You need strong protection when you use harsh chemicals. Teflon lined valves give you the best resistance to chemicals. They are also tough and dependable. Science tests show ptfe works better than EPDM, Viton, and metal in harsh places. The table below shows why teflon and ptfe are better:

| Material | Chemical Resistance | Temperature Tolerance | Sealing Performance |

|---|---|---|---|

| PTFE | Excellent | High | Excellent |

| EPDM | Poor | Moderate | Poor |

| Viton | Good | Moderate | Good |

| Metal | Moderate | High | Poor |

You get a good seal in a ball valve, butterfly valve, or electric valve. Teflon lined valves let you work with strong fluids safely.

Corrosive Applications

Corrosive applications mean working with fluids that can harm regular valves. These fluids include strong chemicals, acids, bases, and solvents. They can quickly damage normal valves. This damage may cause leaks or contamination.

Risks to Valves

Chemical Attack

Valves used with corrosive substances face strong acids and bases. Some common chemicals you might see are:

- Hydrochloric Acid (HCl)

- Hydrofluoric Acid (HF)

- Sulfuric Acid (H2SO4)

- Nitric Acid (HNO3)

- Acetic Acid (CH3COOH)

- Chlorine (Cl2)

- Phosgene (COCl2)

- Alkali like Sodium Hydroxide (NaOH)

- Ammonia (NH3)

- Saltwater

These chemicals can hurt the inside of valves. Over time, this can cause pits, cracks, or even make the valve break. You need strong materials for these tough jobs.

Safety Hazards

If a valve breaks in a corrosive application, it is dangerous. Leaks can let out harmful chemicals. These chemicals can hurt workers or damage machines. Sometimes, even a small leak can start a fire or explosion. It can also cause toxic exposure. You must pick valves that keep people and equipment safe.

Industry Examples

Many industries need valves that work with chemical and corrosive fluids. The table below shows how different industries need special valves for certain chemicals:

| Industry | Specific Requirements |

|---|---|

| Chemical Industry | Needs non-metallic valves like rubber-lined or plastic for hydrochloric acid. Stainless steel for nitric acid. Titanium alloys for high temperatures. High alloy stainless steel or fluorine plastic for concentrated acetic acid. Fluorine-lined valves for sulfuric acid. |

Pharmaceutical and food processing must keep fluids clean. High-purity PTFE valves help meet strict rules. These valves do not react with fluids. This stops contamination. You also follow rules from groups like 3-A Sanitary Standards and NSF International. The smooth inside of these valves keeps particles and germs from sticking. This keeps your product safe.

Tip: Always make sure your valves meet the right purity and corrosion standards for your industry. This helps you avoid problems and keeps your process safe.

Teflon Lined Valves Science

PTFE Chemical Resistance

Molecular Structure

It is important to know why ptfe works well with strong chemicals. The answer is in how its molecules are built. Ptfe has about 41% crystallinity. It also has 76% fluorine. These numbers help ptfe fight off chemical damage.

- Big fluorine atoms cover the carbon atoms. This stops chemicals from breaking the chain.

- Ptfe makes strong C-F bonds. These bonds form a hard shield around the carbon.

- The material does not mix with protonated substances. This keeps ptfe steady with strong acids or bases.

- Ptfe stays stable with harsh chemicals. You can use it with concentrated sulfuric acid and other strong chemicals.

Ptfe does not react with most chemicals. This gives it high chemical resistance. Teflon lined valves use this to keep your system safe.

All-Wetted Surface Design

Teflon lined valves have an all-wetted surface design. Every part that touches the fluid is covered with ptfe. This keeps harsh fluids away from the metal parts. The metal body and trim do not touch the aggressive fluids.

The ptfe lining acts as a strong barrier. You do not need to worry about contamination. The smooth surface stops particles and germs from sticking. This keeps your process clean and safe. The ptfe coating also works in very hot or cold places. You can use these valves in many industries without trouble.

Tip: Pick valves with full ptfe lining for strong chemicals. This lowers maintenance and makes things safer.

Durability in Harsh Media

You want valves that last a long time. Teflon lined valves last longer than metal valves without lining. The ptfe coating stops corrosion and wear. You spend less time and money fixing them.

Here is a quick look at how long these valves last:

| Valve Type | Average Service Lifespan |

|---|---|

| PTFE Lined Valves | 5-7 years |

| Unlined Metal Valves | Shorter than PTFE due to corrosion susceptibility |

Teflon lined valves work well for a long time. The ptfe coating keeps your system working in tough places. You avoid leaks and breakdowns. This keeps workers and equipment safe.

Teflon Performance Evidence

Laboratory Data

Corrosion Rates

You want to know how ptfe stands up to harsh chemicals over time. Scientists have tested ptfe in labs with strong acids, bases, and solvents. These tests show that ptfe has very low corrosion rates. The strong C-F bonds in teflon make it almost impossible for most chemicals to break down the material. When you use teflon lined valves, you get a barrier that keeps corrosive substances away from metal parts. This means you see less pitting, cracking, or swelling. The coating on these valves does not wear away quickly, even when you use them every day.

You can trust ptfe to keep its shape and strength. The coating stays smooth, so you do not get leaks or blockages. This high level of corrosion protection helps your valves last longer and work better. You avoid the common problems that happen with metal or rubber-lined valves.

Industry Standards

ASTM, API, ISO

You need to make sure your valves meet strict industry standards. These standards prove that teflon lined valves can handle tough jobs. Here is a table that shows the main standards for ptfe valves:

| Category | Standard |

|---|---|

| Design & Manufacturing | BS 5351 / ISO 17292 |

| Testing & Inspection | API 598 |

| Face to Face | AS PER ANSI B 16.10 |

| End Connections | FLANGED AS PER ANSI B 16.5 |

| Standard Resin Spec. | FEP : ASTM D 2116 |

| PFA : ASTM D 3307 |

These standards check everything from design to testing. They make sure the ptfe coating is thick enough and covers all the parts that touch the fluid. They also test the valves for leaks and pressure. When you choose valves that meet these standards, you know you are getting high corrosion resistance and safety.

Real-World Case Studies

You can see the power of ptfe and teflon in real factories and plants. Here are some examples:

- A chemical processing plant had leaks from agitator packing because of harsh chemicals. The old packing used 10 rings of ptfe, but each ring did not get enough pressure. This caused leaks. When the plant changed the setup, the leaks stopped. This shows that ptfe works well, but you must use it the right way.

- A nickel plant had leaking flanges. This raised safety and environmental worries. The plant switched to ptfe products for sealing. The leaks stopped, and the plant became safer.

- A petrochemical plant had high temperature steam leaking from valve stems. This was dangerous and cost a lot to fix. The plant started using ptfe for packing. The leaks went away, and the valves lasted longer.

These stories show that teflon lined valves give you real results. You get better durability, fewer leaks, and lower costs. The ptfe coating protects your valves from corrosion, even in the toughest places.

Note: You should watch for common failure modes. For example, do not use ptfe lined valves above 150°C. High temperatures can soften the coating. Negative pressure can make the lining bulge or peel. Hard particles in the fluid can scratch the inside. Always size your valves right to avoid vibration and breakage.

Here is a table of common failure modes and how to avoid them:

| Failure Mode | Description |

|---|---|

| Temperature Limits | Keep use below 150°C. Long-term use should stay under 120°C to stop softening and deformation. |

| Avoid Negative Pressure | Negative pressure can make the lining bulge or peel off. |

| Control Pressure and Differential | High pressure can break bellows, especially in ptfe-bellows sealed valves. |

| Avoid Abrasives | Hard particles can damage the valve. Use special alloys if needed. |

| Proper Sizing | Oversized valves can vibrate and break. Size them right for your system. |

You get the best results when you follow these tips. Teflon and ptfe give you strong corrosion resistance, long durability, and safe operation. You can trust these valves to handle corrosive substances and keep your process running smoothly.

Other Corrosion-Resistant Rubber Materials

EPDM (Ethylene Propylene Diene Monomer)

Chemical Resistance Profile

EPDM is used in many valves because it resists water and steam. It also works with some weak acids. This rubber does not do well with oils or fuels. Most solvents can also damage it. If you use EPDM with strong chemicals, it can break down over time. PTFE can handle many more harsh substances. It stands up to strong acids and bases. This makes PTFE a better pick for chemical plants that need strong protection.

Typical Applications

EPDM is found in systems that move water or steam. It is also used with mild chemicals. You see it in cooling towers and water treatment plants. Some food processing lines use it too. Do not use EPDM if the fluid has oils or strong solvents. For harsh chemicals, you need a valve with a stronger coating.

Viton (FKM)

Performance in Aggressive Media

Viton is another rubber used in valve linings. It can handle many chemicals but not as well as PTFE. PTFE can resist 98% sulfuric acid without damage. Viton fails fast in hydrofluoric acid. PTFE does not absorb chlorinated solvents. Viton can swell and lose its shape. For very harsh chemicals, PTFE lasts longer and works better.

Temperature and Chemical Limits

Let’s look at how Viton and PTFE compare:

| Property | Viton | PTFE |

|---|---|---|

| Chemical Compatibility | Limited in aggressive chemicals | Excellent resistance to a wide range of chemicals |

| Temperature Range | High temperature resistance | Handles both high and low temperatures |

Viton works well at high heat and with many chemicals. But it can break down with strong bases or some solvents. PTFE keeps its strength even in these tough spots. This makes PTFE safer for extreme jobs.

Butyl Rubber

Acid and Alkali Resistance

Butyl rubber gives some protection from acids and alkalis. But it is not as good as PTFE. PTFE has better chemical resistance, even with harsh chemicals. Butyl rubber can start to break down with strong acids or bases over time.

- PTFE can handle more chemicals than butyl rubber.

- Butyl rubber breaks down faster in tough places.

Industrial Use Cases

Butyl rubber is used in valves for air and water. It is also used with some mild chemicals. It works in low-pressure systems. It is best where strong chemical attack is not likely. For strong acids or bases, pick a valve with PTFE coating. This keeps things safer and lasts longer.

Tip: Always match the valve lining to your chemicals. This helps stop leaks and keeps your system safe.

Neoprene

General Corrosion Resistance

Neoprene is a common rubber used for valve linings. It can resist many chemicals, like mild acids and bases. Neoprene also stands up to ozone and weather changes. You can use it outside where the weather changes a lot. Water and air do not break down neoprene fast. This makes it good for outdoor systems.

But neoprene does not work well with strong acids or harsh chemicals. If you use it with tough fluids, it might swell or crack after some time. Neoprene is best for places with only a little chemical exposure. It works well in cooling water, wastewater, and some food lines.

Suitability for Solvents and Oils

Neoprene can handle many oils and some solvents. You can use it in systems that move oil or lubricants. Neoprene does not soak up oil, so it keeps its shape. This helps stop leaks and keeps things running well.

If you use strong solvents or harsh chemicals, neoprene may not last. It can get soft or lose its strength. You should pick PTFE for those tough jobs. Neoprene is good for general valves, but not for chemical plants or refineries.

Comparative Limitations vs. PTFE

Longevity and Chemical Compatibility

When you compare neoprene, EPDM, Viton, and butyl to PTFE, you see big differences. PTFE is better at resisting chemicals and high heat. You can use PTFE where rubber would not work. PTFE does not react with most chemicals, so it lasts longer in tough places.

Rubber linings are more flexible and seal moving parts well. They work great in systems that move a lot. But rubber can break down in strong chemicals or high heat. PTFE can bend under pressure, which is not good in high-stress places. Use rubber for flexible seals, but PTFE for tough chemicals and heat.

Key Points:

- PTFE is great at resisting chemicals and heat.

- Rubber is stretchy and seals moving parts well.

- PTFE is best for chemical plants, food gear, and medical tools.

- Rubber is best when you need something flexible.

Maintenance and Replacement Considerations

You need to check rubber-lined valves often. Here are some steps to follow:

- Look at the rubber lining for damage or wear.

- Clean the valve to get rid of fluids or dirt.

- Oil the actuator and moving parts often.

- Fix or change broken parts right away.

- Change the rubber lining when it gets old.

- Adjust the valve’s actuator to keep it working.

- Teach your team how to care for the valves.

PTFE-lined valves do not need as much care. You spend less time checking and fixing them. PTFE does not get damaged by chemicals, so you avoid many problems. Rubber linings need more care, especially in tough places. Plan to check and replace them often to keep your system safe and working well.

Types of Teflon Lined Valves

Ball Valves

Design Features

PTFE ball valves have a simple design that works well. The main part is a ball with a hole in it. You turn the handle to open or close the valve. The PTFE lining covers every part that touches the fluid. This keeps the metal safe from harsh chemicals. The smooth PTFE helps the ball move easily. This makes sure you get a tight seal each time.

Here is a table that shows how PTFE lining helps ptfe ball valves in tough places:

| Feature | Benefit for Corrosive Applications |

|---|---|

| PTFE lining covers all wetted parts | Prevents corrosion and chemical attack |

| Smooth PTFE surface | Reduces friction and wear, making operation easier |

| Non-reactive barrier | Keeps aggressive chemicals away from metal parts |

| Long-lasting protection | Extends valve life and lowers maintenance needs |

| Consistent tight seal | Prevents leaks, even with strong acids and bases |

You can count on ptfe ball valves in harsh places. The PTFE lining gives strong protection from chemical damage.

Typical Applications

PTFE ball valves are used in many jobs. Chemical plants use them for acids and bases. Water treatment plants use them for safe flow. Food and drug companies use them to keep things clean. These valves are good when you need to stop leaks. You can add electric actuators for remote control. PTFE ball valves help you handle strong fluids safely.

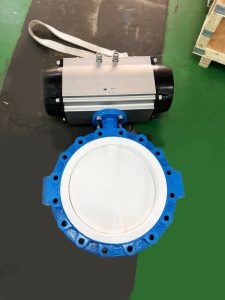

Butterfly Valves

Sealing Mechanism

Butterfly valves have a disc that turns inside the pipe. When you turn the handle, the disc opens or closes the flow. The PTFE lining covers the disc and inside of the valve. This keeps the valve safe from harsh chemicals. The PTFE surface helps the disc move smoothly. You get a good seal every time. You can open or close the valve fast and control the flow easily.

Corrosive Media Suitability

PTFE lined butterfly valves work well in tough jobs. They resist damage from strong chemicals and fluids. These valves keep working even when it is hot. You can use them with electric actuators for better control. PTFE lined butterfly valves need less care, so you save time and money.

Here are some common uses for PTFE lined butterfly valves:

- Chemical plants that need strong resistance to acids and bases.

- Petrochemical sites where you must control aggressive or corrosive media.

- Pharmaceutical factories that require precise flow and clean processes.

Tip: Pick PTFE lined butterfly valves for great chemical resistance, high heat, and less maintenance.

Gate Valves

Flow Control Capabilities

Gate valves use a flat or wedge gate to block or let fluid pass. When you lift the gate, fluid moves through. When you lower it, the flow stops. PTFE lined gate valves give you good control over flow. The PTFE lining keeps the valve safe from chemicals. You can use these valves with slurries or rough fluids. The smooth PTFE stops wear and clogging. PTFE lined gate valves last longer than ones without lining.

Here is a table that compares PTFE lined gate valves to unlined valves:

| Parameter | PTFE Lined Gate Valves | Unlined Gate Valves |

|---|---|---|

| Corrosion Resistance | Excellent | Susceptible to corrosion |

| Temperature Range | Wide, depends on PTFE | Limited |

| Longevity | Long-lasting, resists abrasion | Shorter lifespan, prone to wear |

Installation Considerations

Put PTFE lined gate valves where you need good shutoff and flow control. Make sure the valve fits your pipe and pressure needs. Do not use them above PTFE’s safe temperature. Check that the lining covers all parts that touch fluid. PTFE lined gate valves need less care than metal or rubber-lined ones. They help keep your system safe and working, even with strong chemicals.

Plug Valves

Operation Principle

You use plug valves when you need a simple way to control flow. The main part is a cylindrical or tapered plug that rotates inside the valve body. You turn the handle, and the plug moves to open or close the passage. The plug has a hole through it. When the hole lines up with the pipe, fluid flows. When you turn the plug, the hole moves away, and the flow stops.

The PTFE lining covers all surfaces that touch the fluid. This lining acts as a shield. It keeps strong chemicals from reaching the metal parts. You get a smooth surface, so the plug moves easily. The lining also helps you avoid leaks. You can use plug valves for on-off control or throttling. They work well with thick fluids, slurries, and aggressive chemicals.

Tip: Plug valves with PTFE lining give you reliable shutoff in places where corrosion is a big risk.

Maintenance Requirements

You want valves that are easy to care for. Plug valves with PTFE lining need less maintenance than metal or rubber-lined types. The PTFE surface resists sticking and buildup. You do not have to clean them as often. The lining also stops wear, so you do not need to replace parts frequently.

Here are some steps you can follow to keep your plug valves working well:

- Check the PTFE lining for scratches or peeling.

- Make sure the plug turns smoothly.

- Clean the valve if you see buildup from thick fluids.

- Lubricate the handle if it feels stiff.

- Replace the lining if you notice damage.

Plug valves with PTFE lining last longer in harsh places. You spend less time fixing leaks or changing parts. This saves you money and keeps your system safe.

Globe Valves

Precision Control

You use globe valves when you need to control flow with accuracy. The main part is a movable disc that presses against a seat. You turn the handwheel, and the disc moves up or down. This changes the size of the opening. You can adjust the flow rate very precisely.

The PTFE lining covers the disc and seat. This lining gives you a smooth surface. It stops chemicals from attacking the metal. You get tight shutoff and fine control, even with strong acids or bases. The PTFE lining also reduces friction. You do not need much force to turn the handwheel.

| Feature | Benefit in Corrosive Applications |

|---|---|

| PTFE-lined disc & seat | Prevents corrosion and leaks |

| Smooth movement | Allows precise flow adjustment |

| Non-reactive surface | Handles aggressive chemicals safely |

Common Use Cases

You find globe valves in places where you need to control flow carefully. Chemical plants use them for dosing acids and bases. Water treatment systems use them to adjust flow rates. Pharmaceutical factories rely on globe valves to keep processes clean and accurate.

PTFE-lined globe valves work well with steam, hot water, and strong chemicals. You can use them in mixing tanks, reactors, and pipelines. The PTFE lining keeps your product pure and your equipment safe.

Note: Choose globe valves with PTFE lining for jobs that need both precision and strong chemical resistance. You get better control and longer service life.

Teflon vs. Other Materials

Metal Valves

Corrosion Resistance

Metal valves are used in many factories. They look tough, but they can rust. If you use acids or bases, metal can get damaged fast. Rust and pits make the valve weak. This can cause leaks. Teflon lined valves protect much better. The teflon layer acts like a shield. It stops most chemicals from touching the metal. Chemical plants use teflon and ptfe lined valves for strong protection. These valves resist acids, bases, and solvents well. The table below shows how different linings work:

| Valve Type | Corrosion Resistance | Notes |

|---|---|---|

| PTFE Lined | Strong protection against acids, bases, solvents | Good for chemical plants |

| PFA Lined | Superior protection, even in harsh environments | Fewer defects, better chemical barrier |

Lifespan

Metal valves seem strong, but they do not last long. Corrosion makes them wear out faster. You might need to change them often in tough places. Teflon lined valves last longer. The ptfe lining stops chemicals from hurting the valve. You fix them less and save money. This longer life is a big reason to pick teflon lined valves instead of metal ones.

Rubber Lined Valves

Chemical Compatibility

Rubber lined valves work with some chemicals, but not all. EPDM and Viton can handle weak acids or water. Strong acids, bases, or solvents can break down rubber. Teflon lined valves work with many more chemicals. The ptfe lining does not react with most fluids. You get better protection. When you compare them, teflon lined valves are better for chemical plants.

Maintenance

Rubber lined valves need more checking. You must look for cracks or swelling in the lining. If the rubber breaks, you can get leaks. This means more downtime. Teflon lined valves need less care. The ptfe layer stays smooth and does not wear out fast. You save time and do not need to replace them often. This is another reason teflon lined valves are better.

Cost-Benefit

You want to know how much these valves cost. Teflon lined valves cost more at first. But you save money later. The table below compares costs for metal and ptfe valves:

| Aspect | Metal Valves | PTFE Valves |

|---|---|---|

| Material Cost | High | Moderate to High |

| Installation | Heavy, complex | Light, simple |

| Maintenance | Expensive, frequent | Lower, less frequent |

- Teflon lined valves are lighter. You can install them faster and easier.

- You spend less on fixing them because ptfe resists corrosion.

- You do not need to replace them as often, so you save money.

When you look at all the facts, teflon lined valves are a better deal. You get strong protection, longer life, and lower costs. This makes them a smart choice for tough chemicals.

User Benefits

Reduced Downtime

You want your system to keep working all the time. Teflon lined valves help you reach this goal. PTFE makes a strong shield against harsh chemicals. You do not have to worry about things breaking often. PTFE-lined equipment can last for many years in tough places. This means you spend less time fixing or changing valves. Your process keeps going without stopping.

- PTFE-lined plug valves help stop downtime.

- You do not get sudden problems from corrosion.

- Your team can work on making products, not fixing things.

When you use teflon lined valves, you have fewer shutdowns. Your plant keeps working well. You save money because you do not lose time from surprise issues.

Maintenance Savings

You want to spend less on taking care of your valves. Teflon gives you almost no-maintenance use in many jobs. PTFE stands up to chemicals, so you do not need to check valves a lot. The smooth teflon surface stops stuff from building up. You spend less money on cleaning and fixing.

Here is a table that shows how teflon lined valves help you save on maintenance:

| Feature | Benefit |

|---|---|

| PTFE lining | Fewer repairs needed |

| Non-stick surface | Less cleaning required |

| Long-lasting protection | Lower replacement costs |

You get valves you can trust year after year. You do not have to buy new parts all the time. Your money goes further because you avoid big repair bills and lost time.

Tip: Pick PTFE-lined valves for strong chemicals. You will pay less for maintenance and your valves will last longer.

Safety & Compliance

You want your workplace to be safe. Teflon lined valves help stop leaks and spills. PTFE does not react with most chemicals, so you avoid dangerous messes. The strong lining keeps harmful fluids inside the valve. You follow safety rules and meet industry standards.

- Teflon lined valves help you follow chemical safety rules.

- You lower the chance of workers touching dangerous fluids.

- Your team works in a safer place.

You can trust teflon to keep your process safe. You can handle strong chemicals without worry. Your company follows the law and keeps everyone safe.

Note: Good valves with PTFE lining help you feel safe. You protect your workers, your machines, and your company’s good name.

Choosing Teflon Lined Gate Valves

Selection Criteria

When you choose teflon lined gate valves for your system, you need to look at several important factors. These valves must handle tough chemicals and keep your process safe. Here are the main things you should check:

- Make sure the valve works with the media in your system. PTFE resists most acids, bases, and solvents.

- Check the temperature and pressure ratings. Teflon can handle a wide range, but you must stay within safe limits.

- If you move slurries or fluids with particles, look for valves with good abrasion resistance.

- The seal material should also resist the chemicals you use. PTFE seals often work best.

- See if the valve meets fugitive emission standards like ISO 15848-1. This helps prevent leaks and keeps your plant safe.

Tip: Always match the valve’s features to your process needs. This helps you avoid problems and keeps your system running smoothly.

Application Fit

You want teflon lined gate valves that fit your exact job. Think about the type of fluid you move. If you use strong acids or bases, PTFE gives you the best protection. Teflon lined valves work well in chemical plants, water treatment, and food processing. These valves also help when you need to keep your product pure. The smooth teflon surface stops contamination and buildup.

If your process has high pressure or temperature, check the valve’s ratings. Teflon lined gate valves can handle many tough jobs, but you must stay within their limits. For slurries or fluids with grit, pick a valve with extra abrasion resistance. This keeps the lining from wearing out too fast.

Note: Teflon lined gate valves are a smart choice for any place where corrosion is a risk. You get long life and fewer leaks.

Installation Tips

Proper installation helps your teflon lined gate valves last longer. Here are some best practices:

- Inspect the valve before you install it. Look for damage to the teflon lining.

- Clean the pipe and flange surfaces. Dirt or grit can scratch the PTFE.

- Use the right gaskets and bolts. Tighten them evenly to avoid stress on the lining.

- Do not over-tighten. Too much force can crack the teflon.

- After installation, test the valve for leaks at low pressure first.

- Train your team to handle and maintain teflon lined gate valves with care.

A careful installation keeps the PTFE lining in good shape. You get better performance and less downtime. Teflon lined gate valves give you strong protection from corrosion and chemical attack when you install them the right way.

You want the best protection for your system. Teflon lined valves give you unmatched safety against corrosion. Science shows that these valves last longer and need less care than other options. You can trust them to keep your process clean and safe. If you work with harsh chemicals, choose teflon lined valves for peace of mind and long-term savings.

FAQ

What chemicals can Teflon lined valves handle?

Teflon lined valves work with most acids, bases, and solvents. PTFE stands up to almost all chemicals in factories. Always look at a chart to check if your fluid is safe.

How long do Teflon lined valves last?

Teflon lined valves can last 5 to 7 years in tough places. Check them often to spot any damage or wear early.

Can I use Teflon lined valves at high temperatures?

Use Teflon lined valves only below 150°C (302°F). PTFE gets soft if it gets hotter. For best results, keep them under 120°C (248°F) for a long time.

Are Teflon lined valves safe for food and pharmaceuticals?

Yes! PTFE does not react with food or medicine. The smooth lining keeps things clean and meets strict rules.

How do I maintain Teflon lined valves?

Tip: Look for scratches or peeling on the lining. Clean the valve often. Do not use sharp tools that could hurt the PTFE.

What types of valves can have Teflon linings?

You can get Teflon linings in ball, butterfly, gate, plug, and globe valves. Each kind works well for different flow and control needs.

Do Teflon lined valves cost more than metal valves?

Teflon lined valves cost more at first. You save money later because you do not fix or replace them as much.

Can I use Teflon lined valves with abrasive fluids?

Do not use Teflon lined valves with fluids that have hard bits. Abrasives can scratch or harm the PTFE lining. For these fluids, try special alloys or other options.