plug valves are hard to find in larger sizes. If you need a valve for a big pipe, you might need to look at other options.

- Sometimes, debris or corrosion can make the plug jam. This happens more often with thick or sticky fluids.

You need to think about these points when you decide if a plug valve fits your job. Regular checks and cleaning help you avoid most problems. If you need very precise flow control or have a large system, you may want to consider other types of valves.

Choosing Plug Valves

Application Factors

When you pick a plug valve, you need to think about a few things. Every job is different, so match the valve to what you need. Here is a simple guide to help you choose:

- Know what your job needs. Think about the fluid type, how hot or cold it is, the pressure, and how fast it moves.

- Check if the valve material works with your fluid. Pick materials that do not rust and can handle your fluid.

- Choose the right size and shape. Make sure the valve fits your pipes and lets enough fluid through.

- Decide which valve type is best. Pick lubricated, non-lubricated, or eccentric plug valves for your job.

- Think about how you will use the valve. Choose manual or automatic, depending on how often you need to open or close it.

- Make sure the valve follows safety rules. Check if it meets all the standards for your work.

- Look for easy maintenance. Pick a valve that is simple to fix and lasts a long time.

Some people make mistakes by picking the wrong size, not thinking about changes, or only looking at price. Always think about the total cost, including putting it in, using it, and fixing it.

Safety and Compliance

Safety is very important when you pick valves for jobs with rules. You must follow strict rules to keep everything safe. The table below shows what to check:

| Aspect | Description |

|---|---|

| Safety Regulations | Follow safety valve rules to stop dangerous problems. |

| Compliance Standards | Meet ASME and National Board rules for safety and quality. |

| Maintenance Requirements | Do regular checks and tests to keep valves safe. |

You also need to follow rules like ASME BPVC. These rules tell you how to design, build, and test valves. Tests like hydrostatic and pneumatic make sure the valve works in real life. Regular checks help you find problems early and keep things safe.

Maintenance

Taking care of your plug valves helps them last longer. You should do a few things to avoid trouble and keep your system running. The table below lists the main steps:

| Maintenance Practice | Description |

|---|---|

| Regular Inspection | Look for damage, rust, or problems with how it works. |

| Cleaning and Maintenance | Clean the valve so dirt does not hurt the seal. |

| Lubrication Maintenance | Add grease to moving parts to stop wear and make turning easy. |

| Anti-Corrosion Treatment | Use anti-rust oil or strong materials in tough places. |

| Maintenance History Recording | Write down all work you do to plan and track how the valve works. |

Tip: If you keep checking and cleaning your valves, you will stop most problems. Always write down what you do so you can see patterns and make your system better.

Plug valves are trusted for fast shut-off and strong sealing. They also let fluids move with little resistance in many industries. The table below shows their main uses and why people pick them:

| Type | Main Uses and Benefits |

|---|---|

| Soft Seal | Stops leaks and keeps fluids clean in tough places |

| Oil Lubricated Hard Seal | Works well with high pressure and heat, seals better |

| Lifting | Lowers rubbing and closes tightly |

| Multi-Port | Lets you send fluids different ways or change direction |

Knowing how each plug valve works helps you pick the best one. Always think about what your job needs. If things get tricky, ask experts for help.

FAQ

What is the main purpose of a plug valve?

You use a plug valve to start or stop flow in a pipe. It gives you quick shut-off and works well with many types of fluids, including dirty or thick ones.

Can you use a plug valve for throttling?

You can use a plug valve for moderate throttling. It does not give you fine control like a globe valve. For best results, use it mainly for on/off service.

How do you maintain a plug valve?

You should inspect the valve often. Clean the inside and add grease if needed. Check for leaks or damage. Write down your maintenance work to track the valve’s condition.

Where do you usually install plug valves?

You find plug valves in oil, gas, water, chemical, and sewage systems. They work best in places where you need a tight seal and easy cleaning.

What is the difference between lubricated and non-lubricated plug valves?

Lubricated plug valves use grease to seal and move smoothly. Non-lubricated types use special coatings or sleeves. You pick lubricated for tough jobs and non-lubricated for clean or low-pressure systems.

Are plug valves good for high-pressure systems?

Yes, you can use plug valves in high-pressure systems, especially lubricated or expanding types. Always check the valve’s pressure rating before you install it.

How do you choose the right plug valve size?

You match the valve size to your pipe and flow needs. Check the pipe diameter and how much fluid you want to move. Use the manufacturer’s chart for help.

Can plug valves handle abrasive or dirty fluids?

Yes! Plug valves work well with slurries, mud, and fluids with grit. Their design helps prevent leaks and reduces wear, making them a top choice for tough jobs.