When you compare a 2 piece ball valve vs 3 piece ball valve, you notice some significant differences. The 2 piece ball valve is more affordable and performs well under moderate pressure. In contrast, the 3 piece ball valve can be easily disassembled, making repairs straightforward and potentially saving money in the long run. This type of valve is ideal for high pressure, high temperature, or corrosive environments. The table below outlines the key differences:

| Feature | Two-Piece Ball Valve | Three-Piece Ball Valve |

|---|---|---|

| Cost | Moderate | High |

| Ease of Maintenance | Moderate maintenance ease | Easy disassembly for repairs |

| Application Flexibility | Moderate | High |

| Best Use Cases | Industrial applications with moderate pressure | High-pressure, high-temperature, or corrosive applications |

When considering options like a butterfly valve or an electric valve, it’s crucial to choose the right ball valve for your system to ensure optimal performance.

Key Takeaways

- A 2 piece ball valve costs less. It works well for medium pressure jobs.

- A 3 piece ball valve comes apart easily. This makes fixing and cleaning faster.

- Pick a 2 piece valve for easy tasks. Use it with clean liquids and when you do not need much upkeep.

- Pick a 3 piece valve for tough jobs. It is better for high pressure, high heat, or harsh chemicals.

- Both valves let fluids flow freely. But 3 piece valves are stronger and easier to clean.

- Think about your system’s pressure and how often you need to fix things before you choose a valve.

- It is important to check valves often. Look for leaks and damage to help them last longer.

- In 2025, use 3 piece ball valves for jobs that need easy cleaning and follow health rules.

Ball Valve Basics

How Ball Valves Work

A ball valve helps control liquid or gas in pipes. Inside, there is a round ball with a hole. The ball sits between two seats. When you turn the handle, the ball moves. If the hole matches the pipe, fluid goes through. If you turn the handle sideways, the ball blocks the flow. This makes it easy to stop or start flow fast.

Ball valves are different from other valves because of their special design. The table below shows what makes them unique:

| Feature | Description |

|---|---|

| Floating Ball Design | Gives balanced pressure, helps seal better, and lasts longer. |

| Smooth Flow Engineering | Lets fluid move evenly, lowers turbulence, and keeps pressure steady. |

| Closed Position Functionality | Makes a tight seal when shut, stops leaks, and keeps the system safe. |

| Full Bore Design | Keeps flow steady, which is important for moving fluids smoothly. |

| Construction Variants | Comes in one-piece, two-piece, and three-piece types for different jobs. |

| One-Piece Ball Valves | Small and cheap, good for simple jobs, but you must replace the whole valve if it breaks. |

| Two-Piece Ball Valves | Strong and easy to fix, works well in homes and businesses. |

| Three-Piece Ball Valves | Tough build, easy to install and repair. |

These features help you get a tight seal and stop leaks. They also keep your system working well. The full bore design means fluid moves easily with little pressure loss.

Tip: Always look at the valve’s position before you start your system. This can help you avoid spills or leaks.

Common Uses

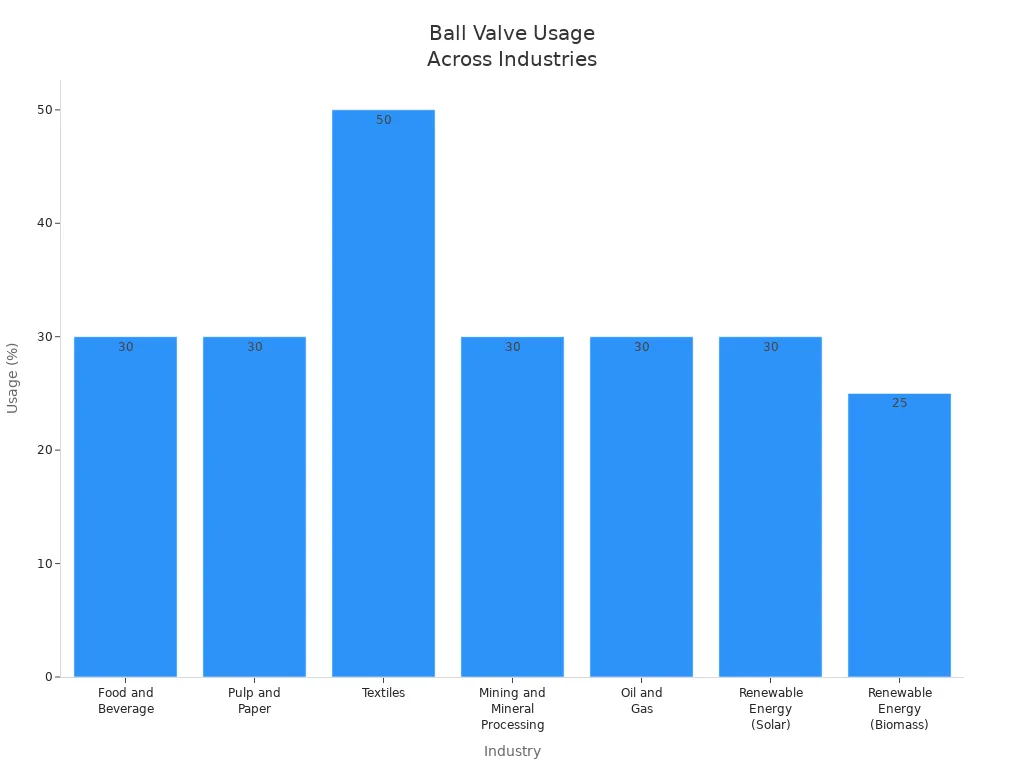

Ball valves are used in many industries because they seal well and work fast. Their design makes them good for easy and tough jobs. Here are some places where ball valves are used most:

| Industry | Ball Valve Usage (%) | Functionality Description |

|---|---|---|

| Food and Beverage | 30% | Seals tightly and works quickly |

| Pulp and Paper | 30% | Keeps chemicals safe with strong sealing |

| Textiles | 50% | Good for dyeing and finishing, very flexible |

| Mining and Mineral Processing | 30% | Seals well and handles many liquids |

| Oil and Gas | 30% | Starts and stops gas flow, handles high pressure |

| Renewable Energy (Solar) | 30% | Controls heat fluids |

| Renewable Energy (Biomass) | 25% | Seals slurries safely |

You see ball valves most in textiles because they need quick shutoff and flexibility. Food and beverage, pulp and paper, and oil and gas also use ball valves for strong seals and easy use. Renewable energy uses ball valves to move fluids safely.

Ball valves are great when you need to stop or start flow quickly. You find them in water plants, chemical factories, and even home plumbing. Their simple design and strong performance make them a smart pick for many jobs.

2 Piece Ball Valve Overview

2 Piece Ball Valve Construction

A 2 piece ball valve has a simple design. The valve body is made of two main parts. These parts fit together and hold the ball inside. This makes the valve easy to use and understand. You can find different ways to connect this valve. Some have a single threaded end. Others use bolts and flanges. Many 2 piece ball valves use NPT connections for a strong seal.

Here is a table showing common construction materials and connection types:

| Construction Materials | Connection Types |

|---|---|

| Main body | Single threaded end connection |

| Bolt and flange connection assembly | |

| NPT connection for metal-to-metal seal |

Most 2 piece ball valves are made from stainless steel or brass. These materials help the valve last longer and stop rust. The design lets you take the valve out of the pipeline if you need to check or replace it. Having two pieces makes this valve more reliable than a one-piece valve.

2 Piece Ball Valve Applications

You can use a 2 piece ball valve in many places. It seals well and is easy to use. Here are some common places where you might see this valve:

- Food & Beverage Industry

- Oil & Gas Industry

- Power Generation Industry

- Pharmaceutical Industry

- Chemical Industry

- Water Treatment Industry

- Waste Water Treatment Industry

The 2 piece ball valve is good for systems that need quick shutoff and tight sealing. You will see it in pipelines for water, chemicals, or gases. Its design helps you control flow with little effort. Many factories and plants pick this valve because it is easy to put in and take care of.

Tip: If your system uses clean fluids and does not need lots of repairs, a 2 piece ball valve is a smart pick.

2 Piece Ball Valve Pros and Cons

You should look at the good and bad sides before picking a 2 piece ball valve. The table below can help you decide:

| Advantages | Disadvantages |

|---|---|

| Quick operation | Unsuitable for throttling |

| Tight sealing | Wear in dirty fluids |

| Long service life | Size limitations in high-pressure systems |

| Versatility | Higher initial costs |

| Low pressure drop | |

| Ease of installation |

A 2 piece ball valve works fast and seals tightly. It lasts a long time and fits many jobs. The valve does not cause much pressure drop, so your system runs well. But it is not good for slowing down flow. Dirty fluids can wear out the inside. There are size limits for high-pressure jobs. The first cost is higher than a one-piece valve, but the good points are worth it.

If you want a valve that is not too expensive, works well, and is reliable, the 2 piece ball valve is a great choice. Its two-piece design makes it easy to use and fix in most factories.

3 Piece Ball Valve Overview

3 Piece Ball Valve Construction

A 3 piece ball valve has a modular design. It is made of three parts: two end caps and a center body. You can take it apart without removing it from the pipeline. This makes cleaning and fixing it much easier. The strong build lets it handle high pressure and heat. It works well in tough places. The leak-proof sealing keeps your system safe and helps stop leaks.

Here is a table that shows how the main features of a 3 piece ball valve help with maintenance and repair:

| Feature | Impact on Maintenance and Repair |

|---|---|

| Modular Design | Lets you disassemble and replace parts without removing the valve from the pipeline. |

| Robust Construction | Handles high pressures and temperatures, perfect for demanding jobs. |

| Leak-proof Sealing | Improves reliability and makes maintenance easier in many industries. |

Tip: If you want to spend less time fixing things, pick a 3 piece ball valve for your system.

3 Piece Ball Valve Applications

You see the 3 piece ball valve in many factories. Its design is great for places that need cleaning often. You can use it in:

- Manufacturing plants

- Systems with Female National Pipe Taper (FNPT) connections

- Socket Weld connections

- Tube Socket Weld connections

The 3 piece ball valve works well in chemical plants and food factories. It is also used in making medicine, water treatment, and oil and gas systems. If you need to clean your system a lot or use strong chemicals, this valve is safe and flexible.

3 Piece Ball Valve Pros and Cons

Think about the good and bad sides before you choose a 3 piece ball valve. Many people in factories like this valve because it is easy to fix and lasts a long time. It costs more at first, but you save money later since you can change parts instead of the whole valve.

Here is a table to help you compare:

| Pros | Cons |

|---|---|

| Easy maintenance and cleaning | Higher initial cost than other valve types |

| Cost-effective over time | |

| Durable and reliable in harsh environments | |

| Versatile and customizable design |

A 3 piece ball valve lasts longer and works better in hard jobs. You can change it to fit what you need. The higher price at the start is worth it because you spend less on repairs. If you want a valve that is easy to fix and strong, the 3 piece ball valve is a smart pick.

Pressure Ratings: 2 Piece vs 3 Piece Ball Valves

Understanding Pressure Ratings

When you pick a ball valve, you must know its pressure rating. The pressure rating shows the highest pressure the valve can take. This helps keep your system safe and working right. Makers set this rating when they design and test the valve. They use strict rules for each valve type.

Many things change the pressure rating of a ball valve:

- The material used to make the valve

- The way the valve is designed

- How the valve is made

- The rules used for testing

If you choose a valve with the wrong pressure rating, it might leak or break. Always check the pressure rating before you put in a valve.

Tip: You can find the pressure rating on the valve body or in the manual. This helps you pick the right valve for your system.

Pressure Ratings for 2 Piece Ball Valves

A 2 piece ball valve works well in systems with medium pressure. You see these valves in water, oil, or gas pipes. Most 2 piece ball valves have pressure ratings from 600 PSI to 1000 PSI. Some strong models can handle more pressure, but always check the label.

The pressure rating depends on the size and material of the valve. Stainless steel 2 piece ball valves usually have higher ratings than brass ones. If you use a 2 piece ball valve in a system with steady, medium pressure, it works well and keeps things safe.

Here are some common pressure classes for 2 piece ball valves:

- 600 PSI (used in many factories)

- 1000 PSI (for systems that need more power)

- Special ratings for unique jobs

Always match the pressure rating to your system’s highest pressure. This keeps your equipment safe and stops leaks.

Pressure Ratings for 3 Piece Ball Valves

A 3 piece ball valve is strong and flexible. You find these valves in places with high pressure and heat. The design lets you use tough materials and thick walls, which raises the pressure rating.

Industry rules often list 3 piece ball valve pressure classes like this:

| Pressure Class | Industry Standard |

|---|---|

| ASME Class 800 | API 608 |

| ASME Class 300 | API 608 |

You can use a 3 piece ball valve in systems that need to handle up to 2000 PSI or more, depending on the model and material. These valves work well in chemical plants, oil and gas pipes, and other hard jobs. The strong build and easy fixing make the 3 piece ball valve a good choice for tough places.

Note: Always check the maker’s data sheet for the exact pressure rating of your 3 piece ball valve. This helps you pick the right valve for your job.

Key Differences and Practical Implications

When you compare 2 piece and 3 piece ball valves, you see clear differences in how they handle pressure. The design and construction of each type play a big role in their performance. You need to know these differences to choose the right valve for your system.

Here is a table that shows how each type handles pressure:

| Feature | 2-Piece Ball Valve | 3-Piece Ball Valve |

|---|---|---|

| Pressure Handling | Best for low to medium pressure. | Suitable for high-pressure applications. |

A 2 piece ball valve works well in systems with low or medium pressure. You often find these valves in water lines, heating systems, and general industrial use. The two-piece body gives you a strong seal, but it does not handle very high pressure as well as a 3 piece valve. If your system does not face extreme conditions, a 2 piece valve can be a cost-effective and reliable choice.

A 3 piece ball valve stands out when you need to manage high pressure. The modular design lets you use thicker materials and stronger seals. You can take the valve apart for cleaning or repairs without removing it from the pipeline. This makes it a favorite in chemical plants, oil and gas lines, and other tough jobs. The three-piece build gives you more stability and safety under stress.

You should also know that some ball valves, like trunnion mounted types, are best for high-pressure work. These valves support the ball at both ends. This design keeps the ball stable and stops it from bending or leaking. You get better control and less risk of damage when the pressure goes up.

2 Piece Ball Valve vs 3 Piece

Maintenance Comparison

When you compare the 2 piece ball valve vs 3 piece, you notice big differences in maintenance. The way each valve is built changes how you fix and clean them. If you use a 2-piece ball valve, you must take it out of the pipeline to change the seals. This takes time and can stop your system from working. You cannot take apart a 2-piece ball valve while it stays in place.

A 3 piece ball valve is easier to take apart. You can remove the end caps and reach the ball, seats, and seals without moving the valve body. This makes cleaning and fixing much faster. You save time and your system does not stop for long. Many workers say that 3 piece ball valves are easier to keep working. You can change seals quickly because you only need to take off the end caps. This helps you do repairs faster and keeps your system running well.

Here is a simple table to show how each ball valve compares for maintenance:

| Feature | 2-Piece Ball Valve | 3-Piece Ball Valve |

|---|---|---|

| Disassembly | Remove from pipeline | Easy disassembly in place |

| Seal Replacement | More difficult | Simple and quick |

| Cleaning | Less convenient | Cleaning is easy |

| Downtime | More | Less |

Tip: If you want less downtime and faster repairs, pick a three-piece ball valve for your system.

Cost Comparison

The 2 piece ball valve vs 3 piece choice often depends on cost. You pay less at first for a 2 piece ball valve. This makes it a good pick for simple jobs or if you do not need to fix it often. The lower price helps you save money when you buy it.

A 3 piece ball valve costs more at the start. But you save money later. You can take it apart easily, so you spend less on fixing and labor. You do not need to buy a whole new valve if one part breaks. You only change the broken part, like the ball or seals. This lowers the total cost over time. Many people find that the 3 piece design saves money in the long run, especially for jobs with lots of use or high pressure.

Here is a simple cost comparison table:

| Cost Factor | 2-Piece Ball Valve | 3-Piece Ball Valve |

|---|---|---|

| Initial Price | Lower | Higher |

| Maintenance Cost | Higher | Lower |

| Replacement Parts | Whole valve | Individual parts |

| Total Ownership Cost | Higher over time | Lower over time |

Note: If your system needs regular fixing, a three-piece ball valve can help you save money over time.

Durability

Durability is important when you look at the 2 piece ball valve vs 3 piece. The 2 piece ball valve works well for many jobs, but it may not last as long in hard conditions. You cannot change worn parts easily, so you might need to replace the whole valve if something breaks. This means it does not last as long for tough jobs.

The 3 piece ball valve is stronger and lasts longer. You can clean and fix it often, which helps it stay in good shape. The design lets you change worn parts like the ball or seals without taking out the valve body. This is important for jobs that need strong sealing and lots of cleaning. The 3 piece ball valve is more durable and works better for hard jobs. You get strong sealing and a longer life because you can keep the valve working well.

Here are some reasons why the 3 piece ball valve lasts longer:

- You can change seals and the ball easily.

- You can clean the valve without taking it out.

- The design helps it seal well in tough jobs.

- You get less downtime and better operation.

If you need a valve for many cycles and hard jobs, the 3 piece ball valve is the best choice. It gives you strong sealing, easy cleaning, and lasts a long time.

Remember: For strong sealing and long-lasting use, the three-piece ball valve is the best pick in most ball valve comparisons.

Application Suitability

When you choose between a 2 piece and a 3 piece ball valve, you need to think about where and how you will use the valve. Each type fits certain jobs better. You want the right valve for your system, so your work stays safe and smooth.

Key Factors to Consider

You should look at these main points before you decide:

- System Pressure: Does your system run at low, medium, or high pressure?

- Maintenance Needs: Will you need to clean or fix the valve often?

- Space and Weight: Do you have limited room or need a lighter valve?

- Budget: How much can you spend now and later?

- Fluid Type: Are you moving clean water, chemicals, or thick liquids?

Comparing Suitability

The table below shows how each valve type matches different needs:

| Factor | 2-Piece Ball Valves | 3-Piece Ball Valves |

|---|---|---|

| Advantages | Compact structure, good sealing, lightweight, low fluid resistance | Versatile, easy to maintain, ideal for complex systems, flexible for customization, suitable for high pressure |

| Disadvantages | Increased risk of leakage, needs regular inspection | More expensive, higher costs due to complexity |

| Common Applications | Food service equipment, liquid filling, automotive fluid filling | Oil and gas, chemical processing, water treatment |

Where 2 Piece Ball Valves Work Best

You should pick a 2 piece ball valve if you need a simple, compact valve. These valves fit well in food service machines, drink dispensers, and car fluid systems. You get good sealing and low resistance, so fluids move easily. You also save space and weight. If your system does not need much cleaning or fixing, a 2 piece valve is a smart choice.

Tip: Use a 2 piece ball valve for clean fluids and steady, moderate pressure. You will spend less money and get reliable flow.

Where 3 Piece Ball Valves Shine

You want a 3 piece ball valve for tough jobs. These valves work well in oil and gas plants, chemical factories, and water treatment systems. You can take them apart without removing them from the pipeline. This makes cleaning and repairs fast and easy. If your system faces high pressure, strong chemicals, or needs regular maintenance, a 3 piece valve gives you more safety and less downtime.

- You can customize a 3 piece valve for special jobs.

- You can swap out worn parts without buying a whole new valve.

- You get strong sealing, even in harsh places.

Full-Bore Flow and Pressure Drop

Both 2 piece and 3 piece ball valves can offer full-bore flow. This means the hole inside the valve matches the pipe size. You get less pressure drop and smoother flow. If your system needs high flow rates, both types can work, but 3 piece valves handle stress and cleaning better.

Making the Right Choice

You should match the valve to your job:

- Pick a 2 piece ball valve for simple, low-maintenance systems with clean fluids.

- Choose a 3 piece ball valve for complex, high-pressure, or dirty systems that need regular care.

Note: Always check your system’s needs before you buy. The right valve keeps your work safe, saves money, and makes repairs easier.

Industry Applications: 2 Piece vs 3 Piece Ball Valves

Oil & Gas Industry

You often see both 2 piece and 3 piece ball valves in the oil and gas industry. Each type fits different needs. If you work with pipelines that carry crude oil or natural gas, you need valves that handle high pressure and tough conditions. The 3 piece ball valve stands out here. You can take it apart for cleaning or repairs without removing it from the line. This saves you time and keeps your system running. You also get better sealing and longer life because you can replace worn parts.

In some parts of the oil and gas process, you may use 2 piece ball valves. These work well for less demanding jobs, like utility lines or low-pressure systems. You get a strong seal and a lower price. If you do not need to clean or fix the valve often, a 2 piece design can save you money.

Key Points:

- Use 3 piece ball valves for high-pressure and critical lines.

- Choose 2 piece ball valves for simple, low-maintenance jobs.

- Regular maintenance and safety checks are important in this industry.

Chemical Processing

Chemical plants need valves that resist corrosion and handle dangerous fluids. You want a valve that you can clean and fix easily. The 3 piece ball valve is a top choice here. You can take it apart, clean it, and put it back together fast. This helps you meet strict safety rules and avoid leaks.

Some chemical processes use 2 piece ball valves for less risky fluids or where you do not need to clean the valve often. You get a good seal and a lower cost. If your system uses harsh chemicals or needs regular cleaning, you should pick a 3 piece valve.

Practical Example:

If you run a line with strong acids, a 3 piece ball valve lets you swap out seals and seats quickly. This keeps your plant safe and running.

Food & Beverage

You must follow strict hygiene rules in the food and beverage industry. Ball valves here need to meet 3-A Sanitary Standards. The latest update, 68-01, says ball valves are “clean-out-of-place” (COP) only. This means you must take the valve apart to clean it. You cannot clean it while it stays in the system. If you do not follow this rule, you risk losing certification and facing hygiene problems.

| Aspect | Details |

|---|---|

| Regulatory Body | 3-A Sanitary Standards, Inc. |

| Standard Update | 68-01 |

| Key Change | Ball valves are COP only, not CIP capable |

| Implications | Manual disassembly for cleaning, more labor and downtime |

| Certification Requirement | Must be marked ‘COP only’ to keep 3-A certification |

| Hygiene Risks | Using in CIP systems can cause contamination |

| Design Limitations | Dead spaces and blockages increase maintenance needs |

You should use 3 piece ball valves if you need to clean your system often. You can take them apart, clean every part, and put them back fast. This helps you meet hygiene rules and avoid contamination. If you use a 2 piece ball valve, you may face more downtime and cleaning challenges. Always check if your valve meets the latest standards before you install it.

Pharmaceuticals

You work in a place where safety and cleanliness are very important. In pharmaceutical plants, you must keep everything clean so nothing gets contaminated. You also have to follow strict rules from groups like the FDA. Here, 3 piece ball valves are the best choice. You can take them apart without removing them from the pipes. This makes cleaning and sterilizing much easier. You save time and lower the chance of contamination.

You need to clean your equipment between each batch. A 3 piece ball valve lets you do this quickly. You can change seals and seats without buying a new valve. This helps you meet hygiene rules and keeps your plant running well. If you use a 2 piece ball valve, you might have longer downtimes. You have to take out the whole valve for deep cleaning or repairs.

Pharmaceutical systems use special materials. Stainless steel is common because it does not rust and is easy to clean. You should always check if your valve meets the newest industry rules.more valves will support automation and remote monitoring. This helps you watch how the valve works and find problems before they stop your system.

Tip: Pick a 3 piece ball valve if you want fast cleaning, easy repairs, and the best hygiene in your pharmaceutical process.

Water Treatment

You need strong valves in water treatment plants. These systems run all day and face tough conditions. Both 2 piece and 3 piece ball valves are used, but your choice depends on the job. For main water lines, you often pick 2 piece ball valves. They seal well and are easy to put in. For places that need lots of cleaning or repairs, 3 piece ball valves are better. You can take them apart fast, which means less downtime.

When you pick a ball valve for water treatment, look at these key things:

| Factor | Description |

|---|---|

| Reliability | Keeps your system working with fewer problems. |

| Durability | Handles strong chemicals and changing temperatures. |

| Material Selection | Stainless steel and PVC last longer in wet places. |

| Valve Design | Pick the right design for your treatment job. |

| Maintenance Requirements | Choose valves that are easy to reach and fix. |

| Regulatory Compliance | Make sure your valves follow the rules. |

| Environmental Factors | Think about temperature and chemical exposure. |

| Cost Considerations | Look at long-term value, not just the price. |

You should also think about valve size, sealing, and if you want manual or automated operation.? more plants will use automated valves to save time and make things safer. Always check if your valve meets local and national rules.

Note: Using materials that do not rust and picking valves that are easy to fix help your water treatment system last longer and work better.

General Industrial Use

You see ball valves in many factories and plants. Both 2 piece and 3 piece ball valves are common. Your choice depends on how often you need to clean or fix the valve. If you want something simple and cheap, a 2 piece ball valve works well. You get good sealing and easy setup. For jobs that need lots of maintenance or handle strong fluids, a 3 piece ball valve is better. You can take it apart, clean it, and change parts without much trouble.

In general industry, you must think about the type of fluid, pressure, and how often you need to service the valve. Many companies now want valves that work with automation. This trend will grow . Automated ball valves help you control flow from far away and reduce manual work.

- Use 2 piece ball valves for simple, steady jobs.

- Choose 3 piece ball valves for tough, high-maintenance tasks.

You should always match the valve to your system’s needs. This keeps your plant safe, efficient, and ready for the future.

Choosing the Right Valve

Key Factors

When you choose between a 2-piece and a 3-piece ball valve, you need to look at several important factors. Each system has different needs. You want the best fit for your job. Here are the main things you should consider:

- Budget:

You need to know how much you can spend. A 2-piece ball valve usually costs less at first. A 3-piece ball valve costs more, but you may save money later because you can replace parts instead of the whole valve. - Maintenance Needs:

Think about how often you need to clean or fix your valve. If you want easy repairs and less downtime, a 3-piece ball valve works better. You can take it apart without removing it from the pipeline. - System Pressure and Temperature:

Check the pressure and temperature in your system. A 3-piece ball valve handles higher pressure and heat. A 2-piece ball valve works well for medium pressure and temperature. - Fluid Type:

Look at what flows through your pipes. If you use clean water or simple fluids, a 2-piece valve is a good choice. If you use harsh chemicals or thick fluids, a 3-piece valve gives you better safety and longer life. - Industry Standards and Trends:

Some industries have strict rules. For example, food and drug plants need valves that are easy to clean. more companies want valves that support automation and remote checks. You should pick a valve that meets these new needs.

Tip: Always check your system’s needs before you buy a valve. This helps you avoid problems and saves money.

Expert Tips

Installation Advice

You want your ball valve to work well from the start. Begin by checking the valve for damage before you install it. Make sure the pipeline is clean and free of debris. Align the valve with the pipe so the flow direction matches the arrow on the valve body. Tighten the connections evenly. Do not over-tighten, as this can damage the seals.

Here are some steps you should follow for a smooth installation:

- Inspect the valve and pipeline for dirt or rust.

- Position the valve so the handle is easy to reach.

- Use the correct tools for tightening.

- Test the valve after installation by opening and closing it several times.

Tip: Always use the right gasket material for your fluid type. This helps prevent leaks and keeps your system safe.

Maintenance Tips

Regular maintenance keeps your ball valve working longer. You should check the valve for leaks and wear every few months. Clean the valve seats and ball if you see buildup. Lubricate moving parts to reduce friction. Replace seals and seats when you notice damage.

Try these maintenance steps to keep your valve in top shape:

- Inspect for leaks around the body and connections.

- Clean the ball and seats with a soft cloth.

- Lubricate the stem and handle if movement feels stiff.

- Change worn seals before they cause bigger problems.

| Maintenance Task | How Often | What to Look For |

|---|---|---|

| Leak inspection | Monthly | Wet spots, drips |

| Cleaning | Quarterly | Dirt, buildup |

| Lubrication | Quarterly | Stiff handle movement |

| Seal replacement | Yearly | Cracks, wear, leaks |

Note: If you use your valve in harsh conditions, check it more often.

Common Mistakes

You can avoid many problems by knowing what mistakes to watch for. Some people install the valve backwards, which blocks flow. Others forget to clean the pipeline before installation. Over-tightening the connections can crush the seals. Skipping regular checks leads to leaks and costly repairs.

Look out for these common mistakes:

- Installing the valve in the wrong direction.

- Ignoring dirt or debris in the pipeline.

- Using the wrong gasket material.

- Forgetting to test the valve after installation.

- Waiting too long to replace worn seals.

?? Alert: Always read the manufacturer’s instructions before you start. This helps you avoid errors and keeps your system safe.

You now know the key differences between 2 piece and 3 piece ball valves. A 2 piece valve gives you a lower cost and works well for simple, low-maintenance jobs. A 3 piece valve lets you clean and repair it easily, making it the best choice for high-pressure or harsh environments.

FAQ

What is the main difference between a 2 piece and a 3 piece ball valve?

You will notice that a 2 piece ball valve has two main body parts, while a 3 piece ball valve has three. The 3 piece design lets you take it apart for cleaning or repairs without removing it from the pipeline.

Can I use a 2 piece ball valve for high-pressure systems?

You can use a 2 piece ball valve for medium pressure. For high-pressure systems, you should choose a 3 piece ball valve. The 3 piece design handles higher pressure and offers better safety.

Which valve is easier to maintain?

You will find the 3 piece ball valve much easier to maintain. You can remove the center section for cleaning or repairs. You do not need to take the whole valve out of the pipeline.

Are 3 piece ball valves more expensive than 2 piece ball valves?

Yes, you will pay more for a 3 piece ball valve at first. Over time, you may save money because you can replace only the worn parts instead of the whole valve.

How do I know which valve to choose for my system?

You should look at your system’s pressure, temperature, and maintenance needs. If you need easy cleaning and repairs, pick a 3 piece valve. For simple jobs with clean fluids, a 2 piece valve works well.

Do both valve types support automation?

You can automate both 2 piece and 3 piece ball valves. You just need to add an actuator. Make sure the valve you choose matches your automation system.

What materials are best for ball valves in harsh environments?

You should choose stainless steel for harsh environments. Stainless steel resists rust and corrosion. It works well with chemicals, high pressure, and high temperatures.