You need strong protection when you work with harsh chemicals and very pure liquids. PFA lined ball valves give you the best chemical resistance, safety, and dependability.

You can feel safe because they have:

- High chemical resistance

- Easy movement with low friction

- No contamination during use

These valves keep chemicals from hurting the valve and stop fluids from touching metal parts. You can use them in chemical plants, water cleaning, hydrogen making, paper mills, mining, and power plants. If you need a ball valve, butterfly valve, or electric valve, you will see why PFA lined ball valves are the best choice.

PFA Lined Ball Valves Overview

Construction

PFA Material

You need a valve that can handle tough chemicals. PFA lined valves help with this job. PFA makes a strong layer inside the valve. This layer keeps metal parts safe from harsh liquids and gases. These valves last longer than PTFE or FEP lined valves. They also work with hotter and stronger chemicals. You can count on them to keep your system safe and clean.

Tip: PFA lined valves are best when you need both strength and purity. They are great for places where leaks or dirt can cause big trouble.

Valve Design

Lined ball valves are made for safety and control. They shut off tightly every time you use them. The ball inside moves easily, so you do not need much force. The PFA lining covers all parts that touch the fluid. This keeps metal from getting exposed, so you avoid rust and leaks. The valve body stays strong, and the PFA lining fights off chemicals.

- Main features of PFA lined ball valves:

- PFA lining protects all parts that touch fluids

- Handles high heat and strong chemicals

- Gives good flow control in tough situations

Applications

Industries

Many industries use PFA lined valves for safety and trust. Chemical plants pick them because strong acids and bases can ruin other valves. Drug and food companies use them to keep things clean and pure. Computer chip makers also use these valves for their purity and strength.

- Common industries using lined ball valves:

- Chemical processing

- Pharmaceuticals

- Food and beverage

- Semiconductor manufacturing

Media Types

PFA lined ball valves work with many fluids and gases. They can handle strong chemicals, harsh fluids, and very pure water. These valves stop solid bits from building up inside. You get long use and fewer leaks or clogs.

- Good fluids for PFA lined valves:

- Strong acids and alkalis

- Solvents

- Ultra-pure water

- Corrosive gases

When you pick PFA lined ball valves, you keep your tools, products, and people safe. You also follow safety rules and lower the chance of costly stops.

Corrosion Resistance

Chemical Barrier

PFA lined ball valves give strong protection from harsh chemicals. The PFA lining makes a tough barrier inside the valve. This barrier keeps metal parts safe from dangerous fluids. You do not need to worry about acids, alkalis, or solvents hurting your equipment. The lining stays steady and does not react with chemicals. This helps your lined ball valve last longer and work better, even in hard places.

Acid and Alkali Protection

You need a valve that can handle strong acids and bases. PFA lined valves give you this safety. The PFA lining blocks acids like sulfuric acid and bases like sodium hydroxide. It keeps these chemicals away from the metal body. You avoid rust, leaks, and expensive repairs. PFA’s chemical resistance makes it great for places where safety and purity are important.

The PFA lining works as a smooth barrier. It keeps the metal parts of valves away from harmful chemicals. This stops acids and alkalis from causing rust. PFA does not react with the chemicals you use. This makes it good for handling strong materials.

Solvent Resistance

Solvents can damage many materials, but not PFA. You can trust PFA lined valves with many solvents and not worry. PFA resists both organic and inorganic solvents. This means you can use these valves in chemical plants, labs, and factories. They work well with strong cleaners and process fluids.

- PFA blocks more chemicals than PTFE, even in tough conditions.

- Both PFA and PTFE resist strong acids, bases, and solvents.

- PFA is best when you need high purity and strong protection, like in drug making and food processing.

Comparison to Metal Valves

Metal valves may seem strong, but they do not resist chemicals as well as lined ball valves. Metal valves can rust when they touch acids, alkalis, or solvents. This can cause leaks, failures, and safety problems. PFA lined ball valves stop these issues. The PFA lining keeps the metal safe and helps the valve last longer.

| Feature | Metal Valves | PFA Lined Ball Valves |

|---|---|---|

| Chemical Resistance | Low to Moderate | Excellent |

| Acid/Alkali Protection | Poor | Outstanding |

| Solvent Resistance | Limited | Superior |

| Lifespan | Shorter | Much Longer |

| Maintenance Needs | High | Low |

When you pick PFA lined valves, you keep your process, tools, and people safe. You also save money because you fix things less and have less downtime.

The PTFE, PFA, or FEP lining makes a smooth barrier that keeps the metal body away from harmful fluids. It does not react with many chemicals, like sulfuric acid and sodium hydroxide. This stops metal corrosion, which is a big problem in valves without lining.

Durability and Reliability

If you pick a lined ball valve, you want it to last long. You want it to work well every time, even when things get tough. PFA lined valves help you feel sure about your choice. They can handle strong chemicals, high heat, and daily use. This means your system keeps working and your money is safe.

Lifespan

Wear Resistance

You need a valve that does not wear out quickly. Different linings protect valves in different ways. Here is how some common materials compare:

| Material | Wear Resistance Characteristics |

|---|---|

| Rubber | Stops scratches; good for rough slurries. |

| PTFE | Smooth surface; helps stop clogs. |

| PFA | Non-stick surface; works well with harsh chemicals but does not focus on wear resistance. |

Rubber linings are good for rough slurries. PTFE gives a smooth surface to help stop blockages. PFA lined valves are best when you need chemical protection and a non-stick surface. You can trust them in places with strong chemicals where other linings might not work. PFA does not focus on stopping scratches, but it keeps your valve safe from chemical damage and buildup.

Temperature Handling

Factories often have high or low temperatures. PFA lined ball valves work well in both hot and cold places. They keep working from -30 °C up to +160 °C. This means you can use them in many different jobs.

| Temperature Range | Description |

|---|---|

| -30 °C to +160 °C | Highest temperature range for PFA lined ball valves in factories |

You get steady performance even when things get hot. PFA lined valves do not lose their chemical protection at high heat. This makes them great for hard jobs with both heat and strong chemicals.

Consistent Performance

You want your lined ball valve to work the same every time. In places with strong chemicals, many valves break early. They wear out or start leaking, which stops work. PFA lined valves help you avoid these problems. PFA’s strong chemical protection keeps the lining safe. Your valve stays tight and safe, even after lots of use.

- Valves in tough places often need to be replaced because they wear out.

- Strong chemicals can make regular valves break and stop working.

- PFA lined ball valves last longer, so you do not have to stop work for repairs.

You keep your tools, products, and team safe. You also save money because you do not have to fix or replace valves as often. With PFA lined ball valves, you get the steady performance you need for important jobs.

Safety and Process Integrity

When you work with dangerous chemicals, you need to trust your valves. PFA lined valves give you that trust. They keep your process safe and protect everyone around.

Leak Prevention

Leaks can cause big problems. You want to stop leaks before they start. PFA lined valves help you do that.

Bubble-Tight Shutoff

You need a valve that closes tight every time. PFA lined ball valves use bi-directional bubble-tight sealing. This means the valve stops flow in both directions. No air or liquid can pass through when you close it. You get a perfect seal, even with strong chemicals or high pressure.

A bubble-tight shutoff keeps your process safe. You avoid spills, protect your equipment, and keep your team out of harm’s way.

Sealing Features

PFA lined valves have special seals. These seals cover all parts that touch the fluid. The lining blocks chemicals from reaching the metal. You do not have to worry about rust or leaks. The seals stay strong, even after many uses.

- Main sealing features:

- Full lining on all wet parts

- Strong seat rings for extra tightness

- No gaps for leaks to start

You get peace of mind knowing your lined ball valve will not let you down.

Safety Compliance

You must follow strict rules in chemical plants. PFA lined ball valves help you meet these rules. They are made for high-risk places. You can trust them to work in tough jobs.

- PFA lined ball check valves are designed for high-risk environments.

- They conform to international safety standards, ensuring optimal performance.

- Compliance with these standards is crucial in preventing failures in critical systems.

When you use PFA lined valves, you protect your workers and your equipment. You also avoid fines and shutdowns. These valves help you pass safety checks and keep your plant running.

Choose PFA lined valves for the best safety and process integrity. You get strong leak prevention, top sealing, and full compliance with safety standards.

Maintenance and Efficiency

Low Maintenance

Cleaning

You want a valve that is easy to clean. PFA lined valves have a smooth and non-stick inside. This stops chemicals and dirt from sticking. You can wash out the valve without much work. You save time and use less cleaning liquid. The smooth lining keeps your process clean. You do not worry about old chemicals mixing with new ones.

Tip: Clean valves help make safer products and lower the chance of mixing.

Repair Frequency

You do not want to stop work for repairs. PFA lined valves are made for hard jobs. They do not get damaged by strong chemicals. You will see fewer leaks and less damage as time goes on. This means you do not need to fix or change your valve often.

- PFA lined valves are made for places with strong chemicals, so you spend less on repairs and they last longer, which saves money.

- Using lined valves helps stop surprise shutdowns and lowers repair costs over time, so you save more.

- In 2023, chemical plants in Europe started using PFA-lined plug valves, which helped them have less downtime and fewer problems, so they spent less on new parts.

Your plant keeps working well. You do not have to worry about fixing valves all the time.

Cost Savings

Emissions Reduction

You care about safety and the earth. PFA lined valves seal tightly and stop leaks. This lowers the chance of bad gases getting out. You follow safety rules and keep workers safe. You also do not get fined for leaks or spills.

A system without leaks saves money and helps your team and customers trust you.

Downtime

Downtime makes you lose money. Every minute your plant stops, you lose work and cash. PFA lined valves help you avoid these problems. They last longer and do not need many repairs. You do not have to stop work to fix or change a valve.

- PFA lined ball valves are known for sealing well for a long time, so they are a smart choice for tough jobs.

- These valves are strong and keep working after many uses, which helps save money when you need to stop or control flow.

You get more work done and better results. You can grow your business instead of fixing valves.

Pick PFA lined valves for less work, fewer repairs, and real savings. You keep your process, your people, and your money safe.

Other Types of PFA Lined Valves

PFA lining is not just for ball valves. You can also find it in gate valves, butterfly valves, and check valves. Each valve type has its own special use. When you pick these valves, you still get strong chemical resistance and long life.

Gate Valves

Design and Function

Gate valves let fluids move in a straight line. You open or close them by moving a gate up or down. This design is good for full flow or tight shutoff. The PFA lining covers every part that touches the fluid. This stops corrosion from happening. Both PFA and PTFE resist chemicals very well. Sometimes, PFA gives even better protection. You can trust PFA lined gate valves with harsh chemicals.

Typical Applications

You see PFA lined gate valves in chemical plants, water treatment, and mining. These valves are best for moving lots of liquid with little pressure loss. They work with acids, alkalis, and solvents. If you need a lined plug valve to stop flow, a PFA lined gate valve is a safe pick.

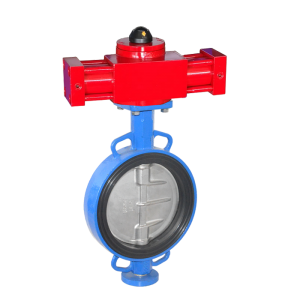

Butterfly Valves

Advantages in Flow Control

Butterfly valves control flow with a simple turn. The disc inside spins to let more or less fluid pass. PFA lined butterfly valves are great for flow control jobs. The PFA lining keeps out strong chemicals and helps the valve last longer. You spend less money fixing or replacing them. The butterfly shape makes it easy to change flow, so your system works well.

Tip: Pick a PFA lined butterfly valve if you need strong chemical resistance and good flow control.

Corrosive Media Suitability

PFA lined butterfly valves can handle the toughest fluids. They work with acids, bases, and solvents without breaking. Their strong build stands up to harsh chemicals. This helps you avoid leaks and stops. These valves are used in chemical plants, wastewater jobs, and places where safety matters. If you need a lined plug valve for flow, a PFA lined butterfly valve is a smart choice.

Check Valves

Backflow Prevention

Check valves stop fluids from going backward. In a PFA lined check valve, the ball closes the valve. When fluid moves forward, the ball lifts up. If the flow goes back, the ball drops and blocks it. The PFA lining gives strong chemical resistance, so the valve works even with harsh chemicals.

- The ball makes sure the valve shuts tight.

- PFA lining keeps out acids, alkalis, and solvents.

- The valve works by itself, so you do not need to adjust it.

Industry Use Cases

You find PFA lined check valves in places with strong chemicals. They are used in chemical plants, drug making, and water cleaning. These valves stop leaks and protect your tools from harm. The PFA lining and careful design mean you get long, leak-free use. If you need a lined plug valve to stop backflow, a PFA lined check valve is a good choice.

Pick PFA lined gate, butterfly, and check valves to keep your process safe from corrosion. You get the same good things as with ball valves—chemical resistance, long life, and safety—for your whole system.

PFA Lined Ball Valve Standards

When you pick PFA lined ball valves, you want them to be safe and work well. These rules make sure your valves are strong and last a long time. You can trust your system if your valves follow the right rules.

International Standards

ISO Standards

Valves need to meet world rules. ISO and ASME rules help make and test valves. Here are some important ones:

| Category | Standards |

|---|---|

| Manufacturing | ISO 17292 / ASME B 16.34 |

| Testing | API 598 / BS EN 12266-1 |

These rules help your valves stay safe under pressure and not rust. You can feel good knowing your valves are like the ones in top factories.

ASTM Specifications

Every valve part must follow strict rules. ASTM rules cover the body, ball, stem, and more. This table shows what to look for:

| Component | ASTM Specification |

|---|---|

| Valve Body | PFA Lined ASTM A395 DCi |

| Ball | PFA Lined ASTM A351, Grade CF8 S.S. |

| Side Piece | PFA Lined ASTM A395 DCi |

| Packing Gland | ASTM A351, Grade CF8 S.S. |

| Stem | PFA Lined, GR.2205 UNS S31803 |

If you see these rules, your valve can handle tough jobs.

API Guidelines

API rules help you get good valves for oil, gas, and chemical plants. API 598 checks for leaks and pressure. Valves that pass these tests keep your process safe.

Testing and Certification

Pressure and Leak Testing

You want to know your valve will not leak. Makers use many tests:

- Hydrostatic Testing: Open the valve halfway. Add pressure to half the max. Check for leaks at all spots.

- Visual Inspection: Look for leaks at the stem, gearbox, and seals.

- High Pressure Gas Testing: Use nitrogen or gas. Move the valve and drain water.

- Leak Verification: Make sure the seat seals all the way when open and closed.

- Seal Maintenance: Fix stops or add sealant if you find leaks.

These steps help your valve shut tight every time.

Chemical Compatibility Tests

You need to know your valve can handle harsh chemicals. Here is how makers check:

- Look at charts to see if each part works with chemicals.

- Test the valve with real fluids and check for leaks or damage.

- Think about heat, strength, and how strong the chemicals are.

- Use fluorine-lined valves for the best protection from acids.

You get a valve that lasts longer and keeps your process clean.

Quality Assurance Procedures

Makers check every valve for problems. They test for leaks, strength, and chemical safety. You get a valve that works right every time.

Industry Compliance

Documentation Requirements

You must keep papers to show your valves meet the rules. Here is what you need:

| Documentation Requirement | Description |

|---|---|

| Material Test Reports (MTRs) | Proof for all valve parts. |

| cGMP Compliance | Follows Good Manufacturing Practices. |

| ASME BPE Compliance | Meets bioprocessing equipment rules. |

| Validation through Testing | Checks for pressure, flow, and cleanliness. |

These papers help your business and help you pass checks.

Traceability and Marking

You want to track every valve from the factory to your plant. Makers put numbers and codes on each valve. This helps you find where any problem started.

Third-Party Certifications

Outside labs test and approve your valves. You get proof your valves are safe and high quality. This helps you feel sure and win trust from customers.

Pick PFA lined ball valves that meet top rules. You keep your process, people, and money safe. You also show you care about safety and quality every day.

Purity and Compliance

You need very clean fluids for some jobs. PFA lined ball valves help keep everything pure. They make sure your process stays safe and clean. You can trust every drop that goes through these valves.

FDA Compliance

Non-Toxic

You want valves that do not add anything bad. PFA lined ball valves follow strict FDA rules for pure and antistatic PFA. This means they are safe for tough jobs. You can use them in drug making and food factories without worry.

- The valves use pure PFA, so it does not react with fluids.

- They are put together without oil or grease, so nothing gets dirty.

- The design has little dead space, so cleaning is easy and less stuff stays inside.

Tip: Pick PFA lined ball valves to keep your product safe and protect your good name.

Odorless

You do not want any weird smells in your fluids. PFA lined ball valves do not smell, even after lots of use. They do not soak up or give off odors. Your fluids keep their real taste and smell. This matters for chemical jobs and places where taste is important.

Microbial Resistance

Ultra-Pure Fluids

You must stop germs from getting in. PFA lined ball valves help with this. The PFA liner is at least 3mm thick. This strong layer keeps out bacteria and other germs. You get great protection from rust, leaks, and germs.

- These valves work well with strong chemicals and pure fluids.

- They stop backflow, so your process stays clean.

- The smooth PFA surface is easy to clean and stops germs from sticking.

You can trust these valves to give you top purity every time. They meet ASME/BPE-1997 rules, which are the best for clean equipment. You know your system will stay safe and clean.

When you pick PFA lined ball valves, you keep your process, products, and customers safe. It is a smart choice for purity and following the rules.

Lined Ball Valve Comparison

PFA Lined Valves vs. Others

You want the best valve for your job. You need to know how each lined ball valve stands up to tough chemicals and daily use. Let’s look at how PFA lined ball valves compare to other options.

| Valve Type | Chemical Resistance | Purity Level | Lifespan | Maintenance Needs |

|---|---|---|---|---|

| PFA Lined Ball Valve | Excellent | Premium purity | Very Long | Very Low |

| PTFE Lined Valves | Very Good | High | Long | Low |

| FEP Lined Valves | Good | High | Medium | Medium |

| Rubber Lined Valve | Moderate | Medium | Short | High |

| Unlined Valve | Poor | Low | Very Short | Very High |

PFA lined ball valves give you the highest chemical resistance. You can trust them with strong acids, bases, and solvents. PTFE lined valves also work well, but PFA gives you better protection in high heat and with aggressive chemicals. FEP lined valves help in less harsh jobs, but they do not last as long. Rubber lined valves work for some slurries, but they cannot handle strong chemicals. Unlined valves fail fast in chemical processing.

You want premium purity for your products. Only PFA lined ball valves keep your fluids clean and safe. PTFE and FEP lined valves help, but PFA gives you the best results. Rubber and unlined valves can add dirt or let chemicals leak.

Tip: If you need a lined plug valve for the toughest jobs, pick PFA. You get the best chemical resistance and the longest life.

Decision Factors

You need to choose the right valve for your plant. Think about these points before you decide:

- Chemical Resistance

You must match the valve to your chemicals. PFA lined ball valves and ptfe lined valves both resist strong acids and bases. FEP lined valves work for mild chemicals. Rubber and unlined valves do not protect well. - Purity Needs

You want premium purity for food, drugs, or electronics. PFA lined ball valves give you the cleanest flow. PTFE lined valves and fep lined valves also help, but PFA is best. - Maintenance and Downtime

You want to avoid repairs. PFA lined ball valves and ptfe lined valves need less work. Rubber and unlined valves break down fast and cost more to fix. - Cost Over Time

You save money with a lined ball valve that lasts. PFA and ptfe lined valves give you long service. FEP lined valves and rubber lined valves need more replacements. - Type of Valve Needed

Sometimes you need a lined plug valve for special flow control. PFA lining works for many valve types, so you can match your needs.

Choose PFA lined ball valves if you want the best chemical resistance, the highest purity, and the lowest maintenance. You protect your process, your people, and your profits.

You want your process to be safe. PFA lined ball valves protect against strong chemicals. They last a long time and do not break easily. You will not have as many leaks. You also spend less money fixing them. Many companies use lined ball valves to keep things clean and safe. The PFA lining works like a shield. It helps your equipment last longer. Pick a lined ball valve for hard jobs. You will feel calm knowing your system is protected.

FAQ

What makes PFA lined ball valves better than PTFE lined valves?

You get stronger chemical resistance and higher purity with PFA. PFA lined ball valves last longer in tough jobs. You protect your process and save money over time. Choose PFA for the best results in harsh environments.

Can you use PFA lined ball valves with high temperatures?

Yes! You can trust PFA lined ball valves up to 160°C. They keep their strength and chemical resistance, even when things get hot. You avoid leaks and damage in high-temperature processes.

Are PFA lined ball valves safe for food and pharmaceuticals?

Absolutely. You meet FDA standards with PFA lined ball valves. You keep your products pure and safe. The valves do not add taste, odor, or toxins. You protect your brand and your customers.

How often do you need to maintain PFA lined ball valves?

You spend less time on maintenance. The smooth PFA lining resists buildup and damage. You clean them easily and rarely need repairs. You keep your plant running and avoid costly shutdowns.

What chemicals can PFA lined ball valves handle?

You can use these valves with strong acids, alkalis, solvents, and ultra-pure water. PFA resists almost every aggressive chemical. You get reliable performance in the harshest environments.

Do PFA lined ball valves prevent leaks?

Yes! You get bubble-tight shutoff and strong seals. You stop leaks before they start. You protect your equipment, your team, and your process from dangerous spills.

How do you know if a PFA lined ball valve meets industry standards?

You should check for ISO, ASTM, and API certifications. Reliable suppliers provide documentation and third-party test results. You ensure safety and compliance by choosing certified valves.

Tip: Always ask for test reports and certifications before you buy. You guarantee quality and peace of mind.